7

SAFETY

RECOGNIZE THE SAFETY ALERT SYMBOL

The above symbol means “ATTENTION! BE ALERT! YOUR PERSONAL SAFETY IS INVOLVED!” Note this

symbol in instructions for important issues concerning your personal safety. Read each message carefully to avoid

personal injury or death.

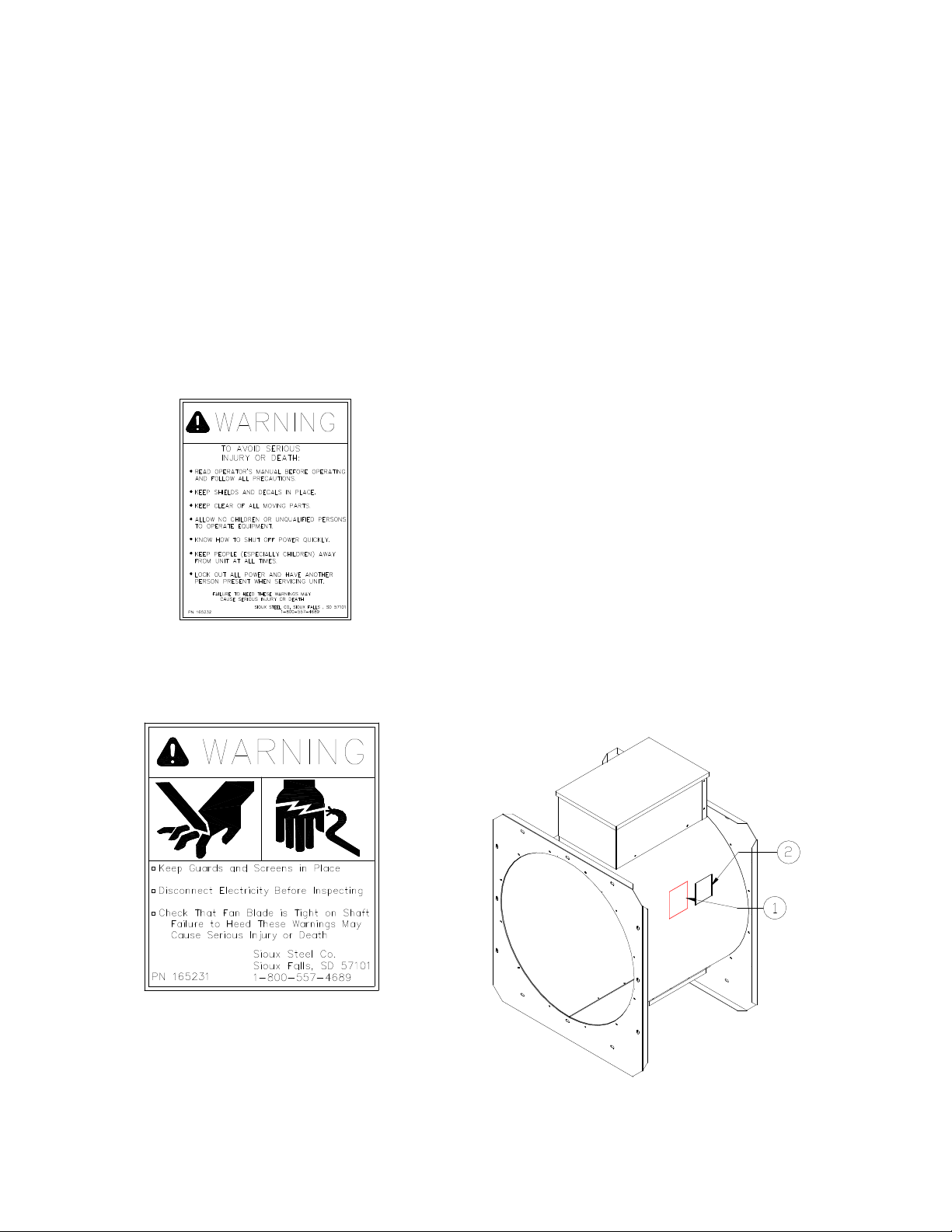

FOLLOW MACHINE SAFETY SIGNS & MESSAGES

Observe safe operating practices. Carefully read this manual and all safety signs on your equipment. Safety signs

must be kept in good condition. Replace missing or damaged safety decals or shields. Safety decals and shields are

available free of charge from Sioux Steel Company, 196 ½ E. 6

th

St., Sioux Falls, SD 57101-1265.

Learn how to use controls and operate equipment. Do not let anyone operate unit (especially youth) without

thorough training of basic operating and safety procedures.

Make no unauthorized modifications to equipment. Modifications may endanger function and/or safety of unit.

Periodically check all mechanical and electrical components. Keep unit in good working condition.

PRACTICE SAFE MAINTENANCE

Read and understand correct service procedures before operating. Keep area clean and dry to prevent accidents.

Machine should never be lubricated, serviced, or adjusted while it is in operation. Hands, feet and clothing must be

kept away from all moving parts. Keep all parts in good condition and properly installed. Fix any damage

immediately. Qualified service personnel should replace worn or broken parts. Any built-up grease, oil, and debris

around machine should be removed.

EMERGENCIES-KNOW WHAT TO DO

A first aid kit should be made readily available.

In the event of fire, a fire extinguisher should be at hand.

Have emergency numbers near your telephone for doctors, emergency medical squad, ambulance service, hospital,

and fire department and also have written directions to your location.

WEAR PROTECTIVE CLOTHING

CLOTHING- Avoid baggy clothes to avoid catching on moving parts.

HEARING PROTECTION- When high noise levels are encountered, ear plugs or muffs should be used.

EYE PROTECTION- Safety glasses should be worn at all times to protect eye from debris.

GLOVES- Always wear gloves to protect hands from sharp edges.

STEEL TOE SHOES- Appropriate shoes should be worn to protect toes from falling debris.

RESPIRATOR- In order to prevent breathing toxic fumes or dust, a respirator may be needed.

HARD HAT- Appropriate headwear should be worn to protect head from falling debris.

FALL PROTECTION- Appropriate fall protection should be worn when working at elevations greater than six (6)

feet.

()*+,-./ -,-. -01*0(+,*23.4-.+5+)1 (61,(7--/-8993..1*91

DANGER 1/

Se ere

*/(9+01:+*(55(*1*0,47+;+./-3::(03+0(-*<7(97=(8*-0

+>-(/1/<(,,.1:3,0(*/1+07-.:1.(-3:(*23.4

WILL993.

(8+.*(*)(:()*-.1/

WARNING .+*)1

Se ere

*/(9+01:+7+;+./-3::(03+0(-*<7(97=(8*-0+>-(/1/=<(,,

.1:3,0(*/1+07-.:1.(-3:(*23.4

COULD993.

(8+.*(*)(:()*-.1/

CAUTION ?1,,-<

Minor

*/(9+01:+7+;+./-3::(03+0(-*<7(97=(8*-0+>-(/1/=<(,,

.1:3,0(*5(*-.-.5-/1.+01(*23.4

WILL-.COULD993.

(8+.*(*)(:()*-.1/

NOTICE

,31

-.

None

%?"