SINNOWA BS Series User manual

Sinnowa Medical Science & Technology Co., LtD

BS3000S Multi-test Analyzer

User’s Manual

BS Series Multitest Analyzer

Contents

1. GENERAL INTRODUCTION

1.1CONFIGURATION AND STRUCTURE.............................................................................................................................1

1.2MAIN FEATURES AND TECHNICAL PARAMETERS.........................................................................................................1

2. INSTALLATION

2.1 INSTALLATION REQUIREMENT....................................................................................................................................2

2.1.1 SPACE REQUIREMENT .................................................................................................................................2

2.1.2 ENVIRONMENTAL REQUIREMENT ...........................................................................................................2

3. BIOCHEMICAL TEST FUNCTIONS AND OPERATION

3.1 WORKING PRINCIPLE ................................................................................................................................................3

3.2 OPERATION ...............................................................................................................................................................3

3.3 PARAMETERS SETTING ..............................................................................................................................................4

3.3.1 TEMERPATURE DISPLAY SETTINGS..........................................................................................................4

3.3.2 PUMP CALIBRATION.....................................................................................................................................5

3.4 INSTRUMENT OPERATION KEYPROCESS

3.4.1 INSTRUMENT PREHEATING ................................................................................................................................5

3.4.2 PIPELINE WASHING ..........................................................................................................................................5

3.4.3 AD AUTO ZERO ..................................................................................................................................................6

4. SPECIFIC PROTEINS TEST FUNCTION AND OPERATION ............................................................................................7

5. MAINTENANCE

5.1 DAILY MAINTENANCE ...............................................................................................................................................7

5.2 WEEKLY MAINTENANCE .............................................................................................................................................8

5.3 MONTHLY MAINTENANCE ...........................................................................................................................................8

5.4 OTHER MAINTENANCE ITEMS ...................................................................................................................................8

6. TROUBLESHOOTING

6.1 MALFUNCTION PHENOMENON .....................................................................................................................................8

6.1.1 THERE ARE MISTAKES WITH AUTO ZERO .......................................................................................................8

6.1.2 WRONG RESULT OR BAB REPETITION ..........................................................................................................9

6.1.3 THE INSTRUMENT DO NOT WORK ..................................................................................................................9

6.1.4 SCREEN DEFINITION CHANGES ....................................................................................................................9

6.1.5 PRINTER KEEPS WALKING ............................................................................................................................9

6.1.6 HEATING TIME IS LONG ..............................................................................................................................9

6.1.7 TESTING TIME SLIGHTLY LONG ..................................................................................................................9

6.2 THE CORRECTIONS AND REPLACEMENTS TO COMMON PARTS OF ANALYZER

6.2.1 THE REPLACEMENT OF FUSE ........................................................................................................................10

6.2.2 THE REPLACEMENT TO LIGHT SOURCE ......................................................................................................10

6.2.3 THE REPLACEMENT TO PERISTALSIS PUMP ..............................................................................................11

6.2.4 THE REPLACEMENT TO PRINTING PAPER ..................................................................................................12

7. TRANSPORTATION ANDSTORAGE

7.1 TRANSPORTATIONS.................................................................................................................................................12

7.2 STORAGE ................................................................................................................................................................12

BS Series Multitest Analyzer

1

1. General Description

BS3000S is an optical multi-test analyzer with Biochemistry and Specific Protein test

functions. The optical system possessing the function of Transmitted light colorimetric detection

and scattering light detection enable the analyzer in multi-test functions.

1.1 Configuration and Structure

BS3000S mainly consists of Control System (single chip microcomputer, touch screen),

Samples and Reagent Incubation system, Optical and Measuring System, Peristaltic Pump Suction

system, Built-in Thermal Printer, etc.

1.2 Main features and technical parameters

The wavelength of transmitted light:

Standard configuration:340nm,405nm,492nm,510nm,546nm,578nm,620nm

Optional: other wavelength available on request within the range from 340nm~810nm

The wavelength of scattering light:670nm,840nm, other wavelength available on

request.

Light source: 6V, 10W halogen lamp, 2 LEDs

Absorbency: 0.000~3.500 OD

Temperature for reaction cuvette: 37℃

Test plate configuration: Flow cell, reaction cuvette for Specific protein. Users can

choose either as needed

Analytical Method:

Photometry: end point, fixed time, kinetic, multi-point, serum blank

Nephelometry: End point Nephelometry, Kinetic nephelometry

Interference light: ≤2.9A

Linearity of absorbency:

Shall meet the following requirements

a) Absorbance within 0.200~≤0.500, the bias should be in ±5%

b) Absorbance within 0.500~≤1.000, the bias should be in ±4%

c) Absorbance within 1.000~≤1.800, the bias should be in ±2%

Stability of absorbency

Touch screen

Built-in printer

PUSH Button

Incubator

Suction probe

BS Series Multitest Analyzer

2

Less than 0.002A within 20minsat 340nm

Repetition of absorbency

Coefficient variance(CV) ≤1.0%

Cross Contamination Rate:

When reaction liquid volume is 1ml, the cross contamination rate should be less than

1% by flow cell test; no cross contamination by using separated cuvette inspection.

2. Installation

In order to ensure the equipment works normally, it must be installed and debugged by the

engineers who are authorized by Sinnowa or Sinnowa authorized organization. For any reasons

to reinstall the analyzer, only the authorized engineer can do the works.

Attention: No authorized installation may make wrong or damage the equipment, the

problem or damage is not in term of free warranty.

2.1 Installation Requirement

2.1.1 Space Requirement

1.Keep the analyzer not less than 100mm distance from wall and other objects for each

side(left, right and back)

2.Ensure enough space for the equipment to place barrel of distilled water and waste

container

2.1.2 Environmental Requirement

1.Working Temperature: 15℃~ 32℃

2.Working Humidity: 30% ~ 70%;

3.Working atmospheric pressure: 860hPa ~ 1060hPa;

4.Power supply: 220V~±10%,50Hz±1 Hz;

5.Fuse: F2AL250V,Ф5x20mm;Fuse:

6.Input Power : 150VA;

7.A good grounding socket within 1meter of the equipment

8.The environment should be in quiet and clean room, and keep away from dust, noise and

power interference.

9. The equipment should keep away from the equipments like Centrifuge, CT, X-ray

machine and radio interference, etc.

10.Avoid direct sunlight and ultraviolet rays and keep away from hot and cool source,

outlet of air condition.

Attention:

The power supply socket should be within 1meter from the analyzer in order to pull out the

plug timely when accident happens

Check if network voltage is the same to the equipment voltage and confirm the power

supply is in stable conditions (the voltage change is within 10%)

BS Series Multitest Analyzer

3

3. Biochemical Test Functions and Operation

3.1 Working Principle

The principle of analyzer is based on Lambert-Beer Law.

3.2 Operation

Switch on the equipment, screen shows as below

Click on the screen and enter the selection interface, then select to enter different menu function,

which can perform edition, setting and testing, etc.

Select “Biochemical” to enter its main interface

Select keys you need

Test: To select the biochemical items to do sample test, after testing, the equipment will

show the test results and print it automatically

Edit: To add, modify, delete and print biochemical items.

Result: Result print, print, delete, QC management, QC statistics and printing general

BS Series Multitest Analyzer

4

report, etc.

Wash: The shortcut key for cleaning, aspiration volume is 1.5ml per keystroke, used to

clean flow cell.

Feed: Used for printer to load papers, pass papers and cut papers

Pump: Calibration for Peristaltic pump aspiration volume

Gain: AD Auto Zero to confirm whether the instrument is in the regular test status.

Filter: Measure and adjust each filter’s AD value, blank value and absorbance

Setup: Show cuvette temperature; set filter number, cuvette diameter, language, aspiration

mode, sleep mode; Hospital and instrument model title Settings; time format and

date/time Settings; screen brightness settings, etc.

3.3 Parameters settings

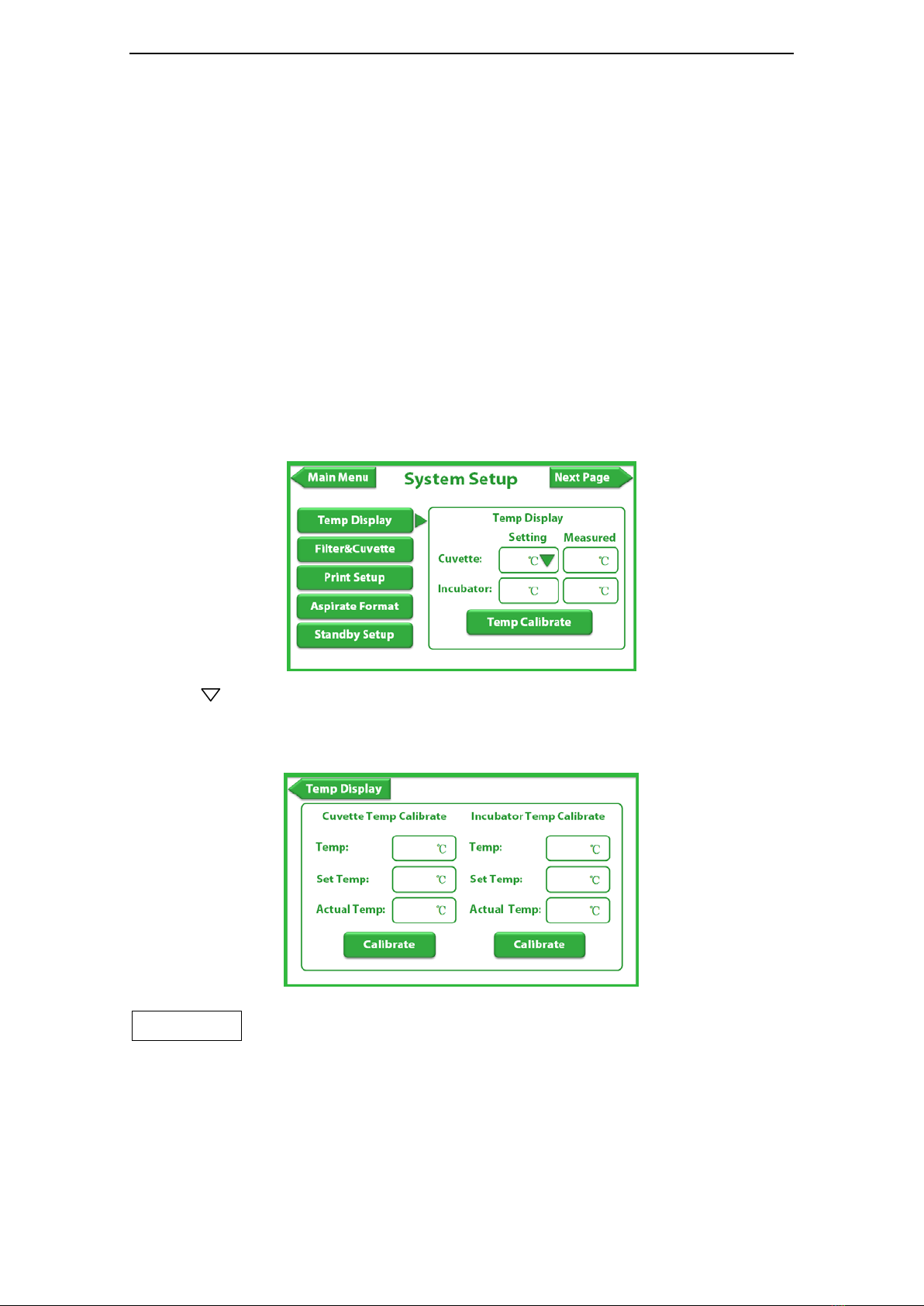

3.3.1 Temperature display Settings

Use to choose Temperature, click main menu to save. This function can only provide

the confirmation on whether temperature is right or not. When testing sample, the

temperature will be shifted according to the test program. Input the password and then input

calibration temperature (for professionals only). Password: 123456.

Attention:

Filter wheel, cuvette, aspiration mode, language setting, screen brightness settings, the

password are all 123456.

3.3.2 Pump calibration

BS Series Multitest Analyzer

5

The default values of the instrument is that 3000ul aspiration sample volume corresponds

to 20000 motor steps. When the aspiration volume is not correct, adjusting is necessary.

Enter into the calibrate interface, input pump calibrate volume, then pour corresponding

distilled water into the tube, insert pipette into water, press PUSH to aspirate. After the

distilled water was sucked done. Press PUSH again, the instrument will display motor step

and exit pump calibration to save step. If the aspiration volume is still not right, repeat the

above operation or input moter steps directly.

3.4 Instrument operation key process

3.4.1 Instrument preheating

Connect to the power and turn on the switch, the instrument should be preheated in

10-30 mins.

3.4.2 Pipeline Washing

Clean the flow cell before using it, enter into the main interface, insert the pipette into

distilled water, and then press wash to start washing, last 5-10 times.

Attention:

●Pay attention to use environmental dustproof, moisture proof, and installation air

conditioning is better, environment temperature in 18-25 ° C is the best working

temperature.

● When external power is not stable, instruments must connect regulated power supply

●Instruments in the process of operation shall not open the cover, so as not to cause

damage to equipment or operator

●Leakage and electrostatic prevention, the instrument should be in good grounding. Line

power socket must have a reliable grounding line to guarantee in a steady state and

security

●After work, wash the instrument 3 times at least immediately to keep the cuvette and

pipeline from liquid waste.

●After finish the testing, the used should be collected and disposed according to the

medical waste.

●The waste pipe end should not be dipped into the waste to avoid poor drainage.

●Use qualified reagent within the period of validity.

BS Series Multitest Analyzer

6

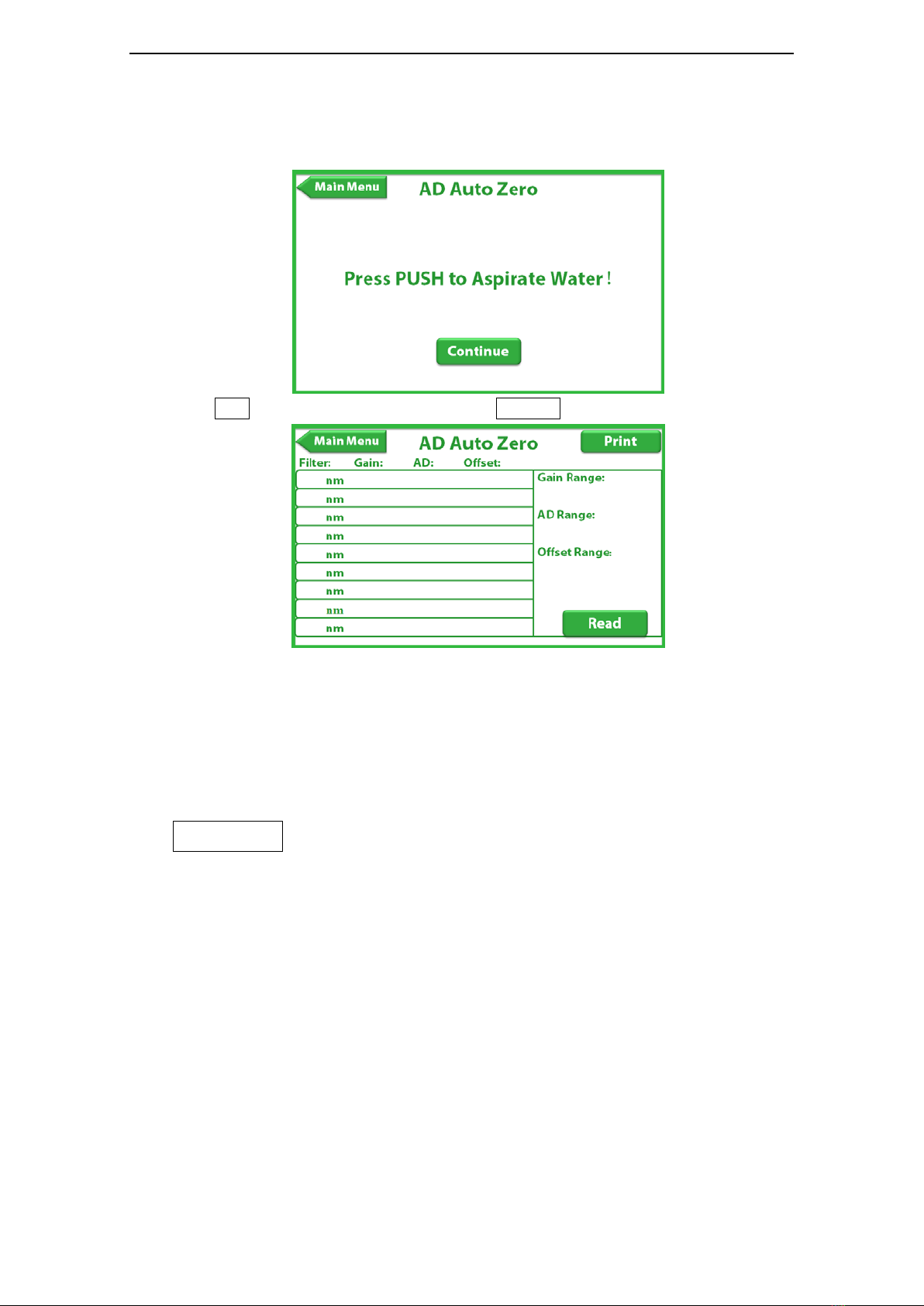

3.4.3 AD Auto Zero

Select AD Auto Zero from the main menu, the screen will show as below:

Press Push to aspirate distilled water and click Continue

And then click read

When AD auto zero, put the aspiration pipe into distilled water, press push, then the

instrument begin to zero. The interface will show Gain coverage, AD value and offset

value, if the value is out of range, there will be alarm reminding.

Attention:

AD auto zero is that the instrument is based on water to measure the initial light

intensity of different wavelength. The gain coverage, AD value and offset value

are calculated together to obtain absorbance. This step is very important; users

should do this step at each starting the instrument.

AD auto zero for flow cell need more distilled water, it is recommended that the

aspiration pipe should insert into distilled water to ensure no bubble when AD

auto zero.

It is also available to use cuvette for AD auto zero; the distilled water in the

cuvette should reach more than 10mm away from the bottom of the cuvette.

BS Series Multitest Analyzer

7

4. Specific Proteins Test Function and Operation

4.1 Principle

Specific proteins test is based on the light scattering principle. When immune complex which

consists of specific proteins meet incident ray in detection System, the intensity of scattered

light at 90 degrees is directly proportional to amount and size of immune complex within certain

limits.

4.2 Operation

Attention:

Choose scattered light when testing specific proteins, put macro cuvettes or micro cuvettes

with adaptors into test pots to proceed. However, the flowing cuvette is not available for

this test. In addition, there should be light-shield upon cuvettes to ensure stability of

detection signal.

Go to the main menu, choose “Specific protein”

The Device starts specific protein testing mode. Selected and set different function keys

according to need. Keys reference is made to “Biochemical” and “Coagulation” menu.

5. Device Maintenance

5.1 Daily Maintenance

Daily maintenance is mainly on washing the flowing cuvette, keep it clean. Before testing,

10 times washing are necessary. After each test, wash 4-5 times is essential. If there are

bubbles in flowing cuvette, you may draw ethanol to soak and flush firstly, then wash it by

BS Series Multitest Analyzer

8

distilled water. When all tests done, please use distilled water flush.

5.2 Weekly Maintenance

Weekly maintenance is on washing the flowing cuvette by detergent. Keeps detergent

resting in cuvette 5-10 min before draining. Then flush it repeatedly by distilled water

Recommended detergent:

1. 20% sodium hypochlorite solution

2. 95% absolute ethanol

3. Dedicated Detergent for chemistry analyzer

5.3 Monthly Maintenance

Daily maintenance is mainly about cleaning dust and stains on the casing, correct sample

absorption amount of peristaltic pump.

5.4 Other Maintenance Items

Generally using coagulation cuvette and micro detector cuvette to perform “Coagulation”

and “Specific Protein”. Cuvettes should be properly kept away from scratching. Cuvettes

and magnetic rods should be original parts of Sinnowa to avoid obtaining wrong results.

6. Troubleshooting

This chapter explains all kind of malfunctions, which often happen in the routine operations.

Besides, it analyzes the related reasons about malfunctions and supplies some methods against

the malfunctions.

Warnings:

●You must turn off the analyzer, cut off the power, and then remove the power plug from the

socket. The repair work must be taken by SINNOWA professional trained men.

●The analyzer must use suited power supply and voltage. Or else, the damage which is

caused against this order is out of SINNOWA’s responsibility.

Caution:

●Analysis of samples may give incorrect test results in the case of instrument malfunction. If

there is a fault detected in the sample, be sure to troubleshoot before use.

●Sample, quality control samples, calibration samples, wasted liquid and so on have potential

biochemistry risk. The operator must comply with the laboratory regulations about the

safety operator to wear personal protective device (like: laboratory protective clothing,

gloves etc.), and accordance with local government regulations to dispose the waste

materials generated by the instrument detection.

6.1 Malfunction phenomenon and maintenance

Please take measures to eliminate the malfunctions which occur in use or before use according

to relevant troubleshooting. If the malfunctions still exist, please contact the after service of

SINNOWAor our local franchiser as soon as possible. We are pleasure to serve you.

6.1.1 Malfunction phenomenon: There are mistakes with auto zero

Possible causations: There is no distilled water in Cuvettes;

BS Series Multitest Analyzer

9

Cuvettes are dirty (need to wash);

There is air bubble in Cuvettes (need to wash);

Pipette is connected wrongly, leaks or blocked;

Peristalsis pump hitch;

Filter is aging or damaged;

Instrument bulb burned out.

6.1.2 Malfunction phenomenon: Wrong result or bad repetition

Possible causations: There is air bubble in Cuvettes (need to wash); Peristalsis pump pipe is

not installed properly or leaks; Aspiration is abnormal, need to recalibrate the pump; Voltage is

not stable, need to connect regulated power; whether the sample is hemolytic or whether the

reagent is invalid.

6.1.3 The instrument does not work

Cause: Fuse burn-out or behind power interface is poor connected.

Maintenance: Replace the fuse, check the interface.

6.1.4 Screen definition changes

Cause: Due to the local ac voltage is different; Led display voltage is not the same, but in

general all in the visible range

Maintenance: Open the instrument, find the cable of main board connecting with the display,

you can see a blue 203 potentiometer; adjust the potentiometer to change the definition.

6.1.5 Printer keeps walking

Cause: The cable of printer head connecting with control panel is loose.

Maintenance: the cable of printer head connecting with control panel is white, open the

instrument, take off the printer head, and compress the interface.

Attention: Be careful about the white cable and the printer head cable do not drag too hard.

6.1.6 Heating time is long

Cause:

a) Effect of ambient temperature (Especially in winter), increase indoor environment

temperature, keep the environment temperature to 10℃~30℃;

b) The heating voltage is insufficient could lead to a longer heating time. Please open the

instrument, use the digital multimeter to test the voltage of incubator heating rod, if there is no

voltage, and replace the heating rod.

Maintenance: Against the possible reasons check and maintenance individually.

6.1.7 Testing time slightly long

Cause: Plasma (serum) and reagent do not have enough incubate time. Or Instrument needs

calibration again.

BS Series Multitest Analyzer

10

Maintenance: Plasma (serum) and reagent incubate more than 3 minutes in winter it should

around 5 minutes. Or reference to the manual, run the calibration procedure to calibration.

6.2 The corrections and replacements to common parts of

analyzer

In order to make the analyzer’s running reliable, it’s necessary to proofread or replace some

parts of analyzer and take effective maintenance.

Attention:

●The user must be trained by our professional engineers before they take maintenance and

replacements alone.

6.2.1 The replacements of fuse

The concrete steps of replacement are as follows:

1. Turn off the power of analyzer and pull out the power cord.

2. Pull the power wire from the power socket of mainframe and elicit the fuse housing.

3. Take out the fuse housing and install a new fuse into fuse housing.

4. Plug the fuse housing into original position

Warning:

●The operator must use fuse of appointed specification.

6.2.2 The replacement to light source

The standard configuration of the instrument has a halogen lamp set in the opposite position of

detector; Two LED light sources are disposed on two adjacent sides of the detection position

and the detector.

It needs replacing while the lamp is damaged or has been working for 2 years.

The steps as follows:

1. 15 minutes after analyzer’s turnoff

2. Open the analyzer

3. Unload cuvettes pallet

4. Unplug the Plugin of the lamp connected to power

5. Unscrew the screws, remove the lamp

6. New lamp fitted in accordance with the above order

BS Series Multitest Analyzer

11

7. Loosen the screws on the side of the lamp bracket

8. Turn on the power switch, enter into the instrument interface, enter into the interface of A/D

signal detection, select any one wavelength, and test the signal value, at this time up and

down to adjust the position of the lamp to fix it until the A/D value at the maximum signal

value points.

The replacement to LED: when instrument scattering detection is in abnormal, the LED light

source should be checked or replaced.

Attention:

●After change the lamp and LED, Please check and confirm the light source and cable are

secure connected, and after calibration, then it can put into normal use.

Warnings:

●Do turn off the power supply before replacing the lamp.

●It is dangerous to take replacement when the analyzer has been shut just now. Because, the

temperature is very high. It should wait for the temperature decrease then replace the lamp.

●Do not touch the new lamp surface; otherwise it could change characteristics of the lamp. If

it is found that the lamp surface has fingerprints or other stains, it can be canceled by cloth

with rubbing alcohol.

6.2.3 The replacement to peristalsis pump

The steps as follows:

1. Open the covering on the instrument side face

2. Pull out two pump pipe

3. Take the coarse joint from the set screws, pull out the pump on the coarse joint

4. Inset the new peristalsis pump on the coarse joint through the set screws

5. According to the Figure 4 connect pump pipe

Figure 4

Attention:

●Unplug the pump pipe should be very careful, to prevent break incoming point and outlet

point

●In order to guarantee the reliability of the test, need to inspect the peristaltic pump pipe

every month

BS Series Multitest Analyzer

12

●Replacement of the pump pipe must be provided by SINNOWA, do not use other types of

pump pipe to replace

6.2.4 Replacement to printing paper

The steps as follows:

1. Open printer covering, take away the old printing paper

2. Load the new printing paper into the paper slot

3. Cut paper port to flat, put the paper to the formfeed, push tight

4. Press FEED, look the paper port to the appropriate position

5. Cover printer cover, paper was finished

7. TRANSPORTS AND STORAGE

7.1Transport

Transport should be in accordance with the regulations implementing of order contract, Away

from the toxic, harmful, corrosive substances

It should be to prevent severe shocks, rain and exposure, overturned not be permitted in

transportation.

7.2 Storage

It should be stored in environment temperature −5℃~50℃, Relative humidity no more than

80%, well-ventilated indoor. It shouldn’t storage with toxic, harmful, corrosive materials stored.

This manual suits for next models

1

Table of contents