Assembly instructions for kit #17

All rights reserved. 2014 Simple Motors, LLC ♦www.simplemotor.com ♦ 5

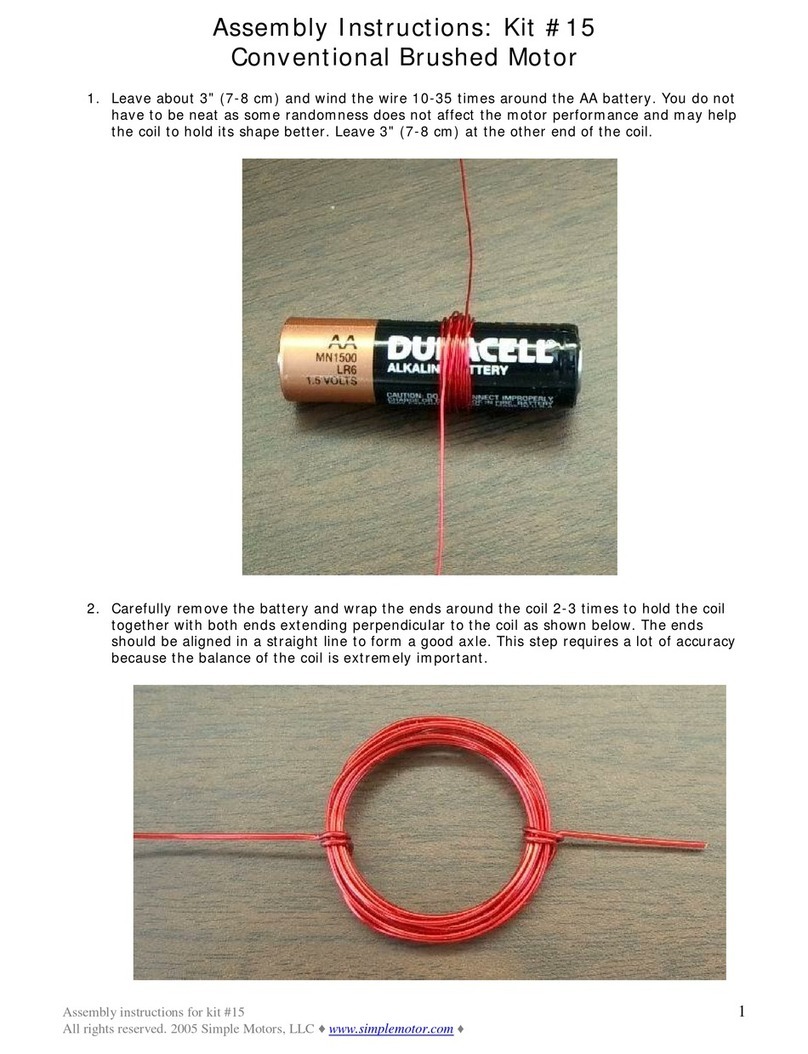

9. You may add two beads on the coil ends. These beads reduce the friction between the coil

and the stands.

If you want to measure the speed of your motor bend the coil ends as shown. Visit

http://simplemotor.com/motor-speed-measurement/ for information on how to measure

the speed of rotating coil in RPM.

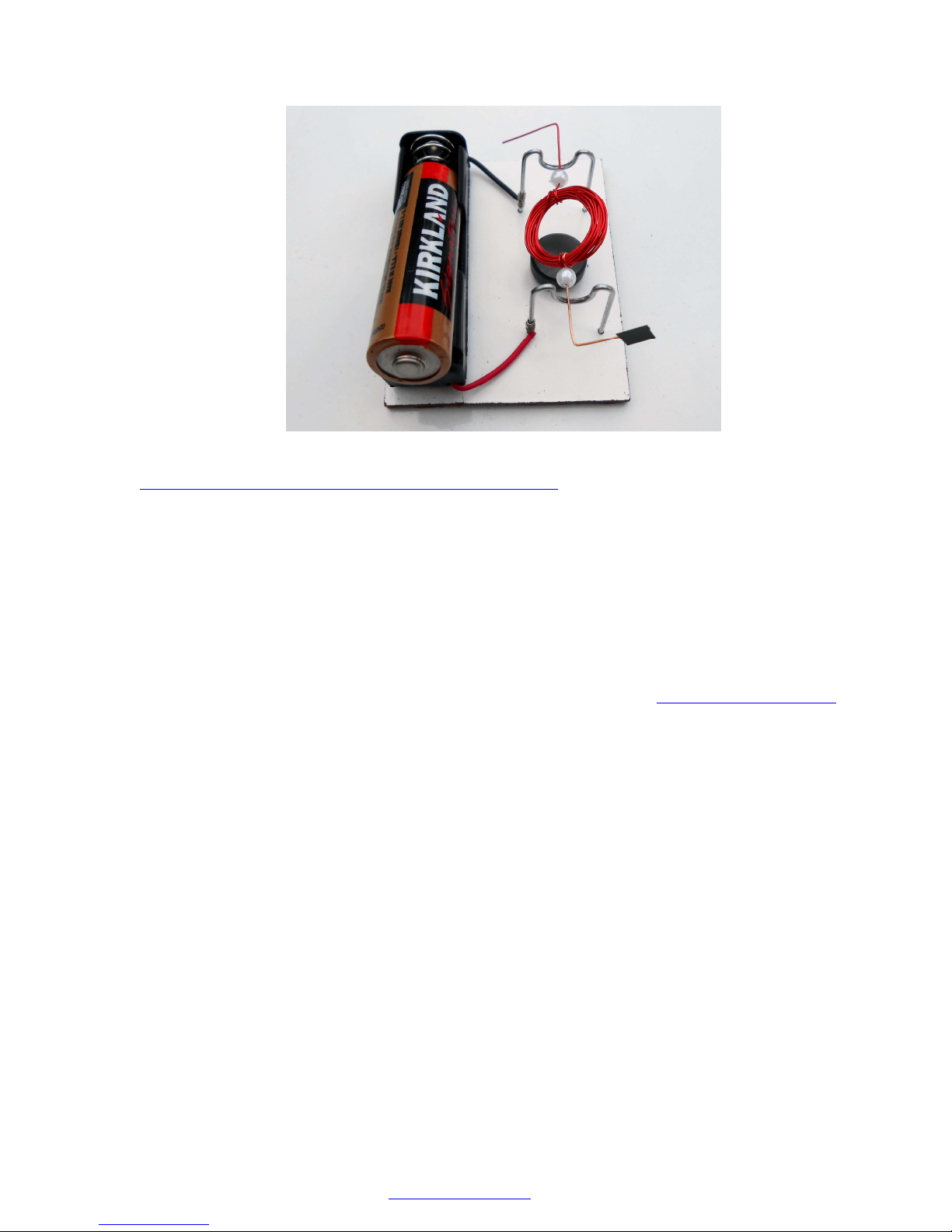

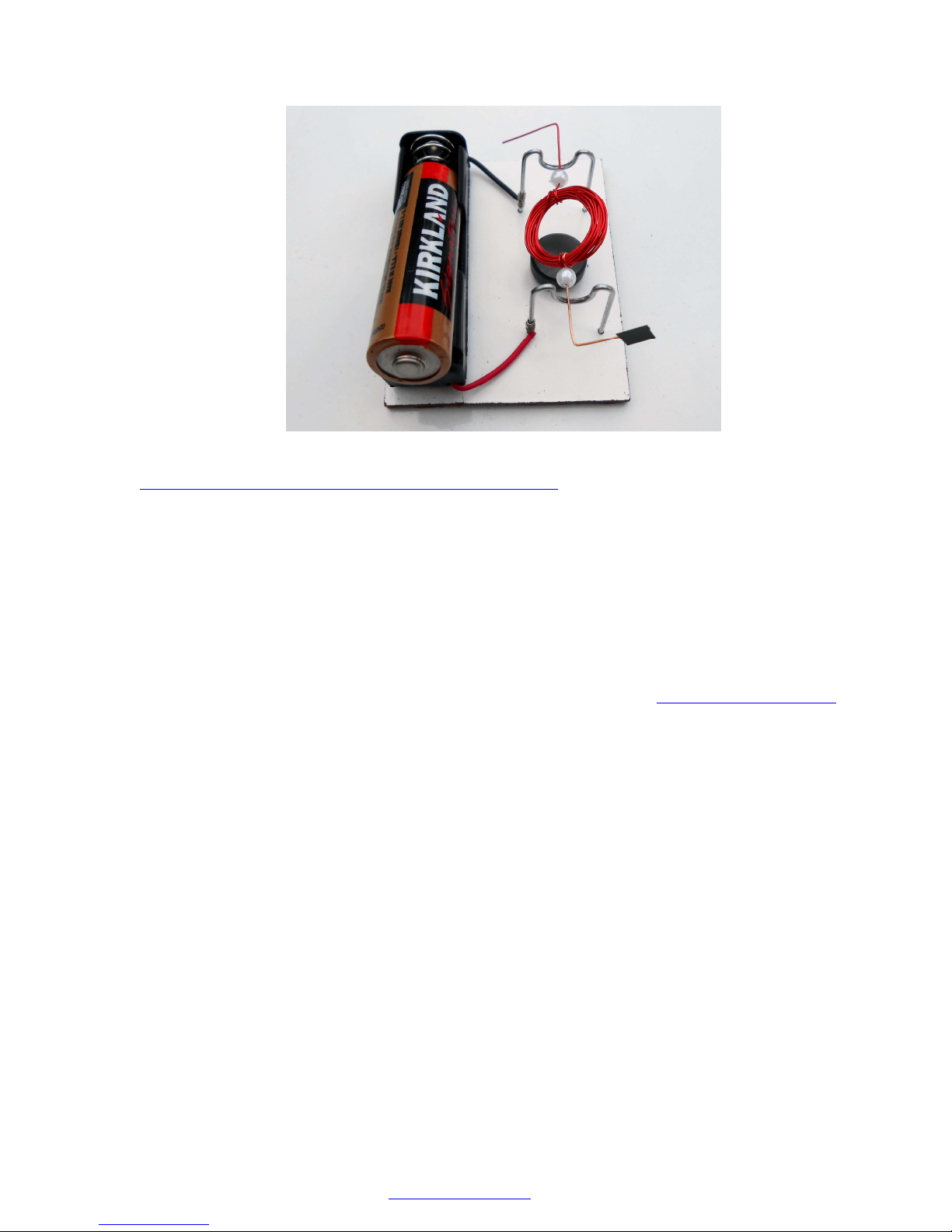

Your motor is ready! Depending on the coil position the motor may start immediately or you

might need to give it a slight push. The motor usually spins in one direction so you should

try to spin it slightly in both directions.

If your motor doesn't work, ensure that the rotor is balanced and can rotate freely and

check the insulation. Properly removed insulation leaves shiny copper on one end. Half of

the other end should also have shiny copper color while the other half should be the color of

the original insulation as shown in step 3. Make sure the battery is fresh. If the motor still

does not work – check Troubleshooting section at our web site at www.simplemotor.com.

Clean carbon buildup (black stuff) on coil ends and metal stands often.

CAUTION: Do not leave the motor connected to the batteries if the rotor is stalled. This

motor consumes a lot of electricity and could drain the batteries quickly even if it does not

spin.

How it works

When un-insulated (bare copper) parts of the coil wire contact the metal stands the current

from the battery flows through the coil making it an electromagnet with North and South

poles. This electromagnet interacts with the permanent magnet (North and South poles

attract each other while the same poles repel). Motor starts to spin until the contact is

broken when an insulated part of the coil end comes into contact with the stand. However,

the coil continues to spin due to inertia and then the process continues. Technically

speaking this motor is a single pole pulse motor.