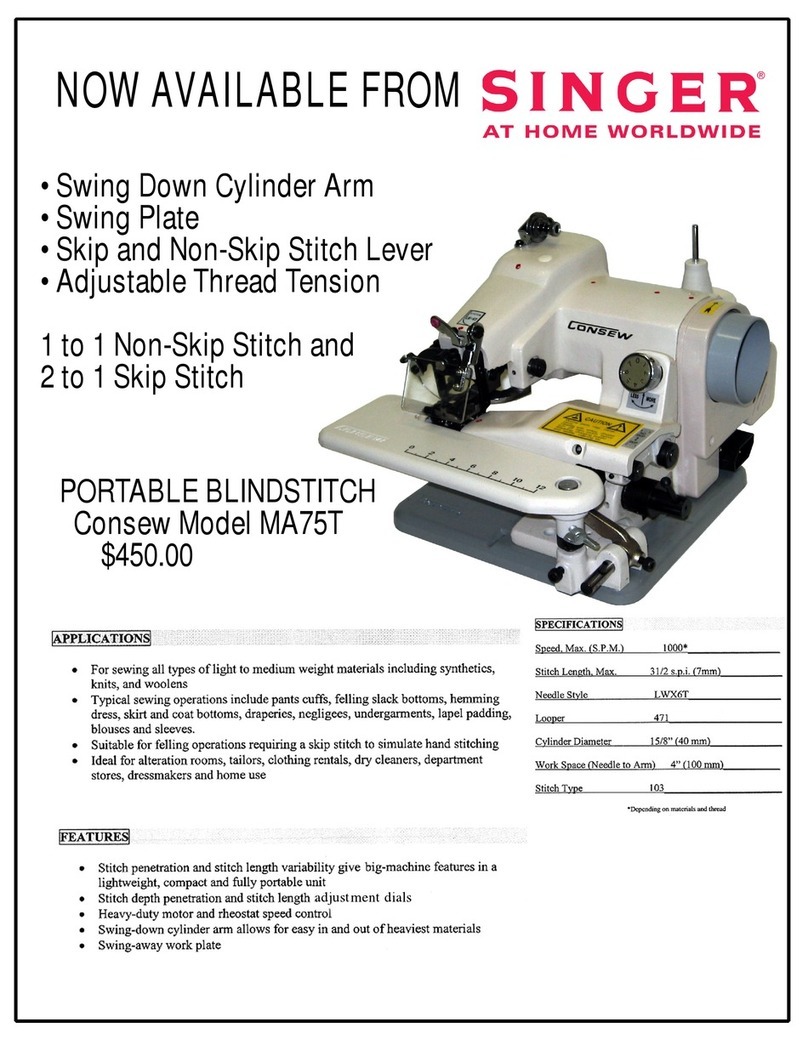

DESCRIPTION

Machine

270-37

is a single needle, single thread, lockstitch

machine

designed

for

sewing

two and

four

hole buttons on clothing. The

machine

sews a single

row

of stitches parallel to

the

cylinder

when

sewing

two

hole

buttons

and

two

rows

of stitches parallel to the

cylinder

with two right angle cross-over stitches

when

sewing

four

hole buttons.

Automatic in operation, the machine is equipped with a sewing reel which is located inside

the

hook

body.

Thread

is

wound

on reel

from

upper

thread

supply

during

the Initial needle pene

tration. Then,without a break in thread or interruption

in

machine

cycle, stitch

formation

begins.

Reel

thread is passed

through

upper

thread

loop

on each successive stitch to

form

aregular

lockstitch. Thus only one thread is required to

form

a complete stitch pattern and no stitch

starting ends of thread are present. At the end of the stitching pattern, thread is

trimmed

and

excess thread is

removed

from

reel and

drawn

away by a suction type air

pump.

GENERAL

CHARACTERISTICS

18 Stitches

...

6parallel, 2cross-over, 6parallel,

4tying.

Rotating

Hook with

Thread

Reel

. . .

makes

two

revolutions

to

each

revolution

of arm

shaft.

Rotary Hook

Shaft,

, . driven by spiral bevel gear

from

vertical

arm

shaft.

Throat Plate . . . equipped with scissor type trim

ming mechanism for cutting thread at completion of

stitch

pattern.

Button Clomp . . , accommodates 14 to 50 ligne

buttons.

Work

Plate

...

if specified, at additional cost.

Feed

Cam . . . controls operation of button clamp.

Safety Interlock . . . prevents clamp

from

being

lifted when machine is in operation.

Belt

Guard . . . fully

encloses

driving belt and

stop

motion

device.

TENSION

REGULATOR

PRE-TENSION

PULL-OFF

LOOP

THREAD

GUIDE

RING

FACE

PLATE

THROAT

PLATE

ROTATING

HOOK

WITH

REEL

CYLINDER

COVER

\

BUTTON

CLAMP

r.

ARM

COVER

(SIDE)

BELT

GUARD

COVER

FEED

CAM