Singer 491UTT User manual

Other Singer Sewing Machine manuals

Singer

Singer 145W302 Setup guide

Singer

Singer 107-1 Installation and operation manual

Singer

Singer 300U101A User manual

Singer

Singer 291U User manual

Singer

Singer 398054 User manual

Singer

Singer 112W138 User manual

Singer

Singer 145W102 Quick start guide

Singer

Singer 136W102 Quick start guide

Singer

Singer 44-82 User manual

Singer

Singer 7174; 7184 User manual

Singer

Singer 2110 User manual

Singer

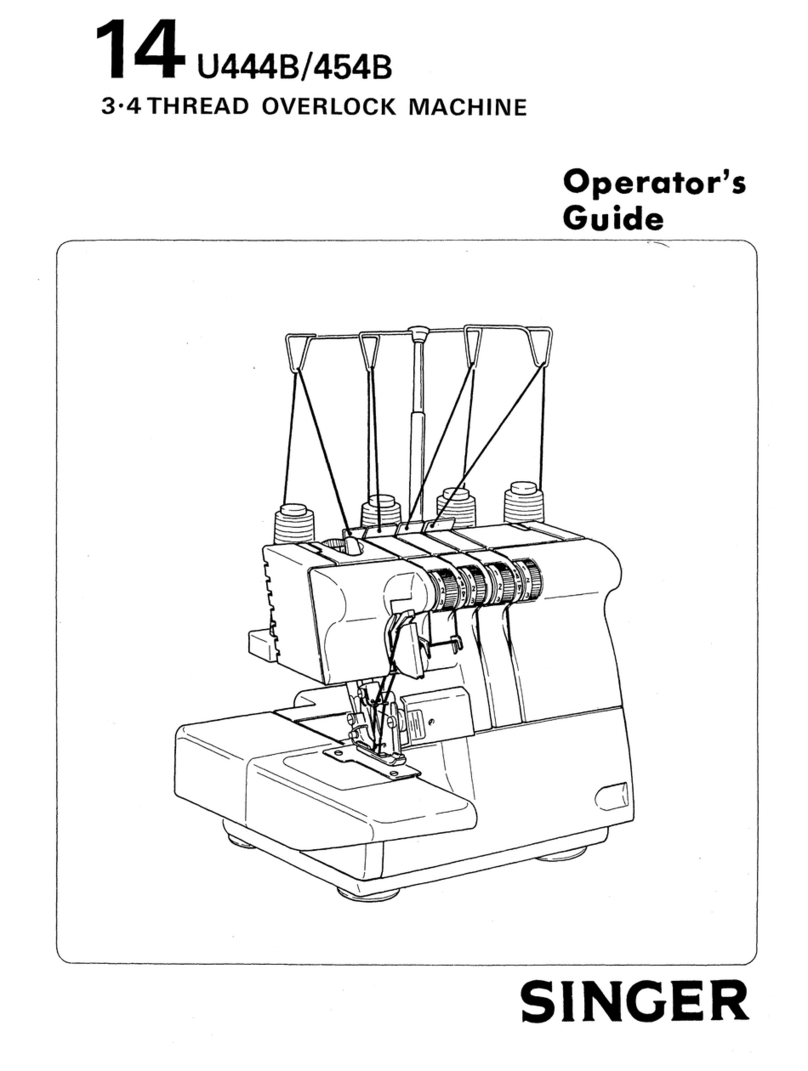

Singer 14 U444B Manual

Singer

Singer 4552 User manual

Singer

Singer 5100 Series User manual

Singer

Singer 14U46B Manual

Singer

Singer BRF40 User manual

Singer

Singer 14U 32A User manual

Singer

Singer 591V200A User manual

Singer

Singer 144W204 Quick start guide

Singer

Singer One User manual