Sirman PPJ 10 SC Specification sheet

2

INTRODUCTION

This manual has been written to provide the client with all information concerning the

machine and the norms pertaining to it, apart from the use and maintenance instructions which

enable it to be used in the best way possible, therefore maintaining its efficiency through time.

This manual must be given to all personnel who will use or do maintenance on the machine.

INDEX OF CHAPTERS

CHAP. 1 - MACHINE INFORMATION page 4

1.1 - GENERAL PRECAUTIONS

1.2 - SAFETY DEVICES INSTALLED ON THE MACHINE

1.3 - DESCRIPTION OF THE MACHINE

1.3.1 - General description

1.3.2 - Constructive features

1.3.3 - Machine makeup

CHAP. 2 - TECHNICAL DATA page 6

2.1 - DIMENSIONS, WEIGHT, CHARACTERISTICS ...

CHAP. 3 - RECEIVING THE MACHINE page 8

3.1 - SHIPPING THE MACHINE

3.2 - CHECKING THE PACKAGE UPON RECEIPT

3.3 - DISPOSING OF THE PACKAGE

CHAP. 4 - INSTALLATION page 9

4.1 - MACHINE PLACEMENT

4.2 - ELECTRICAL CONNECTIONS

4.2.1 - PPJ/LCJ SC with single-phase motor

4.2.2 - PPJ/LCJ SC with three-phase motor

4.3 - ELECTRICAL DIAGRAMS

4.3.1 - Diagram of electrical system single-phase

4.3.2 - Diagram of electrical system three-phase

4.4 - OPERATIONAL CHECK

CHAP. 5 - MACHINE USE page 12

5.1 - CONTROLS

5.2 - LOADING AND WORKING THE PRODUCT

CHAP. 6 - ROUTINE CLEANING page 13

6.1 - GENERALITIES

3

CHAP. 7 - MAINTENANCE page 14

7.1 - GENERALITIES

7.2 - BELT

7.3 - FEET

7.4 - FEEDING CABLE

CHAP. 8 - DISMANTLING page 14

8.1 - PUTTING IT OUT OF WORK

8.2 - WEEE Waste of Electric and Electronic Equipment

4

CHAP. 1 - MACHINE INFORMATION

1.1 - GENERAL PRECAUTIONS

•The machine must only be used by trained personnel who are perfectly aware of the safety norms

contained in this manual.

•If there is a turnover of staff, promptly provide proper training for new personnel.

•Even if safety devices are installed on the machine do not place hands near moving parts and avoid

touching the machine with wet or damp hands.

•Before carrying out any type of maintenance or cleaning, disconnect the machine plug from the

electrical outlet.

•The machine must only be used by trained personnel who are perfectly aware of the safety norms

contained in this manual.

•If there is a turnover of staff, promptly provide proper training for new personnel.

•Even if safety devices are installed on the machine do not place hands near moving parts and avoid

touching the machine with wet or damp hands.

•Before carrying out any type of maintenance or cleaning, disconnect the machine plug from the

electrical outlet.

•When intervening for mainteannce or cleaning purposes (therefore the protections are removed)

carefully evaluate residual risks .

•During maintenance or cleaning always concentrate on the operations in progress.

•Regularly check the state of the feeding cable (completely unwinding the cable, avoiding twisting it, is

advisable to avoid potential risks); a worn or broken cable can present serious danger of the electrical

kind; avoid compressing the wire with weights, leaving it in contact with hot or sharp surfaces and

pulling on it to unplug it from the outlet.

•If the machine shows signs of malfunctioning or does not work, do not use it or try to repair it; contact

the “Assistance Center”, indicated on the back of this manual.

•The combination of the OUT and START pushbuttons must only be used for unloading the worked

product.

•The machine must only be used for cleaning potatoes / mussels / onions.

•The manufacturer is not responsible in the following cases:

if the machine is mishandled or the safety devices are installed by unauthorized personnel;

if components are replaced with unoriginal parts;

if the instructions in this manual are not followed carefully;

if the machine surfaces are treated with inappropriate products ( inflammable, corrosive or harmful

substances).

1.2 - SAFETY DEVICES INSTALLED ON THE MACHINE

The safety devices against risks of electrical nature conform with the directives 2006/95/CEE,

1935/2004CEE, while the mechanical safety devices conform with the directives 2006/42 CEE.

The machine is equipped with:

• a starting device consisting of a control card insulated in IP 34, 24 Volts,

which enables:

turning the machine on and off;

5

- controlling the unloading of the product;

- controlling the safety micros;

a micro, which causes the machine to stop in case the cover or discharge door opens (see FIG. n°1), does

not allow the machine to turn on if it is not in the closed position;

an N.V.R. device in the control circuit which requires the machine to be restarted if there is an

accidental lack of electricity and it enables restarting the machine only by using the START pushbutton;

Furthermore the machine is equipped with an upper transparent cover which enables checking the

working of the product in progress without any risks.

1.3 - DESCRIPTION OF THE MACHINE

1.3.1 - General description

The line of CE professional PPJ/LCJ SC has been designed and manufactured by our company with the

precise objective of guaranteeing:

- maximum safety during use, cleaning and maintenance;

-maximum hygiene, the result of the careful selection of materials which come into contact with foodstuffs

and due to the elimination of sharp edges from the part which comes into contact with the product, in

such a way to guarantee easy and thorough cleaning;

-all the components are robust and stable;

-maximum silence thanks to the belt transmission.

1.3.2 - Constructive features

Professional I PPJ/LCJ SC are made of AISI 304 steel.

The discharge door is polished aluminum; the adjustable feet are stainless steel; the cover is made of AISI

304 steel, the work plate is aluminum with the disk made of AISI 304 steel; the internal walls of the

container are in abrasive resin to enable a higher level of abrasion with the product to be worked.

6

13

12

KEY:

1. Hopper

2. Cover block hinge

3. Pan

4. Pan block hinge

5. Feet

6. Controls

7. Flanged feet

8. Structure

9. Discharge door

10. Cover

11. Water inlet

12. Stand

13. Sieve

NB: there is the possibility of adding the sieve to the

stand to collect waste.

1.3.3 - Machine makeup

FIG. n°1 - General view of the machine

2

6

1

4

5

8

3

7

9

11

10

7

TAB. n°1 - MEASUREMENTS AND TECHNICAL FEATURES

ATTENTION:The electrical characteristics the machine is prearranged for are indicated by a plate

(attached to the back); before connecting the machine see 4.2 electrical connection.

CHAP. 2 - TECHNICAL DATA

2.1 - DIMENSIONS, WEIGHT, CHARACTERISTICS ... FIG. n°2 -

Drawings of dimensions

Model u.u

.

PPJ10 SC LCJ10 SC PPJ20 SC LCJ 20 SC

Power source

A x B mm 203x282 203x282 295x337 295x337

C x D x E mm 470x544x910 470x544x910 560x650x1090 560x650x1090

H mm 110 110 110 110

Capacity kg 10 10 20 20

Output/h. kg/h. 170 170 340 340

Motor Watt/Hp 735 / 1 735 / 1 1102 / 1,5 1102 / 1,5

Revolutions rpm 320 150 275 150

Net weight kg 41,5 41,5 52 52

Noise level dB 07≤ 07≤ 07≤ 07≤

230-230-400V/5

8

CHAP. 3 - RECEIVING THE MACHINE

3.1 - SHIPPING THE MACHINE (see FIG. n°3)

The machine leaves our warehouses correctly packaged, such a package consists of: a) an

external box in robust cardboard and a wooden pallet;

b) ) the achine;

c) ) is manual;

d) ) the compliance certificate.

If requested/ordered:

e) stand with sieve.

FIG. n°3 - Package description

b)

e)

a)

c)

d)

9

3.2 - CHECKING THE PACKAGE UPON RECEIPT

When the package is received, if there is no external damage, open the package and check that all the

material is inside (see FIG. n°3).

If the package shows signs of mishandling, bumps or falls upon delivery, the shipping company must

be made aware of the damage within 3 days of the delivery date indicated on the documents, and a

detailed report must be written on the damage to the machine. Do not overturn the package!! When the

package is being moved make sure that it is firmly held in the four fundamental points (keeping it

parallel to the floor).

3.3 - DISPOSING OF THE PACKAGE

The package components (cardboard, pallets, plastic and polyurethan foam strap) are produced like solid

urban waste, therefore they can easily be disposed of.

If the machine is installed in countries with particular norms, dispose of the packages according to

the laws in force.

CHAP. 4 - INSTALLATION

4.1 - MACHINE PLACEMENT

When choosing the plane the machine will be placed on the dimensions shown in Tab. 1 must be

considered (based on the model), therefore the surfaces must be wide enough to hold it, and it must be

well-levelled and dry.

Prearrange a discharge tube (ø60 mm.) under the machine and a drain trap on the floor, or a floor grate

to collect the water or other waste material.

Furthermore the machine must be placed as near as possible to a faucet (ø12 mm.), which enables the

feeding tube to be easily and safely attached (see FIG. n°4).Once the machine is placed proceed to

blocking it by fastening it to the floor with the setscrews on the flanged feet.

Furthermore the machine must be placed in an

environment with a maximum humidity of Load ø12 75%, which is not salty and

has a temperature

between +5°C and +25°C; in any case in

environments which do not bring about its

malfunctioning.

Fig. n°4 - Discharge diagram

Discharge

ø60

230

mm

120

mm

Discharge ø60

10

4.2 - ELECTRICAL CONNECTIONS

4.2.1 - PPJ/LCJ SC with single-phase motor

The machine is outfitted with a feeding cable with a cross section area of 3x1.5 mm2, length 1.5m.

Connect the machine to 230V./50Hz by means of a blue CEI plug, interposing a magnetothermic-

differential switch of 10A, ∆I = 0.03A. At this point make sure that the grounding system works

perfectly.

Furthermore check that the data shown on the serial number-technical plate (FIG. n°5) correspond to the

data on the delivery notes.

4.2.2 - PPJ/LCJ SC with three-phase motor

The machine is outfitted with a feeding cable with a cross section area of 5 x 1.5 mm²; length 5.1 ≅m.

Connect the machine to the 400V./50Hz three-phase electrical network by means of a CEI plug,

interposing a magnetothermic-differential switch of 10 A, ∆I = 0.03 A.

At this point make sure that the grounding system works perfectly.

Before finally connecting the machine to the three-phase feeder line, check the direction of rotation of

the cap by pressing the START pushbutton (see FIG. n.°9) then immediately stop it by pressing the STOP

pushbutton.

The direction of rotation of the cap seen from the discharge outlet must be

counterclockwise; if the direction of rotation is not exact, invert two of the three

feeding wires in the plug or outlet (see FIG. n°7).

The three-phase motor can run with a tension of either 230 V.or 400V. If not otherwise specified the

connections are carried out for 400V.; to adapt to a three-phase 230V. network ask for assistance from the

“ASSISTANCE CENTER”.

FIG. n°5 - Serial number-technical plate

11

4.3 - ELECTRICAL DIAGRAMS

4.3.1 - Diagram of the electrical system single-phase

FIG. n°6

FIG. n°7

4.3.2 - Diagram of electrical system three-phase

12

4.4 - OPERATIONAL CHECK

Before proceeding to testing make sure the upper cover and the discharge door are well-blocked, then check

the running of the machine with the following procedure:

1 check that the upper cover and the discharge door are closed well;

2 press the START ‘I’ pushbutton and then the STOP one;

3 check if the machine stops when running by opening the cover or discharge

door, and once it is closed if the machine restarts by pushing the START pushbutton;

4to discharge the material open the discharge door, keeping it open with your

right hand and at the same time pushing the OUT and START ‘I’ buttons on the pushbutton strip with

your left hand; the machine will start by unloading the potatoes by centrifugal force.

CHAP. 5 - MACHINE USE

5.1 - CONTROLS

The controls are located as follows.

FIG. n°8 - Cap rotation

1OUT is the pushbutton for the automatic

discharge of the product; it works only if it is pressed at the

same time as the START ‘I’ button.

2 STOP ‘O’ is the pushbutton to stop the

machine and START ‘I’ is the pushbutton to start the machine.

3Timer (max time 5 min.).

FIG. n°9 - Position of controls

1

2

3

13

5.2 - LOADING AND WORKING

THE PRODUCT (see FIG. n°10)

NB: The goods to be worked are loaded gradually on the cap from the

upper cover when the motor is off. Adhere to the following procedure:

1load the product from the upper cover, making sure

that the discharge door is closed well;

2 check that the machine is not too full and that the

level of the product does not go over the abrasive

band inside the machine;

3 close the upper cover;

4open the water flow using the faucet on the hopper;

Running:

1 set the desired work time with the timer (max time 5 min.);

2 then start the machine by pressing the START ‘I’ pushbutton;

3if the cover and/or discharge door are accidentally opened or moved while the

machine is running, the machine will stop; when closed press the START ‘I’ button;

4open the water flow using the faucet on the hopper;

5 if the machine is outfitted with a stand with sieve, repeatedly unload the slag

tray, to avoid the water dripping.

Unloading the worked product:

1 close the water faucet and put a big container near the discharge outlet;

2 to unload the material open the discharge door, keeping it open with your right

hand; press the OUT and START ‘I’ pushbutton at the same time with your

left hand; the machine will start unloading the product by centrifugal force;

3 once the unloading is complete the machine will stop by releasing the pushbut-

tons and the discharge door;

N.B.: Avoid making an empty machine turn.

CHAP. 6 - ROUTINE CLEANING

Before starting this chapter it is important to point out that:

The line of professional PPJ/LCJ SC is outfitted with normative measures for the electrical and mechanical

protections both in the working phase and the cleaning and maintenance phases. All the same,

RESIDUAL RISKS exist which cannot be totally eliminated; they concern the danger of contusions

caused by inexpert contact with the external surfaces or abrasive internal ones of the machine.

ATTENTION!: never put hands inside the moving machine.

FIG. n°10 - Loading the product

14

Cleaning and maintenance operations are carried out only when the machine is off and the feeding cable

is unplugged.

6.1 - GENERALITIES

Before cleaning the machine the feeding plug must be disconnected from the

network to completely isolate the machine.

The machine must be cleaned at the end of every work day and all the parts of the machine

(completely removable) which come into direct or indirect contact with the worked foodstuffmust

be carefully cared for.

Both the inside and the outside of themachine must be cleaned because the residual waste can be

seriously damaging.

The machine must not be cleaned with water cleaners, high-pressure jets of water, brushes, and

anything else which can damage it on the surface. Acidic, corrosive or inflammmable substances

must not be used.

If the machine has a stand with a sieve repeat-edly empty the slag tray to avoid the water dripping.

CHAP. 7 - MAINTENANCE

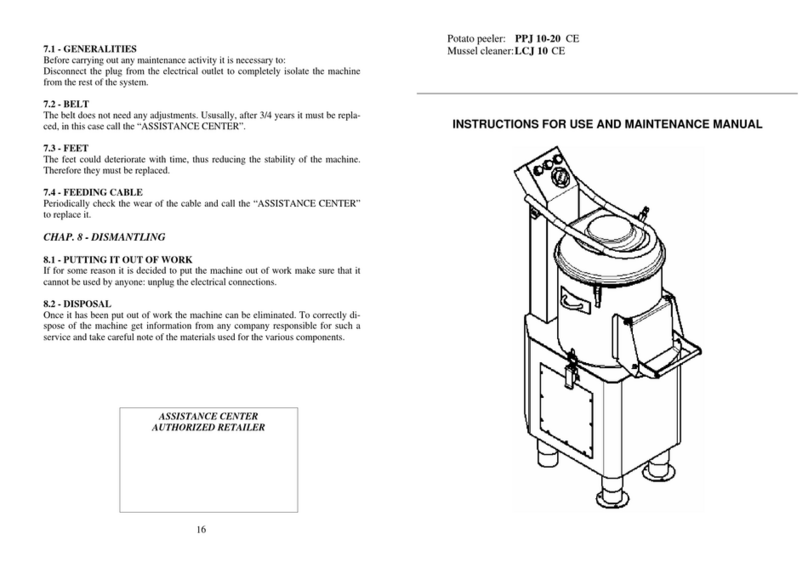

7.1 - GENERALITIES

Before carrying out any maintenance activity it is necessary to:

Disconnect the plug from the electrical outlet to completely isolate the machine from the rest of the

system.

7.2 - BELT

The belt does not need any adjustments. Ususally, after 3/4 years it must be repla-ced, in this case call

the “ASSISTANCE CENTER”.

7.3 - FEET

The feet could deteriorate with time, thus reducing the stability of the machine. Therefore they must

be replaced.

7.4 - FEEDING CABLE

Periodically check the wear of the cable and call the “ASSISTANCE CENTER” to replace it.

CHAP. 8 - DISMANTLING

8.1 - PUTTING IT OUT OF WORK

If for some reason it is decided to put the machine out of work make sure that it cannot be used by

anyone: unplug the electrical connections.

15

8.2 - WEEE Waste of Electric and Electronic Equipment

Directive 2002/95/EC, 2002/96/EC and 2003/108/EC on the restriction of the use of certain hazardous

substances in electrical and electronic equipment, and waste electrical and electronic equipment

This symbol, crossed out wheelie bin, on the product or on its packaging indi-cates that this product

must not be disposed of with your other household waste.

Separate waste collection of this appliance is organised and managed by the manufacturer. It is the

user’s responsibility to contact the manufacturer and fol-low the waste treatment system the manufacturer

has adopted for separate waste collection.

The separate collection and recycling of your waste equipment at the time of dis-posal will help to

conserve natural resources and ensure that it is recycled in a manner that protects human health and the

environment.

16

ASSISTANCE CENTER

AUTHORIZED RETAILER

8

CHAP. 3 - RECEIVING THE MACHINE

3.1 - SHIPPING THE MACHINE (see FIG. n°3)

The machine leaves our warehouses correctly packaged, such a package consists

of: a) an external box in robust cardboard and a wooden pallet;

b) the machine;

c) this manual;

d) the CE compliance certificate.

If requested/ordered:

e) stand with sieve.

FIG. n°3 - Package description

b)

e)

a)

c)

d)

9

3.2 - CHECKING THE PACKAGE UPON RECEIPT

When the package is received, if there is no external damage, open the package

and check that all the material is inside (see FIG. n°3).

If the package shows signs of mishandling, bumps or falls upon delivery, the

shipping company must be made aware of the damage within 3 days of the

delivery date indicated on the documents, and a detailed report must be written on

the damage to the machine. Do not overturn the package!! When the package is

being moved make sure that it is firmly held in the four fundamental points

(keeping it parallel to the floor).

3.3 - DISPOSING OF THE PACKAGE

The package components (cardboard, pallets, plastic and polyurethan foam strap)

are produced like solid urban waste, therefore they can easily be disposed of.

If the machine is installed in countries with particular norms, dispose of the

packages according to the laws in force.

CHAP. 4 - INSTALLATION

4.1 - MACHINE PLACEMENT

When choosing the plane the machine will be placed on the dimensions shown in

Tab. 1 must be considered (based on the model), therefore the surfaces must be wide

enough to hold it, and it must be well-levelled and dry.

Prearrange a discharge tube (ø60 mm.) under the machine and a drain trap on the

floor, or a floor grate to collect the water or other waste material.

Furthermore the machine must be placed as near as possible to a faucet (ø12 mm.),

which enables the feeding tube to be easily and safely attached (see FIG. n°4).

Once the machine is placed proceed to blocking it by fastening it to the floor with

the setscrews on the flanged feet.

Furthermore the machine must be placed in an

environment with a maximum humidity of

75%, which is not salty and has a temperature

between +5°C and +25°C; in any case in

environments which do not bring about its

malfunctioning.

Fig. n°4 - Discharge diagram

Discharge ø60

230 mm

120 mm

Load ø12

Discharge ø60

This manual suits for next models

3

Table of contents

Other Sirman Kitchen Appliance manuals

Sirman

Sirman TC RIO 22 User manual

Sirman

Sirman PLL 300 User manual

Sirman

Sirman Topaz 195 Operating instructions

Sirman

Sirman PALLADIO EVO 330 Operating instructions

Sirman

Sirman Easyvac 25 User manual

Sirman

Sirman Stromboli Assembly instructions

Sirman

Sirman PPJ20 Specification sheet

Sirman

Sirman Mirra Series Operating instructions

Sirman

Sirman MNT 300 Operating instructions