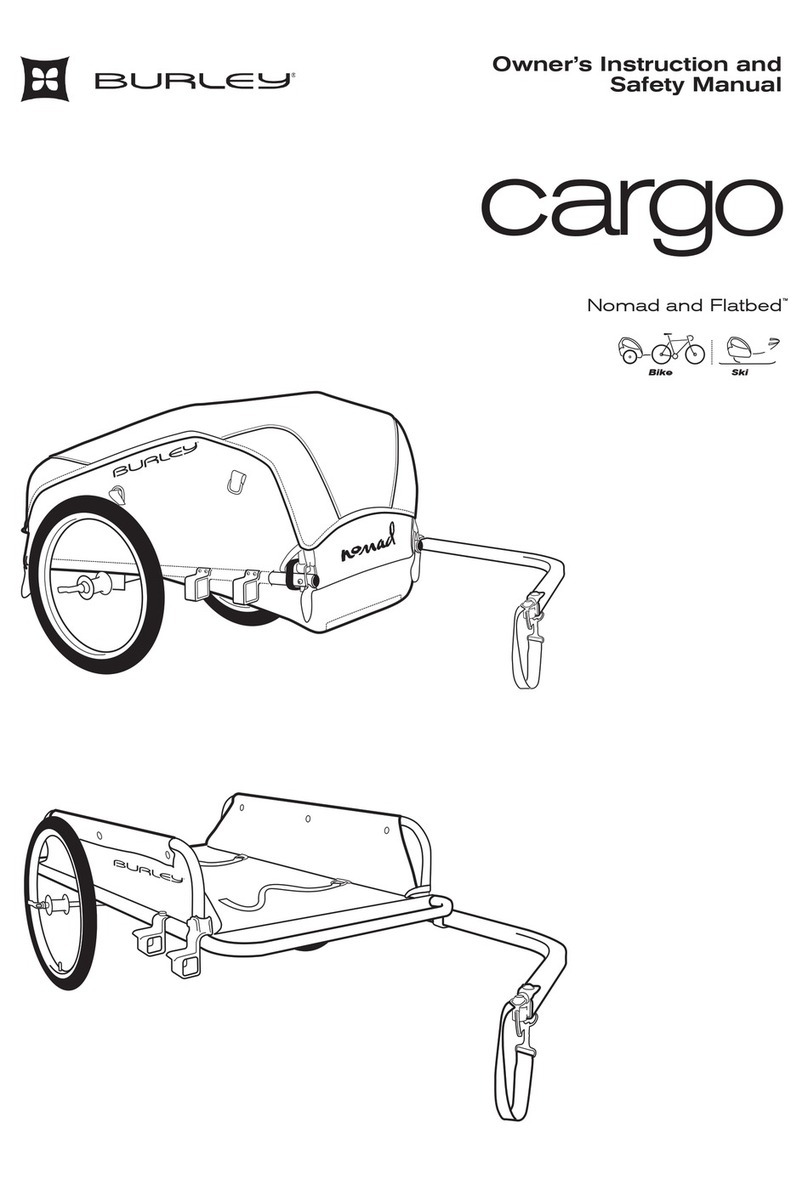

Simpson SWT-525172 User manual

Part Number 7119888 / ENGLISH REV 1 - 12/2022

SAVE THIS MANUAL FOR FUTURE REFERENCE

USE AND CARE MANUAL

WATER TRAILER

READ THIS MANUAL CAREFULLY BEFORE OPERATION

Failure to follow the instructions and safety precautions in this manual can result

in property damage, serious injury and/or death.

NOTE: Photographs and line drawings used in this manual are for reference only and may not

represent your specic model.

If your unit is not working or if there are parts missing or broken, please DO NOT RETURN IT TO THE

PLACE OF PURCHASE. Contact our Customer Service Department by calling 1-877-362-4271 or

emailing [email protected]

LOOK BEFORE YOU PUMP!

Page II

NOTES

THIS PAGE WAS INTENTIONALLY LEFT BLANK

Page 1

SAVE THIS MANUAL FOR FUTURE USE

Write down the model number, serial number, and purchase date of this product in the spaces

provided below then keep this manual with the purchase receipt(s) for future reference.

Keep this manual for future reference. This manual should be considered a permanent part

of the product and stay with it. This manual should be available to anyone operating the

product(s) it covers. This manual should remain with the product(s) it covers if sold to a new

owner. If the manual becomes damaged, lost, or otherwise unusable, you may download

a new copy from the product pages at www.simpsoncleaning.com or contact customer

support by calling 1-877-362-4271.

Model Number:

Serial Number:

Purchase Date:

Page 2

TABLE OF CONTENTS

DISCLAIMERS 5

Hazard Alert Symbols 4

Additional Instructions 4

Read this Manual Before Operating 4

4SAFETY INSTRUCTIONS

COMPONENT LOCATION 6

PRESSURE FILLING THE TANK 9

SETTING THE FLOW VALVES 10

SETTING THE MANIFOLD VALVES 11

SIDE PORT (DISCHARGE OR SUCTION)

12

FILLING THE TANK FROM A

STANDING WATER SOURCE

13

USING THE SIDE PORT OUTPUT 15

USING THE SPRAY BAR 16

DRAINING THE SYSTEM FOR

STORAGE (WINTERIZE)

17

Draining the System 17

TRAILERING SYSTEM 18

Trailer Coupler 18

OPERATING CHECKLIST 22

Location 22

High Altitude Operation 22

Operating Conditions 22

Checking the Engine Oil 24

Checking Fuel 25

Adjusting the Trailer Coupler Height 19

Trailer Electrical System 20

PRESSURE FILL PIPE INSTALLATION 8

Page 3

27STARTING THE ENGINE

29

TURNING THE ENGINE OFF

29

TROUBLESHOOTING

MAINTENANCE 30

Pump Maintenance 30

Exterior Pump Cleaning 30

Interior Pump Cleaning 31

Engine Maintenance 33

Plumbing Maintenance 33

Trailer Maintenance 33

ENGINE LONGTERM STORAGE 34

Storing for Two Months or Less 34

Storing for More Than Two Months 34

WARRANTY 35

CAUTION:CAUTION:

NOTICE

Page 4

This manual contains important safety information and instructions. Do not operate

this product until you have read, and completely understand all safety, operation, and

maintenance instructions listed in this manual. Failure to follow the information contained

in this manual will result in property damage, injury, and/or death.

NOTE: The warnings and precautions discussed in this manual cannot cover all conditions

and situations that may occur. The operator must understand awareness and caution are

factors which cannot be built into this product and so must be exercised by the operator.

READ THIS MANUAL BEFORE OPERATING

ADDITIONAL INSTRUCTIONS

Be sure to understand the safety symbols and denitions listed below. Each symbol

contains one of four words: DANGER, WARNING, CAUTION, NOTICE, indicating

dierent levels of hazard severity. These symbols are used throughout this manual and

are followed information about a specic hazard, the consequences of the hazard, and

instructions on how to avoid the hazard. Failure to heed these symbols and follow the

instructions provided with them will result in property damage, injury, and/or death.

HAZARD ALERT SYMBOLS

Indicates an imminently dangerous situation, which if not

avoided, will result in property damage, serious injury, and/

or death.

Indicates a potentially hazardous situation, which if not

avoided, could result in property damage, serious injury, and/

or death.

Indicates a hazardous situation, which if not avoided, could

result in property damage and/or minor to moderate injury.

Indicates information considered important, but not directly

hazard related.

SAFETY INSTRUCTIONS

Along with this manual, be sure to read any additional instructions provided both on and

with the product, attached equipment, accessories, and the engine powering the product.

Pay careful attention to all additional safety rules and instructions on proper startup,

operation, and shutdown procedures. Always use any recommended protective apparel

that may be needed to operate the equipment safely.

DANGER:DANGER:

WARNING:WARNING:

Attempting to start the engine incorrectly or using the unit incorrectly can result in engine

and/or pump failure and may cause serious injury or death. To avoid these hazards, be

sure to read, understand, and follow the steps outlined in the OPERATING CHECKLIST

section of the owner’s manual before starting the engine and follow all the guidelines for

proper use of the unit.

OPERATING CHECKLIST

WARNING:WARNING:

The SIMPSON Water Trailer is designed to be used only with fresh or gray water. Do not

pump or transport euent, black (sewage) water or any types of chemicals. Do not pump

or transport any uid that is intended for human consumption.

FLUID USAGE

WARNING:WARNING:

Page 5

This product and the engine exhaust can expose you to chemicals which are known to

the state of California to cause cancer, birth defects, or other reproductive harm. For

more information on California Proposition 65, go to www.P65Warnings.ca.gov.

CALIFORNIA PROPOSITION 65 WARNING

POLYCYCLIC AROMATIC HYDROCARBON WARNING

The air lter element and air box assembly may contain polycyclic aromatic hydrocarbons

(PAHs). Some PAHs may cause cancer. To avoid exposure to PAHs, wear gloves when

performing air lter maintenance.

DISCLAIMERS

SAVE THIS MANUAL FOR FUTURE USE.

All information in this publication was based on the latest product information

available at the time of printing. The FNA Group reserves the right to update,

change, and/or improve the product and this document at any time, without

notice and without incurring any obligation.

This manual may cover more than one machine. The pictures and gures

in the manual should be used for reference only. There may be dierences

between your product and the pictures, drawings and diagrams in this manual.

If you loan, rent or sell this machine, be sure to include all instructional materials

with the unit!

Page 6

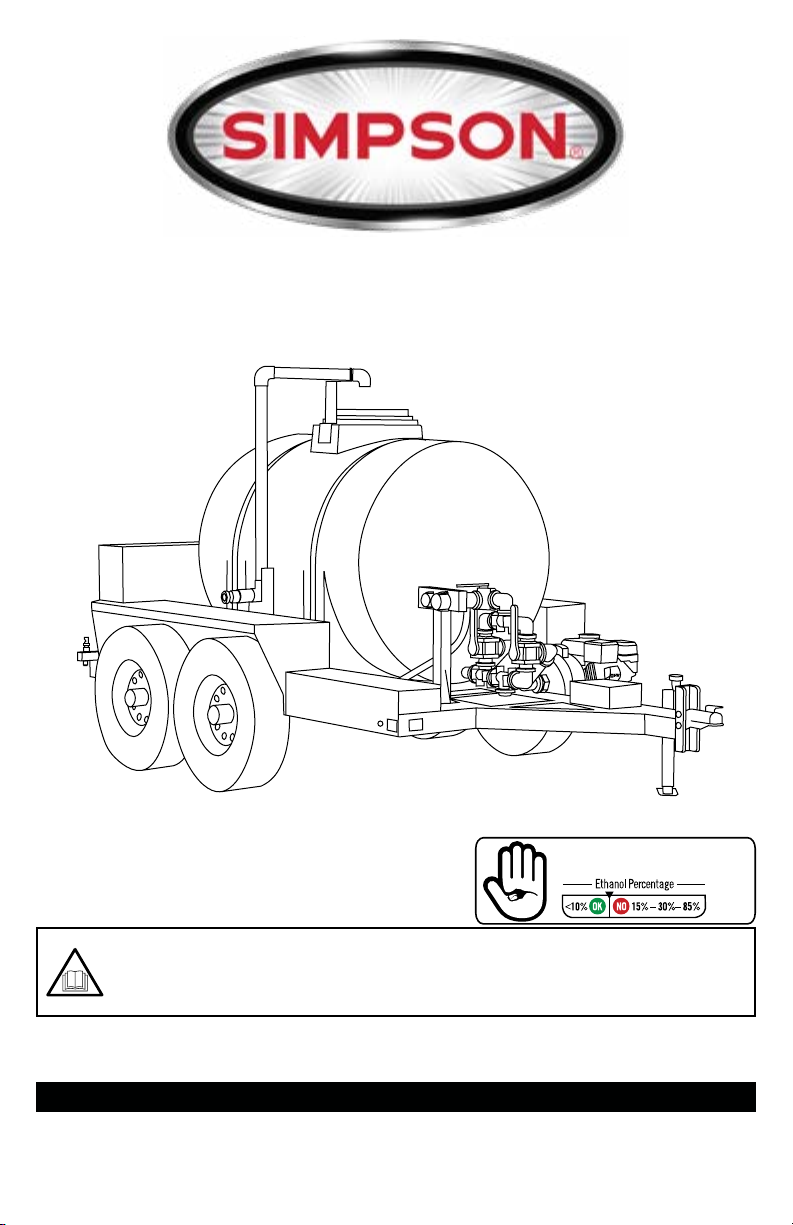

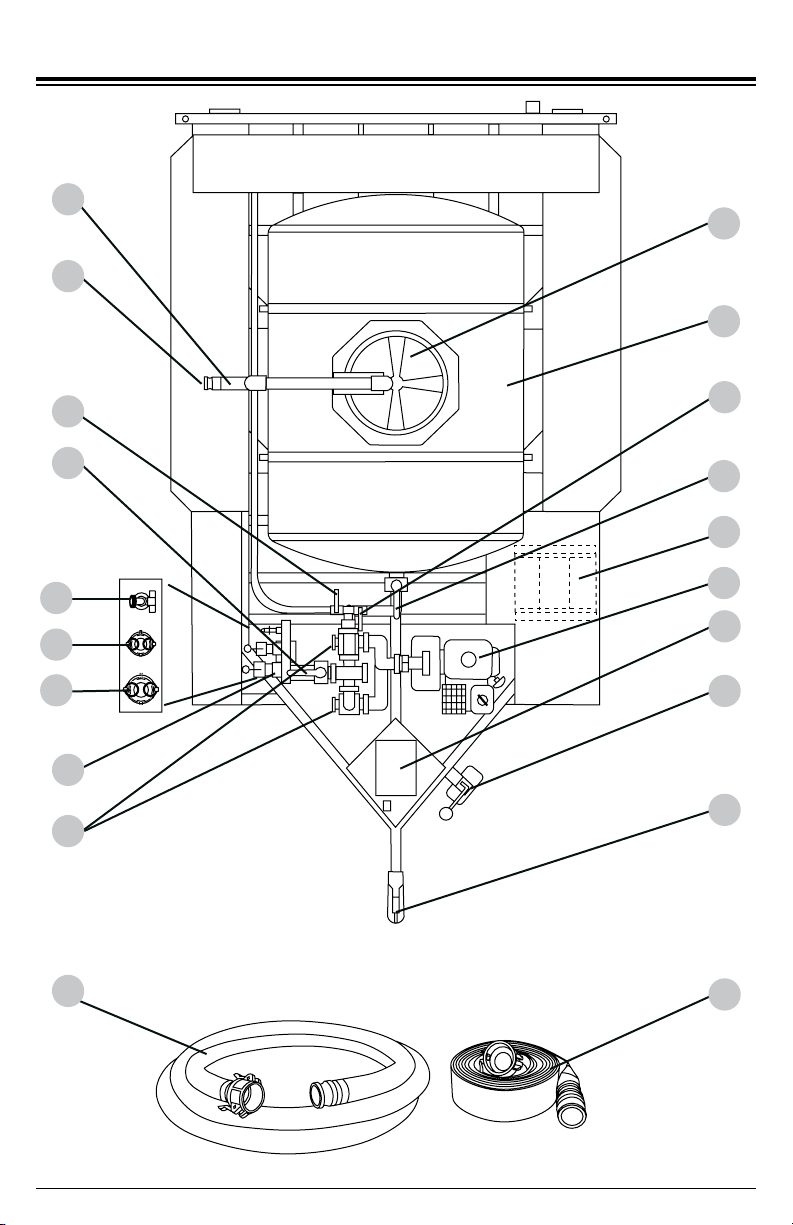

COMPONENT LOCATION

1

2

4

6

8

9

13

11

7

15

5

25

26

27

310

12

14

16

17

Page 7

18 19 20 21 22 23

3. Spray bar control valve, see page 11.

4. Side port control valve, see page 11.

5. Side port, see page 12.

6. Flow control valves, see page 10.

8. Vented tank cover.

9. Tank.

10.

Hose reel (optional) valve, see page 11.

11.

Tank valve, see page 11.

15. Trailer jack.

16. Trailer coupler, see page 18.

18. Red turn/brake light.

19. License plate holder.

20. License plate light.

21. Hose storage bin.

22. Spray bar assembly, see page 16.

23. Spray nozzle (one of two).

24. Amber marker light.

25. Side port garden hose bibb.

1. Pressure ll pipe, see pages 8 & 9.

2. Pressure ll pipe 2” hose connector.

7. 20ft (6.1M) Suction rated hose.

17. 50ft (15.2M) lay at discharge hose.

26. Side port 1.5” connector.

27. Side port 2” connector.

12. Hose reel (optional).

24

14. Protective cover for electrical

components including the break-

away system control, see page 21.

13.

Gasoline powered pump, see page 27

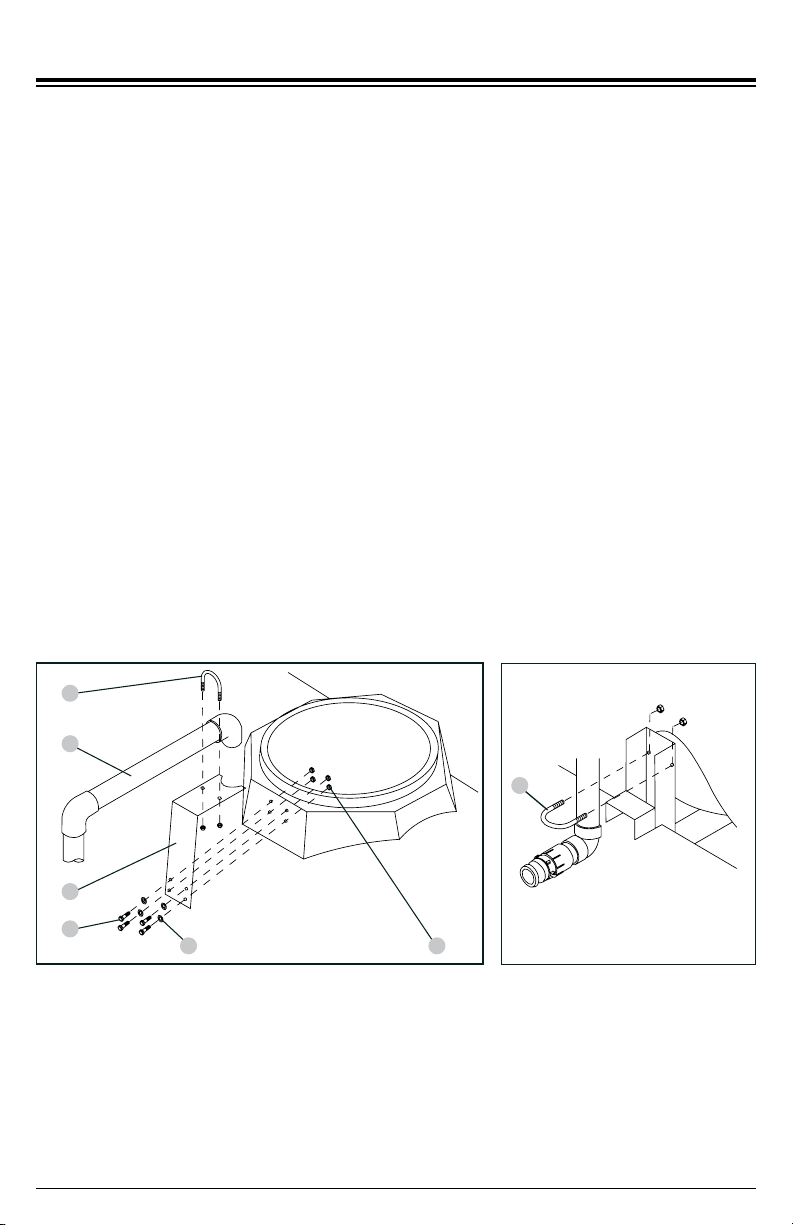

PRESSURE FILL PIPE INSTALLATION

The following tools are required:

(2) 1/2” open end wrenches

(1) 9/16” open end wrench

Please locate the pressure ll pipe in the hose storage bin at the rear of the trailer. Along

with it will be a bag containing the required hardware and U-bolts. Unwrap the protective

plastic from the pipe.

Step 1: Remove the cover from the top of the tank.

Step 2: Using the 5/16” hex bolts (2), 5/16” at washers (3) and 5/16” nylon insert lock

nuts (4), attach the ll pipe bracket (1) to the tank using 1/2” open end wrenches

(Fig. A).

Step 3: Place the pressure ll pipe (5) allowing the elbow to t into the circular relief of

the bracket (Fig. A). Attach using one of the included U-bolts (6). At this time,

only hand thread the nuts, do not tighten.

1

2

3 4

6

5

Fig. A

Step 4: Using the remaining U-bolt (6), attach the pressure ll pipe to the lower bracket

(Fig. B). Tighten both U-bolts using a 9/16” open end wrench.

Step 5: Place the cover back onto the tank.

Fig. B

6

Page 8

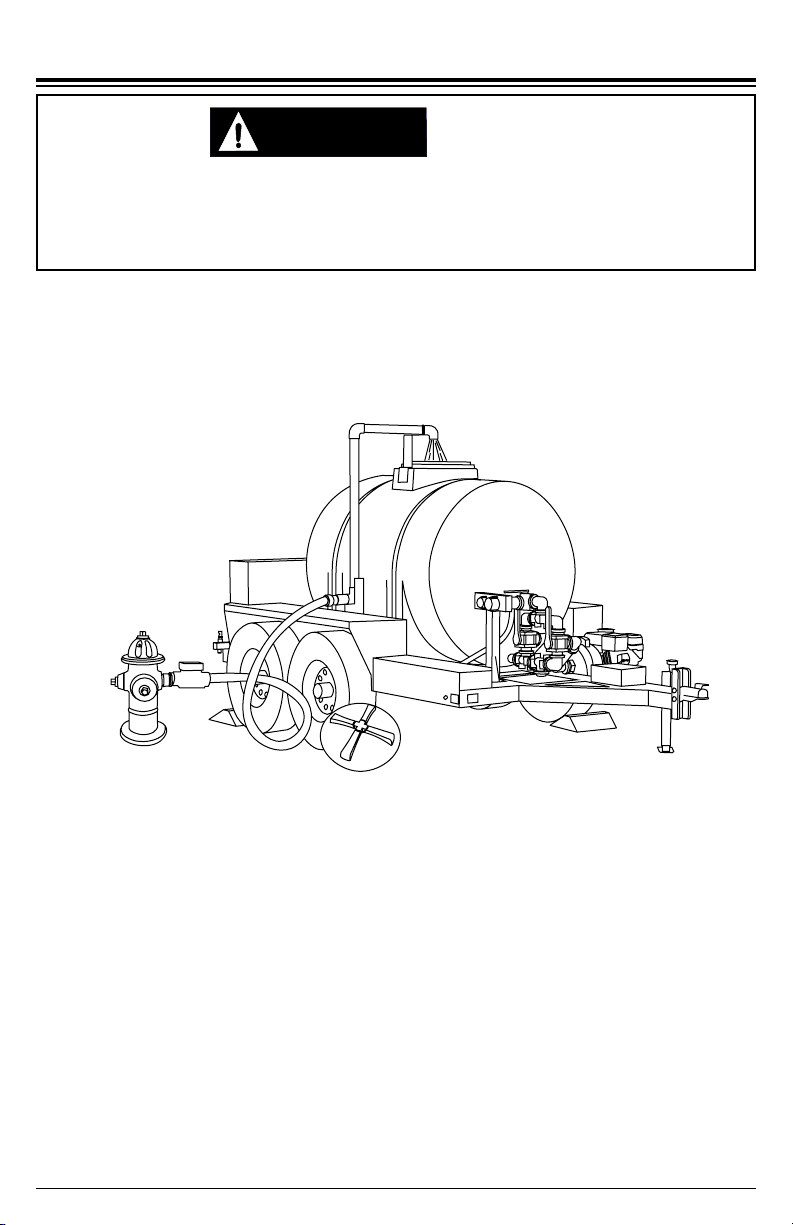

PRESSURE FILLING THE TANK

CAUTION:CAUTION:

Page 9

The tank can be lled from a pressurized water source by using the 2” tank ll on

the passenger’s side of the trailer. NOTE: Do not use a re hydrant unless you have

contacted your local municipality. Typically the water will need to be metered and a

back ow preventer may need to be placed with the meter by the municipal water

department.

1. Remove the cover of the tank.

2. Connect a 2” hose from the pressurized water source to the ll connector.

3. Turn on the water source allowing the tank to ll to the required level.

4. Turn o the water source then disconnect the hose from the ll pipe.

5. Place the cover back onto the tank, secure.

Whenever the trailer is disconnected from the tow vehicle, the trailer should be parked

on a level surface and with the wheels chocked (not included). Trailers with non-chocked

wheels can roll when parked on non-level pavement or when accidentally bumped from

another vehicle leading to injury/death and property damage.

TRAILER MOVEMENT

SETTING THE FLOW VALVES

Page 10

Along with the ability to pump water out (to the spray bar, for example), the SIMPSON

Water Trailer also has the capability to ll its tank from a standing water source such

as a lake, stream or pond.

To pump water from the tank (pump position) the valve handles must be set in the

upward position, (Fig. 1).

The ow valves are what routes the water through the pump. The valves must be set

so the water can either be sent to, or taken from, the tank.

In order to ll the tank (draw position) the valve handles must be set in the downward

position, (Fig. 2).

Fig. 1 (Pump Position) Fig. 2 (Draw Position)

Input

Output

CAUTION:CAUTION:

Failure to properly set the valves can cause damage to the pump and the piping. Always

set the valves and verify the pump is properly primed before starting the engine.

PUMP DAMAGE

Input

Output

NOTICE

This pump will not prime when dry. Running the pump dry without priming can damage the

pump assembly and seals. Damage caused by running dry is not covered by warranty.

To avoid damaging the seals and pump assembly, do not run the pump when it is dry

without priming.

PUMP PRIMING

SETTING THE MANIFOLD VALVES

Page 11

Above the pump is a horizontal manifold (Fig. 3) that contains two valves (spray bar

valve and the passenger’s port side valve). See USING THE SPRAY BAR or USING

THE SIDE PORT, to determine which valve to use. Below the horizontal manifold is

the tank valve.

Spray bar

valve

Passenger’s

side port

Driver’s

side port

(optional)

The valve is open (water ows through) when the handle is in-line with the valve body.

The valve is closed (water cannot ow) when the handle is perpendicular to the valve

body. (See Fig. 4)

Passenger’s side port valve Driver’s side port valve (optional)

Fig. 3

Fig. 4

Valve closed Valve open

Tank valve

Hose reel

(optional)

valve

SIDE PORT (DISCHARGE or SUCTION)

Always have the dust covers in place and locked before moving the trailer. Loose covers

may come free at highway speeds leading to injury. Make it a point each time you will be

moving the trailer to inspect the dust covers and verify they are properly locked.

DUST COVERS

WARNING:WARNING:

Page 12

The side ports allows you to send water out to a hose (for example, irrigation) or using

a hose to draw water into the tank (1.5 or 2” only).

The port assembly contains a 1.5” hose connector, a 2” hose connector and a standard

3/4” garden hose bibb. (See Fig. 5)

1.5” Hose 2” Hose

3/4” Hose bibb

Fig. 5

The 1.5” and 2” hose connectors have cam lever dust covers (Fig. 6) that are chained

to the side port for retention. Always have the covers in place and locked before

moving the trailer. Loose covers may come free at highway speeds leading to injury.

CAUTION:CAUTION:

When pumping from a standing source using the side port, only use the 1.5” or 2” hose

connectors. The 3/4” hose bibb is too restrictive and could damage the pump due to

insucient water ow.

PUMP DAMAGE

Fig. 6

Place the cover on the hose

connector then rotate the

cams to lock the cover onto

the connector.

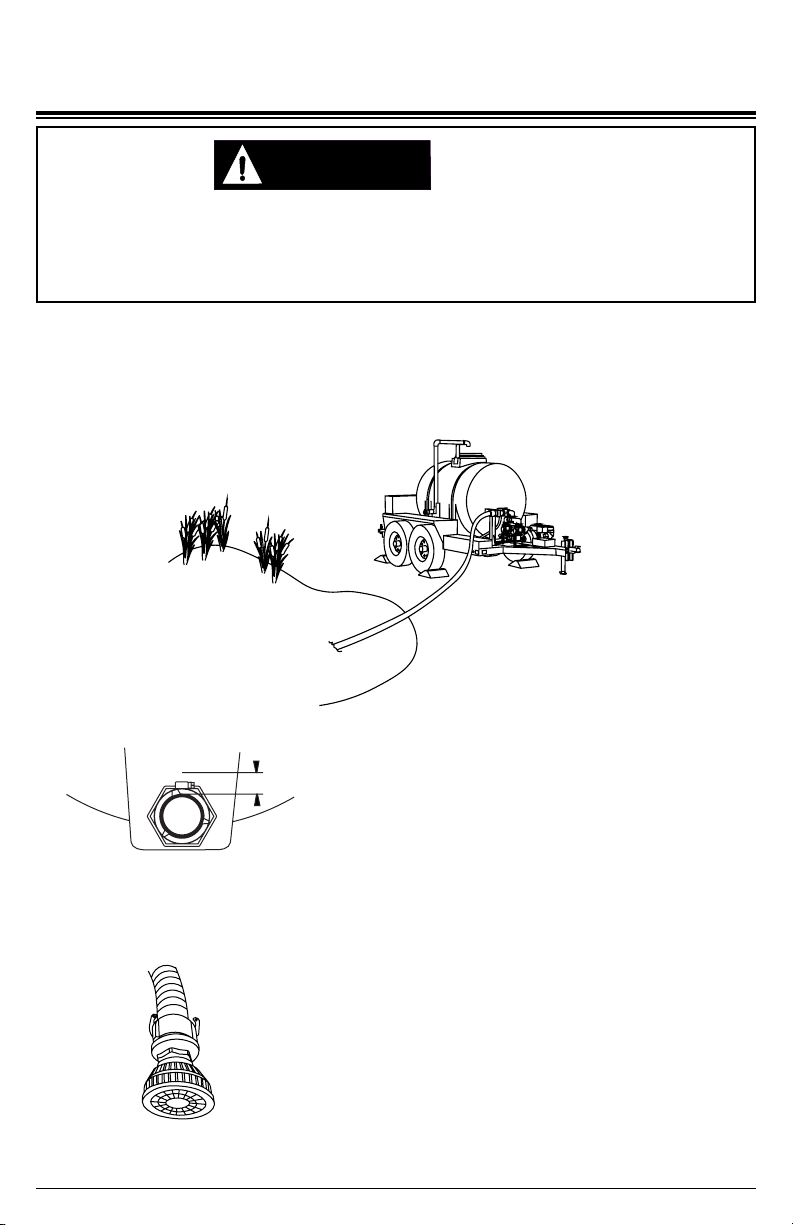

FILLING THE TANK FROM A STANDING

WATER SOURCE

Page 13

Besides lling the tank from a pressurized sources of water, you also have the ability

to ll the tank from a standing source of water (Fig. 7) such as a lake, stream or pond.

In order to do this, you will need to use the 2” rigid suction hose and the on-board

pump. We recommend using a strainer / lter (not included) on the suction hose.

Fig. 7

2. Place a lter / strainer (not included) onto the end

of the rigid suction hose (Fig. 9), before placing the

hose into the water. NOTE: The total lift from the

lter / strainer to the level of the side port must not

exceed 25 feet (7.6 meters).

1. In order to ll the tank from a standing source,

you must have water in the tank at a minimum of

1” above the outlet pipe (Fig. 8). If you do not have

a sucient amount of water in the tank, you will

need to ll the tank from a pressurized source; see

PRESSURE FILLING THE TANK.

Fig. 9

Fig. 8

1” min.

Whenever the trailer is disconnected from the tow vehicle, the trailer should be parked

on a level surface and with the wheels chocked (not included). Trailers with non-chocked

wheels can roll when parked on non-level pavement or when accidentally bumped from

another vehicle leading to injury/death and property damage.

TRAILER MOVEMENT

CAUTION:CAUTION:

NOTICE

Page 14

3. Connect the other end of the hose to the side port (Fig. 5).

4. Remove the primer cover on the pump (Fig. 10) then ll the pump with water. Place

the cover back onto the funnel, tighten.

6. Move the ow valves to the DRAW position (Fig. 2).

7. Make sure the spray bar and side port valves are CLOSED (Figs. 3 & 4).

CAUTION:CAUTION:

In order to ll the tank with the DRAW function, you must have at least one inch of water

above the outlet pipe of the tank. Water below this level may not be sucient to prime

the suction hose.

PUMP DAMAGE

8. Using the STARTING THE ENGINE instructions, start the engine of the pump.

9. Move the side port valve to OPEN (Fig. 4). You may notice air bubbles in the tank as

the water starts to ow. If the pump fails to prime, stop the engine and repeat step 4.

10. Wait until the tank is lled to the required level.

11. Once the tank is lled, move the side port valve to CLOSED.

12. Shut o the engine by using the SHUTDOWN instructions.

13. Move the tank valve to the CLOSED position

.

Fig. 10

We recommended having a lter (not included) on the end of the suction hose. Not using

a lter can introduce debris into the pump and the tank that may cause damage. Always

place the lter at a depth where air cannot be introduced into the system, but do not allow

it to sit on the muddy bottom of the source.

5. Move the tank valve to OPEN (Fig. 3).

14. Disconnect the hose then place the cover on the hose bard; lock into place (Fi

g. 6).

PUMP DAMAGE

USING THE SIDE PORT OUTPUT

Page 15

The side port outputs can be used for a variety watering uses. As talked about in

SIDE PORT (DISCHARGE or SUCTION), you have the ability to use a standard 3/4”

garden hose, a 1.5” or a 2” hose as the output. In order to use these outputs, make

sure the tank is fully lled or has enough water for your application. Do not allow the

pump to go dry as damage may occur.

2. Ensure the pump is primed. If you start to remove the primer cover and water

begins to ow out, it is primed. If not, remove the cover and ll the pump with water

(Fig. 10). Thread the cover back onto the funnel, tighten.

3. Move the ow valves to the PUMP position (Fig. 1).

4. Make sure the spray bar and side port valves are closed (Figs. 3 & 4).

5. Connect the hose to the appropriate side port connection (1.5”, 2” or 3/4” garden

hose).(Fig. 5).

6. If using a 3/4” garden hose, rotate the hose bibb handle to ON (Fig. 11).

7. Using the STARTING THE ENGINE instructions, start the engine of the pump.

8. Move the side port valve to OPEN (Fig. 4).

9. Use the output until your application is completed or you have met the minimum

allowed amount of water in the tank. DO NOT allow the tank to pump dry.

10. Move the side port valve to CLOSED.

11. Shut o the engine by using the SHUTDOWN instructions.

13. Disconnect the hose then place the cover on the hose bard, lock into place (Fi

g. 6)

-or- rotate the hose bibb handle to CLOSED.

Fig. 11

OFF ON

CAUTION:CAUTION:

Never allow the tank water level to fall below a level of one inch above the outlet pipe of

the tank. If the tank fully drains, pump damage may occur from lack of water and you will

only be able to rell the tank from a pressurized water source.

PUMP DAMAGE

1. Move the tank valve to OPEN (Fig. 3).

12. Move the tank valve to CLOSED.

USING THE SPRAY BAR

Page 16

The spray bar allows you to water down areas for dust reduction as well as washing

the pavement of loose dirt and debris. In order to use the spray bar, make sure the

tank is fully lled or has enough water for your application. Do not allow the pump to

go dry as damage may occur.

CAUTION:CAUTION:

Never allow the tank water level to fall below a level of one inch above the outlet pipe of

the tank. If the tank fully drains, pump damage may occur from lack of water and you will

only be able to rell the tank from a pressurized water source.

PUMP DAMAGE

2. Ensure the pump is primed. If you start to remove the primer cover and water

begins to ow out, it is primed. If not, remove the cover and ll the pump with water

(Fig. 10). Place the cover back onto the funnel, tighten.

3. Move the ow valves to the PUMP position (Fig. 1).

4. Make sure the spray bar and side port valves are closed (Figs. 3 & 4).

5. Using the STARTING THE ENGINE instructions, start the engine of the pump.

6. Move the spray bar valve to OPEN (Fig. 4).

7. Use the spray bar until your application is completed or you have met the minimum

allowed amount of water in the tank. DO NOT allow the tank to pump dry.

8. Move the spray bar valve to CLOSED.

9. Shut o the engine by using the SHUTDOWN instructions.

1. Move the tank valve to OPEN (Fig. 3).

10. Move the tank valve to CLOSED.

Page 17

DRAINING THE SYSTEM FOR STORAGE (WINTERIZE)

When you will not be using the trailer for an extended period of time or there is a

chance of freezing weather, you should drain the system.

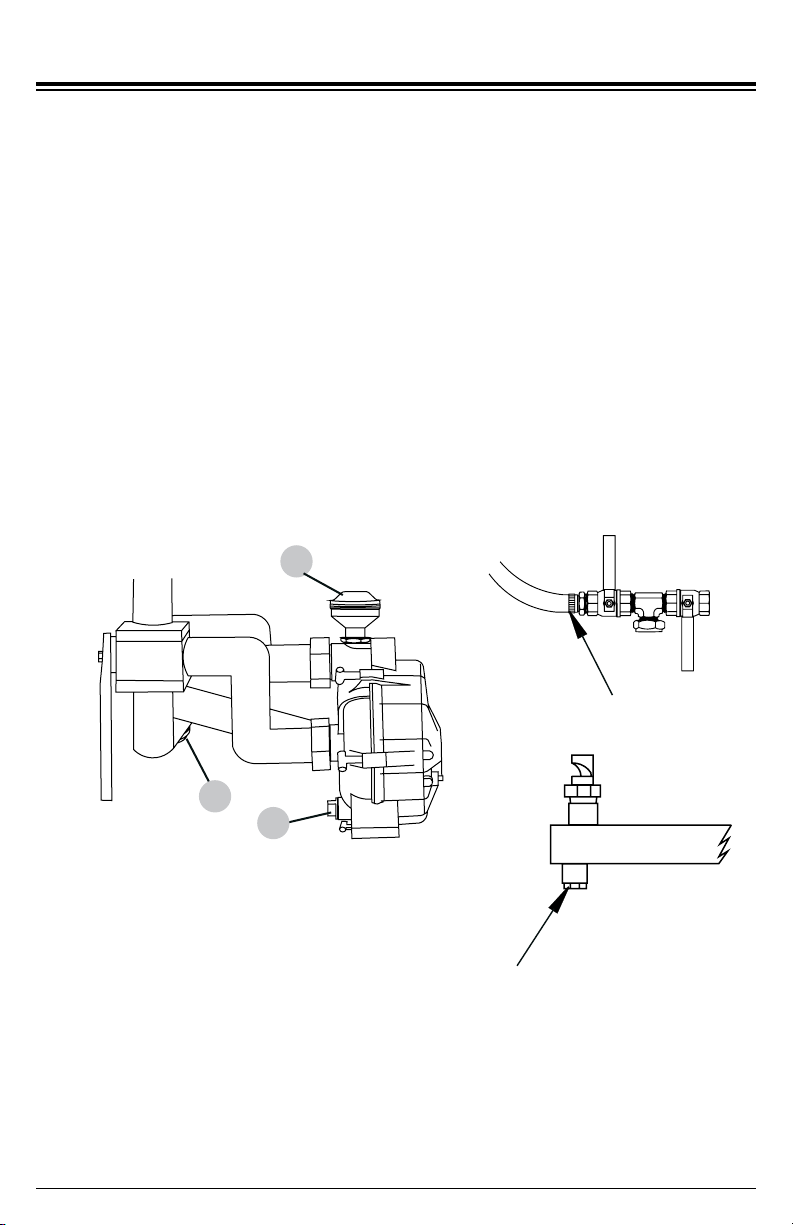

2.

Using a screw or nut driver, loosen the worm screw clamp (Fig. 12-A). Carefully

remove it and the manifold plug from the tee ange.

3. Remove the drain plug on the bottom of the pump (Fig. 12 - B).

1. Ensure the trailer is as level as possible.

4. Remove the primer cover from the pump allowing air into the pump (Fig. 12 - C).

5. As the system drains, operate the ow valves (Figs. 1 & 2) to allow any trapped

water to drain.

6. Once the water has stopped owing, replace the caps and manifold plug; tighten.

C

Fig. 12

7. Move the tank valve to the CLOSED position.

DRAINING THE SYSTEM

A

4. Open the tank valve to allow the tank to empty

8. Using a screw or nut driver, loosen the hose clamp (Fig. 13). Carefully remove the

hose and lower it allowing residual water to drain.

9. Remove the drain plugs from the bottom of the spray bar near each nozzle (Fig. 14).

10. Allow any trapped water to drain from the hose and the spray bar.

Fig. 13

Fig. 14

11. Thread in the drain plugs; tighten.

12. Align the hose assembly back with the manifold, position the clamp and tighten.

B

NOTICE

Page 18

TRAILERING SYSTEM

The trailer coupler of the SIMPSON Water Trailer is adjustable in height. It is important

to keep the trailer as level as possible with the tow vehicle. This is accomplished by

raising or lowering the coupler within the channel.

1

2

3

4

5

6

7

8

1. Coupler retaining bolt and nylon-insert locknut

2. Safety cable retaining hair pin -or- cotter pin

Safety cable assembly

4. Safety pin and lanyard

5. Latch

6. Coupler

7. Coupler channel

8. Snap hook

3.

Whenever the trailer is disconnected from the tow vehicle, the trailer should be parked

on a level surface and with the wheels chocked (not included). Trailers with non-chocked

wheels can roll when parked on non-level pavement or when accidentally bumped from

another vehicle leading to injury/death and property damage.

TRAILER MOVEMENT

CAUTION:CAUTION:

TRAILER COUPLER

When the trailer was ordered, you

should have picked the coupler

that matched your hitch. If you did

not specify a coupler or did not

receive one, please contact our

Customer Service Department by

calling 1-877-362-4271 or emailing

Table of contents