2.3.3.

3

Version 1 – GBR(23/06/2021) D-502-0152

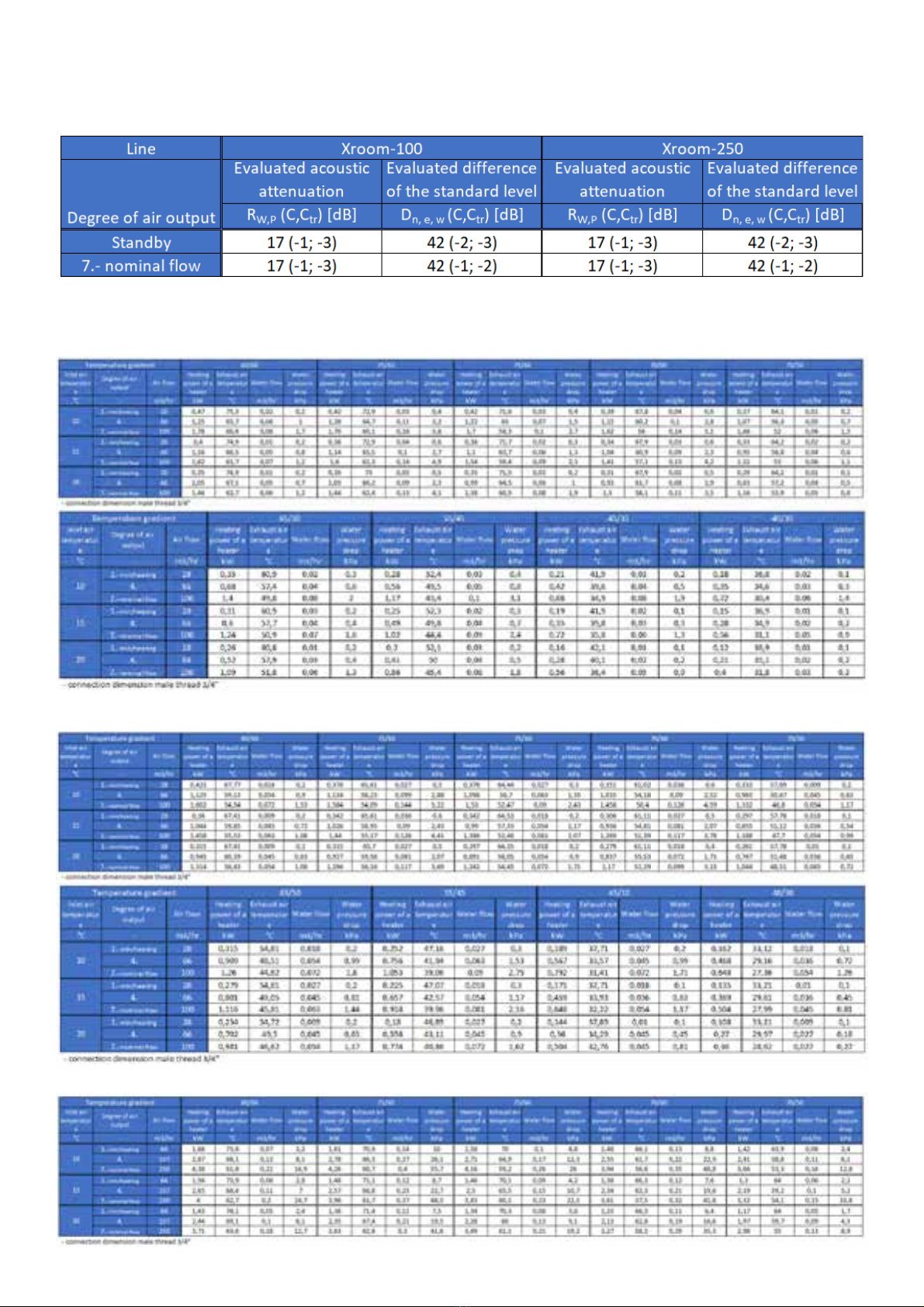

Technical data of water heaters........................................................................................................................................................... 16

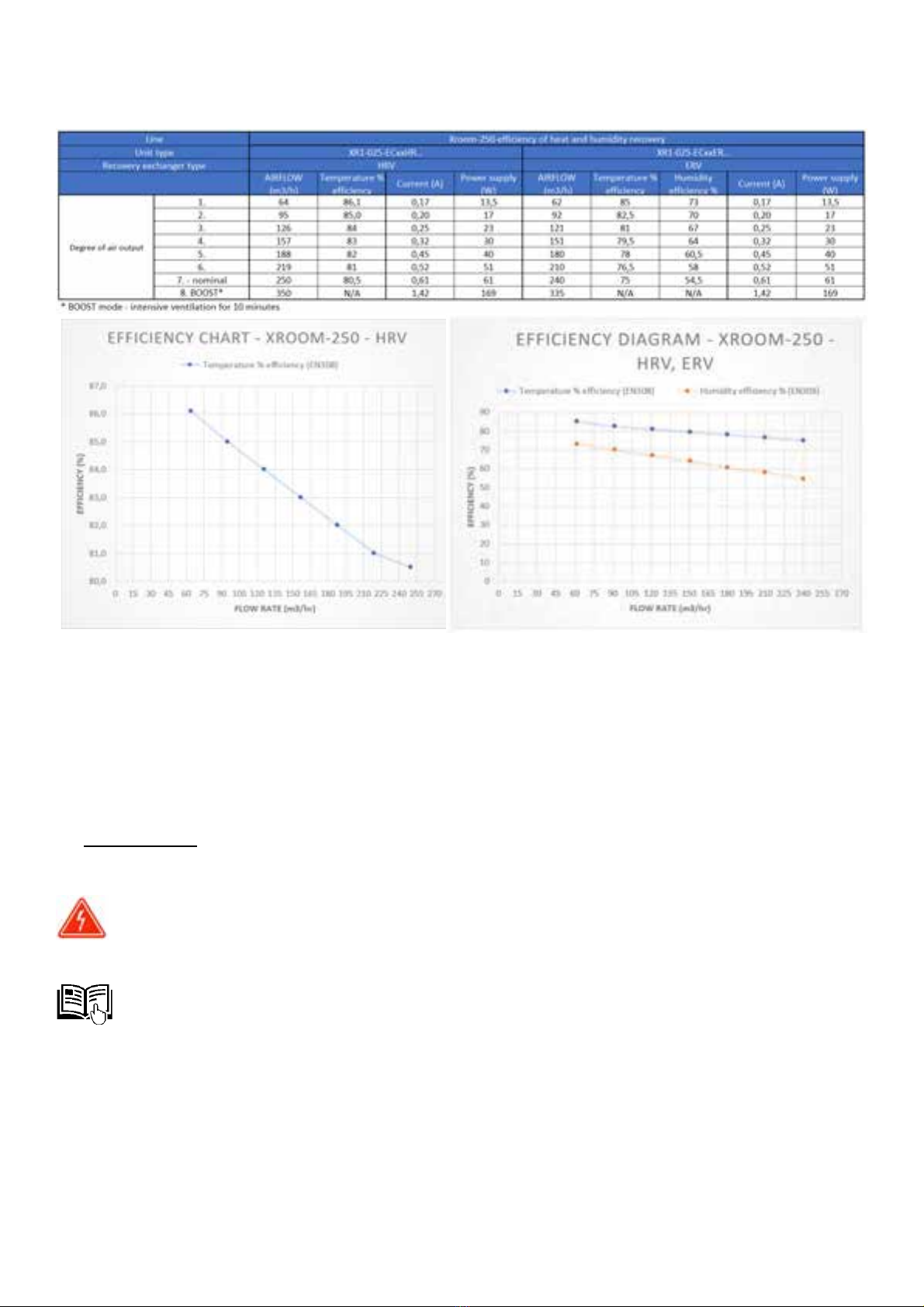

2.3.4. Heat and moisture recovery efficiency ................................................................................................................................................ 17

3. Unit Installation ....................................................................................................................................................................... 18

3.1.

3.1.1.

3.1.2.

General information, recommendations, and safety when installing the Xroom units............................................... 18

Electrical safety before installation of the unit.................................................................................................................................... 18

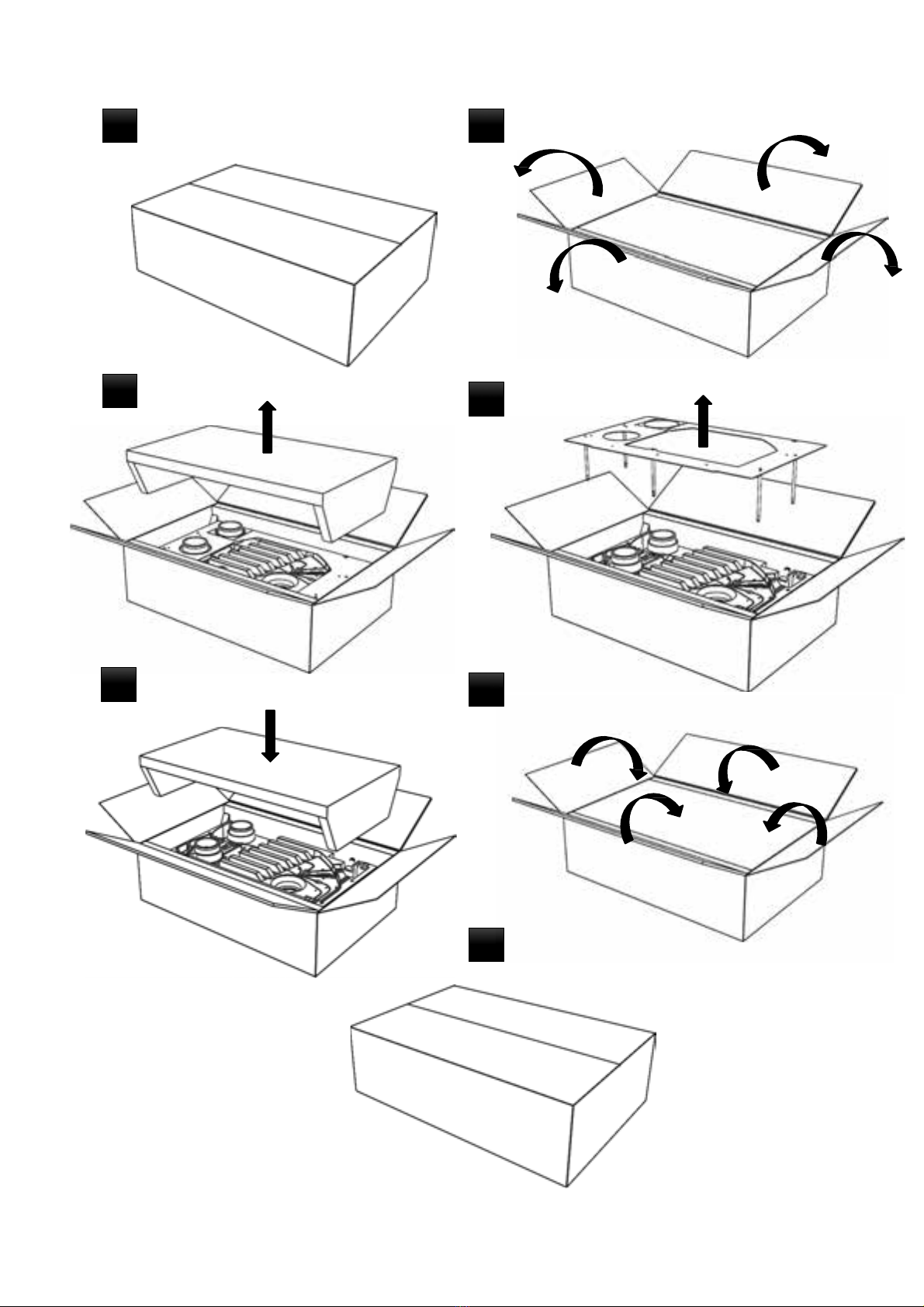

Unpacking ............................................................................................................................................................................................. 18

3.1.2.1.

3.1.2.2.

3.1.3.

Unpacking the Xroom Unit –Box 1 ...................................................................................................................................................... 18

Unpacking Installation –Box 2 ............................................................................................................................................................. 20

Unit Location ........................................................................................................................................................................................ 21

3.1.3.1. Location During the Building Reconstruction ...................................................................................................................................... 21

3.1.3.2.

3.1.3.3.

3.1.4.

3.1.5.

Location and operation of the unit in the area with a furnace (fire place) ......................................................................................... 21

Unit Location and Operation in the Area with an Air Conditioning Unit ............................................................................................ 21

Minimum Installation Distances .......................................................................................................................................................... 21

Installation Positions of the Xroom Unit.............................................................................................................................................. 22

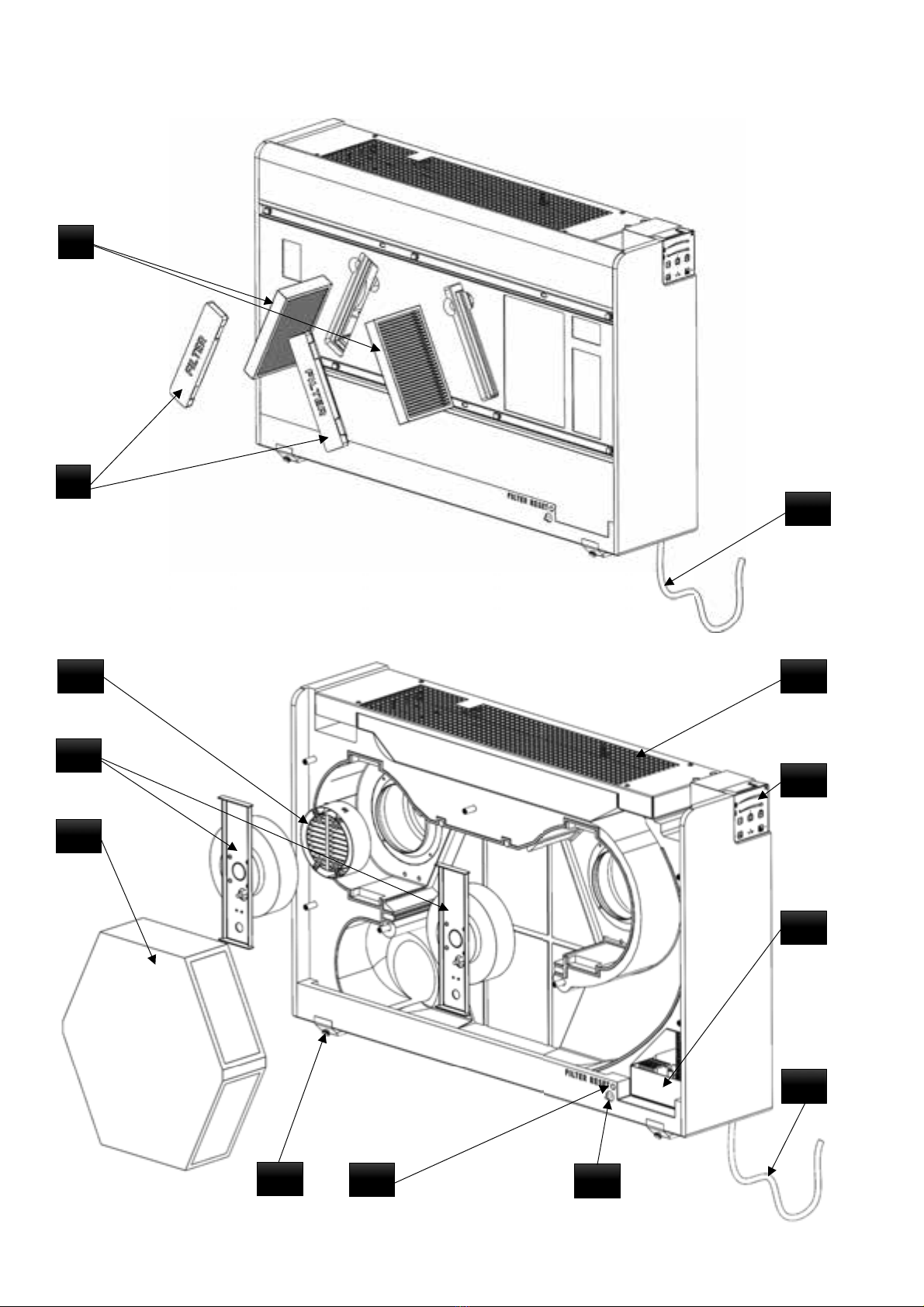

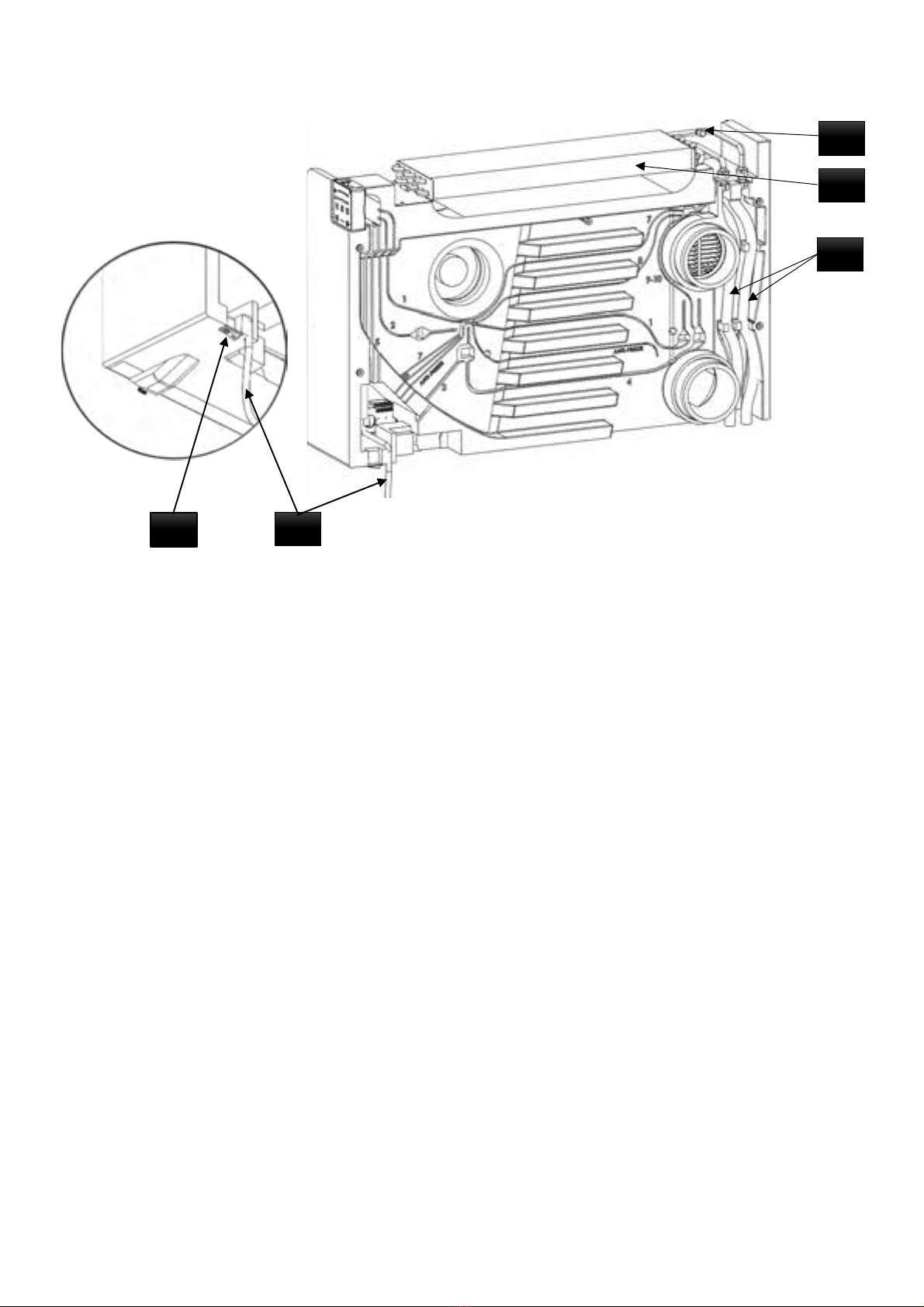

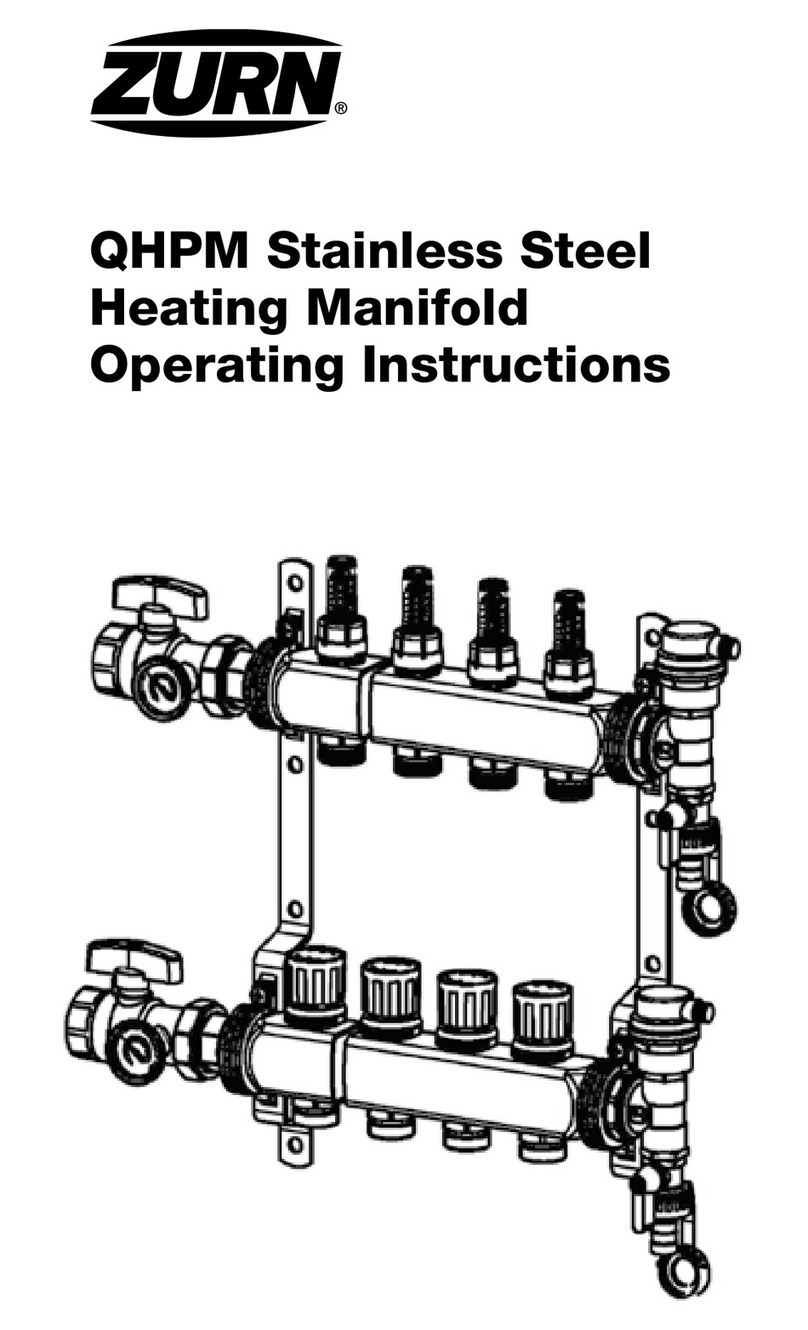

3.2. Xroom Unit Installation ..................................................................................................................................... 22

3.2.1. Installation Components Required for Installation of the Xroom Unit ............................................................................................... 22

3.2.2. Fitting and Mounting the Installation Template with Mounting Pins................................................................................................. 23

3.2.2.1.

3.2.2.2.

Fitting the installation template on the wall when using the construction module........................................................................... 23

Fitting the Installation Template on the Existing Wall ........................................................................................................................ 23

3.2.2.3. Installation Template Mounting .......................................................................................................................................................... 23

3.2.3. Preparation of Piping Holes in the Existing Wall.................................................................................................................................. 24

3.2.4. Preparation of Supply and Drain Piping ...............................................................................................................................................25

3.2.4.1. Extension of piping for walls with a thickness greater than 500 mm.................................................................................................. 26

3.2.4.1.1. Extension of the Supply Piping with a Damper Assembly ................................................................................................................... 26

3.2.4.1.2. Drain piping extension –white plastic tubes....................................................................................................................................... 26

3.2.5. Installation of the Supply and Drainage Piping on the unit................................................................................................................. 27

3.2.6. Gluing Insulating Pads .......................................................................................................................................................................... 28

3.2.7. Installation of the Xroom unit on the wall........................................................................................................................................... 29

3.2.8. Xroom Unit Final Fitting ....................................................................................................................................................................... 29

3.2.8.1. Electric heater variant (XR1-010-ECE1...), without heating –cold (XR1-010-ECS0...) ......................................................................... 29

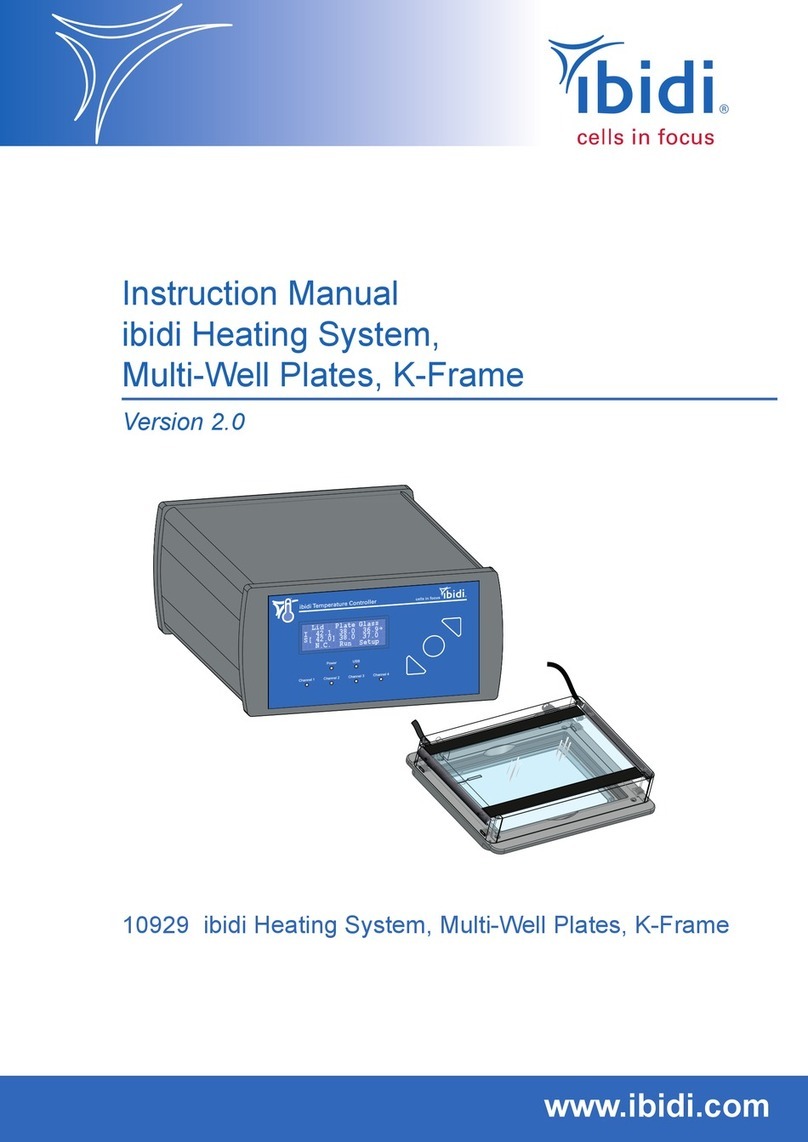

3.2.8.2. Water heater variant (XR1-xxx-ECV1...)............................................................................................................................................... 30

3.2.9. Securing, Insulating Piping in the Wall................................................................................................................................................. 31

3.2.10.

3.2.11.

Fitting the Piping on the Outer Side of the Wall with Outlet .............................................................................................................. 32

Installation of the Front Metal Cover................................................................................................................................................... 32

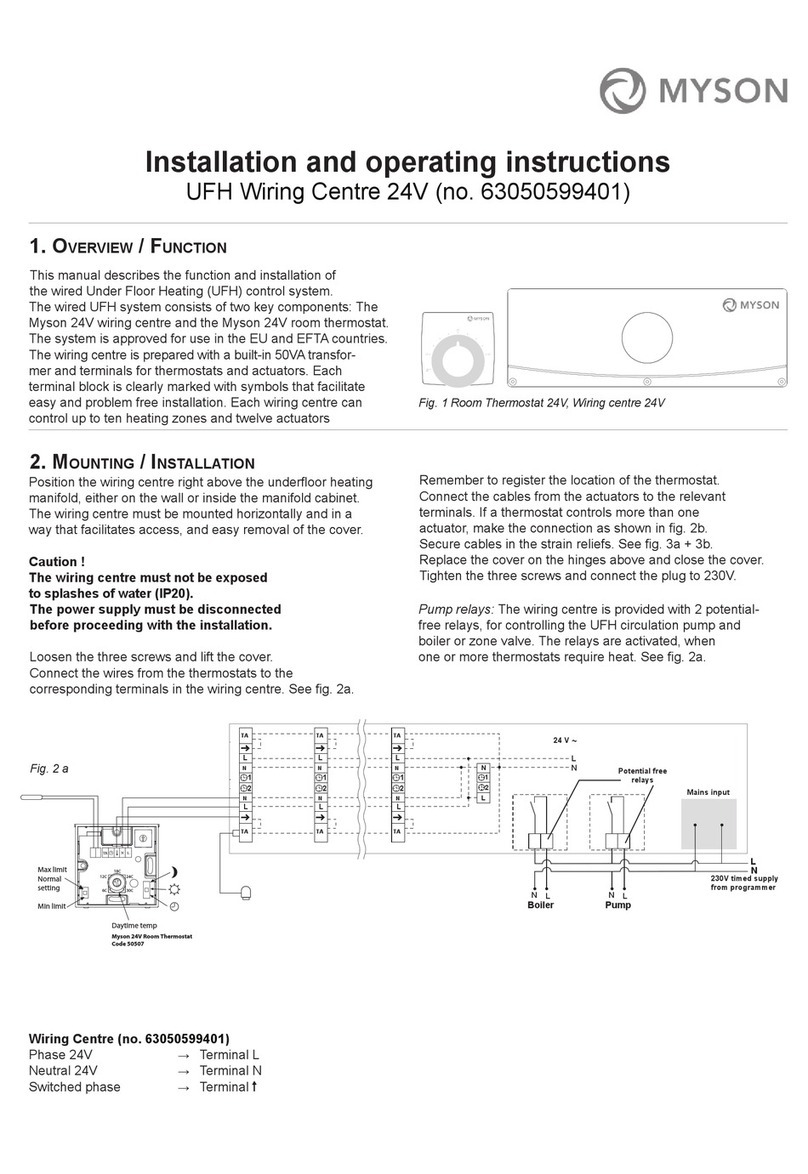

3.3. Electrical Installation –Connection to Mains ...................................................................................................... 33

3.3.1. General Information –Safety ............................................................................................................................................................... 33

3.3.2. Connection to Mains ............................................................................................................................................................................ 33

3.3.2.1.

3.3.2.2.

3.3.2.3.

3.3.3.

Connection of the Unit to the Wiring Box............................................................................................................................................ 34

Connecting the Unit to the Electrical Outlet ........................................................................................................................................ 34

Recommended Xroom Unit Protection................................................................................................................................................ 34

Display of electrical parameters........................................................................................................................................................... 34

4. Regulation ................................................................................................................................................................................ 35

4.1.

4.2.

4.2.1.

General Information –Safety ......................................................................................................................................... 35

Electrical Accessories to the Xroom Unit ....................................................................................................................... 35

Connecting Electrical Accessories ..............................................................................................................................35