Singer 46K15 User manual

Other Singer Sewing Machine manuals

Singer

Singer 14SH644 User manual

Singer

Singer Sewing Machine User manual

Singer

Singer 20U-109 User manual

Singer

Singer 111W155 User manual

Singer

Singer 1669U101 User manual

Singer

Singer 153W102 Quick start guide

Singer

Singer 114W101 User manual

Singer

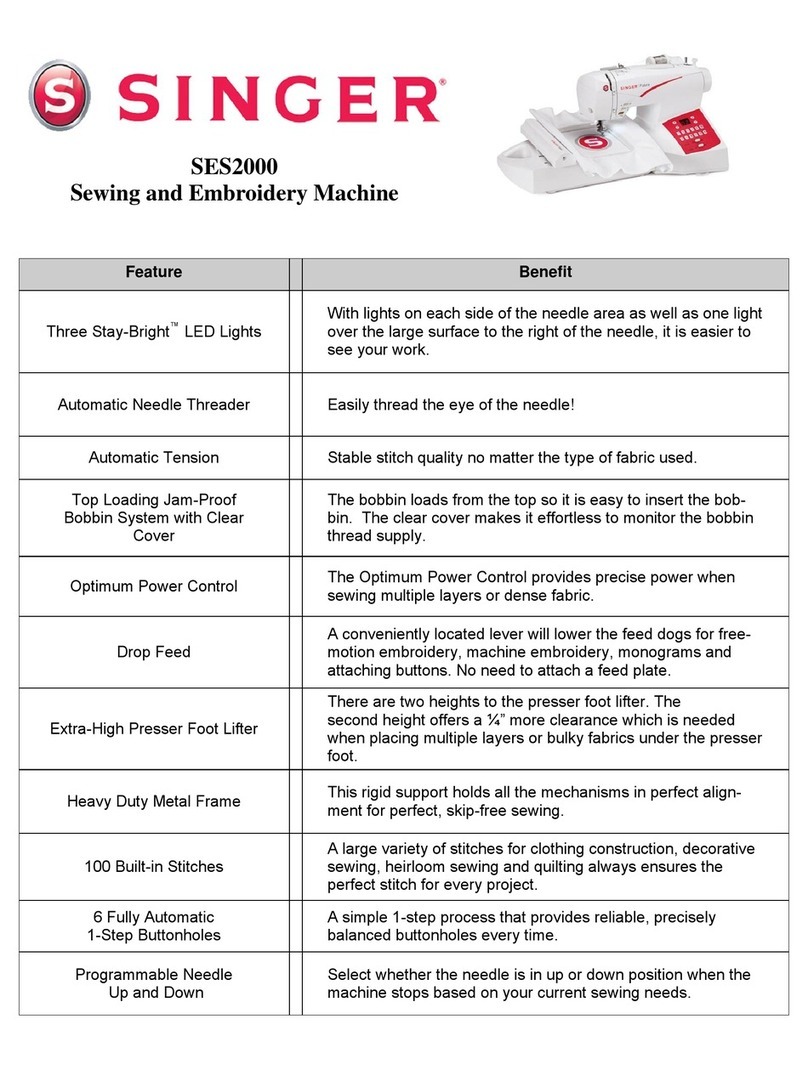

Singer Futura SES2000 User manual

Singer

Singer 1022 User manual

Singer

Singer 400W102 User manual

Singer

Singer 10uj13 User manual

Singer

Singer 246K21 User manual

Singer

Singer CONFIDENCE 7463 User manual

Singer

Singer 299U User manual

Singer

Singer 52-56 User manual

Singer

Singer 143G2 User manual

Singer

Singer WHITE User manual

Singer

Singer 635D User manual

Singer

Singer 147-81 User manual

Singer

Singer 140W1 Quick start guide