Sirman Mirra Series Operating instructions

1

OPERATING AND MAINTENANCE MANUAL

Professional slicer: M220C - 220A.I.C - 250C - 275C - 300 M Vert. 220C - 250C -

275C

M Vert. BS 250C - 275/C - 300

Ed. 05/2011

2

INTRODUCTION

This manual is meant to provide customers with information on the slicer and its

specifications and the necessary operating and maintenance instructions in order to

guarantee the best possible use of the machine and preserve its efficiency in the long term.

This manual is to be used by qualified and skilled people well informed about the use of the

slicer and its periodical maintenance.

TABLE OF CONTENTS

CHAP. 1 - INFORMATION ON THE SLICER pag. 4

1.1 - GENERAL PRECAUTIONS

1.2 - SAFETY SYSTEMS INSTALLED IN THE SLICER

1.2.1 -mechanical safety system

1.2.2 -electrical safety system

1.3 - SPECIFICATIONS OF THE SLICER

1.3.1 - general description

1.3.2 -construction features

1.3.3 -slicer components

CHAP. 2 - TECHNICAL DATA pag. 8

2.1 - OVERALL DIMENSIONS, WEIGHT, CHARACTERISTICS

CHAP. 3 - SUPPLY OF THE SLICER pag. 12

3.1 - DISPATCH OF THE SLICER

3.2 - PACKAGE CHECK UPON ARRIVAL

-PACKAGING DISPOSAL

CHAP. 4 - INSTALLATION pag. 13

4.1 - SETTING UP OF THE SLICER

4.2 - ELECTRIC CONNECTION

4.2.1 -slicer equipped with a single-phase motor

4.2.2 -slicer equipped with a three-phase motor

4.3 - ELECTRIC CIRCUIT DIAGRAM

4.3.1 - Diagram of the single-phase electric circuit - S Push-button panel

4.3.2 - Diagram of the three-phase electric circuit - S Push-button panel

4.3.3 - Diagram of the single-phase electric circuit - Professional switch

4.4 - FUNCTIONING CHECK

CHAP. 5 - OPERATING OF THE SLICER pag. 17

5.1 - CONTROLS

5.2 - LOADING AND SLICING OF FOODSTUFFS

5.3 - SHARPENING OF BLADE

CHAP. 6 - ORDINARY CLEANING pag. 20

6.1 - GENERAL FEATURES

6.2 - SLICER CLEANING PROCEDURE

6.2.1 - meat hopper cleaning

6.2.2 - blade, blade guard and ring cleaning

3.3

3

6.2.3 - sharpener cleaning of the sharpener

6.2.4 - deflector cleaning of the deflector

CHAP. 7- MAINTENANCE AND USEFUL ADVICE pag. 22

7.1 - GENERAL FEATURES

7.2 - belt

7.3 - feet

7.4 - power supply cord

7.5 - blade

7.6 - grinding mole

7.7 - lubrication of sliding guides

7.8 - label of the push-button panel

CHAP. 8 - MACHINE DISPOSAL pag. 23

8.1- PUTTING THE MACHINE OUT OF SERVICE

8.2 - WEEE Waste of Electric and Electronic Equipment

4

CHAP. 1 - INFORMATION ON THE SLICER

1.1 - GENERAL PRECAUTIONS

•The slicer must be operated only byhighly qualified people who are fully aware of the safety

measures described in this manual.

•In case of a personnel turn over, training is to be provided in advance.

•Although the slicer is equipped with safety devices in the dangerous points, it is recommended

not to touch the blade and the moving components.

•Before starting cleaning andmaintenance, disconnect the slicer plug from the supply socket.

•Assess the residual risks carefully whenprotection devices are removed to carry out cleaning and

maintenance.

•Cleaning and maintenance require great concentration.

•A regular control of the electric supply cords is absolutely necessary; a worn-out or damaged cord

can expose users to great electric shock hazard.

•If the slicer shows malfunctions, it is recommended not to use it and to abstain from trying to repair it;

please call the “SERVICE CENTRE”.

•Do not use the slicer for frozen products, meat and fish with bones and any products other than

foodstuffs

Do not use the slicer without the help of the meat pusher, when the meat is nearly finished.

Do not place yourself in a dangerous position, the blade may cause injuries.

The manufacturer is not liable in the following cases:

⇒if the slicer has been tampered bynon-authorized personnel;

⇒if some parts have been substituted by non original spare parts;

⇒if the instructions contained in this manual are not followed accurately;

⇒if the slicer is not cleaned and oiled with the right products.

1.2 - SAFETY SYSTEMS INSTALLED IN THE SLICER

1.2.1 - MECHANICAL SAFETY SYSTEM

The mechanical safetysystem of the slicer described in this manual complies with EC directives

2006/42 and regulations EN 1974.

The safety system includes (see 1.3.3):

-blade guard;

-ring;

-cover;

-meat pusher;

-meat pusher knob with ring nut and spacer;

-hand cover on the meat hopper;

-carriage only removable when the thickness gauge is set in the “0” position, at the end of its travel and

towards the operating side.

1.2.2 - ELECTRICAL SAFETY SYSTEM

The safety system installed to protect users against electrical risks is in compliance with EC directives

2006/95, 2004/108 and mod. 2006/.

The slicer is equipped with:

5

-a micro-switch which stops the slicer in case the tie rod for blade guard is removed (see FIG. n°1); the

micro-switch prevents from restarting the slicer if the guard has not been set in the switch-off position.

-a relay in the control box which requires the restarting of the slicer when a power cut occurs. Even though

CE professional slicers are provided with electrical and mechanical protections (when the slicer is

working and for maintenance and cleaning operations), there are still RESIDUAL RISKS that cannot

be eliminated completely; these risks are mentionned in this manual under WARNING. The blade and

other parts of the machine can cause cuts and injuries.

1.3 - SPECIFICATIONS OF THE SLICER

1.3.1 - general description

Our firm has designed and manufactured the CE line of professional slicers to cut foodstuffs (as salami

and meat) in order to guarantee:

-the highest degree of safety in functioning, cleaning and maintenance;

-the highesthygienic standards due to an accurate choice of materialsand a smooth design of the slicer

components which come into contact with products so as to obtain easy and total cleaning and easy

disassembly;

-the greatest accuracy in cutting foodstuffs thanks to a cam mechanism;

-solidity and stability of components;

-the highest degree of noiselessness due to belt drive;

-great handiness.

1.3.2 - construction features

The professional slicers CE are made of an aluminium alloy (Peraluman Mg5) treated by anodic

oxidation. This procedure guarantees high hygienic standards of the parts interested by the cut and

resistance to acids, salts and oxidation processes.

The blade is made of chromium plated steel 100Cr6; it is grinded and hardened to guarantee an accurate and

sharp cut of products also after it has been resharpened. The other components of the slicer are made of

ABS, LEXAN, PLEXIGLAS and stainless steel AISI 430 or 304.

6

1.3.3 - Slicer components

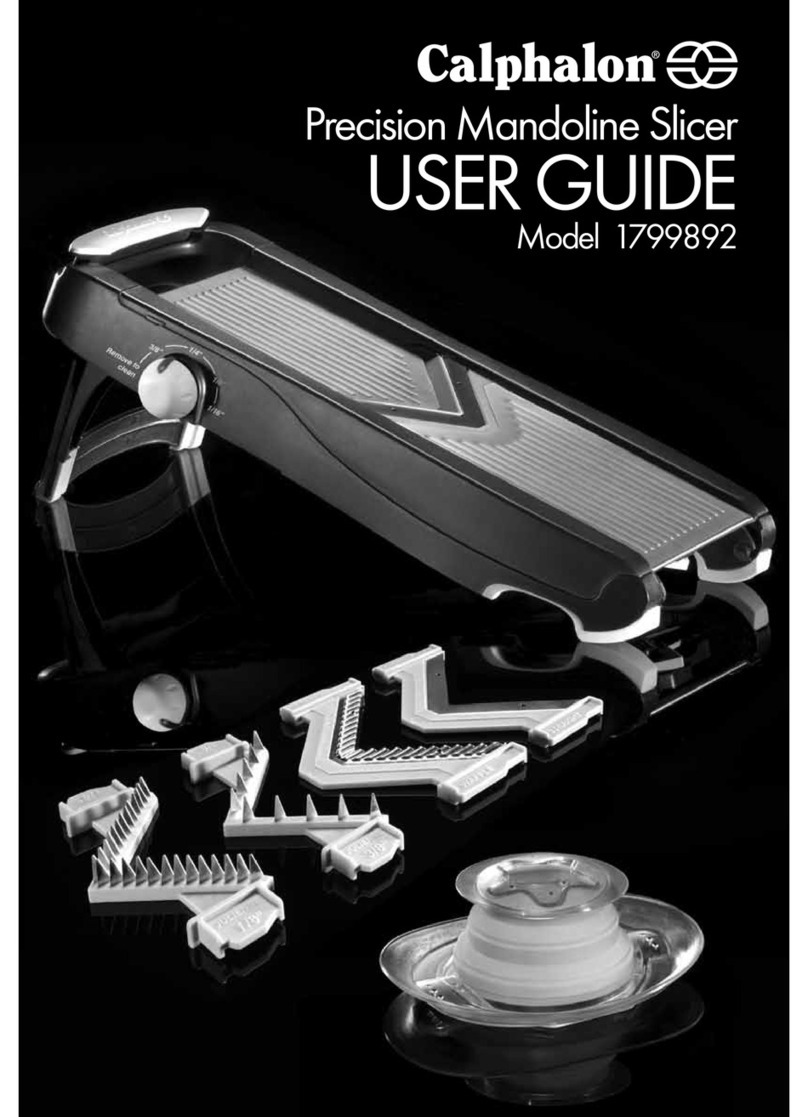

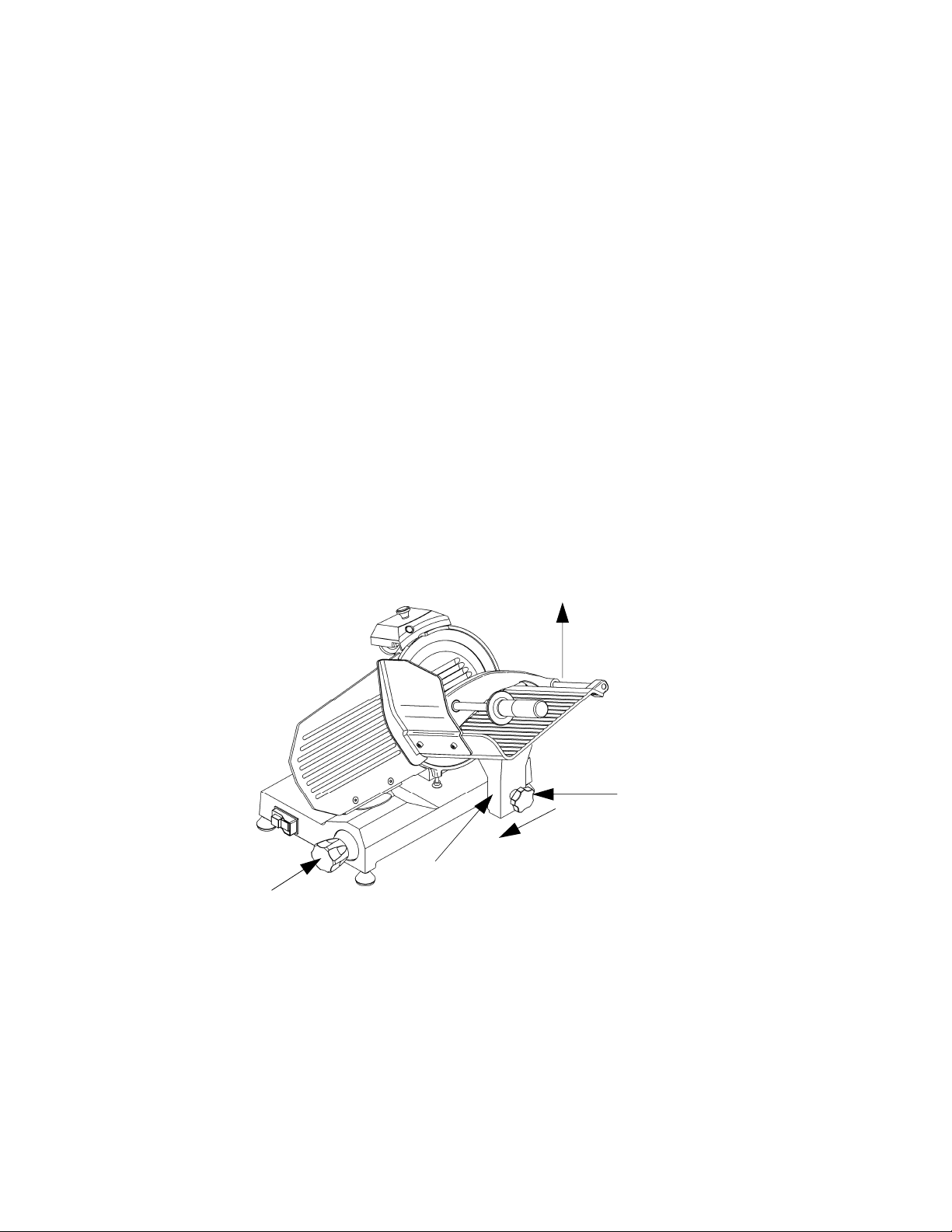

FIG. n°1a - General view of the slicer M / M Vert.

16

11

12

13

14

15

17

18

19

20

1

2

3

4

5

6

7

8

10

21

LEGEND:

M / M Vert.

1. Blade guard

2. Hand cover

3. Thickness gauge (plate)

4. Push-button panel

5. Dial knob

6. Feet

7. Carriage locking knob

8. Stem

9. Meat press

10. Meat hopper

11. Sharpener

12. Sharpener locking knob

13. Tie rod for blade guard

14. Power supply cord

15. Base

16. Rating plate - serial number

17. Thickness gauge support

18. Blade

19. Deflector

20. Meat press knob

21. Ring

7

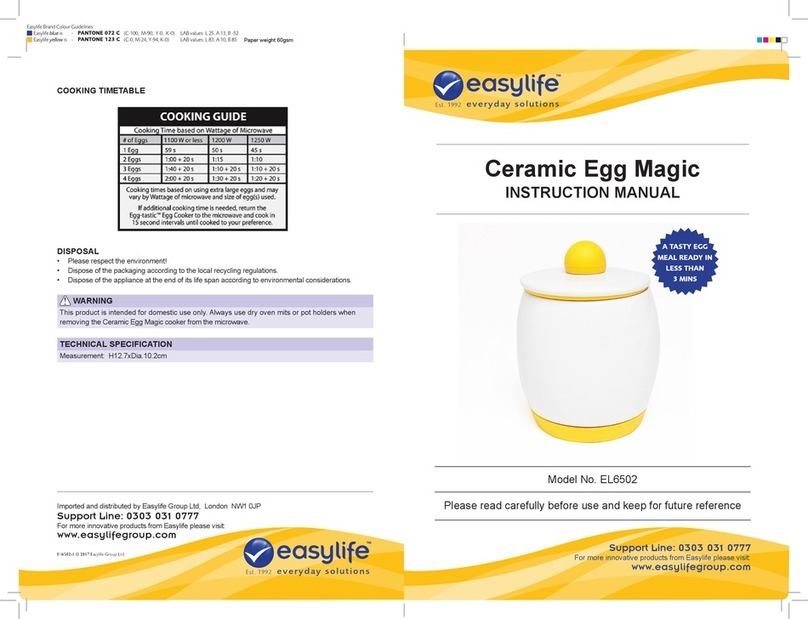

5

6

15

16

13

19

18

11

20

17

12

22

10

9

14

1

2

3

4

7

8

9

LEGEND:

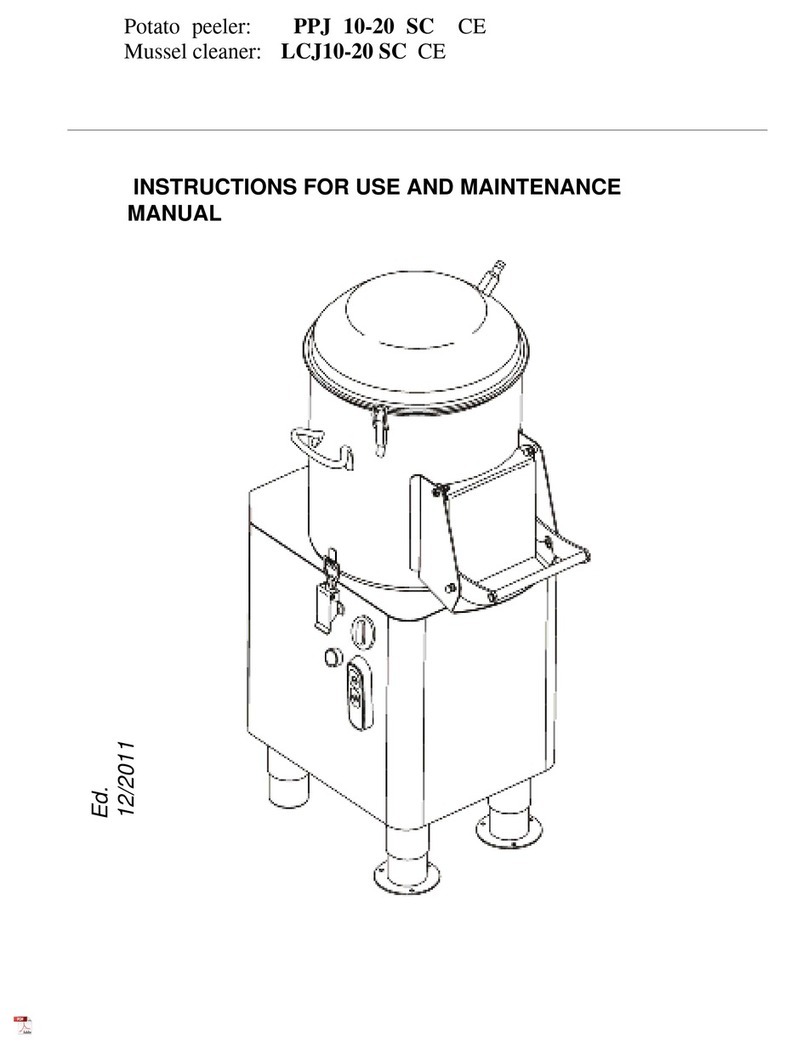

FIG. n°1b - General view of the slicer M Vert. BS

M Vert. BS

1. Blade guard

2. Hand cover

3. Thickness gauge (plate)

4. Push-button panel

5. Dial knob

6. Feet

7. Carriage locking knob

8. Stem

9. Meat press

10. Meat hopper

11. Sharpener

12. Sharpener locking knob

13. Tie rod for blade guard

14. Power supply cord

15. Base

16. Rating plate - serial number

17. Thickness gauge support

18. Blade

19. Deflector

20. Meat press knob

21. Ring

22. BS Hopper push-handle

8

CHAP. 2 - TECHNICAL DATA

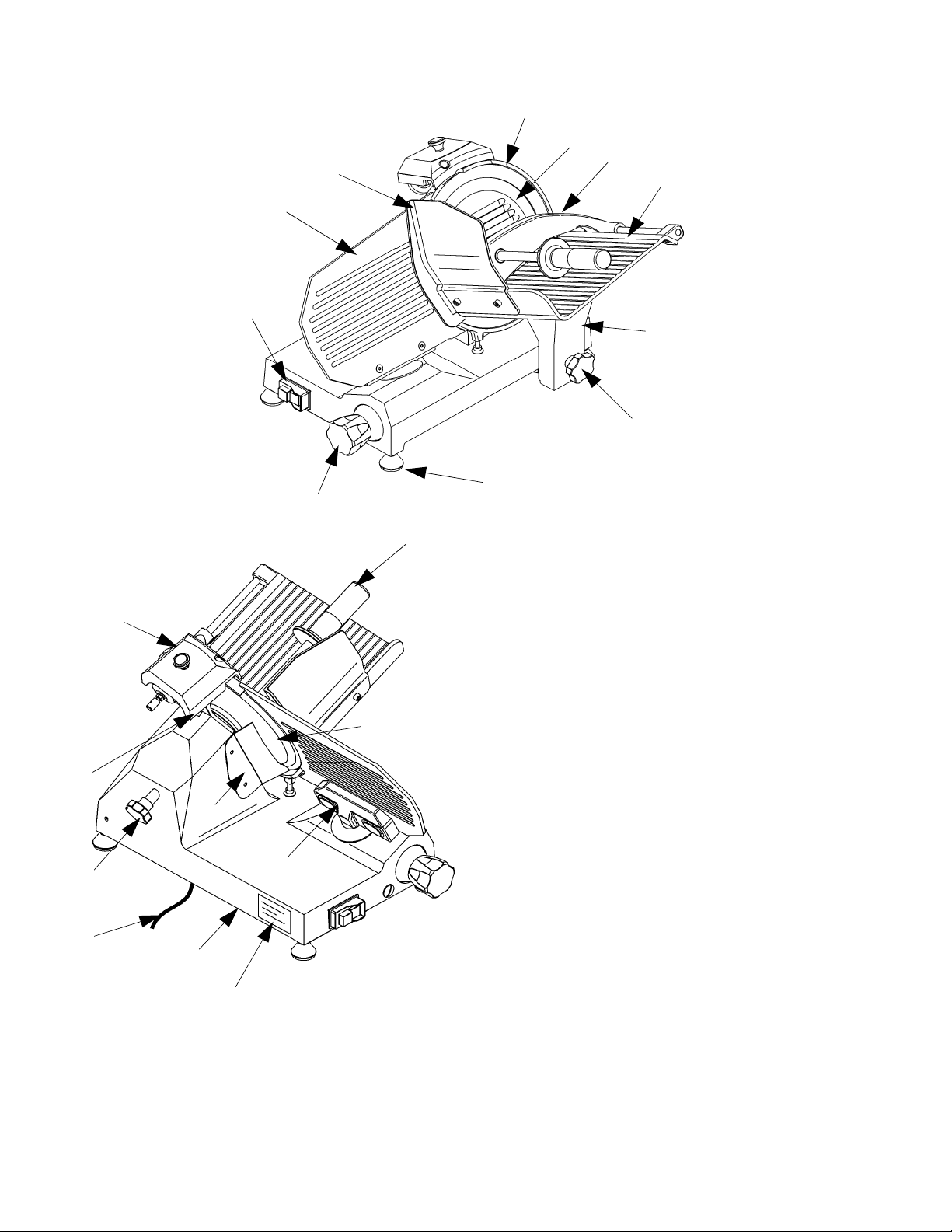

2.1 - OVERALL DIMENSIONS, WEIGHT, CHARACTERISTICS ... FIG. n°2 -

Drawings of the overall dimensions

M Vert. BS

M / M Vert.

9

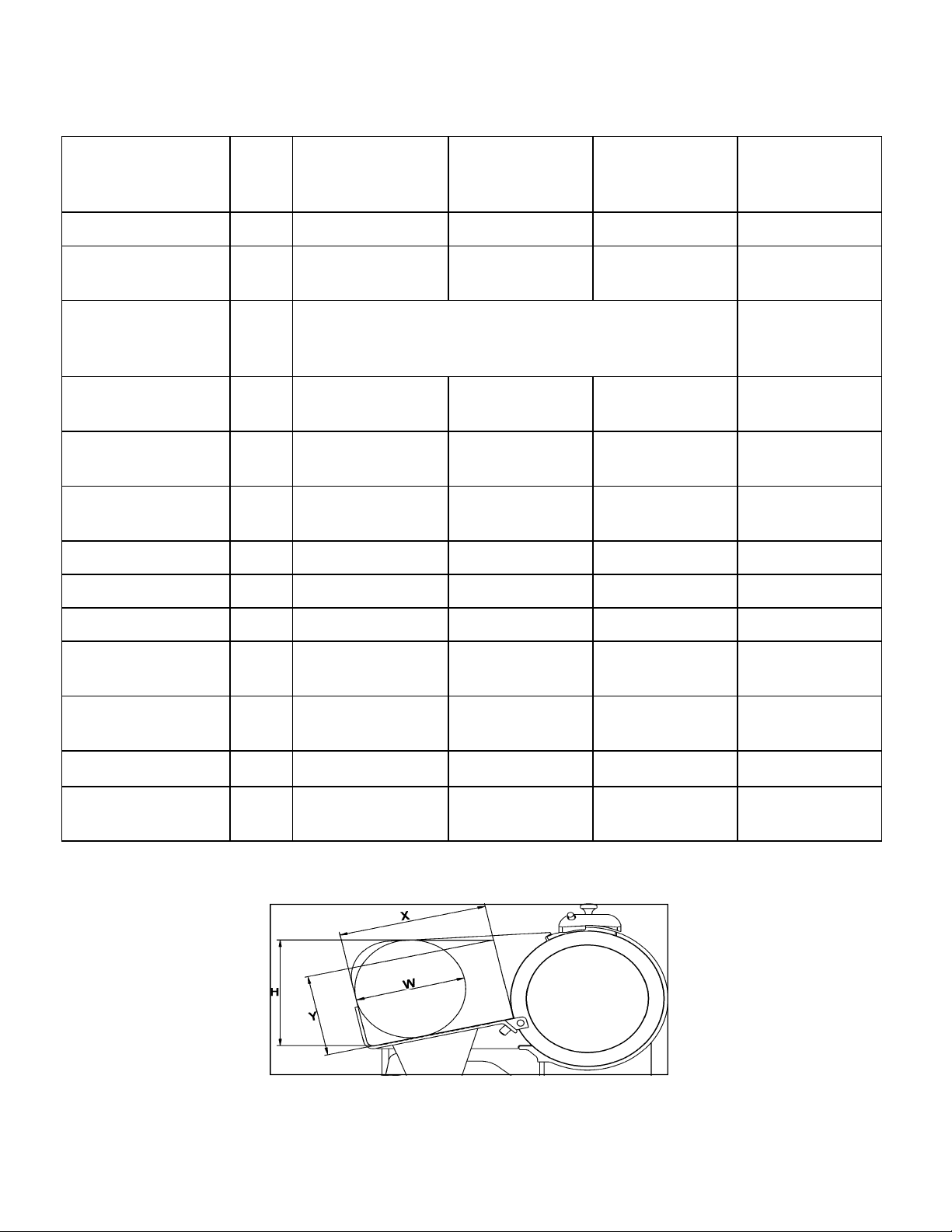

TAB. n°1 - OVERALL DIMENSIONS AND TECHNICAL CHARACTERISTICS.

MODEL U.m. M

220 C

220 AI C

M

250 C M

275 C M

300

øBlade mm 220 250 275 300

Motor W

Hp 147

0,20 147

0,20 147

0,20 210

0,29

Power Supply 1Ph

3Ph 230V / 50Hz 230V / 50Hz

230-230-40

50Hz

Cut thickness mm 13 13 13 13

Run

of carriage mm 245 245 245 285

Hopper size mm 230x230 230x230 230x230 250x275

A x B mm 395x245 395x245 395x245 435x295

C x D x E mm 480x560x370 500x560x370 535x560x370 600x610x420

F x D x G mm 570x560x475 570x560x475 570x560x475 640x610x510

X

Y mm 210

135 215

145 215

165 250

185

H

W mm 170

160 180

170 200

190 225

210

Net weight Kg 15 16 17 20,5

Noise level dB 60≤ 60≤ 60≤ 60≤

10

TAB. n°2 - OVERALL DIMENSIONS AND TECHNICAL CHARACTERISTICS.

MODEL U.m. M Vert.

220 C M Vert.

250 C M Vert.

275 C

ø Blade mm 220 250 275

Motor W

Hp 147

0,20 147

0,20 147

0,20

Power Supply 1Ph

Cut thickness mm 13 13 13

Run

of carriage mm 225 230 220

Hopper size mm 230x235 230x235 230x235

A x B mm 400x260 400x260 400x260

C x D x E mm 500x535x400 510x535x410 530x535x420

F x D x G mm 570x535x405 570x535x410 570x535x425

X

Y mm 205

150 205

170 225

205

H

W mm 150

150 170

170 205

205

Net weight Kg 16,5

Noise level dB 60≤ 60≤ 60≤

230V / 50Hz

17,5 18,5

11

WARNING: Electrical features of the slicer are shown in the rating plate placed on the back side of the

machine; before connecting the slicer to the electric system see § 4.2. Electric connections.

TAB. n°3 -OVERALL DIMENSIONS AND TECHNICAL CHARACTERISTICS.

MODEL U.m. M Vert.

250 C BS M Vert.

275 C BS M Vert.

275 BS M Vert.

300 BS

øBlade mm 250 275 275 300

Motor W

Hp 147

0,20 147

0,20 210

0,29 210

0,29

Power Supply 1Ph

3Ph 230V / 50Hz 230V / 50Hz 230V / 50Hz 230V / 50Hz

230-230-40

50Hz

Cut thickness mm 13 13 13 13

Run

of carriage mm 215 225 220 265

Hopper size mm 275x270 260x275 285x260 260x275

A x B mm 400x260 400x260 440x300 440x300

C x D x E mm 510x480x415 530x480x420 580x500x455 585x540x460

F x D x G mm 700x480x600 700x480x770 740x500x630 740x540x770

X

Y mm 270

190 270

200 255

205 255

215

H

W mm 190

190 200

200 205

205 215

215

Net weight Kg 21,5 22,5 26 27

Noise level dB 60≤ 60≤ 60≤ 60≤

12

CHAP. 3 - SUPPLY OF THE SLICER

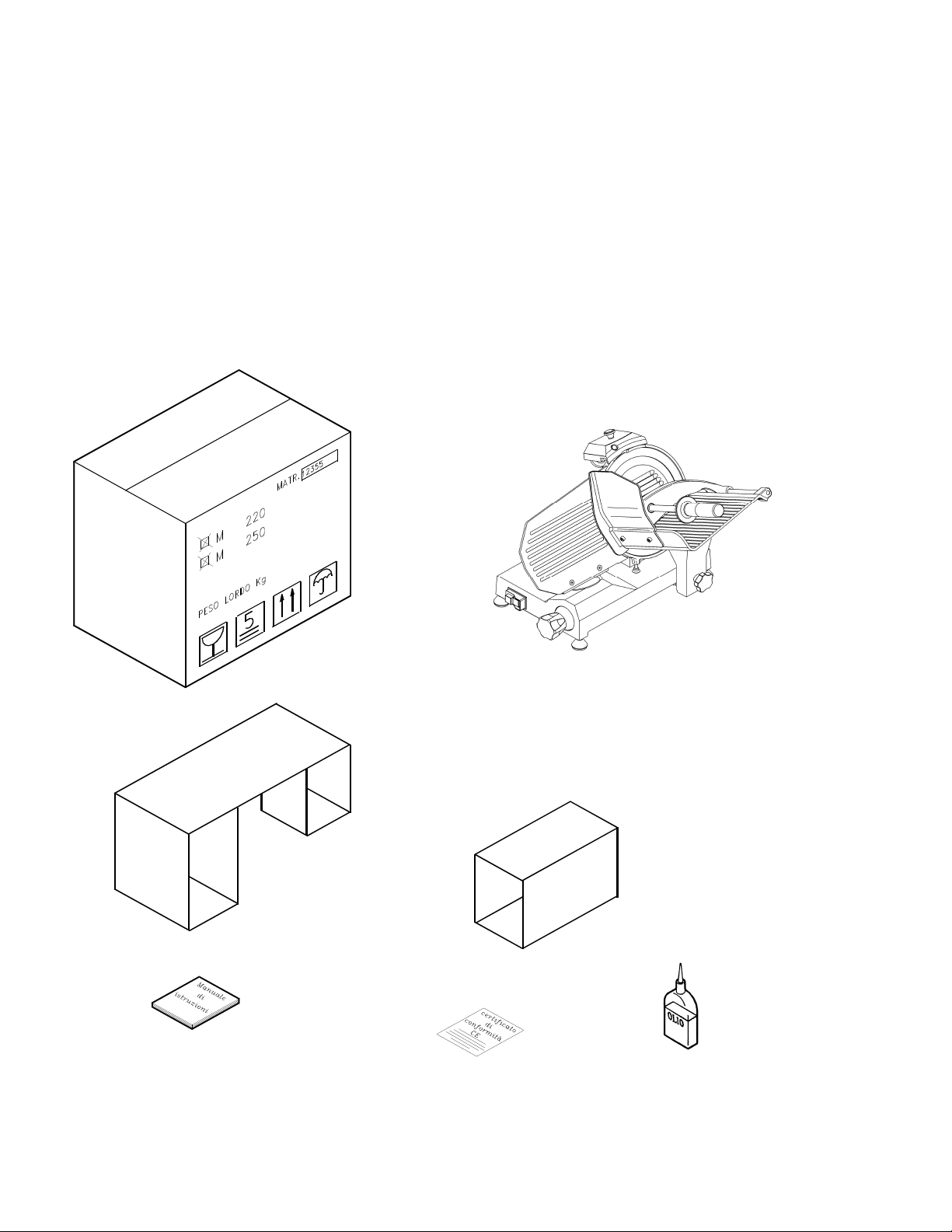

3.1 - DISPATCH OF THE SLICER (see FIG. n° 3)

Slicers are accurately packed and then dispatched from our warehouses; the package includes:

FIG. n°3 - Description of the package

a)

c)

e)

f)

b)

d)

a) a strong cardboard box;

b) the slicer;

c) two cardboard filling grafts to keep the slicer stable;

d) this manual;

e) an oil phial;

f) EC conformity declaration.

13

3.2 - PACKAGE CHECK UPON ARRIVAL

If no external damage is evident on the package upon its arrival, open it and check that all the components

are inside (see FIG. n°3). If the package has suffered from rough handling, bumps or crashes, the carrier

must be informed about any damage; moreover a detailed report on the extent of the damage caused to the

machine must be filled within three days fromthe delivery date shown in the shipping documents. Do not

overturn the package!! When the package is transported, makesure, the box is lifted by the 4 corners

(parallel to the ground).

3.3 - PACKAGING DISPOSAL

The components of the packaging (cardboard box, pallets, plastic straps and polyurethane) are urban solid

waste; therefore they can be easily disposed.

If the slicer is tobe installed in countries where specific regulations are in force, packaging must be

disposed in compliance with them.

CHAP. 4 - INSTALLATION

4.1 - SETTING UP OF THE SLICER

The slicer must be installed upon a working table suitable for the slicer’s overall dimensions shown in

Table 1-2-3 (according to themodel); therefore it must be adequately large, well levelled, dry, smooth,

resistent, stable and placed at a height of 80 cm from the ground. Moreover the machine must be installed in

aroom with max. 75% not salinehumidity at atemperature between +5°C and 35°C; that is to say in a

place that does not provoke the slicer failure.

4.2 - ELECTRIC CONNECTION

4.2.1 - slicer equipped with a single-phase motor

The slicer is equipped with a power supply cord (section of 3x1mm² and length of 1.5m) and a “SHUKO”

plug.

Connect the slicer with a 230 Volt - 50 Herz electric circuit by interposing a differential-

magnetothermic switch of 10A, ∆I = 0,03A. Check that the earthing is fully operational. Moreover check

that features on the rating plate - serial number (FIG. n°4) correspond to the features shown in the

consignment and delivery note.

4.2.2 - slicer equipped with a three- phase motor

The slicer is equipped with a power supply cord with a section of 5x1mm²and a length of 1.5m.

Connect theslicer with a 400 Volt - 50 Herz three-phase electric circuit bymeans of aCEI plug

interposing a differential-magnetothermic switch of 10A., ∆I = 0,03A.. Check that the earthing is fully

operational. Before connecting the machine to the three-phase power supply circuit, check the direction of

blade rotation by pushing the button “I” (ON) (see CHAP. 5.1 FIG. n°8) and immediately afterwards the

cut-off button “0” (OFF).

The direction of blade rotation must be anti-clockwise looking at the machine from the blade guard side

(see FIG. n°5).

FIG. n°4 - Rating plate - serial number

14

If the direction of rotation is wrong, reverse two of the three power supply cords in the plug or

in the socket (black and grey).

Three-phase motors installed in CE professional slicers can work with both 230 V. three-phase tension and

400 V. tension.

Unless otherwise specified, connections are made with 400 V. power supply; call the“SERVICE

CENTRE” if matching with the 230 V three-phase circuit. is required.

FIG. n°5 - Sense of blade rotation

4.3 - ELECTRICCIRCUIT ARRANGEMENT

4.3.1 - arrangement of the single-phase electric circuit - Push-button panel

FIG. n°6 - Single-phase electric system arrangement

15

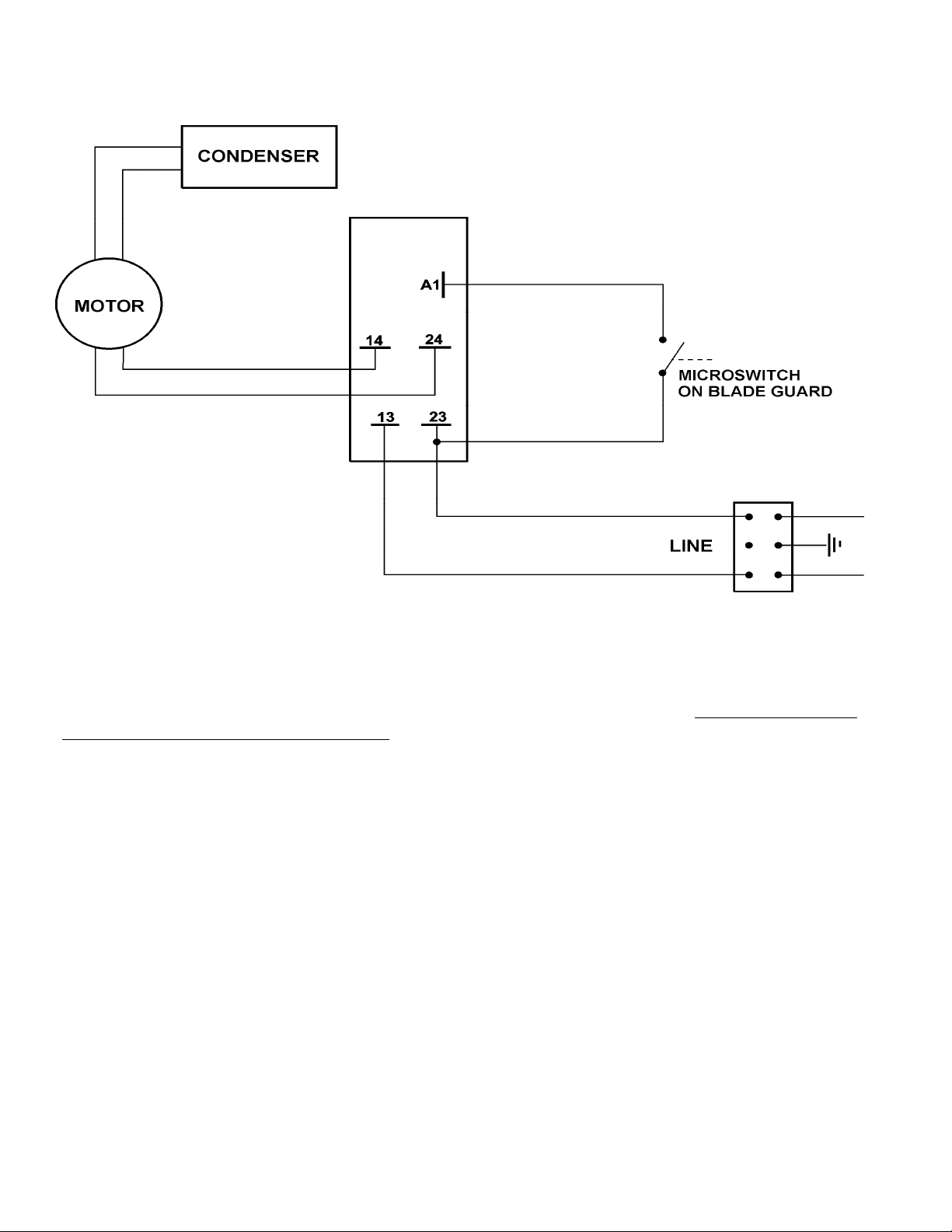

4.3.2 - arrangement of the three-phase electric circuit -Push-button panel

FIG. n°7 - Three-phase electric system arrangement

16

4.4 - FUNCTIONING CHECK

Before testing the slicer check that the meat hopper is blocked and then trythe functioning according to

the following procedure:

1 push the switch-on button “I” (ON) and the switch-off button “0” (OFF);

2 check the sliding of the meat hopper and meat pusher;

3 check the functioning and adjustment of the plate through the dial knob;

4 check the functioning of the sharper (see § 5.3,FIG. n°11 a-b-c);

5 check that the meat hopper can bedisassembled only with the dial knob set in the “0”

position and that, after disassembling the machine, the knob remains in this position; 6 check that the

slicer stops functioning by unscrewing the tie rod for blade guard.

4.3.3 - arrangement of the single-phase electric circuit - Schalter Profi

FIG. n°8 - Single-phase electric system arrangement - Schalter Profi

17

CHAP. 5 - OPERATING OF THE SLICER

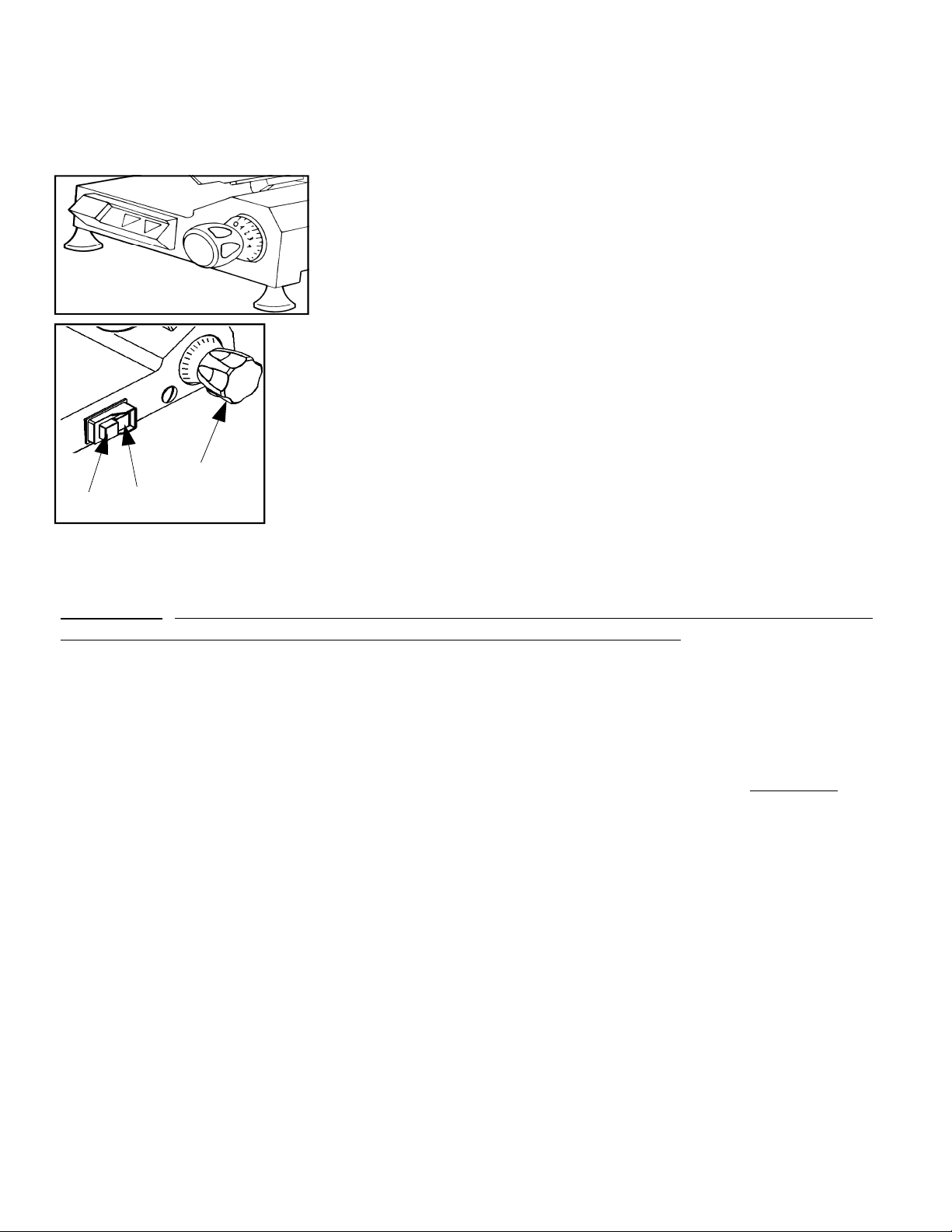

5.1 - CONTROLS

Controls are placed on the left hand side of the base as shown in the picture above.

5.2 - LOADING AND SLICING OF FOODSTUFFS

WARNING: Products to be cut must be loaded on the meat hopper only when the dial knob is set to the “0”

position and pay attention to the blade and the sharp edges.

The procedure is as follows:

1 once the product has been loaded onto the meat hopper and placed against the plate, stop it

with the arm provided with gripping points;

2 adjust the dial knob so as to obtain the desired cutting thickness;

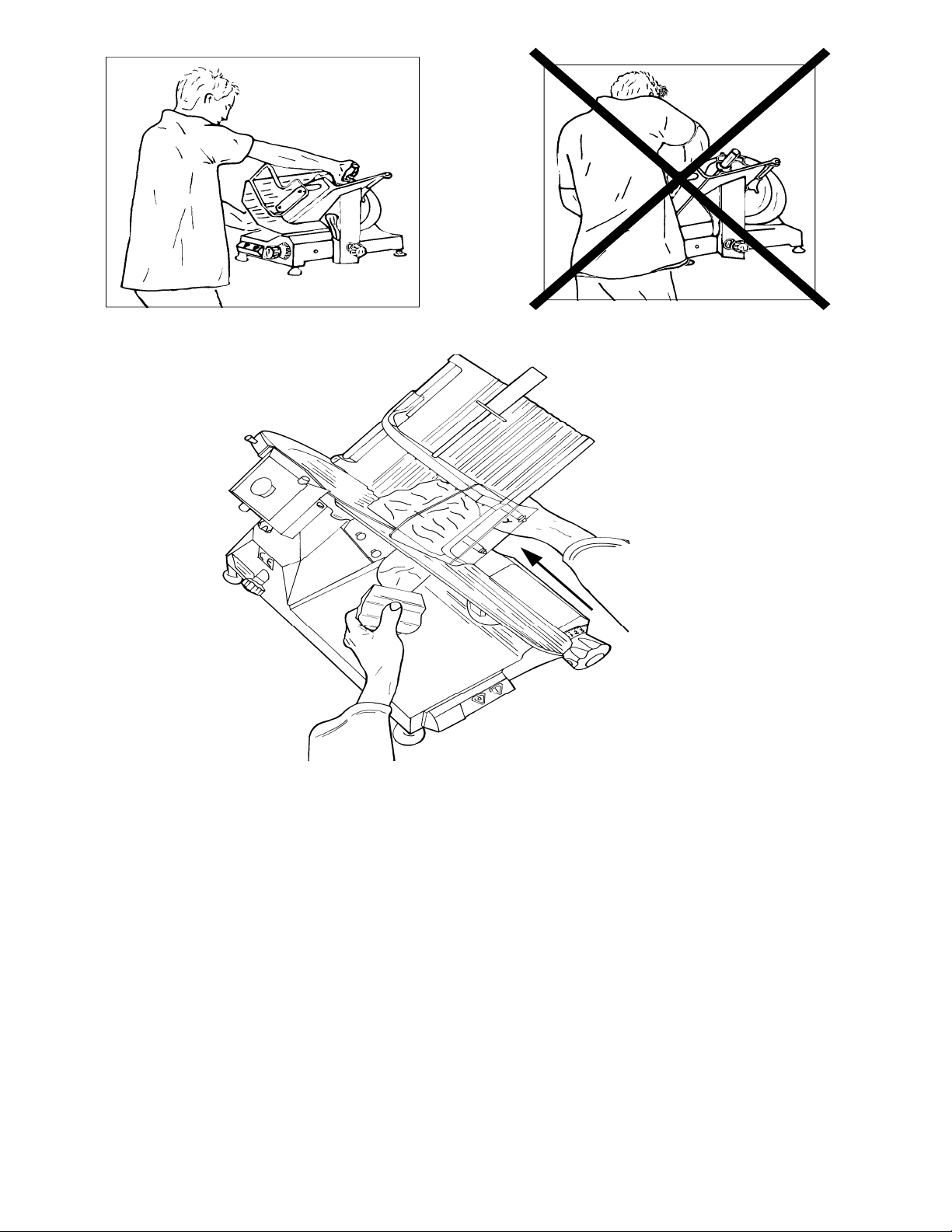

3 to avoid accidents, the person who is cutting has to face the machine and stand correctly:

put the right hand on the meat pusher, and then the left one beside the deflector (do not touch the

blade); the body must be perpendicular to the working surface (see FIG. n°10a). WARNING:Pay

the maximum attention: no members of your body should enter in contact with the blade (see

FIG. n°10b);

4 push the switch-on button “I”;

5 smoothly push the carriage (meat hopper + meat pusher + stem) towards the blade without

exerting pressure on foodstuffs with the meat pusher since they have their own force of gravity which

exerts pressure on the thickness gauge. The blade will easily cut foodstuffs and slices will be guided by

the deflector onto the collecting plate (see FIG. n°11);

6 do not operate the slicer without foodstuffs;

7 once foodstuffs have been cut, set the dial knob in the “0” position and switch off the

machine by setting the switch to the “0” position;

8 resharpen the blade as soon as slices show a rough or frayed surface and the cutting

becomes difficult (see 5.3).

1Dial knob to adjust the

cuttingthickness.

2 Switch-on button “I”. 3

Switch-off button “0”.

FIG. n°9 - Position of controls

3 2 1

18

FIG. n°10a - Right position FIG. n°10b - Bad position

FIG. n°11 - Meat cut

19

5.3 - SHARPENING OF BLADE (see FIG. n°12 a-b-c)

WARNING: Before proceding with blade sharpening,

remain alert to the RESIDUAL RISKS (see §1.2.2) that

refer to the hazard of injury if the instructions below are

not followed.

The blade must be sharpened periodically and as soon as it

becomes blunt; the following detailed instructions are to be

carried out:

1 clean the blade accurately with denaturated alcohol to

remove grease after the plug has been disconnected from the

socket;

2 unscrew the knob (1), lift (a) the sharpener (2) up to the

locking position and rotate it 180° (b) (see FIG. n°12a). Then

let it move to the end (c) so that the blade is positioned

between the two grinding moles. Lock the knob;

3switch-on the slicer by pushing the button “I” (ON);

4 push the small button (3) (see FIG. n°12b), let the blade

rotate against the grinding mole for 30/40 sec. to produce burr on

the blade edge;

5 push buttons simultaneously for 3/4 seconds (3 and 4) and

then leave them simultaneously (see FIG. n°12c);

6 it is recommended to clean the grinding moles by

following the sharpening (see 6.2.3);

7 once sharpening has been completed,return the slicer to its

original setting with the reverse procedure.

NOTE: Do not prolong the burring operation beyond 3/4 sec.

in order to prevent the dangerous twisting of the blade cutting

edge.

FIG. n°12a

FIG. n°12b

FIG. n°12c

b 2

a

3

3

4

1

20

CHAP. 6 - ORDINARY CLEANING

6.1 - GENERAL FEATURES

•The slicer cleaning must be carried out atleast once a day or more frequently, if necessary.

•Cleaning must be extremely accurate for thoseparts of the slicer which are directly or

indirectly in contact with foodstuffs.

•The slicer must not be cleaned with water-cleaners and high pressure jets of water, but use

water and neutral detergent. Do not use other detergents. Tools, brushes and other

devices likely to damage the slicer’s surface must not be used.

Before carrying our any cleaning operation it is necessary to:

1) disconnect the power supply plug from the socket to isolate the slicer from the rest of the

electric circuit completely;

2) set the dial knob adjusting the plate to the “0” position.

WARNING: Pay attention to residual risks due to cutting and/or sharp edges.

6.2 - SLICER CLEANING PROCEDURE

6.2.1 - meat hopper cleaning (see FIG. n°13)

The carriage (meat hopper + arm + stem) is easily removable:

-with the dial knob set in the “0” position (1);

-the carriage (2) at the end of its run (a) near the controls;

-unscrew the handwheel (3), slide the carriage upwards (b);

-after having removed the carriage, it is possible to clean accurately the meat hopper with hot

water and neutral detergent (PH 7).

FIG. n°13 - Release of the carriage

3

a

1 2

b

This manual suits for next models

8

Table of contents

Other Sirman Kitchen Appliance manuals

Sirman

Sirman Topaz 195 Operating instructions

Sirman

Sirman PPJ 10 SC Specification sheet

Sirman

Sirman Easyvac 25 User manual

Sirman

Sirman PPJ20 Specification sheet

Sirman

Sirman PLL 300 User manual

Sirman

Sirman MNT 300 Operating instructions

Sirman

Sirman PALLADIO EVO 330 Operating instructions

Sirman

Sirman TC RIO 22 User manual

Sirman

Sirman Stromboli Assembly instructions