Singer 591V User manual

Other Singer Sewing Machine manuals

Singer

Singer 331K1 User manual

Singer

Singer 29-4 User manual

Singer

Singer 414 User manual

Singer

Singer 123W-1 Installation and operation manual

Singer

Singer 1505 User manual

Singer

Singer 246K43 Troubleshooting guide

Singer

Singer 560 User manual

Singer

Singer 400W23 User manual

Singer

Singer 4423 User manual

Singer

Singer 610D User manual

Singer

Singer 70-105 Quick start guide

Singer

Singer 15-91 User manual

Singer

Singer 491UTT User manual

Singer

Singer 107W14 Quick start guide

Singer

Singer 144W301 Quick start guide

Singer

Singer 770A51 User manual

Singer

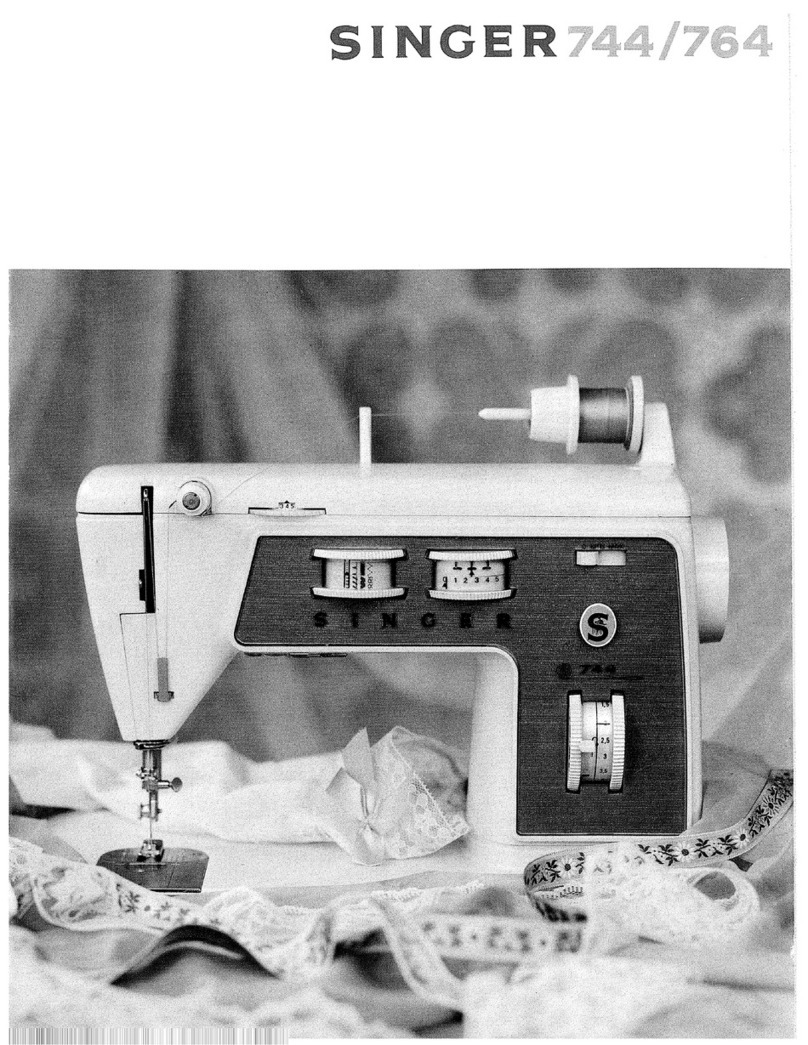

Singer 764 User manual

Singer

Singer 6215 User manual

Singer

Singer 147-29 User manual

Singer

Singer M3330 User manual