Sinapsi EQUOBOX SIN.EQLC250 User manual

S I N AP S I S . r . l .

V i a d e l l e Q u e r c e 1 1 / 1 3

0 6 0 8 3 B a s t i a U m b r a ( P G ) I t a l y

T . + 3 9 075 8011604 F .+ 3 9 075 8014602

w w w . s i n a p s i t e c h . i t |i n f o @ s i n a p s i t e c h . i t

EQUOBOX SIN.EQLC250

M-Bus Level Converter

Adapter/Repeater

User Guide

Rev 1.0

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 2

TABLE OF CONTENTS

1. M-BUS OVERVIEW ........................................................................................................................................... 3

1.1 DESCRIPTION of the M-Bus System ..................................................................................................... 3

1.2 Addressing............................................................................................................................................... 3

1.3 Sizing the M-Bus System ....................................................................................................................... 4

1.4 BUS signal specifications ....................................................................................................................... 4

2. SIN.EQLC250 INSTALLATION ......................................................................................................................... 5

2.1 Description of the SIN.EQLC250 ........................................................................................................... 5

2.2 Operating modes of power supply ...................................................................................................... 6

2.3 Connection terminals............................................................................................................................. 7

2.4 Topology and connection of the M-Bus network............................................................................... 8

2.5 SIN.EQLC250 operation modes ............................................................................................................ 9

2.6Status LED.............................................................................................................................................. 10

2.7 Short circuit protection........................................................................................................................ 10

2.8 Firmware update .................................................................................................................................. 11

3. Troubleshooting............................................................................................................................................ 12

4. Technical features......................................................................................................................................... 13

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 3

1. M-BUS OVERVIEW

1.1 DESCRIPTION of the M-Bus System

The M-Bus (Meter Bus) system is a communication protocol compliant with the EN13757-2 standard.

The M-Bus System provides the following advantages:

•High level of data transmission security

•Low wiring costs

•Long distances without requiring repeaters

•Large number of central units

•Detection of both battery-powered and mains-powered devices

•Automatic device recognition

•Vast array of systems and components available

•Different types of bus topology: linear, star, and tree

Figure 1 - Bus topologies

1.2 Addressing

The M-Bus uses two types of addressing modes to detect the devices:

•Primary address: up to 250 primary addresses can be allocated within an M-Bus plant. The

primary address is normally allocated while setting up the central units.

•Secondary address: the secondary address consists of 8 bytes and allows the allocation of any

number. By default, the secondary address of the devices is the same as the manufacturer

serial number. This type of allocation prevents bus conflicts.

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 4

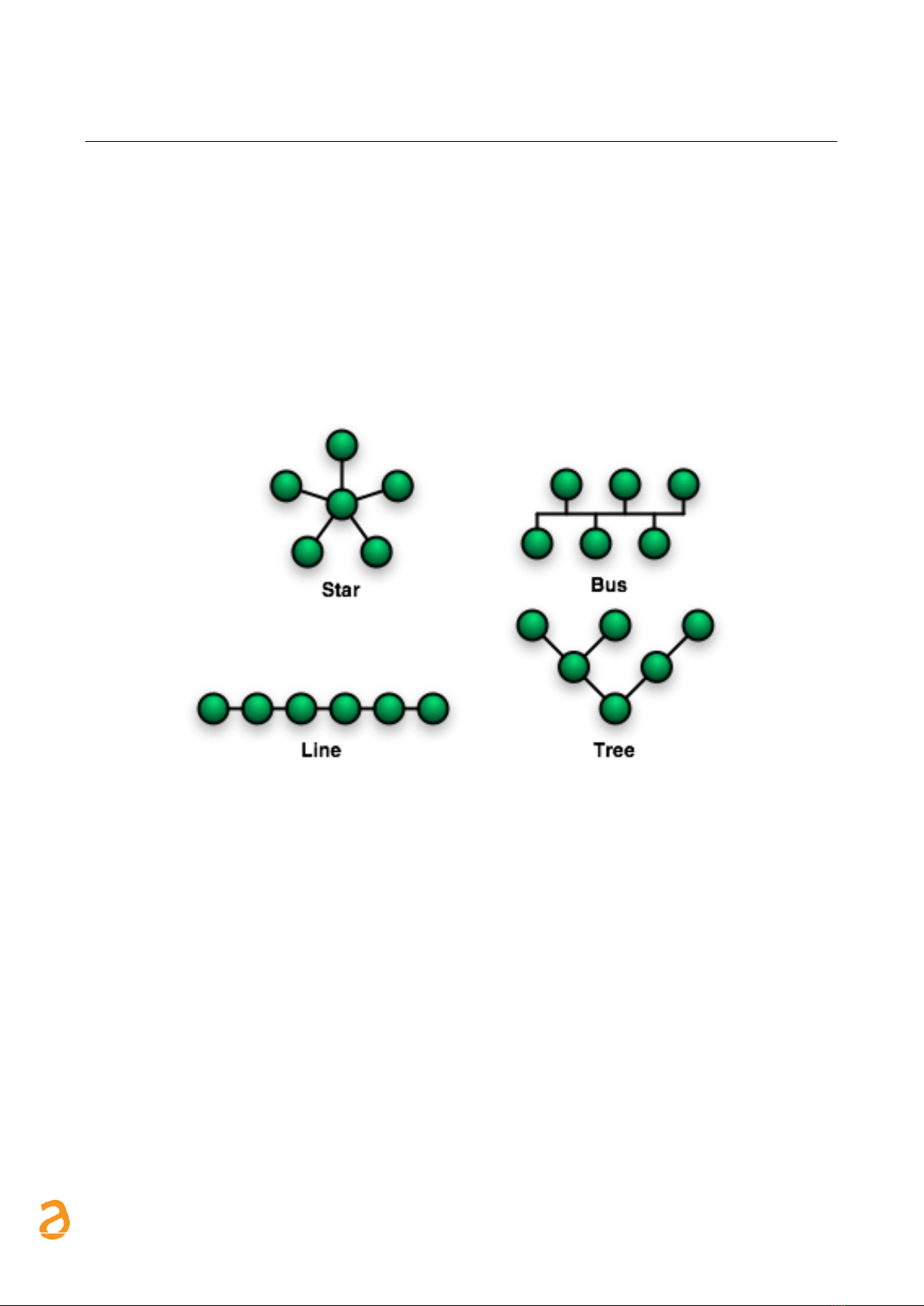

1.3 Sizing the M-Bus System

Cable type

•Shielded telephone cable 0.5mm²

•Cable maximum capacitive load: 152 nF/km

If you are using a cable with lower section, adapt the maximum length and the number of slaves

Follow the instructions provided in the table to size the M-Bus system

Type of plant

Maximum

distance

Overall cable

length

Cross-section

Number of

devices

(slaves)

Max.

transmission

rate

Small residential

buildings

350 m

1000 m

0.8 mm2

250

9600 Baud

Large residential

buildings

350 m

4000 m

0.8 mm2

250

2400 Baud

64

9600 Baud

Small complex

1000 m

4000 m

0.8 mm2

64

2400 Baud

Large

developments

…3000 m*

5000 m

1.5 mm2

64

2400 Baud

Direct vicinity

…5000 m*

7000 m

1.5 mm2

16

300 Baud

Point-to-point

connection

…10000 m*

10000 m

1.5 mm2

1

300 Baud

*Shielded cabling required at a distance in excess of 1000 m (see EN13757-2).

1.4 BUS signal specifications

M-Bus system

u.m.

Condition

Minimum

Typical

Maximum

Unit of

measure

ment

Number of devices per

segment

n

SIN.EQLC250

0

250

Transmission rate

T

300

2400

9600

Bd

Bus Voltage (Master)

UM

IM=0…400mA

30

39

42

V

Bus Voltage (slave)

US,R

30

42

V

Bus current (Master)

IM,V

SIN.EQLC250

0

375

mA

Current (slave)

IS,R

US=30…42V

0.75

1.2

1.5

mA

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 5

2. SIN.EQLC250 INSTALLATION

2.1 Description of the SIN.EQLC250

SIN.EQLC250 is a unit that reads M-Bus devices in compliance with the EN 13757-2 standard.

The level converter/repeater SIN.EQLC250 is the interface between M-Bus device and a read system.

It consists of a level converter and the associated power supply. In fact, the level converter and

associated power supply form a unit: no addition transformer or auxiliary power required.

The SIN.EQLC250 unit can be used in different ways:

•Connect up to 250 M-Bus devices (max. 250 simply M-Bus loads (*))

•Can be connected with the M-Bus web server of Equobox family (SIN.EQRTUEVO1T, SIN.EQRTU1,

SIN.EQRTU1T, SIN.EQRTU1X, SIN.EQRTU4), PXC devices, other M-Bus read / configuration systems

•Up to 6 level converters connected in parallel on an M-Bus network

•Up to 5 level converters as repeater (in series) on an M-Bus network

•Via RS-232 or RS-485 interfaces to read device data via the PXC device or a PC (level converter)

•Remote reading of M-Bus devices via M-Bus web server SIN.EQRTUEVO1T (Cloud).

*A unit M-Bus load is ≤1,5mA

NOTE: You can use the level converter at your own risk as an interface as well to suitable software and

devices by third-party manufacturers.

NOTE: The level converter is galvanically isolated. It protects against short circuits.

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 6

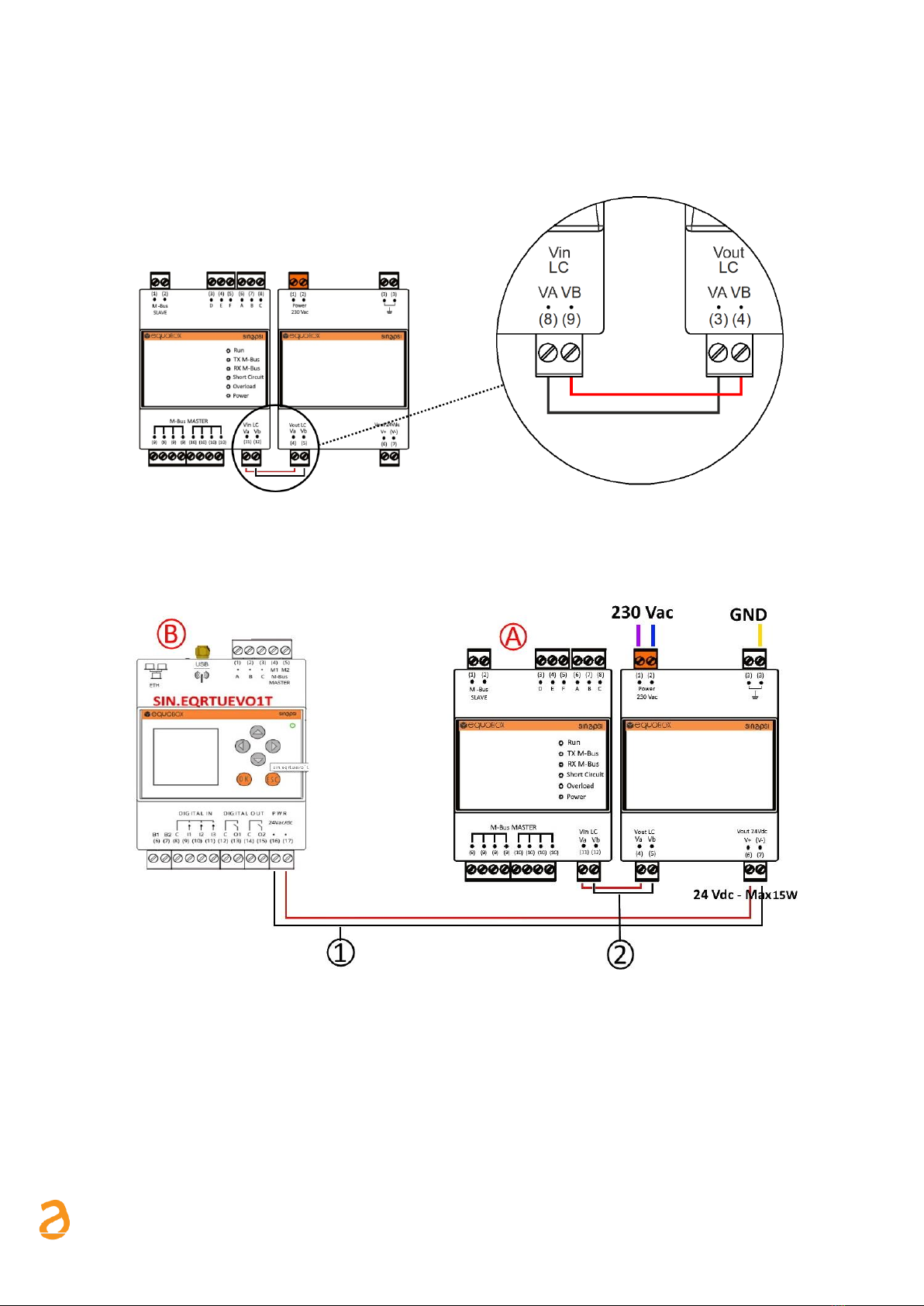

2.2 Operating modes of power supply

The power supply can be employed as follows:

•To power the level converter

1

Level converter / repeater

2

Power supply

•To power the M-Bus web server SIN.EQRTUxxx (*).In the example below there is the datalogger

SIN.EQRTUEVO1T.

A

Web server SIN.EQRTUxxx.

1

Connection web server SIN.EQRTUxxx with

auxiliary power supply (24Vdc) of SIN.EQLC250

B

Level converter/repeater SIN.EQLC250

2

Connection level converter/repeater with

power supply

* SIN.EQRTUxxx: SIN.EQRTU1, SIN.EQRTU4, SIN.EQRTU1T, SIN.EQRTU1X, SIN.EQRTUEVO1T

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 7

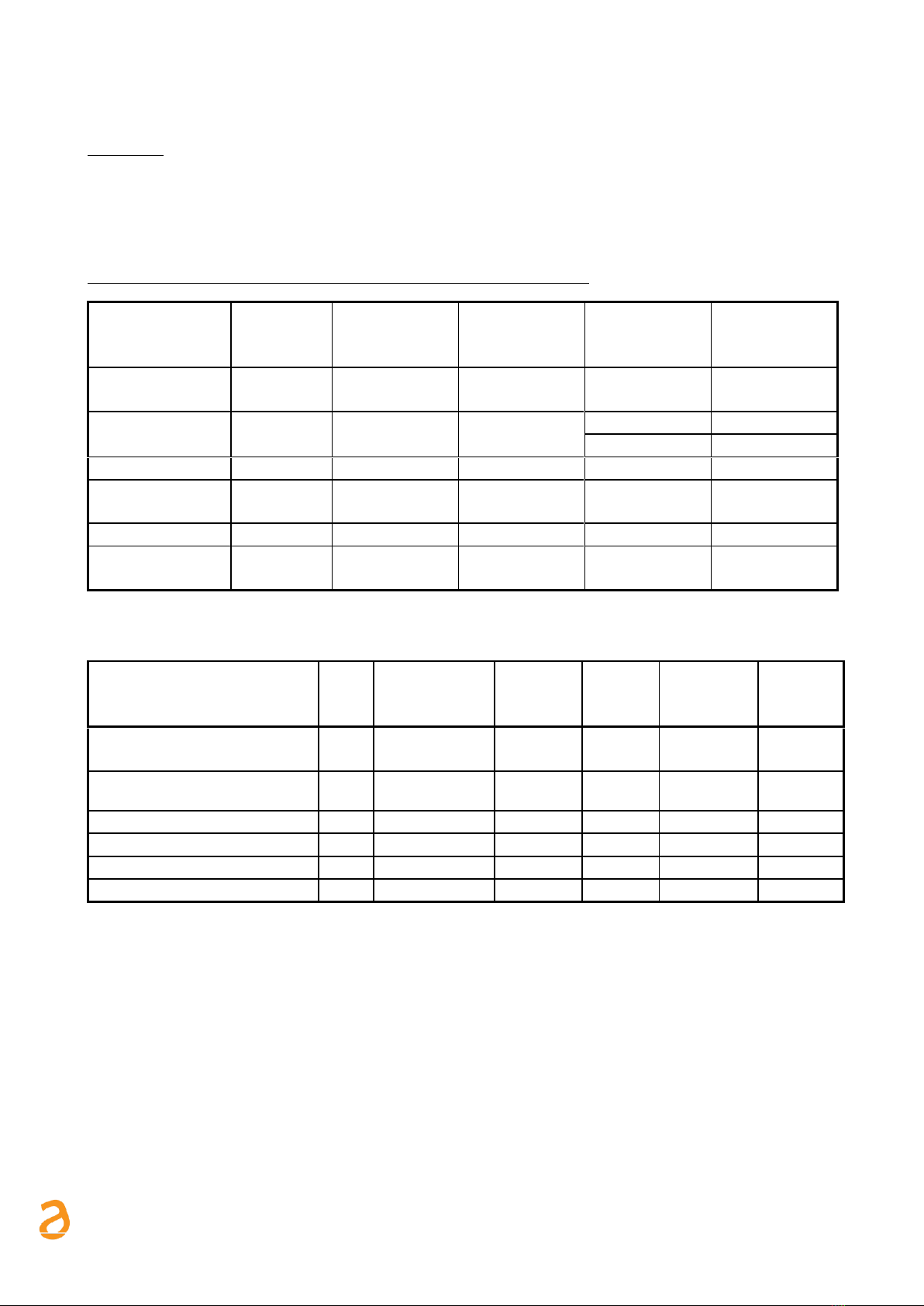

2.3 Connection terminals

SIN.EQLC250 looks like a device for mounting on DIN rail. The connectors/LEDs present are listed

below:

Figure 2 –Features and connectors Level Converter (SIN.EQLC250)

A

Main voltage AC 230 V

B

Power supply for level converter

(1) –Pin 1 for main power –230 Vac

(2) –Pin 2 for main power –230 Vac

(4) –power supply = (11) level converter

(5) –power supply = (12) level converter

C

Power out 24Vdc for web server (15W)

D

Electrical grounding

(6) - Pin V+ Output for datalogger

(7) - Pin V- Output for datalogger

(3) - Earth

E

Serial interface

F

Firmware update button

Serial interface RS232 and RS485 to connect

to a PC or M-Bus master.

Push button for reset and firmware update

RS-232:

A = TX

B = RX

C = GND

RS-485:

D = REF

E = D-

F = D+

G

M-Bus Slave

H

M-BUS Master interface

(1) –Pin 1 for M-Bus network to extend

(Repeater mode)

(2) –Pin 2 for M-Bus network to extend

(Repeater mode)

(9) –Pin 1 for connection M-Bus devices

(Master mode)

(10) –Pin 2 for connection M-Bus devices

(Master mode)

I

Status LED

Ref. Chap 2.6

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 8

2.4 Topology and connection of the M-Bus network

M-Bus technology allows good freedom of choice regarding network topology. It is possible to connect

the devices present in the plant according to a star, linear, tree topology or mixed as seen in 3 and 4.

However, ring topology (Figure 5 –Ring topology NOT ALLOWED) is not allowed. It is also not necessary

to observe any polarity of the bus, thus simplifying installation.

Figure 3 –Star Topology

Figure 4 –Mixed Topology

Figure 5 –Ring topology NOT ALLOWED

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 9

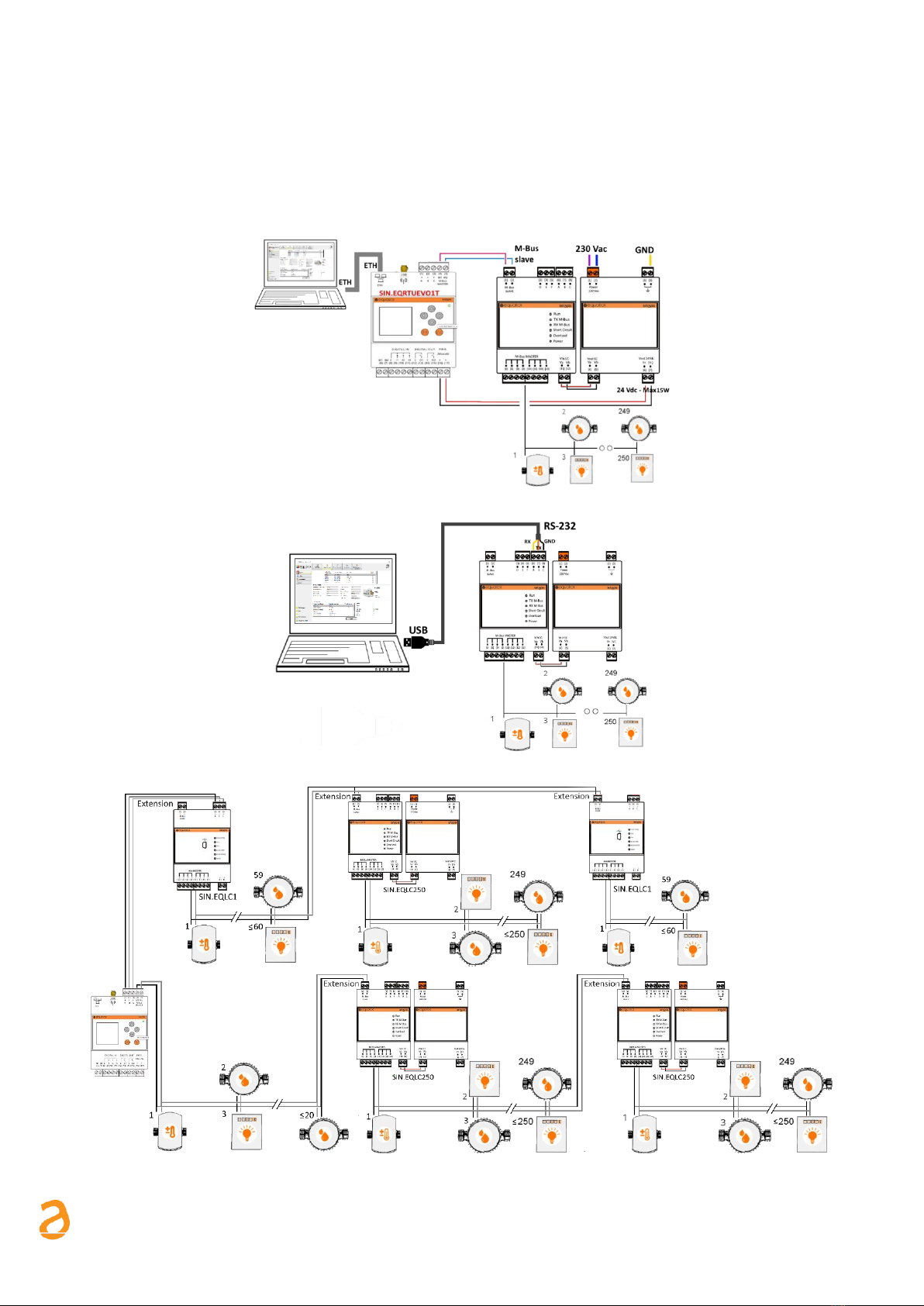

2.5 SIN.EQLC250 operation modes

SIN.EQLC250 can be used with M-Bus communication interface for SIN.EQRTUxxx datalogger (Figure 6)

or with a PC with EQUOBOX TOOLKIT software (SIN.EQSW1) (Figure 7) or as a repeater/extender of an

M-Bus network (Figure 8). The following figures show the connection diagrams for the different

operation modes.

Figure 6 –M-Bus communication interface for SIN.EQRTUxxx datalogger

Figure 7 –Connection a PC with EQUOBOX TOOLKIT software (SIN.EQSW1)

Figure 8 –Repeater/extender of an M-Bus network

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 10

2.6 Status LED

There are 6 LEDs present on the SIN.EQLC250 device, which indicate the operating status as shown in

the figure:

Figure 9 - Status indicators

Run

The (green) LED indicates the operational state of the device.

●Blinking at 1 Hz (slow) -> Device functions are being set up. No communication.

●Blinking at 10 Hz (fast) -> Device update pending.

●On -> The device is operational.

TX M-Bus

The (green) LED indicates the transmission state on the M-Bus network (terminals 9 and 10).

●On -> Data is transmitting.

●Off -> No data is transmitting.

RX M-Bus

The (orange) LED indicates the receive state of data on the M-Bus network (terminals 9 and 10).

●On -> Data is being received.

●Off -> No data is being received.

Short Circuit

The (red) LED indicates a short circuit on the bus, very high traffic, or a collision.

Overload

The (orange) LED indicates a bus overload that may prevent correct operation.

●On -> Bus overload that detected.

●Off -> No bus overload detected.

Power

The (green) LED indicates the state of the level converter power supply.

●On -> The device power supply is correct.

●Off -> Device power is not correct or unavailable.

2.7 Short circuit protection

During normal operation of the level converter, if a data collision occurs during communication with

the meters on the "M-Bus Master" bus, the "Short Circuit" LED may turn on.

In the case instead of a real c.c. (short circuit) in the absence of communication, the "M-Bus Master"

bus is disconnected (∆VM-Bus = 0) for a time equal to:

-5 seconds to the first short circuit detected.

-60 seconds per second consecutive short circuit detected.

-5 minutes to the third consecutive short circuit.

-24 hours from the fourth attempt onwards until the short circuit situation is resolved.

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 11

NOTE: If the conflict causing the short circuit signal is resolved during the power suspension on the "M-

Bus Master" bus, the level converter will continue to keep the bus de-energized until the expected reset

or until the device restarts or it feeds itself manually.

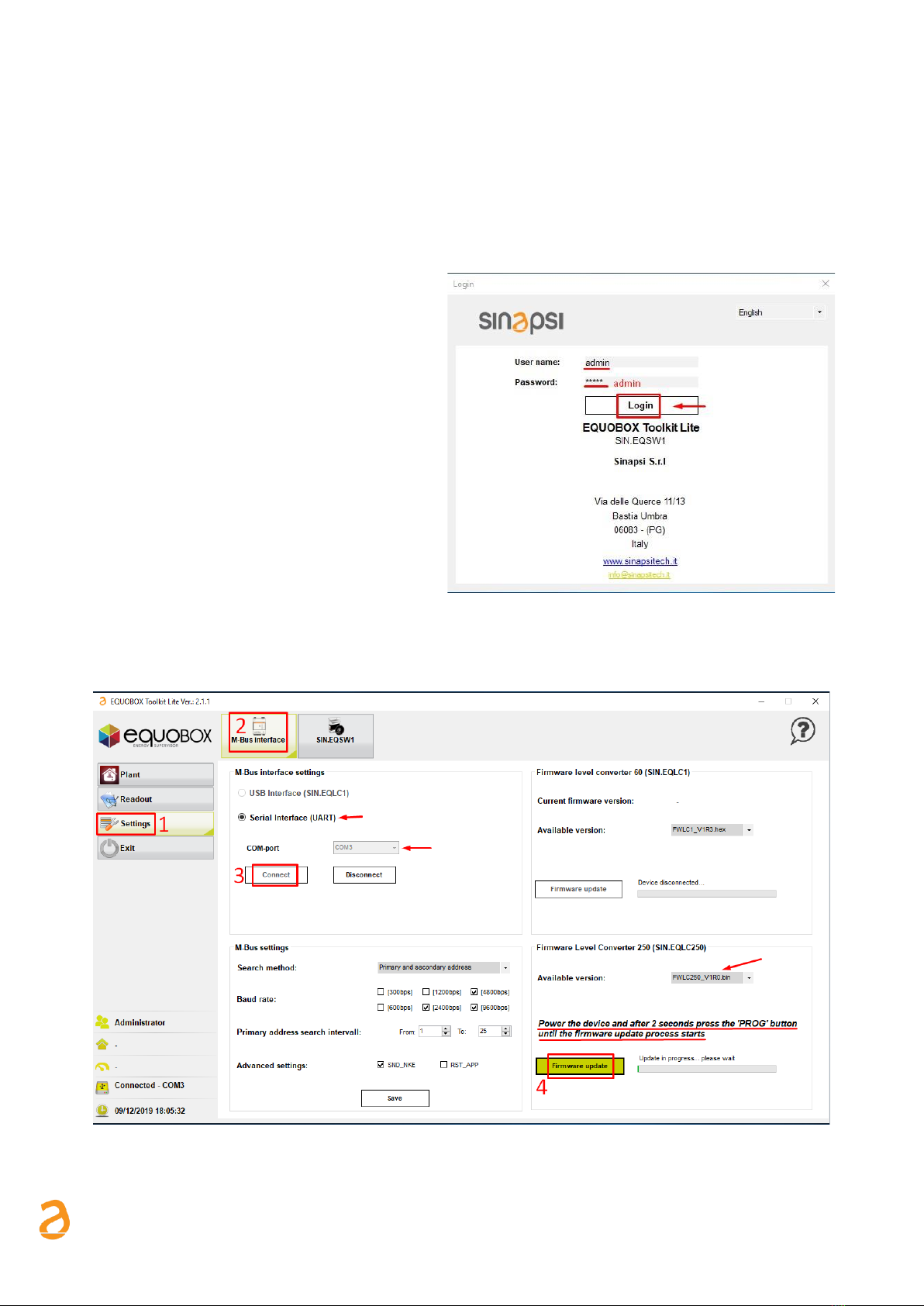

2.8 Firmware update

Through the EQUOBOX TOOLKIT Lite software (SIN.EQSW1) from version 2.0.15, it is possible to update

the version of firmware in SIN.EQLC250 if it is necessary (*).

•Enter the default credentials:

User: admin

Password: admin

•Select the Settings menu (1)

•Select the M-Bus interface tab (2)

•If unchecked, check the Serial Interface

(UART)

•Select the COM port where the device is

connected

•Connect to the device (3)

•In the Firmware Level Converter 250

(SIN.EQLC250) section:

oSelect the firmware version to be

installed.

oPress the button: Update Firmware (4)

oFollow the software step by step

instructions:

Figure 10 –Login to “Equobox Toolkit Lite”

- Disconnect the SIN.EQLC250 power supply without disconnecting the USB / RS232 cable.

- Power the device and after 2 seconds press and hold the 'PROG' button (F in fig. 2) until the

update process starts

Figure 11 –Firmware update of SIN.EQLC250

*It is not possible to check the firmware version currently installed in SIN.EQLC250

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 12

3. Troubleshooting

1) The device does not turn on (Power LED off)

- Check with multimeter that the supply voltage to the terminals (11) and (12) is 40 V.

2) LED Overload on:

- If the LED is on without any communication (RX and TX LEDs do not blink), there is an overload caused

by a possible short-circuits between the two poles of the bus or from an excessive number of

connected devices. Check the wiring.

3) The datalogger connected to the terminal does not detect some or all devices:

- Check the correct bus connection between the datalogger and terminal G of the SIN.EQLC250

- Check with the multimeter that the voltage on devices not recognized is between 32Vdc-42Vdc

- Verify that the communication settings of the M-Bus datalogger or the SW are compatible with the

devices (speed of communication, addressing)

4) The devices connected to the level converter in repeater mode do not communicate:

- Check the correct power supply

- Check the Run LED is on

- Check that the Short Circuit LED is off

- Check that the M-Bus network is connected to the G terminal of the SIN.EQLC250

- Check the correct voltage in terminals G and H of the repeater which must be between 32 Vdc - 42 Vdc

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 13

4. Technical features

POWER SUPPLY

Rated Voltage

AC 110...240 V

AC frequency

47...63 Hz

M-Bus Slave port absorption (in series)

≤ 3 mA (2 M-Bus Loads)

Rated Power

6W + 0.07 W for each connected M-Bus slave

Maximum consumption

45W, 45VA

Vout: DC 24 V, max. 15 VA

Internal fuse

PTC resistance and varistor

Fusing of supply lines

Circuit breaker:

Max 13 A, type B, C, D per EN 60898

or

Power supply with current limitation at 10 A

CONNECTIONS

M-Bus Slave (terminals 1 and 2):

Connections as a repeater / extender

M-Bus Master (terminals 9 and 10):

Connection to the M-Bus meters

Vout LC (terminals 4 and 5 on power supply) /

Vin LC (terminals 11 and 12 on level converter)

Power supply for level converter/repeater

40 Vdc

Vout 24 Vdc (terminals 6 and 7 on power supply)

DC 24 V, max 15 VA

INTERFACE

RS-232 (terminals A, B and C)

Connections as master to PC (using SIN.EQUSB232) or to data logger

Connect to a PC:

–Terminal A: RX (PC/data logger receiving line)

–Terminal B: TX (PC/data logger transmission line)

–Terminal C: GND (interface reference voltage)

Connection for the M-Bus web server SIN.EQ:

–Terminal 6[A] RS-232 with terminal 1[A] web server

–Terminal 7[B] RS-232 with terminal 2[B] web server

–Terminal 8[C] RS-232 with terminal 3[C] web server

RS-485 (terminals D, E and F)

Connection to connect to a PC or M-Bus devices

Connections to connect to PC/data logger as master:

–Terminal D: REF (interface reference voltage)

–Terminal E: D- (Receive/transmission line potential -)

–Terminal F: D+ (Receive/transmission line potential +)

M-BUS SECTION

Reference standard

EN13757-2 (Physical Layer)

Max. number of M-Bus devices (loads)

250 (≤1,5 mA)

Max. number of devices that can be connected

in cascade mode

6 level converters, of which 5 repeaters

Transmission speed (baud rate)

Minimum: 300bps

Typical: 2400bps

Maximum: 9600bps

M-Bus Master voltage

42V –32V

Bus current

Maximum 395 mA

Short circuit protection

Yes

Galvanic isolation

- RS-232 interface

- M-Bus interface

E Q U O B O X S I N . E Q L C 2 5 0 –U s e r G u i d e R e v . 1 . 0

S I N A P S I S . r . l. | V i a d e l l e Q u e r c e 1 1 / 1 3 - 0 6 0 8 3 B A S T I A U M B R A ( P G ) –I t a l y

T . + 3 9 075 8011604 - F . + 3 9 075 8014602| w w w . s i n a p s i t e c h . i t -i n f o @ s i n a p s i t e c h . i t 14

DIRECTIVES AND STANDARDS

Product standards

EN 62368-1 Information Technology Equipment Safety

Electromagnetic compatibility

For residential and industrial environments

EU conformity (CE)

MOD 07 AA Rev.0

ENVIRONMENTAL COMPATIBILITY

The product environmental declaration MOD 07 AA Rev.0 contains data on environmentally compatible product

design and assessments (RoHS compliance).

DEGREE OF PROTECTION

IP class

IP20 per EN60529

Protection class

II as per EN 62368-1

AMBIENT CONDITIONS

Storage

as per EN 60721-3-1:

Climatic conditions:

Temperature:

Air humidity:

Mechanical conditions:

Class 1K3

-25…+65 °C

5... 95% r.h.

Class 1M2

Transportation

as per EN 60721-3-3:

Climatic conditions:

Temperature:

Air humidity:

Mechanical conditions:

Class 2K3

-20…+65 °C

5... 95% r.h.

Class 2M2

Operation

as per EN 60721-3-3:

Climatic conditions:

Temperature:

Air humidity:

Mechanical conditions:

Class 3K5

-20…+55 °C

5... 95% r.h.

Class 3M2

MECHANICAL FEATURES

Dimensions (HxLxD)

110x71x62 mm (including terminals)

Installation type

35mm DIN rails (EN60715)

Materials and colours

Housing. PC + ASA, RAL 9010 (white)

Weight (level converter with mounting instructions)

0.392 kg for both devices

Packaging

0.055 kg

Table of contents

Popular Adapter manuals by other brands

Saramonic

Saramonic SmartRig II manual

Sony

Sony MSAC-US40 - MemoryStick Flash Memory Card USB 2.0... operating instructions

Panasonic

Panasonic KXTGA575 - 5 Instrucciones de operación

Adaptec

Adaptec 29320A installation guide

IOGear

IOGear GWAVR user manual

Swordfish

Swordfish VariPlug Dual USB operating instructions