From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,.,,,,,,~•"'""'-•"•'""'""Nu,,,.,,,

0

,,,,",,,,,,,.,,,,,,,.,,,,,n,,

0,,,,,,,,,,,,,...,

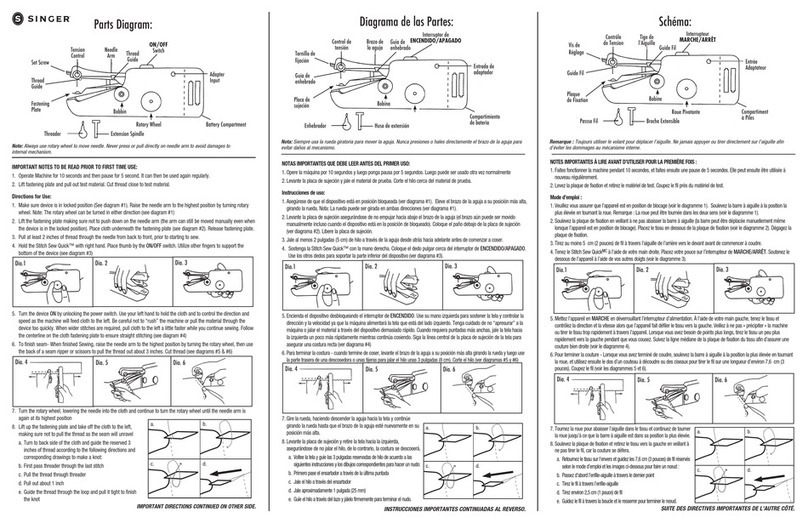

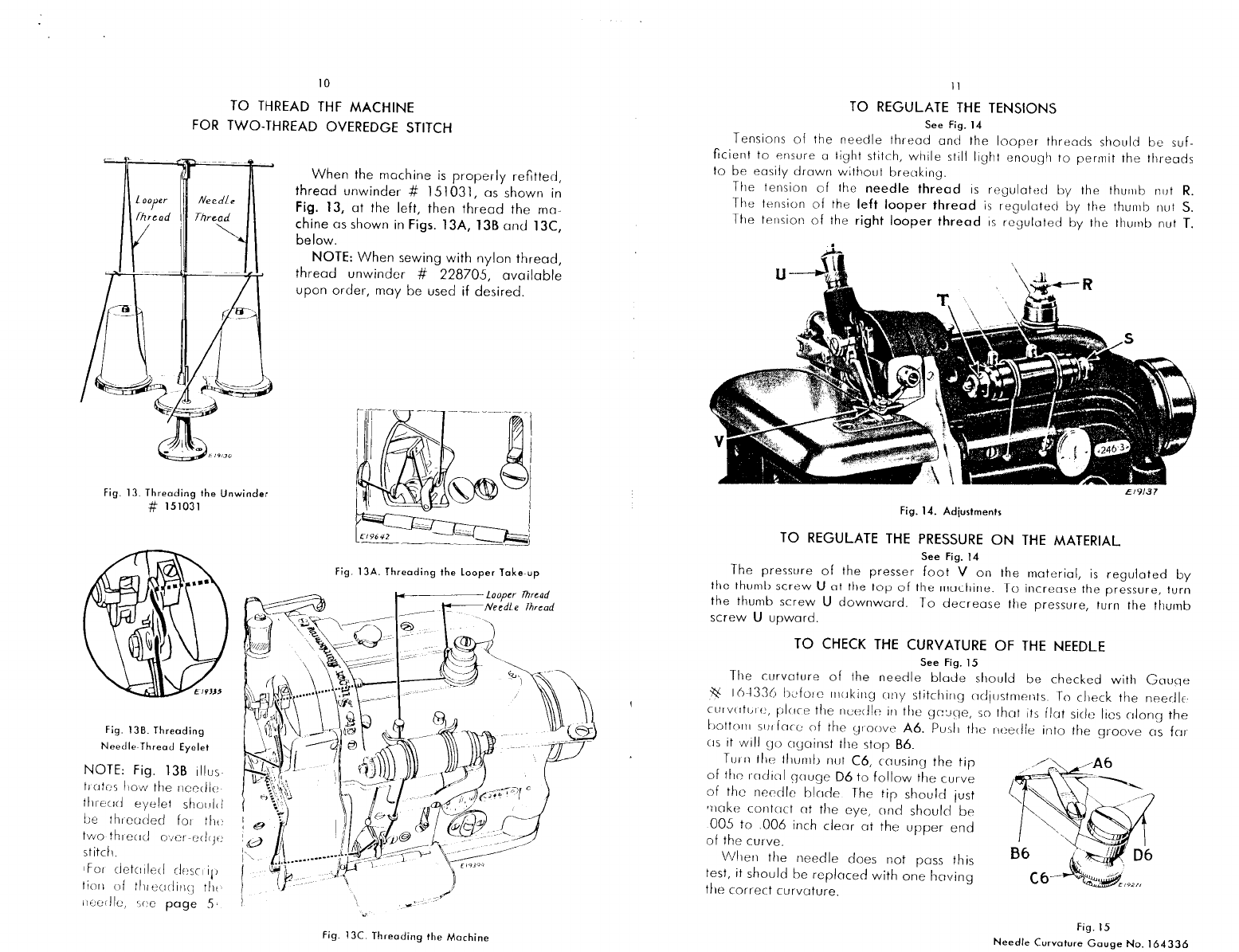

Fig.

7.

Threading

Wire

164196

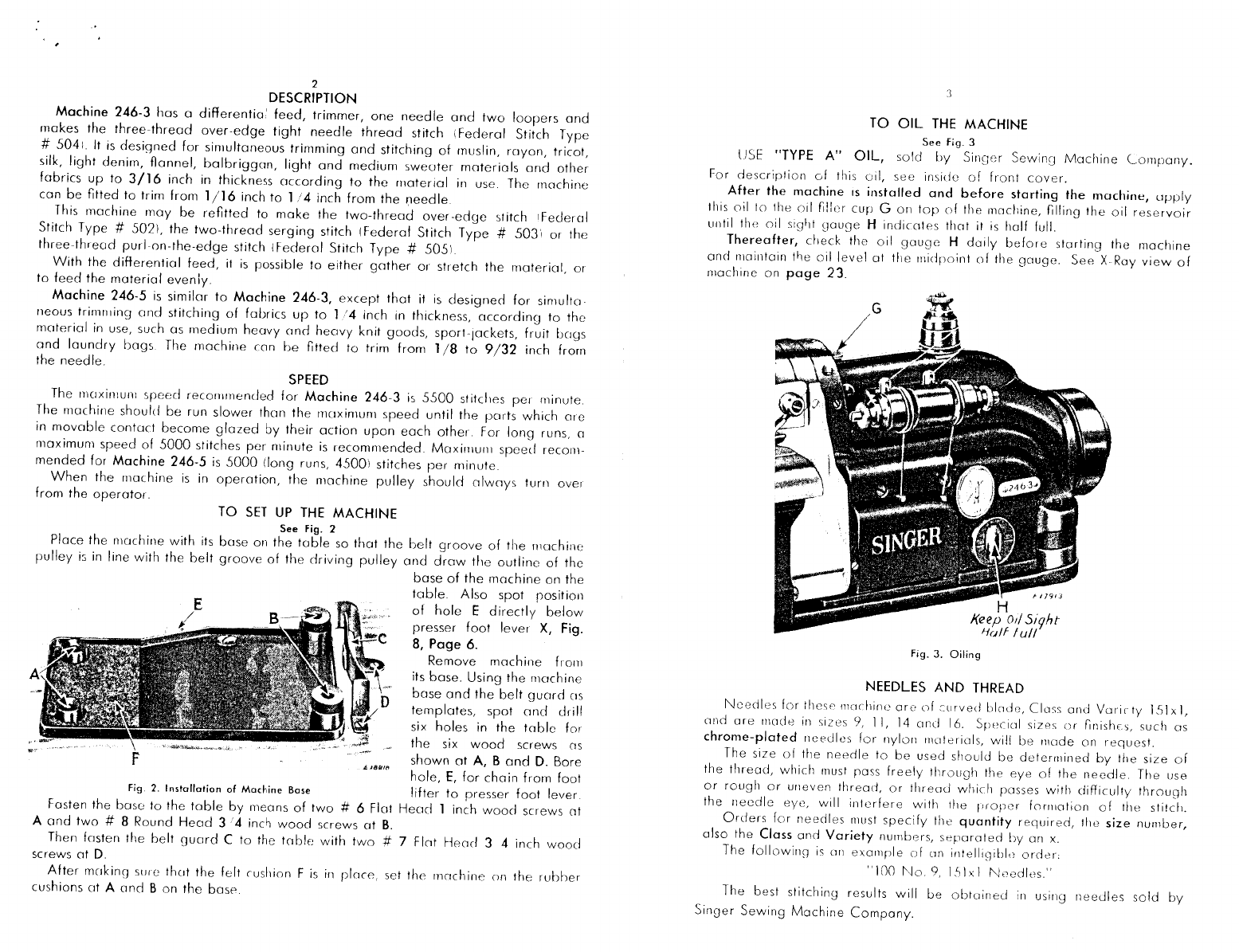

TO

THREAD

THE

RIGHT

LOOPER

(For

Three-Thread

Tight

Stitch)

See

Figs.

8,

9

and

10

L

/792~

CAUTION:

When

threading

right

looper,

be

sure

that

there

is

no

loose

loop

of

thread

on this

looper

to

cause

thread

breakage.

(See

Fig.

9).

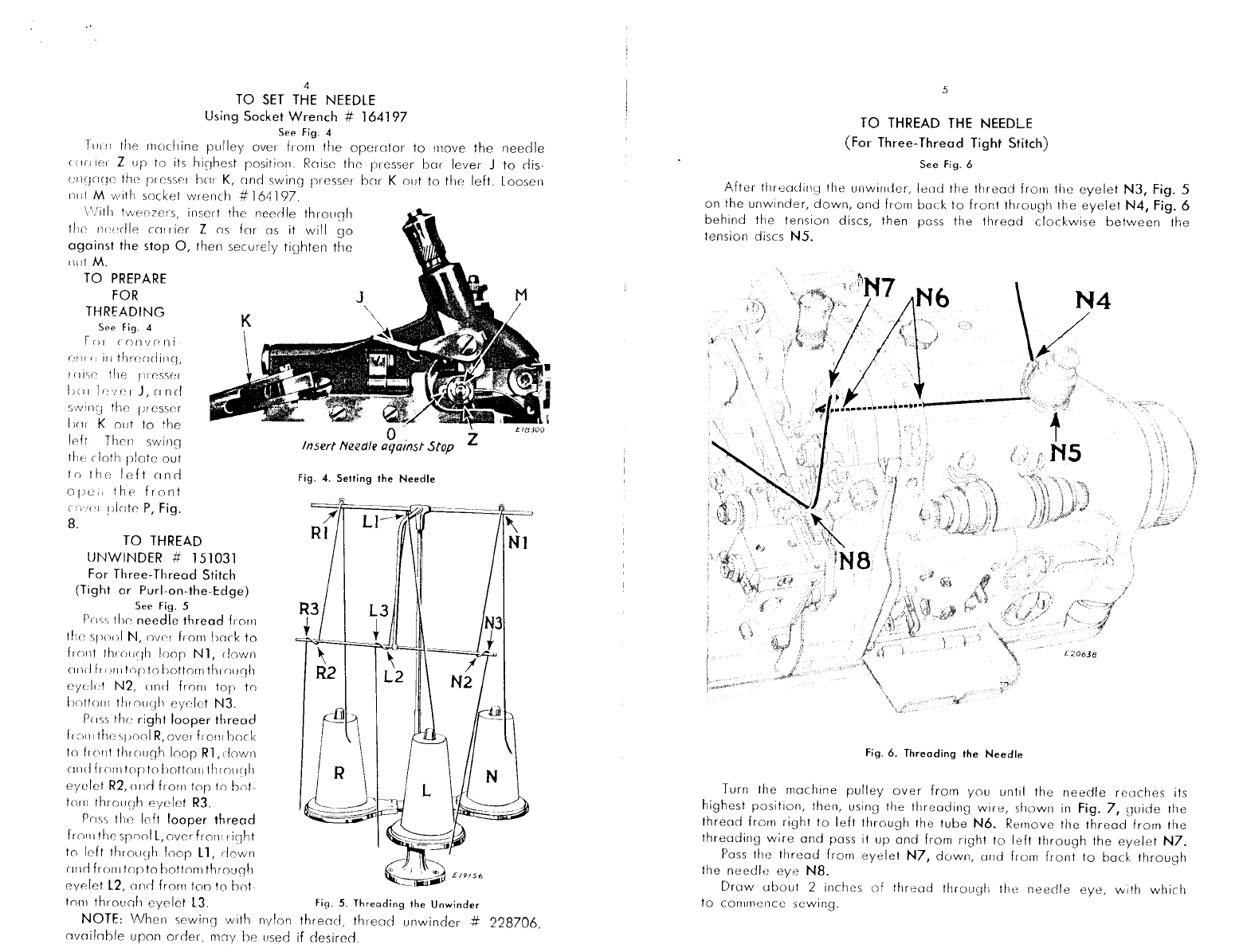

Fig.

8.

Threading

Right

Looper

£19132

7

Turn

the

machine

pulley

over

from

you

until

the

needle

is

ot

its

lowest

posi-

tion.

Then

lead

the

thread

from

eyelet

R3,

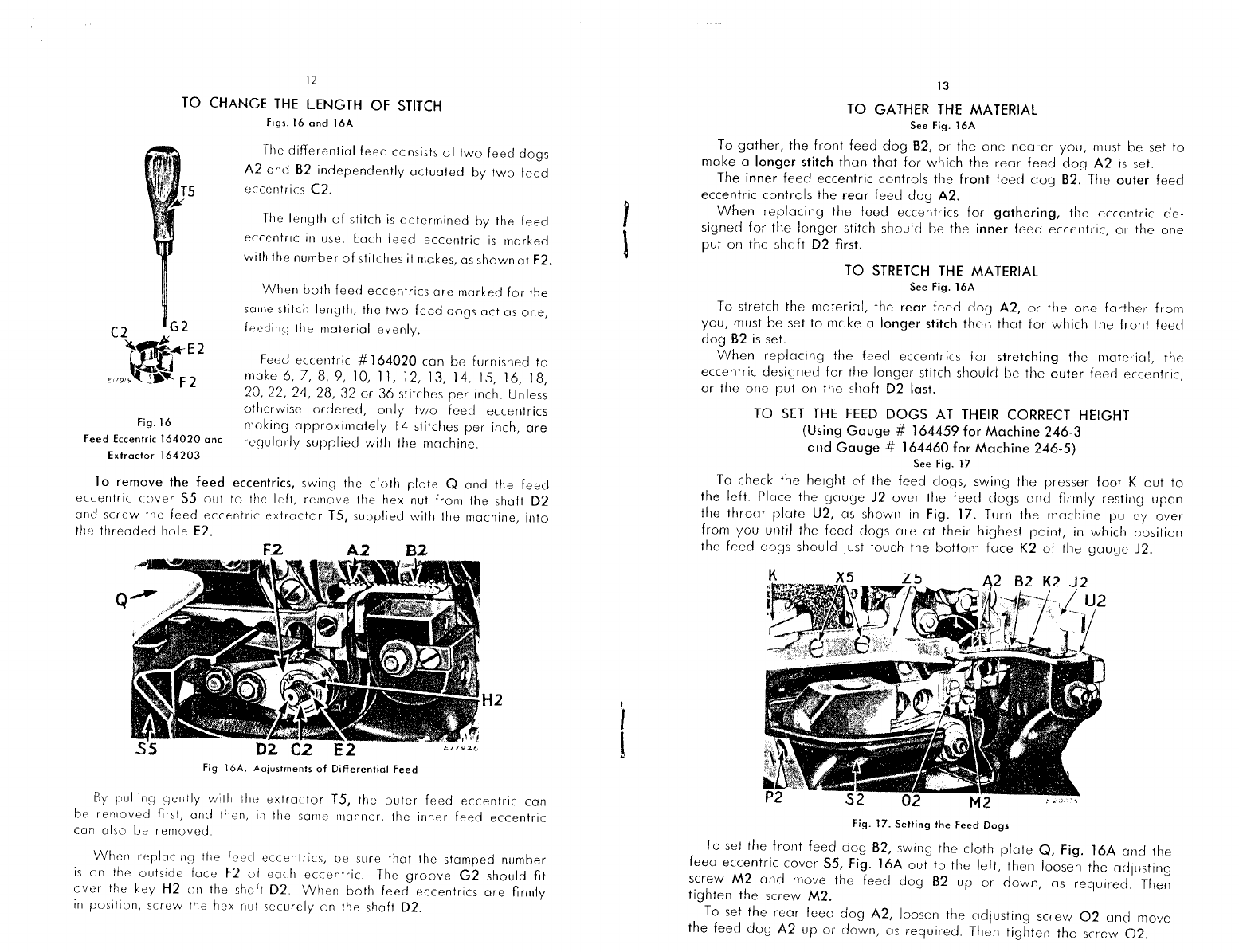

Fig. 5, page 4

on

the

unwinder

and

pass it

from

bock

to

front

through

the

thread

guide

R4,

Fig.

8,

down

under

the

tension

guide

R5,

then

over

mid

between

the

tension

discs

R6.

Pull

the

front

cover

plate

P

forward,

pass

the

thread

down

Fig.

9.

Right

looper

through

the

thread

guide

R7,

Fig. 10,

from

right

to

left

through

the

stripper

eyelet

R8,

from

right

to

left

between

the

right

take-up

and

its

wire

guord

ot

R9,

then

from

right

to

left

through

eye

RlO

in

the

left

toke-up.

Using

the

threading

wire,

shown

in

Fig. 7, page 6,

guide

the

thread

into

the

tube

open

ing

Rl

l.

Draw

the

threading

wire

out

of

the

tube

exit

Rl2,

Fig.

8.

Then pass

the

thread

from

front

to

back

through

the

eye

Rl

3

of

the

right

looper.

(See

CAUTION

on

page

6

and

in

Fig. 9,

obovel

Drow

about

2 inches

of

thread

through

the

eye

of

the

right

looper,

with

which

to

commence

sewing.

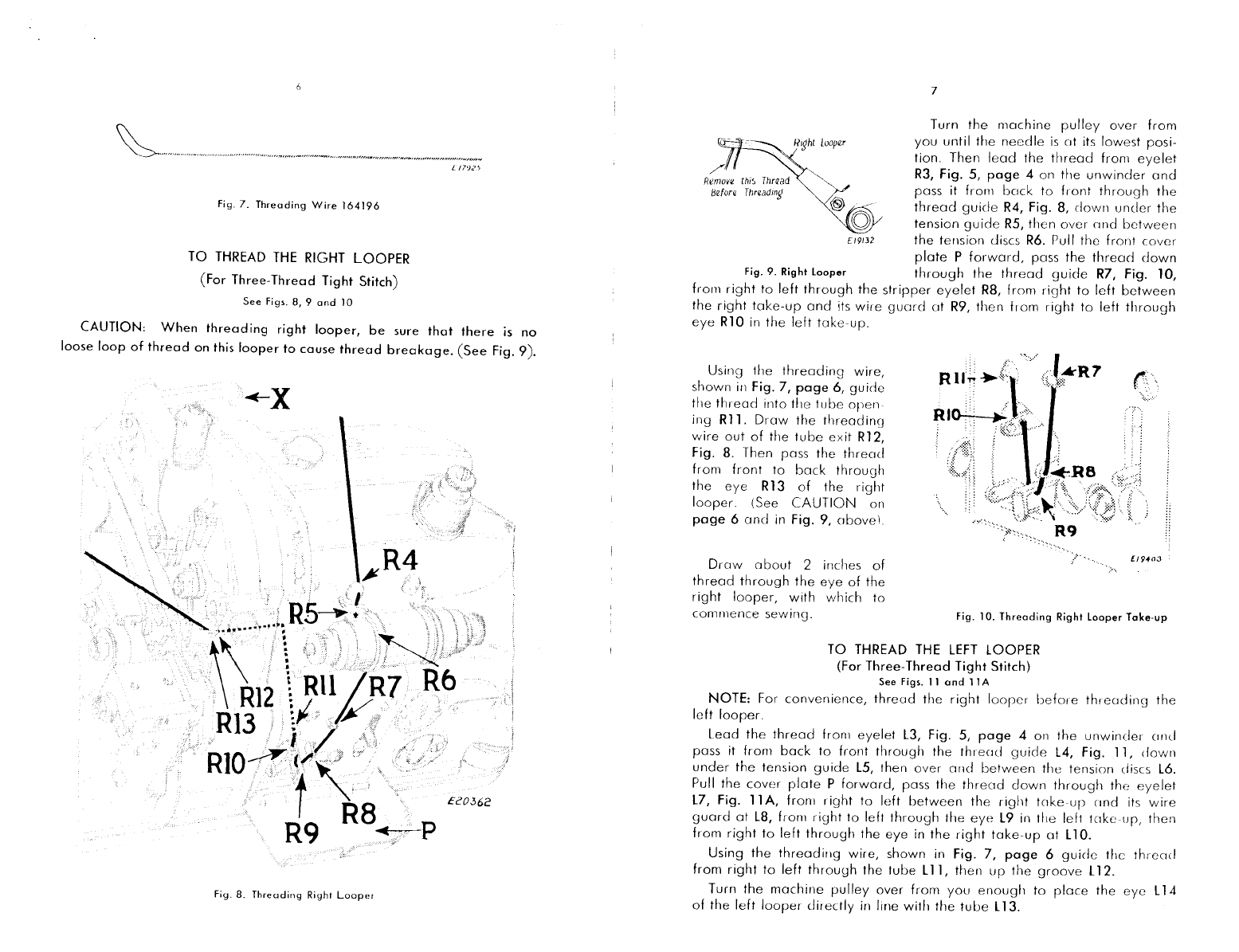

Fig. l

0.

Threading

Right

looper

Toke-up

TO

THREAD THE

LEFT

LOOPER

(For

Three-Thread Tight Stitch)

See

Figs.

11

and

l

lA

NOTE:

For

convenience,

thread

the

right

loorer

before

th,

coding

the

left

loorer.

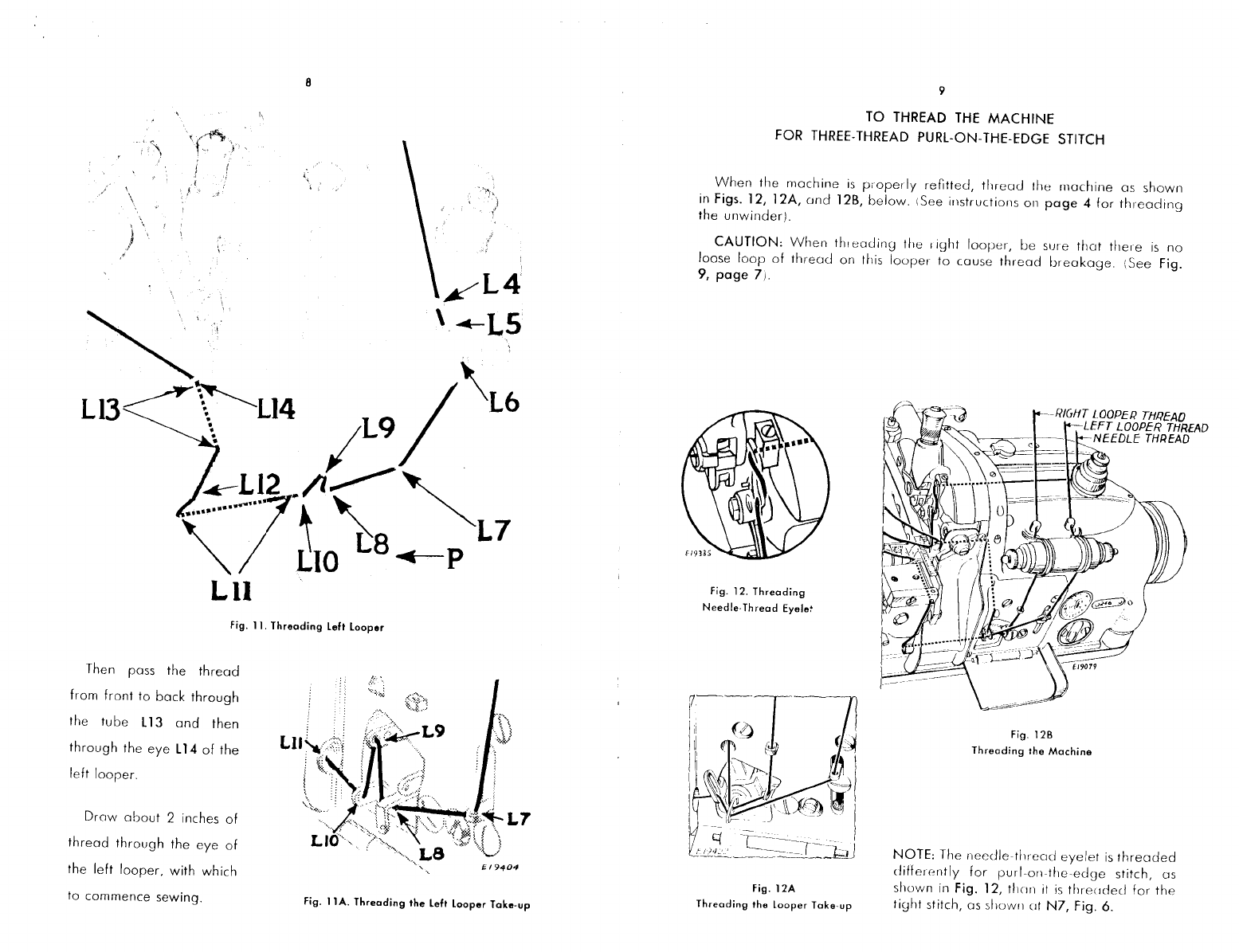

Lead

the

thread

fron1

eyelet

L3, Fig. 5,

page

4 on

the

unwinder

c1nd

pass it

from

back

to

front

through

the

thremJ

guide

L4,

Fig.

l

l,

down

under

the

tension

guide

L5,

then

over

and

between

the

tension

discs

L6.

Pull

the

cover

plate

P

forward,

pass

the

threod

down

through

the

eyelet

L7,

Fig. l l A,

from

right

to

left

between

the

right

toke-up

cind its

wire

guard

at

L8,

from

right

to

left

through

the

eye

L9

in

the

left

tc1ke

ur,

then

from

right

to

left

through

the

eye

in

the

right

take-up

at

Ll 0.

Using

the

threading

wire,

shown

in

Fig. 7,

page

6

guide

the

thread

from

right

to

left

through

the

tube

Ll

l,

then

up

the

groove

L12.

Turn

the

machine

pulley

over

from

you

enough

to

place

the

eye

L

14

of

the

left

looper

directly

in

line

with

the

tube

L

13.