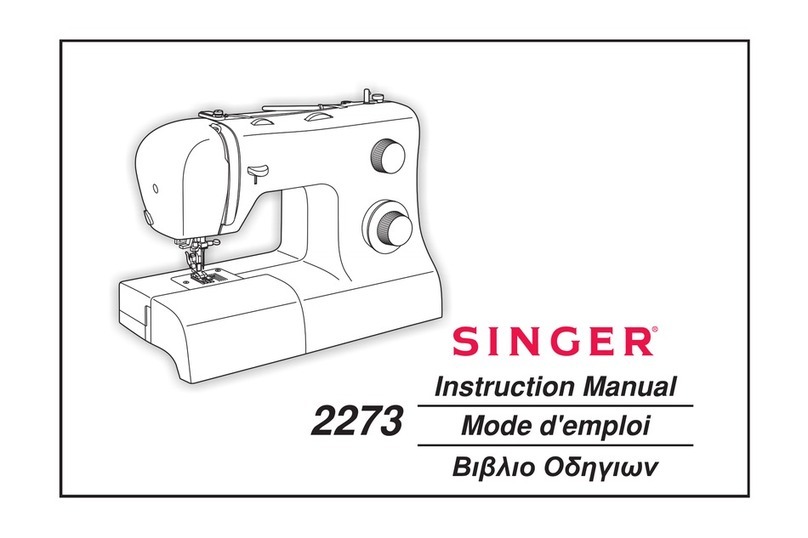

and what they do

1. Bobbin-Winder Tension Disc regulates thread tension for bobbin

winding.

2. Pressure Dial regulates presser-foot pressure on fabric^ It has an all

purpose setting plus settings for extra-light and extra-heavy pressure,

and for darning.

3. Take-up Lever controls flow of needle thread.

4. Presser-Foot Lifter, at back of machine, allows you to raise and

lower presser foot. High-lift position allows easy placement of bulky

fabrics.

5. Thread Cutter is built into presser bar for safety and convenience.

6. Needle Clamp holds single and twin needles and is designed to

eliminate the possibility of inserting needle backwards.

7. Presser Foot h lds fabric against feed. The f t snaps ff f r quick

rem val.

8. Needle Plate lifts out for easy removal. Guidelines on right and left

sides extend to slide plate to help you keep seams straight.

9. Feed moves fabric under the presser foot.

10. Slide Plate pens f r easy rem val and replacement f the b bin, and

raises and l wers the pin that h lds the needle plate in p siti n.

11. xtension Table lets you convert the machine for either flat or tubular

bed sewing.

12. xtension Table Release Push Button unlocks the extension table.

13. Sewing Light illuminates the sewing area.

14. Hand Wheel positions take-up lever and needle. Always turn it

toward you.

15. Bobbin-Winder lets you fill the bobbin with thread quickly and easily.

16. Spool Holder with Horizontal Pin holds thread spools of various

sizes.

17. Snap-in Thread Guide Post provides smooth flow of thread from

spool holderto tension discs.

18. Needle-Thread Tension Dial lets y u select the appr priate tensi n f r

y ur stitch, thread, and fabric. The numbers eliminate guessw rk in

duplicating settings.

19. Needle-Thread Tension Discs, controlled by the tension dial,

regulate thre amount of tension on your needle thread.

Instrukcje obsługi maszyn do szycia firm Polskich jak i zagranicznych np. Singer Toyota Pfaff Gritzner Łucznik rka

maszynykrawieckie.shophurt.pl