Simpson Strong-Tie PT-27 User manual

aa

aa

PT-27 .27 Caliber Semi-Automatic Tool Model

Operator’s

Manual

WARNING — Read before operation

2© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R

A. Training

1. All operators must complete the tool manufacturer’s training before attempting to take

an exam or to operate Simpson Strong-Tie®tools. You must obtain certification of training

from an authorized Simpson Strong-Tie instructor. If such training is not available where you

purchased the tool, call or write Simpson Strong-Tie before attempting to operate the tool

for information on the nearest authorized instructor. Simpson Strong-Tie also offers online

training and certification. For more information, visit your local Simpson Strong-Tie website.

2. Obtaining this instruction is your responsibility.

3. Read this manual completely and understand its contents fully before attempting to

operate the tool. If there is anything in this manual that you do not fully understand, ask

your instructor or call Simpson Strong-Tie for information. Reading and understanding this

manual is your responsibility.

B. Limitations

1. Just as no instruction book of any kind can forewarn a learner against all possible situations

or emergencies that may arise, neither can Simpson Strong-Tie instructors or printed

instructions detail all possible conditions or circumstances surrounding the use of this tool

or its supporting products. Recognizing these circumstances and reacting in a safe manner

is your responsibility.

2. Simpson Strong-Tie disclaims any responsibility for injury or death, which may result

from any disregard of this manual or the verbal instruction of the authorized

Simpson Strong-Tie instructor. Following the rules of safe operation given to you

here and verbally is your responsibility.

SAFETY STARTS WITH YOU

OBTAIN AUTHORIZED TRAINING

Safety Overview

© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R 3

Safety Overview.............................................................................................................. 2

Introduction .................................................................................................................... 3

General Handling of PAT and Powder Loads .................................................................. 4

Making Safe Fastenings.................................................................................................. 5

The “Nevers” of PAT Fastening ....................................................................................... 6

Before Chambering a Powder Load................................................................................ 7

Safe Handling Practices of PAT....................................................................................... 8

Operating Principles of PAT ............................................................................................ 9

Schematic and Parts for the PT-27 Tool .................................................................. 10–11

Principles and Guidelines for Proper Fastening ....................................................... 12–13

How to Load and Fire the PT-27............................................................................. 14–15

Dismantling the PT-27 Tool ........................................................................................... 16

Maintenance and Cleaning .......................................................................................... 17

Troubleshooting Tips .................................................................................................... 18

PT-27 Tool Kit ............................................................................................................... 19

Limited Warranty .......................................................................................................... 20

The Simpson Strong-Tie®PT-27 tool is a low-velocity or indirect-acting, powder-actuated tool (PAT).

Do not attempt to operate this or any other tool before obtaining proper training and

operator certification.

Read this manual carefully

Understanding the safety features, operating principles and limitations of the tool will help you

operate the tool with the greatest SAFETY and efficiency. Simpson Strong-Tie disclaims any

responsibility for incidents resulting from the disregard of these instructions.

Table of Contents

Introduction

4© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R

General handling of powder-actuated tools

1. Always point the tool away from yourself and all bystanders.

2. Open the tool before operating to make sure it is not loaded.

3. Never place your hand or any part of your body over the front of the tool.

4. Never operate the tool without checking to see if the barrel is free of obstructions and that

the tool is clean and in good working condition.

5. Never attempt to alter, modify or manufacture parts for use in your Simpson Strong-Tie®tool;

this can cause malfunctions and result in unsafe functioning of the tool. Use only genuine

Simpson Strong-Tie parts, fasteners and powder loads at all times.

6. Always wear eye and ear protection for operators and bystanders. Head protection is

recommended. Serious injury or death can occur if these safety items are not used.

7. Posting a warning sign, “Warning, Powder-Actuated Tool in Use,” is a minimum warning

where PAT tools are in use. Sign to be at least 8" (203.2 mm) by 10" (254 mm) in size with

1" (25.4 mm) font height letters.

8. Always properly brace yourself when working on scaffolding or ladders.

9. Never use powder-actuated tools in flammable atmospheres.

10. Never use the tool for anything other than its intended purpose.

11. Use common sense and good judgment. Know the material you are fastening into,

making certain it is compatible with the powder-actuated tool.

Handling of powder loads and powder-actuated tools

1. Never carry powder loads in the same pocket or container with fasteners

or any other hard objects.

2. Never use powder-actuated loads in firearms. They are more powerful

than normal small arms ammunition.

3. Never carry a loaded tool from job to job.

4. Never use powder-actuated tools in flammable atmospheres.

5. Never discharge the tool without a fastener. Injury or damage to the tool could result.

6. Never attempt to force a load into the chamber of the tool.

7. Never strike or pry a load.

8. Never leave a loaded tool or the powder loads unattended. Store under lock and key.

General Handling of PAT and Powder Loads

© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R 5

Base material suitability and the center punch test

Before loading the tool or fastening into any material, check the suitability and thickness of the

base material. To check base material suitability, give it the center punch test.

Center punch test

Using the fastener as a punch, take a hammer and strike a solid blow to the actual material you

wish to fasten into, then look for these results:

1. If the point of the fastener is blunted, the material is too hard and is unsuitable. If the material

is too hard, the fastener can ricochet, and possibly escape, striking you or bystanders causing

serious injury or death.

2. If the material cracks or shatters, it is too brittle and is unsuitable. This can result in particles

striking the operator or bystanders, or the fastener could pass completely through the base

material causing serious injury or death.

3. If the fastener sinks into the material with the hammer blow, the material is too soft and is

unsuitable. If the material is too soft, the fastener can pass completely through and strike

someone on the other side causing serious injury or death.

4. If the fastener makes a small indentation in the base, the base material is suitable for

fastening into.

Do not use powder-actuated tools for fastening into these materials:

1. Vertical mortar joints

2. Bricks

3. Hollow block or tile

4. Glazed tile

5. Glass

6. Hardened or tool grade steel

7. Cast iron

8. Welded areas or torch cuts

9. Spring steel

10. Natural rock

Base material thickness

Thickness of the base material is perhaps the most important consideration for good safe

fastenings. In concrete, the thickness must be three times the shank penetration; in other words,

for 1" (25.4 mm) of shank penetration, the concrete must be at least 3" (76.2 mm) thick. In steel,

the thickness must be equal to or greater than the diameter of the shank. Fastening into any base

material, which is too thin, may enable the fastener to pass through and escape — resulting in

serious injury or death.

Making Safe Fastenings

6© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R

Guidelines for safe fastening

1. Never hold the tool at any angle other than perpendicular to the work surface. Make sure that

no debris is present on the surface.

2. Never set a fastener too close to another installed fastener as this can cause a ricochet.

3. Never fasten less than 3" (76.2 mm) from the edge of unsupported concrete or masonry, or

less than

½

" (12.7 mm) from the edge of steel, except for specific applications recommended

by the tool manufacturer.

4. Never fasten into rough, spalled, cracked or uneven concrete. Fasten at least 3" (76.2 mm)

from the outer edge of a spalled area.

5. Never fasten into material that is too hard, such as hardened steel, welds, cast steel, marble,

spring steel, natural rock, etc. This could cause the fastener to shatter and escape and result in

serious injury or death.

6. Never fasten into material that is too brittle, such as glass, glazed brick, glazed tile, slate, etc.

This could cause the material to shatter and result in serious injury or death.

7. Never fasten into material that is too soft, such as wood, plaster, drywall composition board,

plywood, etc. This could cause the fastener to pass through and escape resulting in serious

injury or death.

8. Never leave the chamber loaded. If you decide not to make a fastening after having loaded the

tool, remove both the powder load and fastener from the tool before returning it to its case.

9. Never place your hand or any part of your body over the front of the tool.

10. Never point the tool toward any person, loaded or not.

The “Nevers” of PAT Fastening

© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R 7

PT-27

Model

No.

Shank Dia.

(in./mm)

Head Dia.

(in./mm) Accessory Use Pin Length

(in./mm)

PDPA 0.157/4.00 0.3/7.4 —Attachment of cold-formed steel or wood to structure Max. 2

½

/63.5

PDPAWL 0.157/4.00 0.3/7.4 1" (25.4 mm) washer Attachment of cold-formed steel or wood to structure

with additional bearing surface All

PDPAT 0.157/4.00 0.3/7.4 Top hat Attachment of cold-formed steel to structure

with additional clamping All

PCLDPA 0.157/4.00 0.3/7.4 90˚ clip Attachment of suspended ceilings

and overhead applications All

PECLDPA 0.157/4.00 0.3/7.4 120˚ clip Attachment of suspended ceilings

and overhead applications All

PTRHA 0.157/4.00 0.3/7.4 Threaded hanger clip Attachment of suspended ceiling, piping and

other overhead items using threaded rod All

PINW 0.157/4.00 0.3/7.4 1 7/16" (36.5 mm)

metal washer Attachment of insulation board (metal washers) All

PINWP 0.157/4.00 0.3/7.4 13/8" (34.9 mm)

plastic washer Attachment of insulation board (plastic washers) All

PHBC 0.157/4.00 0.3/7.4 Highway basket clip Attachment of rebar and dowel basket anchorage All

PBXDP 0.157/4.00 0.3/7.4 BX cable clip Attachment of BX cables to structure All

PCC 0.157/4.00 0.3/7.4 Conduit clip Attachment of conduits to structure All

Prepare for loading

1. Always check prior to operating a tool that it is not loaded with a powder load or fastener.

2. Always check to be sure that the tool is clean. Excessive dirt or debris can cause

accidental firing or misfiring of the tool.

3. Never load or fire the tool 3" (76.2 mm) from the edge of unsupported concrete or masonry,

or less than

½

" (12.7 mm).

4. Never use improper powder loads or fasteners in the tool, as this may be unsafe or

damage the tool.

5. Always insert the fastener first, and the load last. Make sure you never double load

the fasteners.

6. Always perform the center punch test as described in this manual before fastening into any

unknown base material.

7. Always make a test fastening with the lowest power loads and work your way up in power

as needed.

Fasteners for the PT Tool

Model No. Description

P27SL2/P27SL2A .27 Cal. — Brown (level 2)

P27SL3/P27SL3A .27 Cal. — Green (level 3)

P27SL4/P27SL4A .27 Cal. — Yellow (level 4)

P27SL5/P27SL5A .27 Cal. — Red (level 5)

Powder Loads for PT-27

Before Chambering a Powder Load

Selecting Fasteners and Loads

Only use fasteners and powder loads designed for this tool as supplied by Simpson Strong-Tie.

8© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R

1. If the powder load does not fire after pulling the trigger, hold the tool firmly against the work

surface for at least 30 seconds. Carefully remove the tool from the work surface making sure to

point it away from yourself and bystanders. Remove the load and dispose of it in a can of water.

Unfired loads must never be thrown in trash containers or carelessly discarded in

any way.

2. NEVER attempt to force or pry an unfired powder load from the chamber with a sharp or pointed

object as this may cause an accidental discharge.

3. NEVER attempt to disassemble a jammed tool containing a live powder load. Tag the tool

“DO NOT USE” and store it safely in a locked case. Call your Simpson Strong-Tie®representative

for tool repair.

4. If at any time during the operation of the tool you feel it is not working properly, STOP using it

and call your Simpson Strong-Tie representative.

5. Check the work surface to be sure it is clear of debris. Clear away any debris so that the tool sits

flush on the work surface.

6. Check the work area for explosive or flammable materials. If any are found, remove them before

operating the tool.

7. Check the chamber of the tool to be sure there is no dirt, grit or foreign objects present.

8. Check the nosepiece to make sure you don’t double load it with fasteners and that it is clear

of any obstruction.

9. Any tool found not to be in proper working condition shall be immediately removed from

service and tagged “Defective Tool” until it has been repaired according to the manufacturer’s

instructions.

BEFORE loading the tool, operate it a few times on a solid surface making certain all parts

move freely and that the firing pin clicks when the tool is fully depressed and the trigger is pulled.

Discharging the tool without a load in the chamber will cause “dry firing,” which will not damage

the tool.

Safe Handling Practices of PAT

© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R 9

SAFETY STARTS WITH YOU

As the powder-actuated tool operator, your safety and the safety of those around you should

always be kept in mind. Consider that the least powerful load used in powder-actuated tools

produce approximately ten times the power of a .22 caliber long rifle cartridge. Respect this

power as you would a chain saw, a lawn mower or a rifle.

There are two types of powder-actuated tools.

CAUTION Powder-actuated tools are capable of fastening into concrete and/or steel. The

fastener enters the work surface with an extreme amount of energy. Make certain not to

misdirect the energy.

Indirect-acting type tool

Indirect-acting type tools work by expanding gases that act directly on a

piston, which drives the piston forward to strike the fastener.

Direct-acting type tool

Direct-acting type tools work by expanding gases that act directly on the

fastener without the use of a piston. Direct-acting tools are no longer

manufactured in North America and are regarded as far less safe to operate

than indirect-acting tools. Simpson Strong-Tie only provides indirect-acting

type tools.

1Powder load

releases energy

3

Power fastener installs

into concrete, cement

block or steel

2Piston drives

forward

Operating Principles of PAT

The PT-27 is an indirect-acting type tool.

10 © 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R

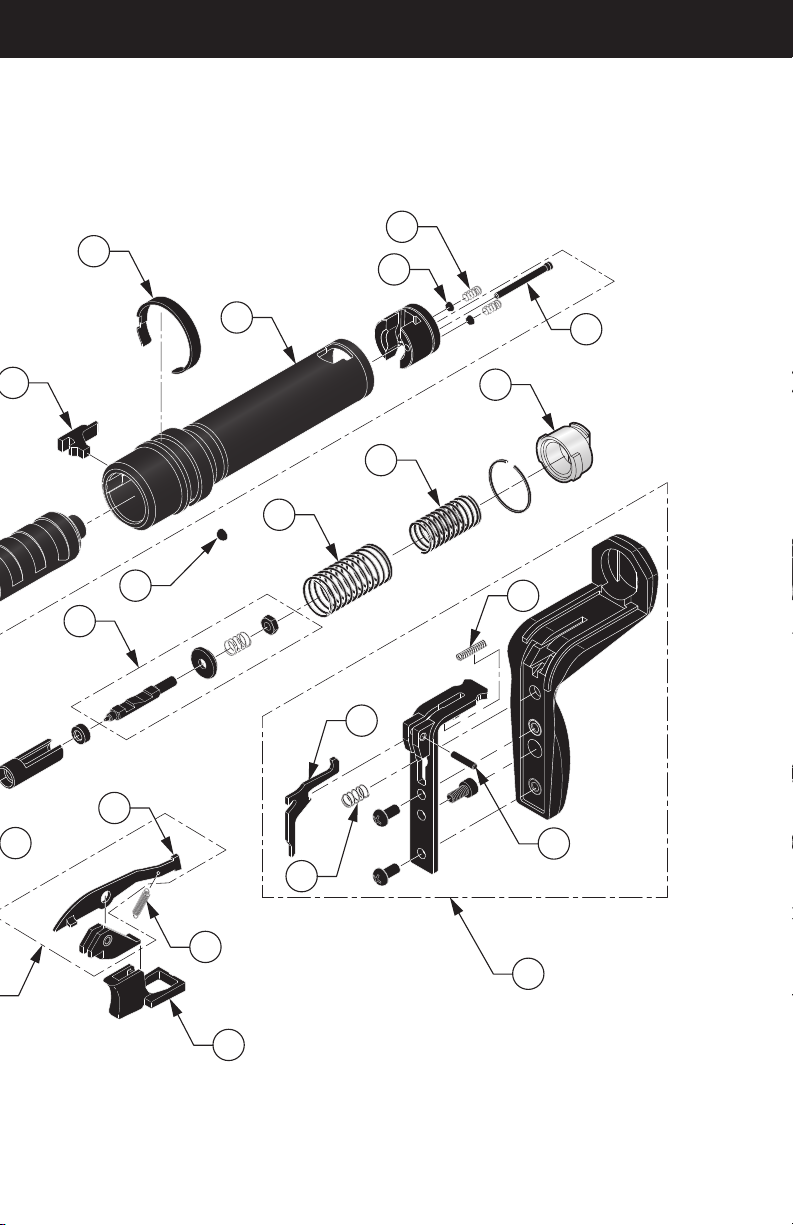

1

8

9

24

11

32

33

4

34

12

7

35

31

23

19

2

14

13

10

22 3

28

29

30

15

16

21

20 18

17

5

6

Schematic and Parts for the PT-27 Tool

1. Body Assembly PT-301001

2. Trigger Pin PT-301034

3. Advance Bar Hold PT-301529

4. Advance Bar PT-301530

5. Advance Bar Spr. PT-301531

6. Trigger PT-301533

7. Screw (Bolt) PT-301015

8. Receiver PT-301100

9. Annular Spring PT-301014

10. Ball Bearing (6 mm) PT-301013

11. Piston Stop PT-301012

12. Push Pin PT-301016

13. Ball Bearing (5 mm) PT-301046

14. Spring (Mag. catch) PT-301047

15. Barrel PT-301006

16. Piston PT-301903

17. Piston Ring PT-301208

18. Nosepiece PT-301010

19. Base plate PT-301009

20. Shear Clip PT-301011

21. Sear Holder PT-301300

22. Sear PT-301023

23. Sear Spring PT-301024

24. Firing Pin Assembly PT-301904

28. Spring (Sear holder) PT-301026

29. Spring (Firing pin) PT-301025

30. Plug PT-301028

31. Rubber Pad Assembly PT-301601

32. Rock Arm PT-301844

33. Spring (Lever) PT-301840

34. Trigger Spring PT-301843

35. Pin, Rock Arm PT-301845

© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R 11

1

8

9

24

11

32

33

4

34

12

7

35

31

23

19

2

14

13

10

22 3

28

29

30

15

16

21

20 18

17

5

6

12 © 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R

Fastening into masonry materials

Masonry materials suitable for fastening into include:

•Poured concrete

•Precast concrete

•Prestressed concrete

•Grout-filled concrete block

•Horizontal grouted joints

Fasteners are primarily held into masonry by a clamping of the concrete around

the fastener. Factors that influence a fastener driven into concrete include:

•Depth of penetration

•Compressive strength of concrete

•Fastener spacing and edge distance

•Fastener shank diameter

•Concrete aggregate

0.145"– 0.157" (3.68 mm – 4.00 mm)

Diameter Shank Penetration

Soft Concrete/Masonry

2,000 psi (13.8 MPa) – 2,500 psi (17.2 MPa) 9–10 times shank diameter

Average Concrete/Masonry

3,500 psi (24.1 MPa) – 4,000 psi (27.6 MPa) 7–8 times shank diameter

Hard Concrete/Masonry

5,000 psi (34.5 MPa) – 6,000 psi (41.4 MPa) 5–6 times shank diameter

PATMI Minimum Fastener Spacing and Edge Distance into Concrete

Shank Diameter (in./mm)

Minimum Fastener

Spacing (in./mm) Edge Distance (in./mm)

0.100/0.254 to 0.156/0.399 4.0/101.6 3.2/81.3

0.157/4.00 to 0.199/5.07 5.1/129.5 3.5/88.9

0.200/5.08 to 0.250/6.35 5.9/149.9 4.0/101.6

Distances per ASTM E1190 and PATMI. Reference Powder Pin Code listing for specific pin

requirements or conditions.

PATMI Recommended Penetration Depths for Optimal Holding Power

Concrete thickness

Concrete thickness must be at least three times the fastener penetration.

Principles and Guidelines for Proper Fastening

© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R 13

PATMI Minimum Fastener Spacing and Edge Distance into Steel

Shank Diameter (in./mm)

Minimum Fastener

Spacing (in./mm) Edge Distance (in./mm)

0.100/0.254 to 0.156/0.399 1.0/25.4 0.5/12.7

0.157/4.00 to 0.199/5.07 1.0/25.4 0.5/12.7

0.200/5.08 to 0.250/6.35 1.6/40.6 1.0/25.4

Distances per ASTM E1190 and PATMI. Reference Powder Pin Code listing for specific pin

requirements or conditions.

Fish-hooking

“Fish-hooking” is when the fastener curves when driven into concrete, due to the fastener hitting

large, hard, or excessive amounts of aggregate, rebar or any hard object. Fish-hooking can reduce

the holding power of the fastener, result in spalling, and may increase unsafe conditions due to

escaping particles. Fish-hooking can be minimized by:

•Reducing shank penetration.

•Increasing shank diameter.

•Using appropriate powder load level. Excessive power can cause overdriving.

•Fastening through a metal disc.

Fastening into steel

The most common type of steel fastened into are structural steel beams, angles, channels, tees

and plates. The holding power of the powder-actuated fastener is a function of the gripping action

of the steel base material around the fastener and the fusion of the fastener to the base material.

Factors that influence the holding power of fasteners in steel

•Shank diameter: Larger shank diameters increase holding power.

•Thickness of steel base material: Thicker base material increases holding power.

•Fastener point penetration: Getting the point to pass through base material by approximately

¼

" (6.35 mm) maximizes holding power.

•Knurled fasteners: Knurling on the fastener provides interlocking of the shank and the base

material that increases the holding power.

14 © 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R

PT-27

PT-27

PT-27

PT-27

PT-27

PT-27

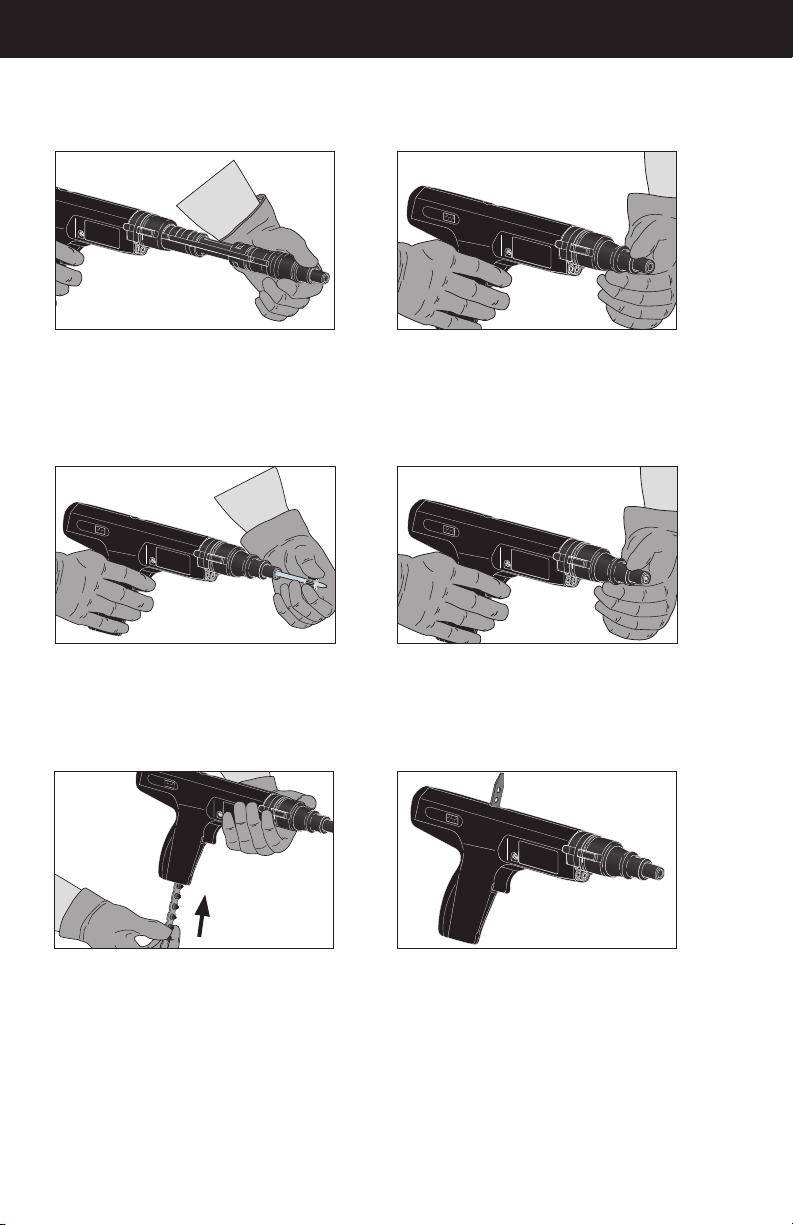

1. Cycle the tool. Grasp the base plate and fastener guide/nosepiece and pull sharply

forward until you feel a positive stop, then pull the base plate and fastener guide/

nosepiece back until it stops and is fully closed. Take care not to pinch your skin

between the base plate and receiver by holding the forward portion of the base plate.

This resets the piston and positions the advance lever in the correct location for

inserting the strip loads.

Never place your hand over the guide/nosepiece of the tool unless inserting a fastener and

then only with the chamber empty.

2. Insert the fastener into the nosepiece of the tool, head or threaded end first. Push

the fastener until the pointed end is even with the face of the nosepiece, or if a

preassembled fastener is used, until the nosepiece is against the fastener accessory.

How to Load and Fire the PT-27 Tool

3. Prior to selecting the power level of the loads, always conduct a center punch test to

determine the suitability of the base material. Always begin with the lowest power loads

(brown) and work your way up in power as needed. Insert the strip load through the

bottom of the handle until it is flush with the bottom.

© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R 15

PT-27

PT-27

PT-27

4. Depress the tool firmly against the work surface using both hands, then pull

the trigger. Make certain you hold the tool perpendicular to the work. Using

the supplied rubber spall stop will help ensure the tool is perpendicular

to the work surface and will help to minimize concrete spalling when the

fastener is installed.

5. After making the fastening, lift the tool off the work surface and pull the base

plate and fastener guide/nosepiece sharply forward. This action resets the

piston and advances the powder load strip to the next powder load.

6. Remove the spent powder strip load by grasping the strip from the top side

of the tool and firmly pull upwards in a smooth motion.

16 © 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R

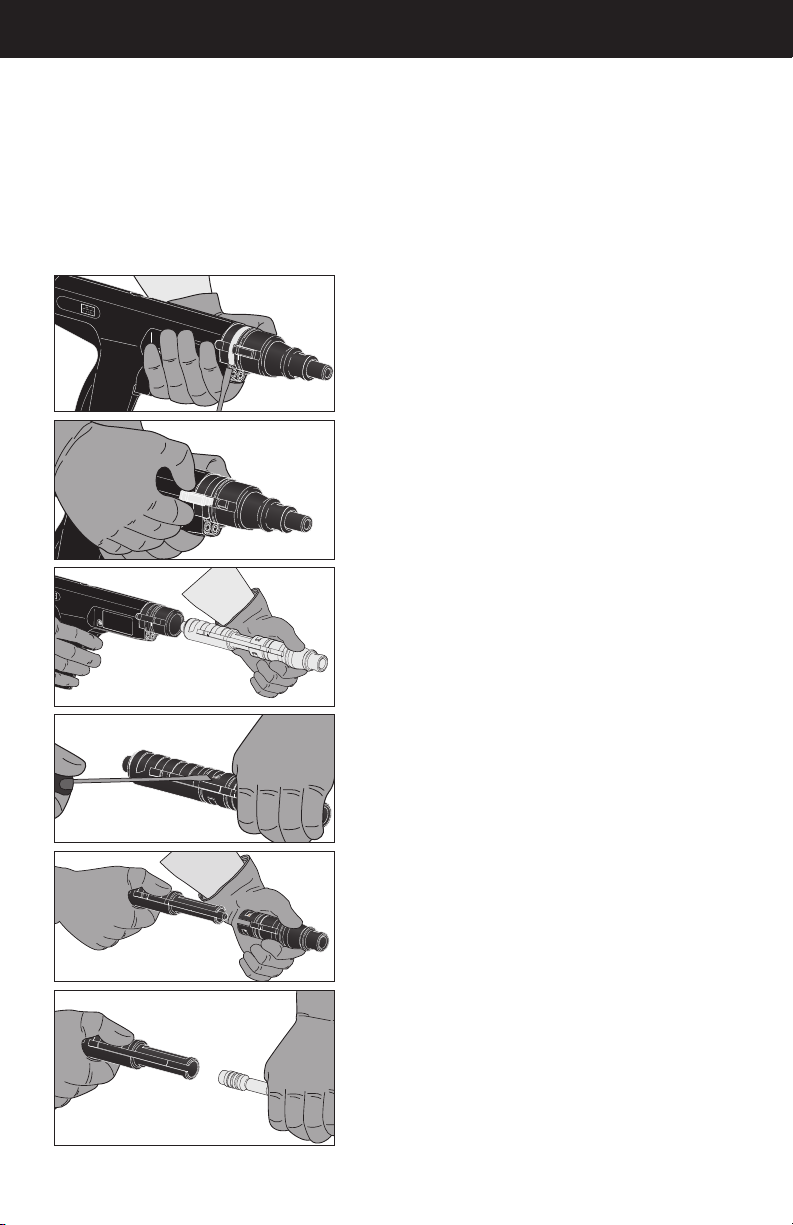

The PT-27 tool has wearable parts that occasionally need replacing, and the tool requires

periodic cleaning. The following is a step-by-step guide to dismantle the tool. Before

dismantling, be sure the tool is not loaded with a powder load or fastener.

Dismantling the tool

PT-27

(1). Rotate the annular spring off

the piston stop with a flat blade

screw driver or long fastener.

Do not over rotate or remove

the annular spring as it holds

a ball bearing in place on

the opposite side.

PT-27

(2). Lift the piston stop out of

its recess slot.

PT-27

(3). Pull the barrel assembly out

the front of the tool.

(4). Lift and remove the

Shear Clip from its recessed

groove with a flat blade

screw driver.

1. Rotate the annular spring off the piston stop with a flat

blade screw driver or long fastener. Do not over rotate

or remove the annular spring as it holds a ball bearing

in place on the opposite side.

2. Lift the piston stop out of its recess slot.

3. Pull the barrel assembly out the front of the tool.

4. Lift and remove the shear clip from its recessed

groove with a flat blade screw driver.

5. Separate the barrel, base plate and fastener

guide/nosepiece.

6. Pull the piston out of the front of the barrel.

The front of the tool is now disassembled for replacing

wearable components.

Reassemble the tool in reverse order of dismantling.

(6). Pull the piston out of

the front of the barrel.

Dismantling the PT-27 Tool

© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R 17

Cleaning the tool

With the front of the tool disassembled, spray a small amount of detergent oil; brush and wipe

clean with a clean towel the following parts:

1. Piston — make sure to clean the chamber end of the piston and wipe the shaft clean.

2. Barrel — clean inside the breech and on the outside of the chamber end of barrel making

sure the breech is free of any dirt or debris.

3. Base plate — remove dirt and residue from inside the base plate.

4. Receiver — remove dirt and residue from inside the receiver.

5. Nosepiece — remove dirt and residue from outside of nosepiece.

Note: Make sure excess detergent oil is wiped clean. Excessive detergent oil attracts

additional dirt.

Maintaining the PT-27 tool

A clean tool is safer and functions better. This tool should be cleaned after each day of use or

after 1,000 continuous fastenings. While cleaning the tool, check the wearable parts such as

the piston and piston ring for signs of wear or damage.

While cleaning the tool, make sure wearable parts are in good condition

1. Piston — if the end is flared or the shaft bent, replace the piston.

2. Shear clip and connection between barrel and base plate. The shear clip should be

reviewed for deformation/bending and the end of barrel for chipping/wear where the

shear clip contacts.

3. Nosepiece — if damaged or worn.

Tool parts to be cleaned or replaced

Inside Receiver

Annular Spring

Shear Clip Slot

Nose Piece

Piston Stop Shear Clip

Piston

Base plate

Barrel

Chamber End of Barrel

or Breech

Maintenance and Cleaning

18 © 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R

Symptom Cause Solution

Overdriving

fasteners

Excessive power Change to next lower power level load strip

Soft base material Check base material – center punch test

Pin too short for application Use longer pin or washer pin

Tool does

not depress

completely

Tool not completely depressed Firmly depress tool before firing

Excessive dirt on chamber, breech or

inside the receiver Properly clean tool

Damaged firing pin or breech Replace damaged parts*

Damaged fastener guide Repair or replace fastener guide

Load misfire Follow safety procedure in manual

Tool did not advance strip See “Strip load will not advance” below

Reduction or

loss of power

Piston is not returned to

rear position

Barrel assembly must be pulled fully forward to

reset piston

Damaged piston or piston ring Replace or repair worn parts*

Damaged piston stop Replace damaged part

Piston will not

fully reset

Excess carbon build-up in barrel Completely clean the tool

Bent or damaged piston Replace piston

Other damaged parts

Tag the tool “Defective – Do not use”

Place the tool in a locked container and

contact your local Simpson Strong-Tie® representative

Plastic debris on piston or

in nosepiece Remove piston, fastener guide and debris

Strip load will

not advance

Strip is inserted incorrectly Check proper installation of strip

Barrel is not fully retracting Remove barrel then reinstall barrel to

reset the strip advance lever

Advance mechanism is damaged Contact your local Simpson Strong-Tie representative

Tag the tool and lock it in a container

Improper strip being used Do not use .25 caliber in this tool

Tool will not

say in closed

position

Ball bearing missing Contact your local Simpson Strong-Tie representative

*Should be performed by qualified individuals.

Troubleshooting Tips

© 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R 19

Contents

•Operator’s manual

•Spall suppressor

•Tools for disassembly

•Safety glasses/ear plugs

•Cleaning brushes

•Operator’s exam and caution sign

Tool is sold in a rugged tool box

PT-27 Tool Kit

Allen Wrench

Kit also includes:

- Operators Manual

- Operators Exam

- P.A.T Warning Sign

Spall

PT-27 Tool

Safety Glasses

Large Round Brush

Small Round Brush

Flat Brush

Ear Plugs

CIA

RADOR

PT-27

20 © 2022 Simpson Strong-Tie Company Inc. T-A-PT-27MNL22-R

Simpson Strong-Tie Company Inc. provides this Limited Warranty to original purchasers of the Simpson

Strong-Tie®brand tool product (“Product”). This Limited Warranty is effective as of the date of purchase.

This Product, if properly stored, maintained and used in compliance with all instructions and warnings,

will be free from substantial defects in material and manufacturing for one year of purchase. This Limited

Warranty does not cover normal wear and tear, as determined by Simpson Strong-Tie in its absolute

discretion, and is null and void with respect to: (a) any Product that was purchased from an unauthorized

dealer, retailer or distributor, (b) any Product that was modified or altered, (c) any Product that was

improperly or inadequately serviced or maintained, (d) any Product that was subject to negligence or

excessive or improper use, including use in improper conditions, as determined by Simpson Strong-Tie

in its absolute discretion, (e) any failure or damage caused by the use of a Product with any accessories

other than authentic Simpson Strong-Tie products, or (f) any Product that was subject to any use not

in accordance with the applicable specifications provided with the Product or on the strongtie.com

website. If any Product fails to conform to this Limited Warranty, original purchaser’s sole and exclusive

remedy is either the replacement or repair, at Simpson Strong-Tie election, of the defective Product.

Original purchaser must return the Product to Simpson Strong-Tie along with satisfactory proof of

purchase, with return shipping prepaid by original purchaser. To obtain warranty service, go to strongtie.

com or contact Simpson Strong-Tie promptly at (800) 999-5099. The repaired or replaced Product is

warranted under the terms of this Limited Warranty.

THE LIMITED WARRANTY HEREIN IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, AND,

WHERE LAWFUL, SIMPSON STRONG-TIE DISCLAIMS ALL OTHER WARRANTIES, INCLUDING

BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE AND WARRANTIES ARISING FROM COURSE OF PERFORMANCE,

COURSE OF DEALING OR TRADE USAGE BEYOND THIS WARRANTY PERIOD. SOME STATES

DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU. WHERE LAWFUL, UNDER NO CIRCUMSTANCES SHALL

SIMPSON STRONG-TIE BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL, PUNITIVE OR SPECIAL

DAMAGES OR DIRECT OR INDIRECT LOSS OF ANY KIND, INCLUDING BUT NOT LIMITED TO

BODILY INJURY, DEATH OR PROPERTY DAMAGE. SIMPSON STRONG-TIE’S ENTIRE LIABILITY

IS LIMITED TO THE PURCHASE PRICE OF THE DEFECTIVE PRODUCT. SOME STATES DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. SIMPSON STRONG-TIE IS

IN NO WAY LIABLE FOR INCIDENTS RESULTING FROM USE WITHOUT PROPER CERTIFICATION

OR DISREGARD OF INSTRUCTIONS AND WARNINGS. THIS LIMITED WARRANTY GIVES YOU

SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM

STATE TO STATE.

For repair information, go to strongtie.com, type in the tool model number in “Search,” locate the

“Repair Forms” section on the page, and choose the repair form for your region.

The PT-27 complies with OSHA requirements and with ANSI A10.3 standards.

One Year Limited Warranty

5956 West Las Positas Boulevard, Pleasanton, CA 94588 • strongtie.com

Table of contents