Singer CLASS 20 User manual

Other Singer Sewing Machine manuals

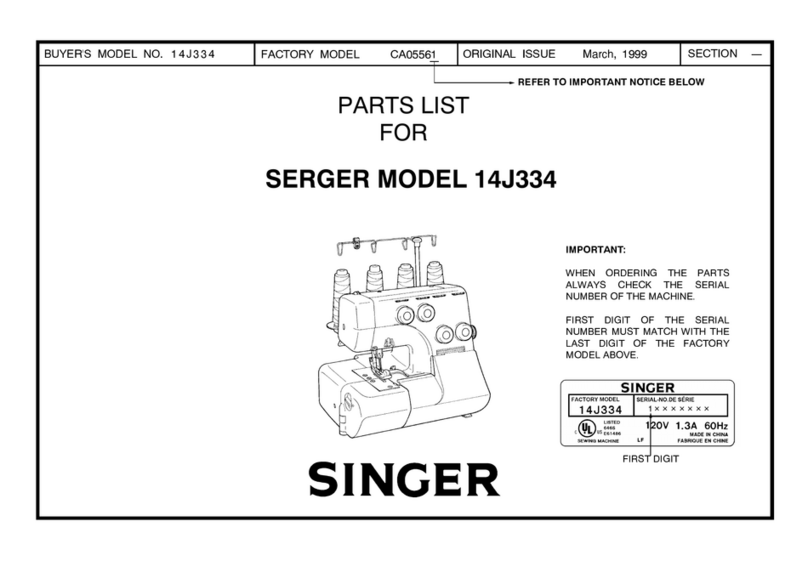

Singer

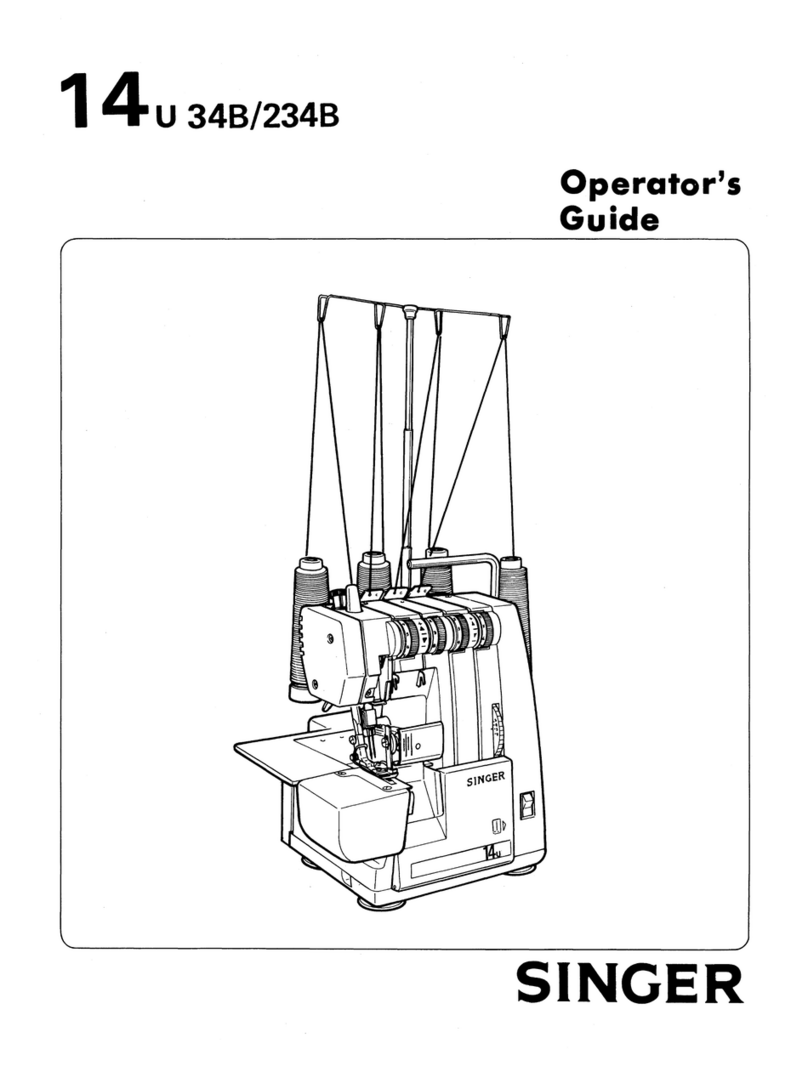

Singer Ultralock 14U 34B/234B Manual

Singer

Singer 12K221 - 1 User manual

Singer

Singer NP050101 User manual

Singer

Singer 211W151 User manual

Singer

Singer 101-1 User manual

Singer

Singer Scholstic 5523 Owner's manual

Singer

Singer 9340 User manual

Singer

Singer S0235 User manual

Singer

Singer 322 User manual

Singer

Singer 32-64 Installation and operation manual

Singer

Singer TINY TAYLOR TT700 User manual

Singer

Singer 2810 User manual

Singer

Singer 138K1 Installation and operation manual

Singer

Singer 144W103 User manual

Singer

Singer 79-101 Quick start guide

Singer

Singer 1425 User manual

Singer

Singer 27 Installation and operation manual

Singer

Singer Futura 4300 User manual

Singer

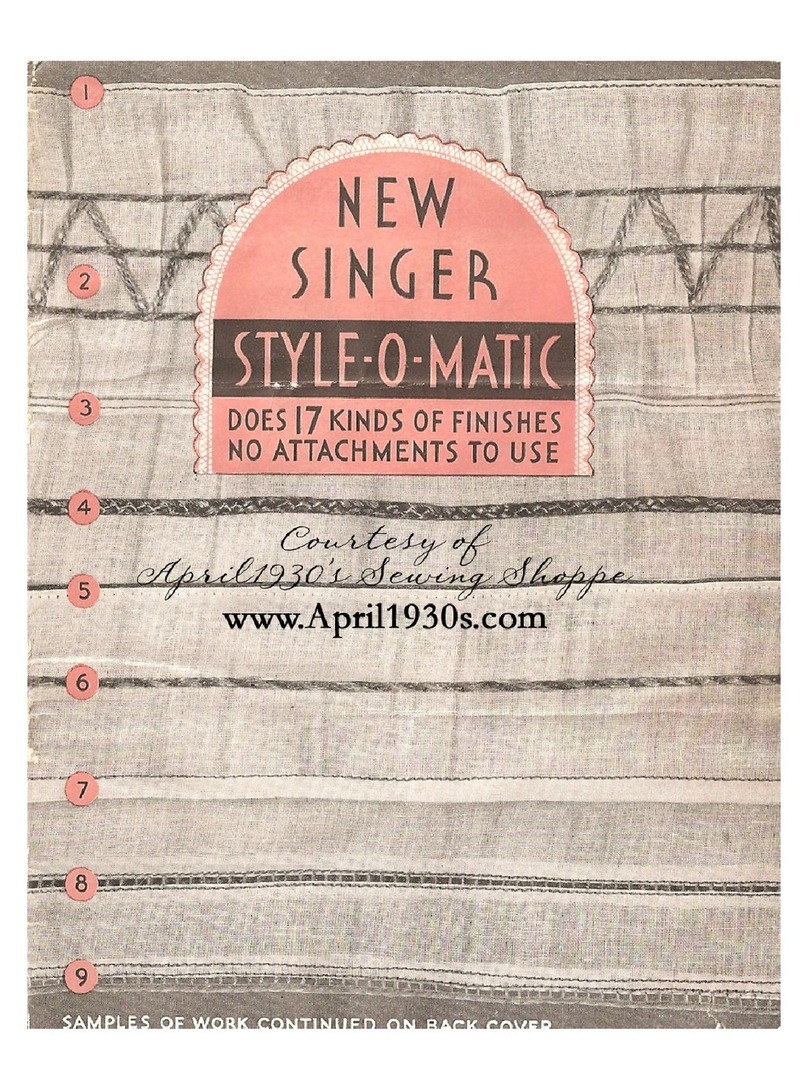

Singer Style-O-Matic User manual

Singer

Singer 300W class User manual