From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

CONTENTS

1. PREFACE ..................................

...

....................................

...

..

..

...

..

...

..

.....

...

..

..

.....

..

.....

...

. 1

2. NOTES ON SAFETY .

...

...

..

.......

..

.........

...

..

..

..

..

....

..

.

.. .. ..

.

..

...

..

..

..

......

..

..

..

......

..

..

...

..

......

..

..

. 1

3.

MEANINGS

OF

THE SYMBOLS ................................................................................. 1

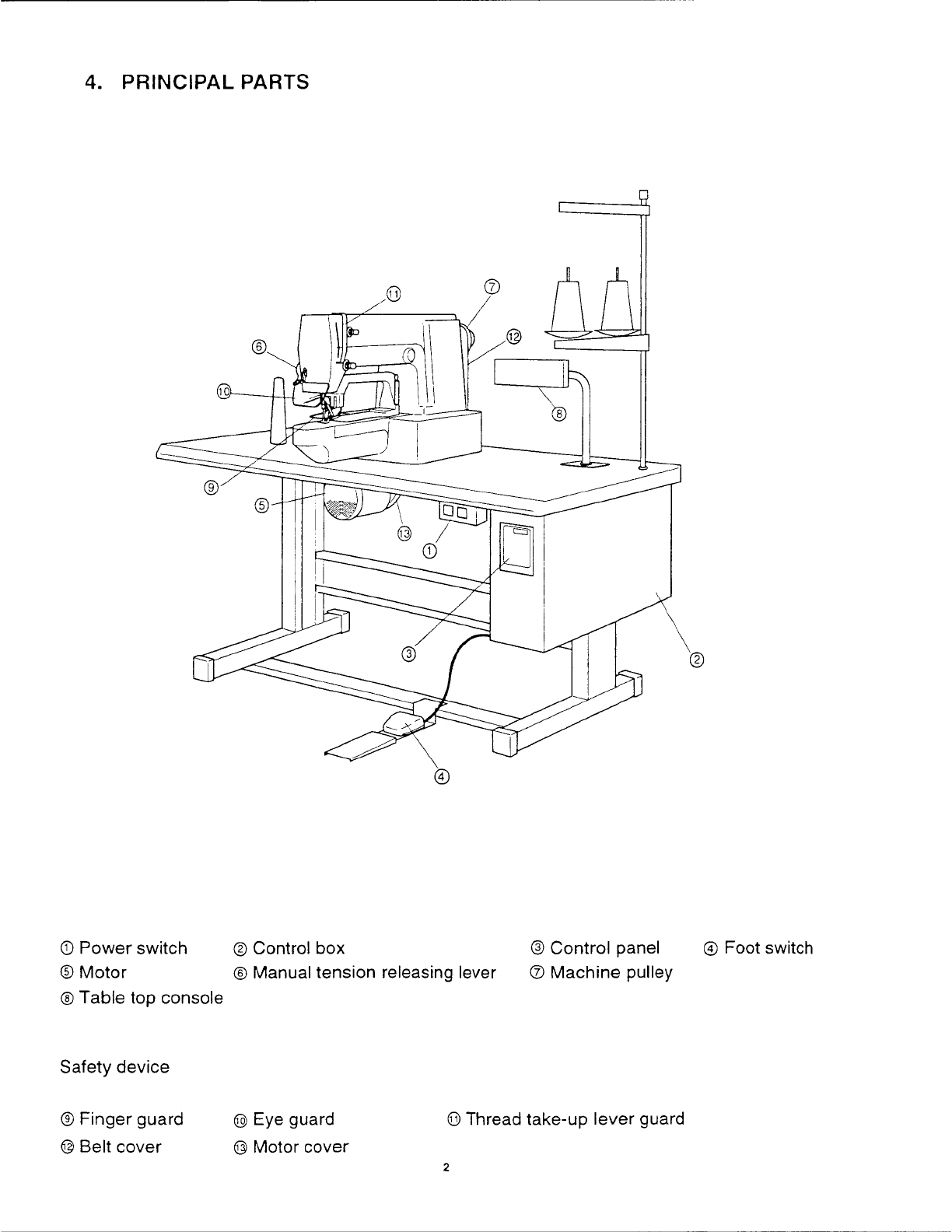

4. PRINCIPAL PARTS ..................................................................................................... 2

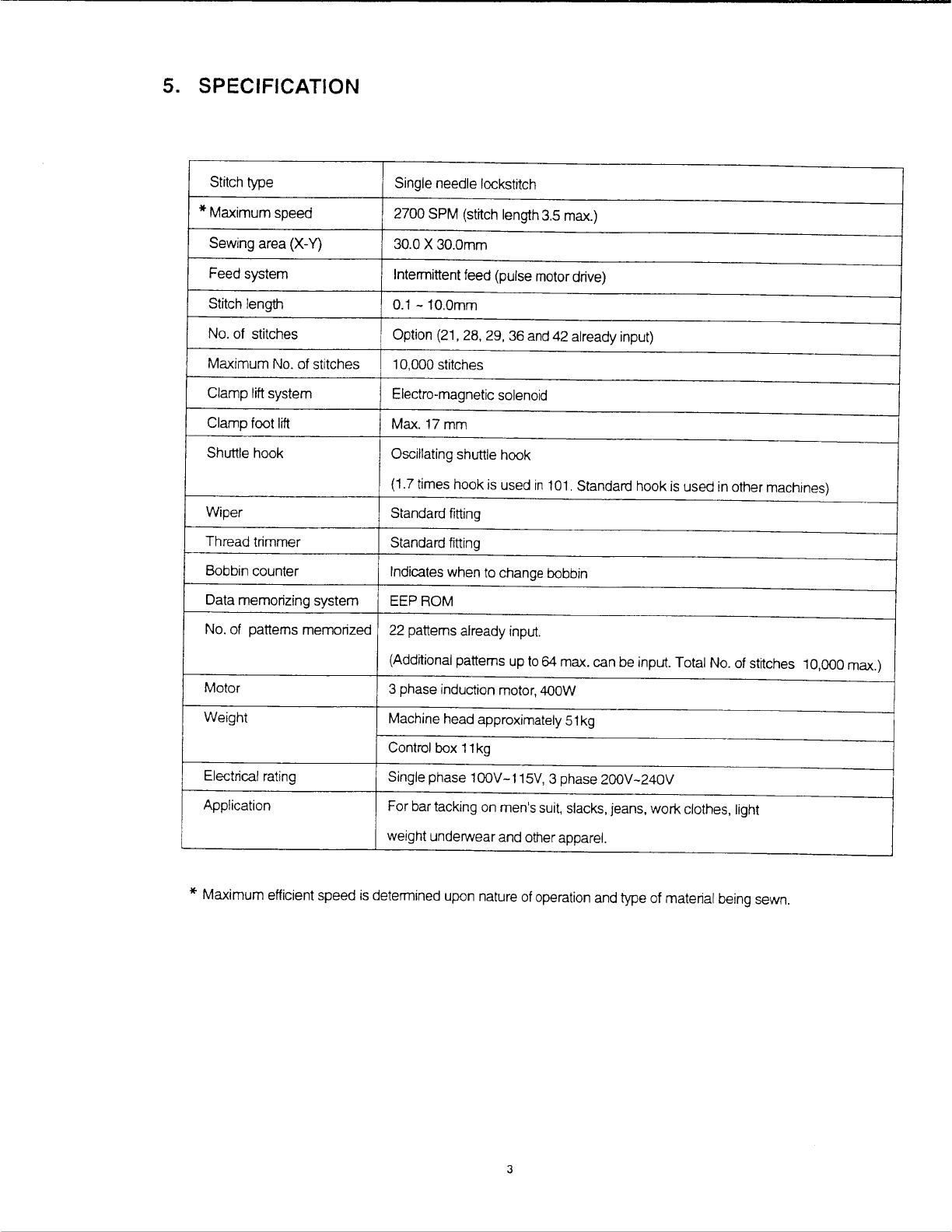

5. SPECIFICATION ........................................................................................................... 3

6. ADJUSTMENT OF NEEDLE AND SHUTTLE ............................................................... 4

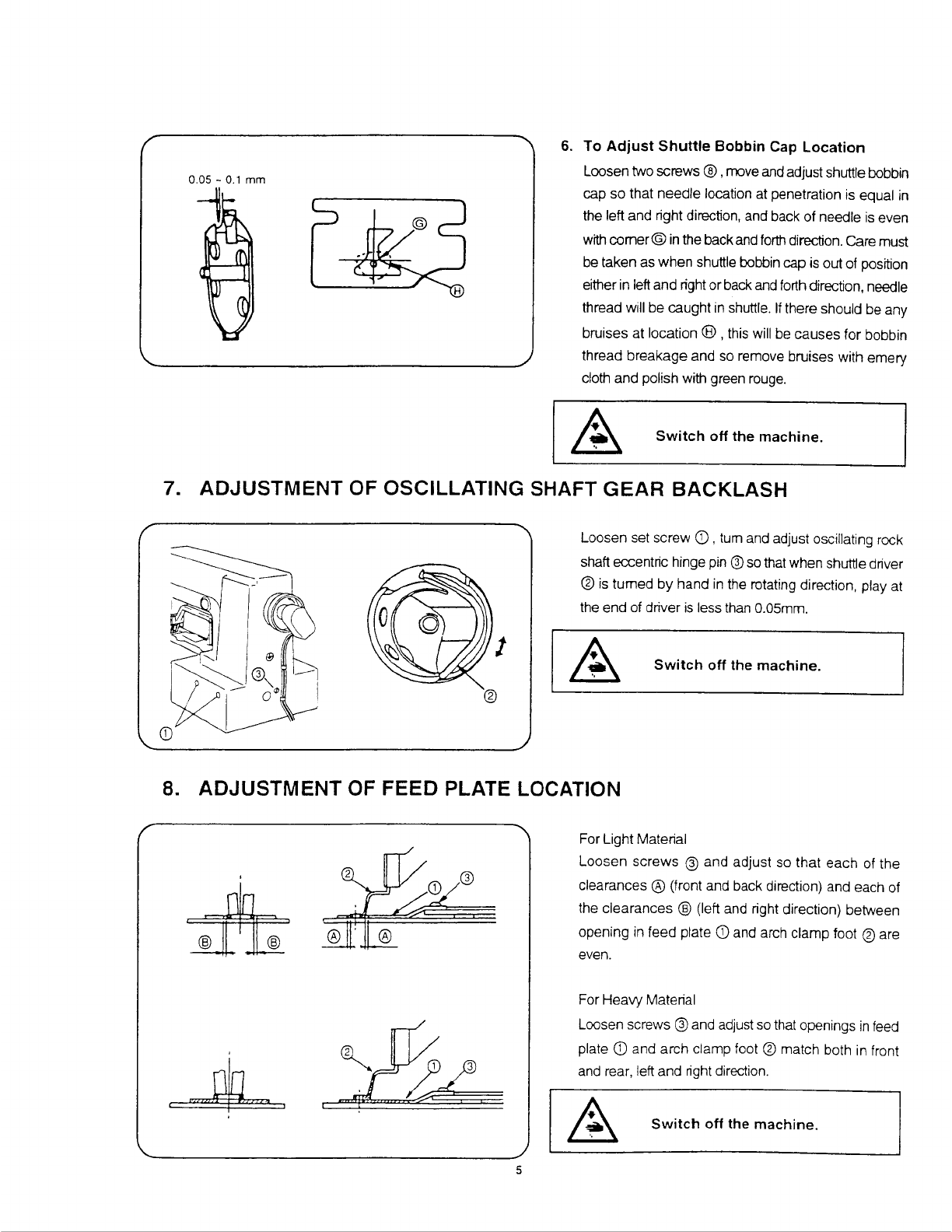

7. ADJUSTMENT OF OSCILLATING SHAFT GEAR BACKLASH ................................... 5

8. ADJUSTMENT OF FEED PLATE LOCATION .............................................................. 5

9.

TO

ADJUST POSITION OF PRESSER FOOT .............................................................. 6

10. TO ADJUST POSITION OF CAM BRACKET ............................................................... 7

11.

ADJUSTMENT OF WIPER HEIGHT ............................................................................. 8

12.

TO

ADJUST TENSION RELEASING BAR SOLENOID ................................................ 8

13.

TO

ADJUST POSITION OF THREAD TRIMMER CAM ................................................ 9

14.

TO

ADJUST HEIGHT OF ROLLER .............................................................................. 1

O

15. TO ADJUST POSITION OF

SHAFT

.............................................................................. 10

16. TO ADJUST LENGTH OF KNIFE BAR OPERATING LEVER CONNECTING ROD .....

11

17. ADJUSTMENT OF KNIFE POSITION ..........................................................................

11

18.

TO

TIME THREAD TRIMMER .....................................................................................

12

19. ADJUSTMENT OF CLAMP FOOT HEIGHT ..................................................................

12

20.

TO

ADJUST SENSOR ...................................................................................................

12

21.

TO

INSTALL SYNCHRONIZER ....................................................................................

13

22.

TO

ADJUST SYNCHRONIZER .....................................................................................13

23. ADJUSTMENT OF BUTTONHOLE SEWING MACHINE (1669U 200) .........................

14

24. ADJUSTMENT

OF

BUTTON SEWING MACHINE (1669U 400) ...................................

16

25. CHECK

MODE

............................................................................................................

21

26. TABLE TOP CONSOLE

CHECK

MODE (OPTION) .....................................................

25

27. ERROR

CODE

NUMBERS............................................................................................

29

28. GREASING POINTS .....................................................................................................30

29. TROUBLE-SHOOTING GUIDE .....................................................................................

31

30. CONTROL BOX DIAGRAM ..........................................................................................

36

31. MAIN

CONTROL

BOARD DIAGRAM ............................................................................

37

32.

D.

C

POWER

SUPPLY BOARD DIAGRAM .................................................................

38

33. INVERTER BOARD DIAGRAM .....................................................................................

38