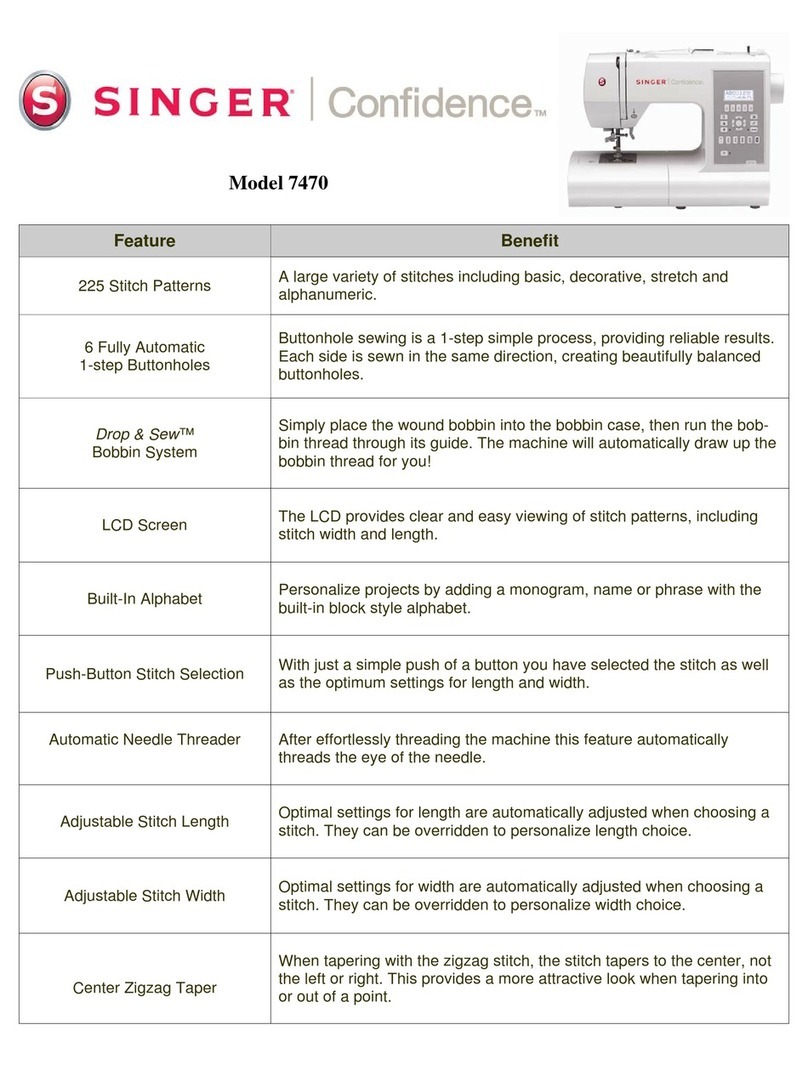

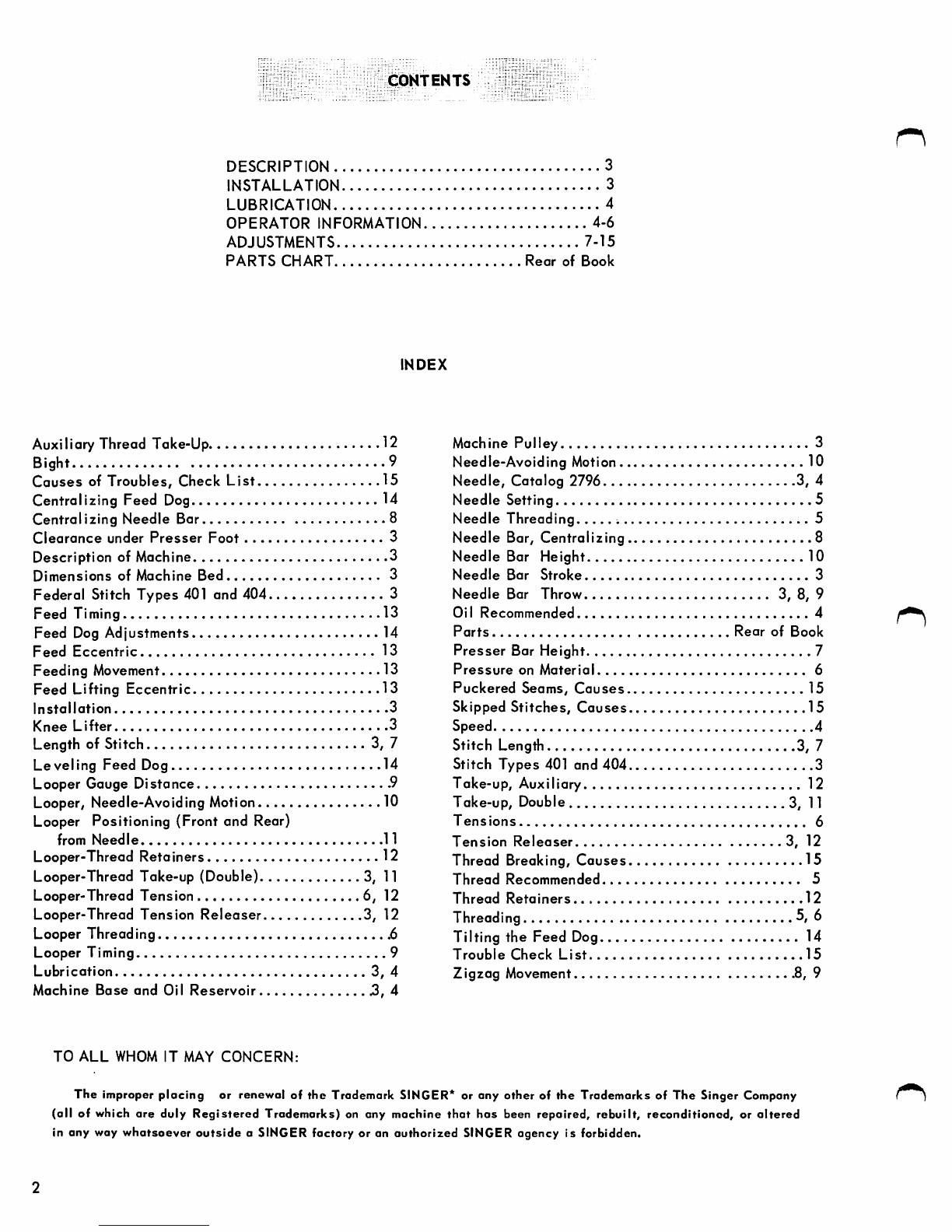

BIGHT

Width

of zig-zag movement of the needle, while

stitching,

is termed the

"BIGHT".

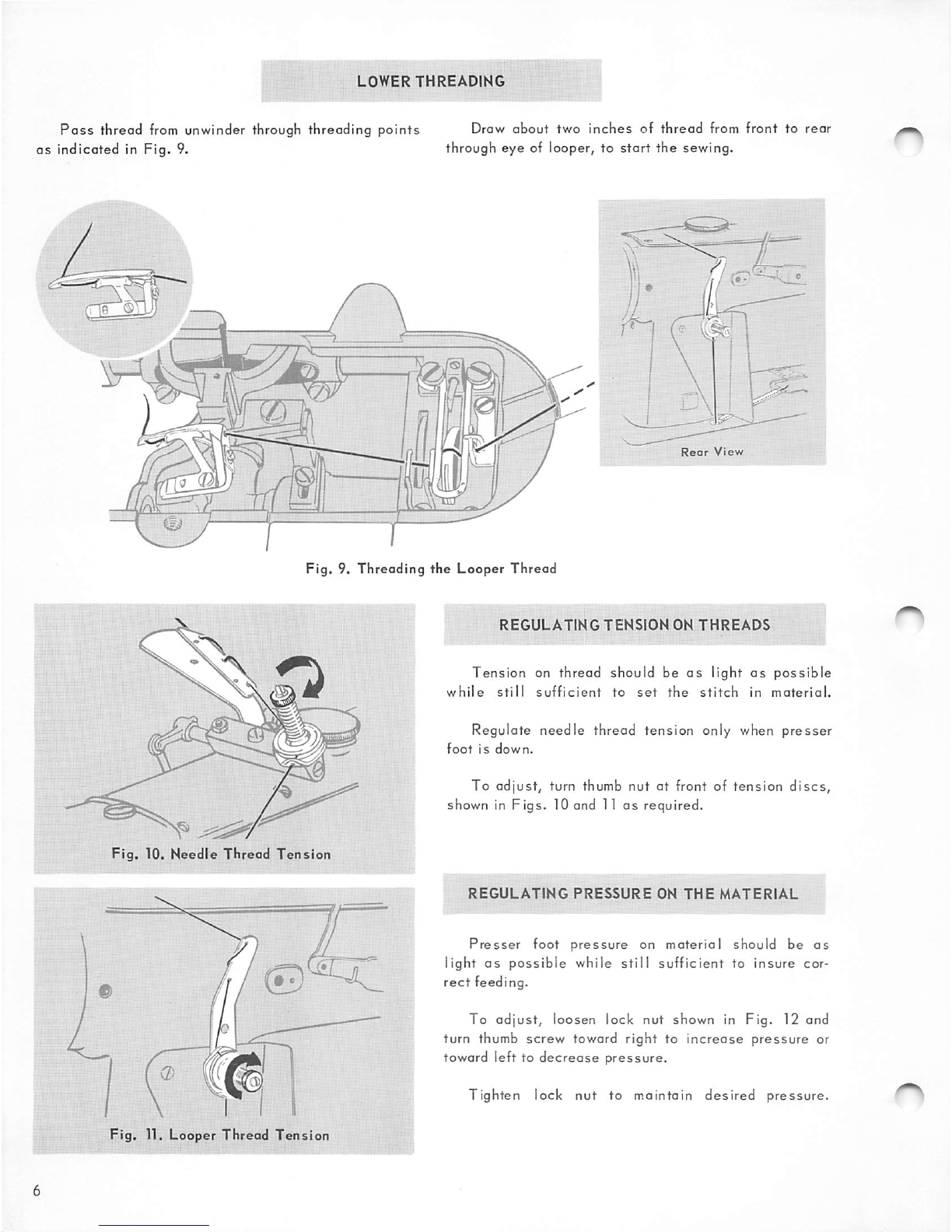

To

adjust

the

width of bight, remove one cover

screw and loosen the other, allowing cover to drop, as

shown in Fig. 19.

Loosen

hex-nut and move lever with

nut

toward left for more bight or toward right for

less

bight,

as

instructed

in Fig. 19.

Tighten hex-nut and

replace

cover.

NOTE: Whenever bight adjustment is changed, looper

gauge must be checked and adjusted

as

instructed

below.

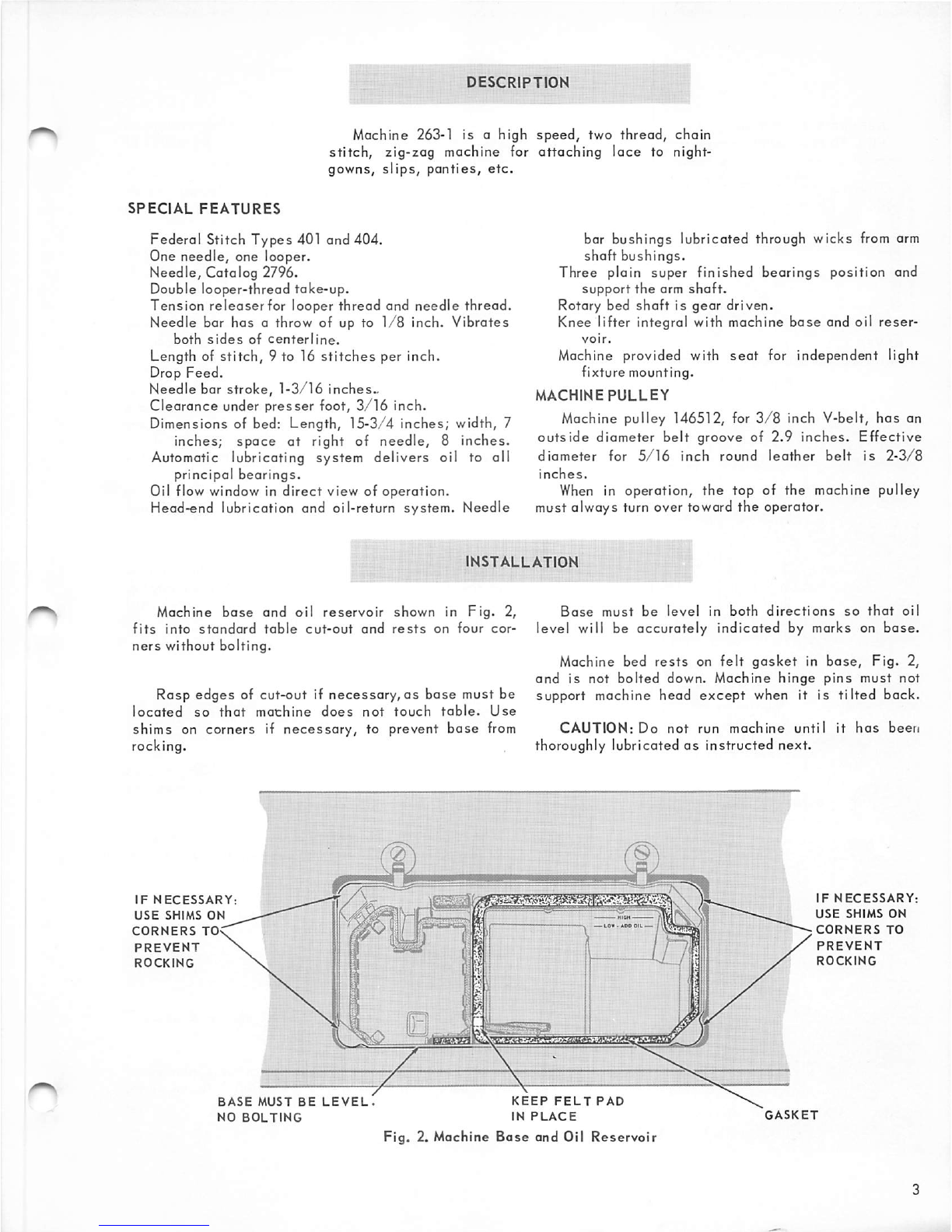

LOOPER

GAUGE

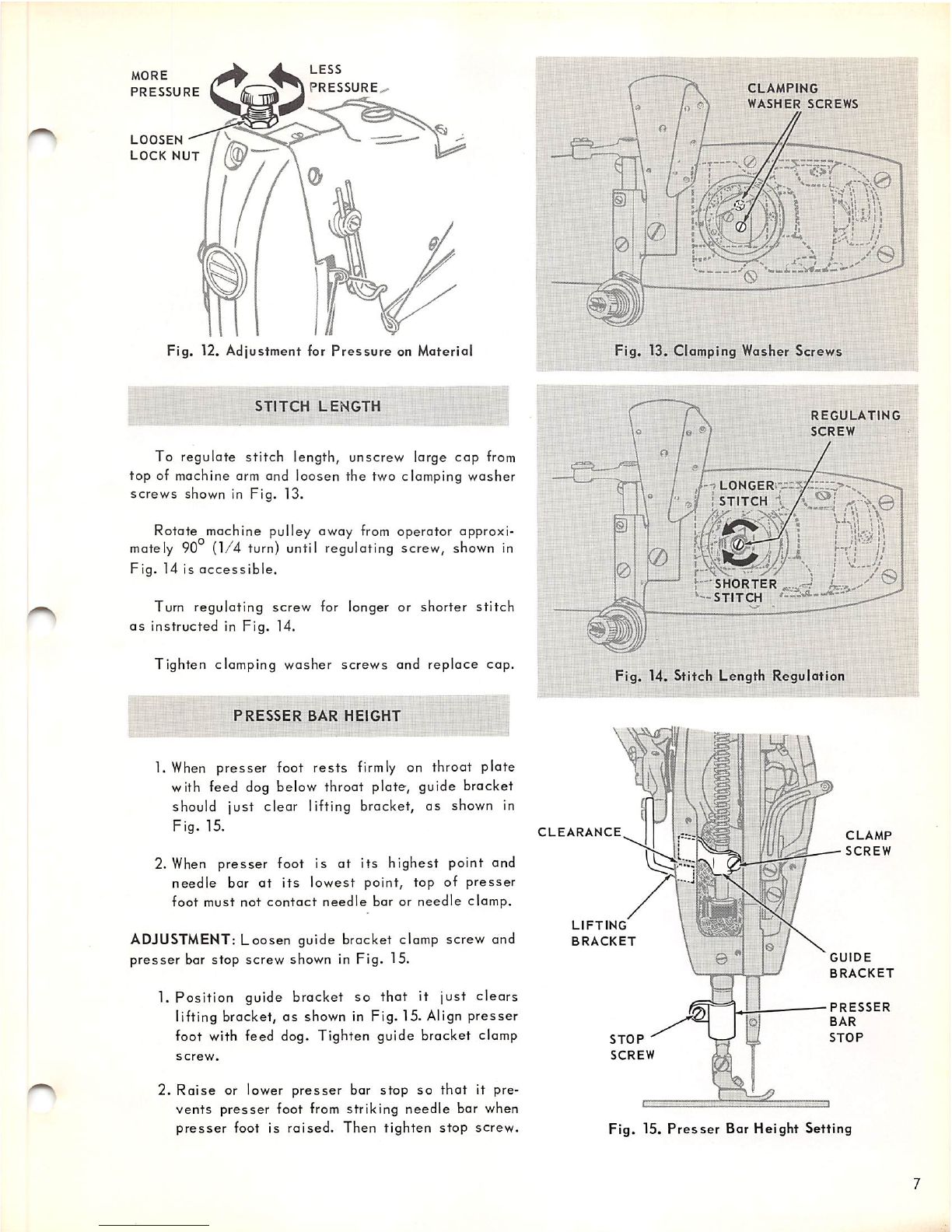

When

needle

is at extreme right position, and looper

is

at end of

backward

stroke,

distance

from

centerline

of

needle

to point of looper should be

5/32

inch,

as

shown in Fig. 20.

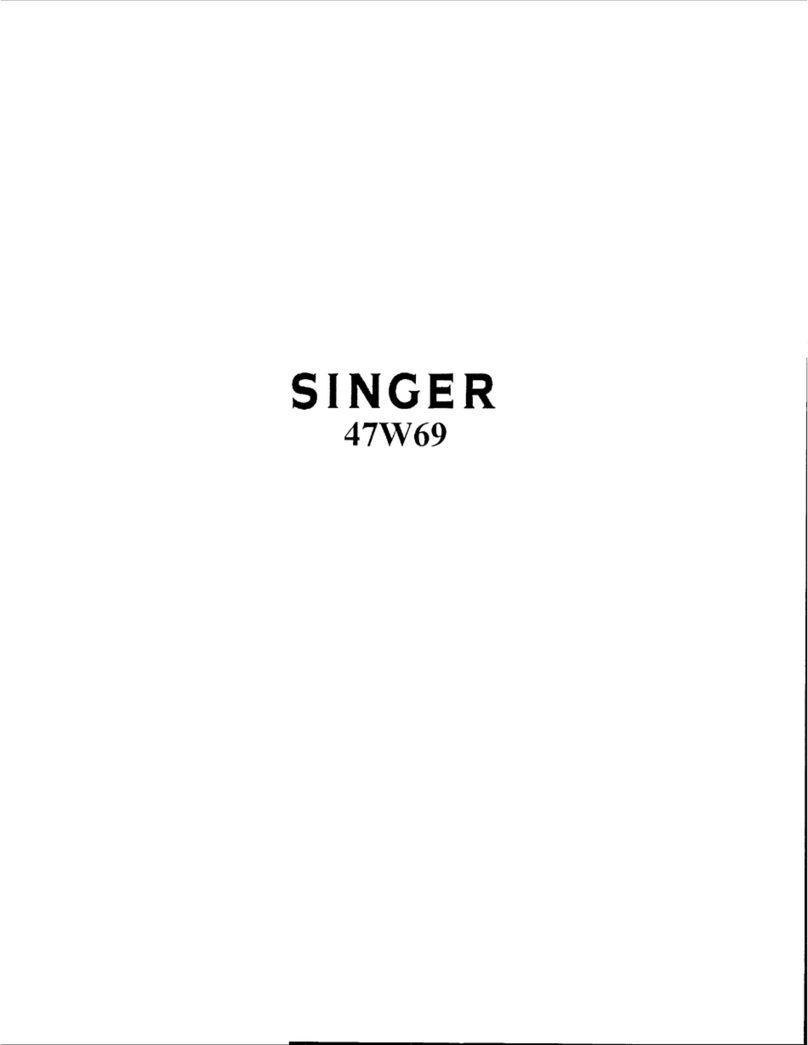

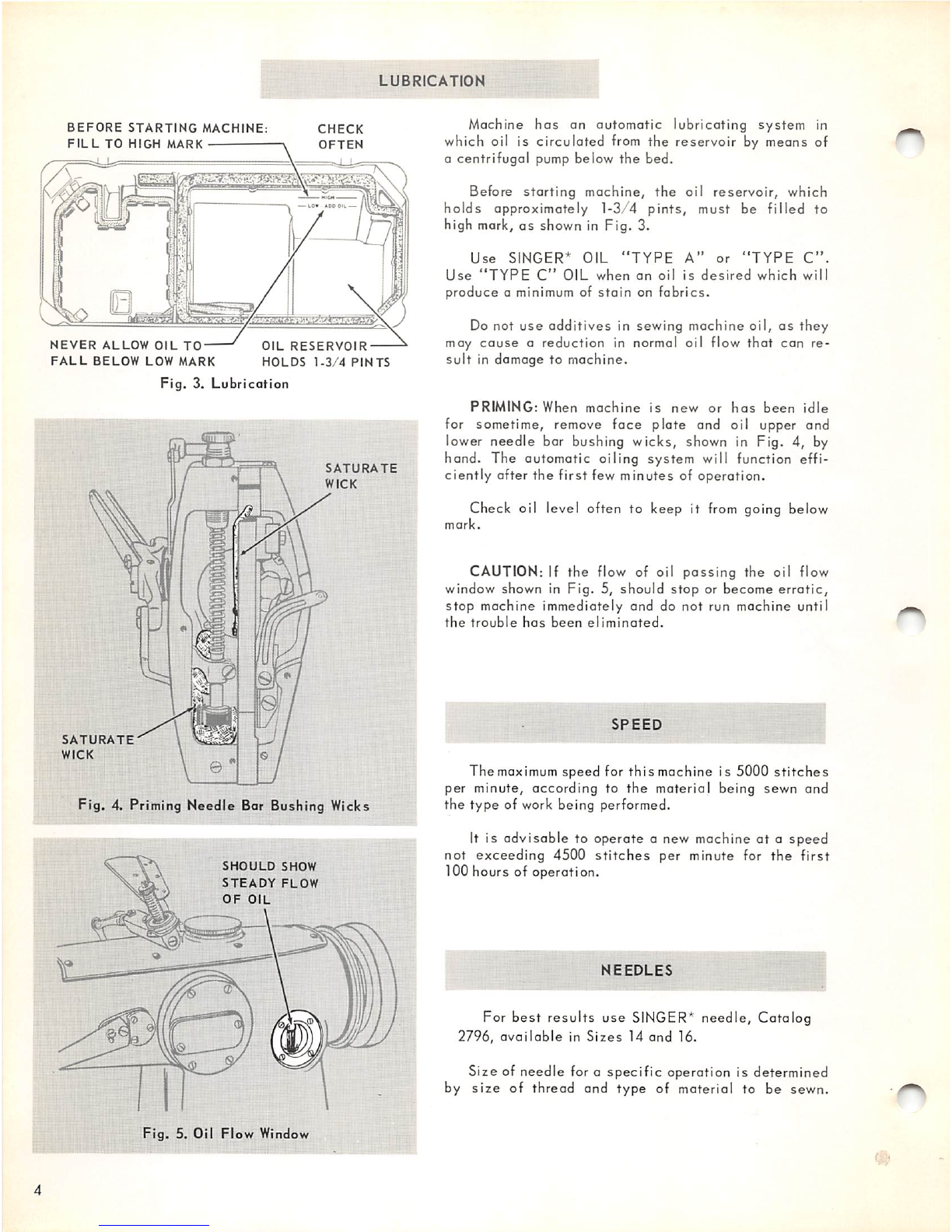

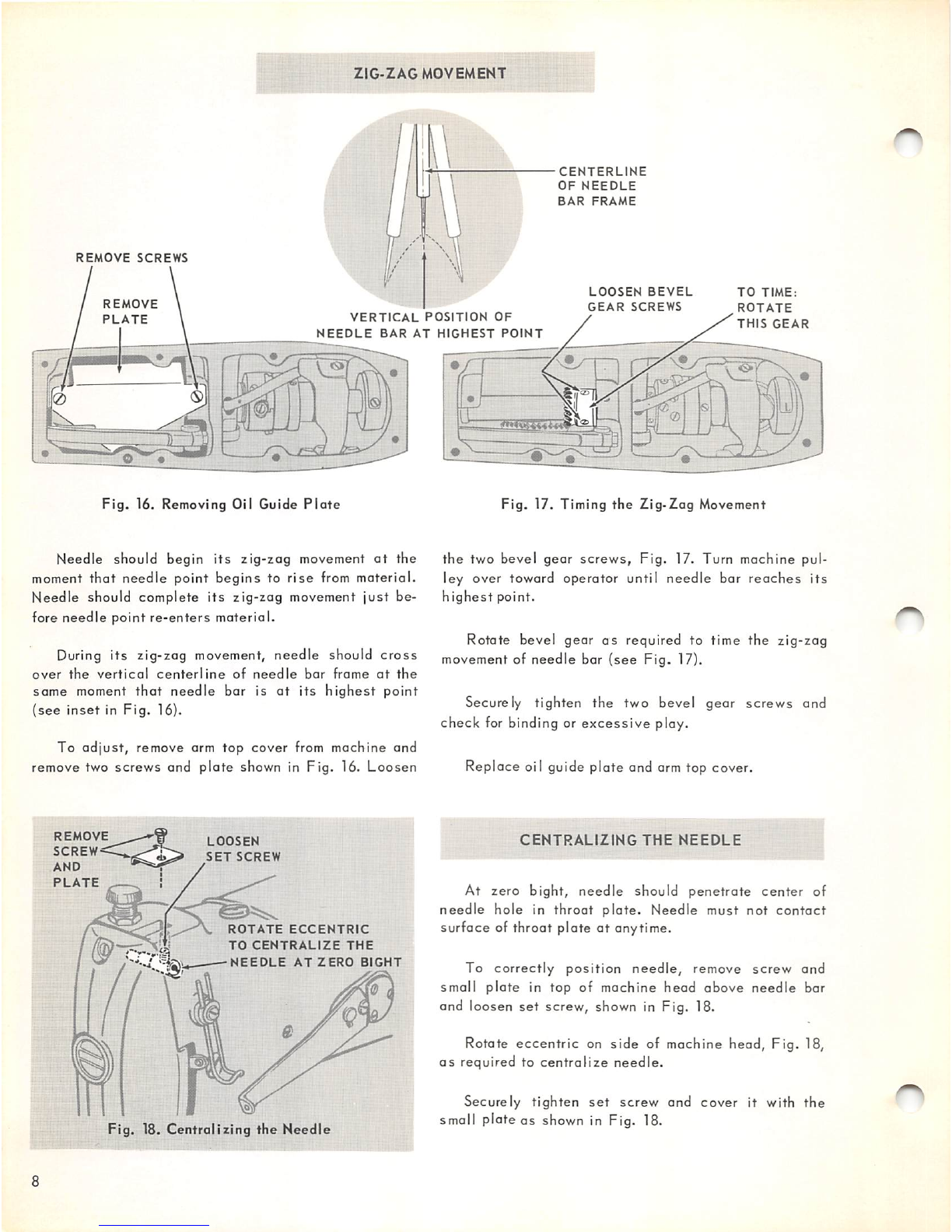

To

adjust,

loosen

clamp

screw

on ball

crank

arm,

shown in

Fig.

21.

Rotate

ball

crank

arm toward

right

or

left,

as

required, to obtain correct

distance.

Tighten ball crank clamp screw.

TIMING

THE

LOOPER

When

needle

bar is

at

its

lowest

position, looper

should be at the end of its backward stroke (just ready

to begin

its

forward

stroke).

To

set

the timing, remove bed

slides,

presser foot,

throat plate and feed dog. Loosen the two bevel gear

screws

located

at

machine pulley end of rotary bed

shaft (see Fig. 19). Turn machine pulley over toward

operator

until

needle

bar is at

lowest

point.

Turn rotary bed shaft (now free of

gear

action)

for

ward or backward by hand to

set

looper

at

extreme

right

position.

Tighten the two bevel

gear

screws

just

enough to

hold above

setting.

Obtain

correct

looper and

needle

eye

positions,

as

instructed

next, before finally

tighten

ing the two bevel gear screws securely.

HEX-NUT

MORE

BIGHT

LESS

BIGHT

Fig. 19. Adjusting Width of Bight

5/32*

NEEDLE

AT

EXTREME

RIGHT

POSITION

LOOPER

AT

END

OF

BACKWARD

STROKE

Fig,

20.

Looper

at

Gauge

Distance

from

Needle

BALL

CRANK

CLAMP

SCREW

TWO

BEVEL

GEAR

SCREWS

ROTARY

BED

SHAFT

Fig. 21. Adjusting and Timing

the

Looper