2

FOREWORD

•This manual is meant to provide Customers with information on the machine and its

specifications, and provides all the necessary operating and maintenance instructions in

order to ensure machine performance and longevity.

•This manual must be kept until the machine is disposed of. This manual should be accessible

to all maintenance and operating personnel.

CONTENTS

CHAP. 1 - RECEIVING THE MACHINE page 4

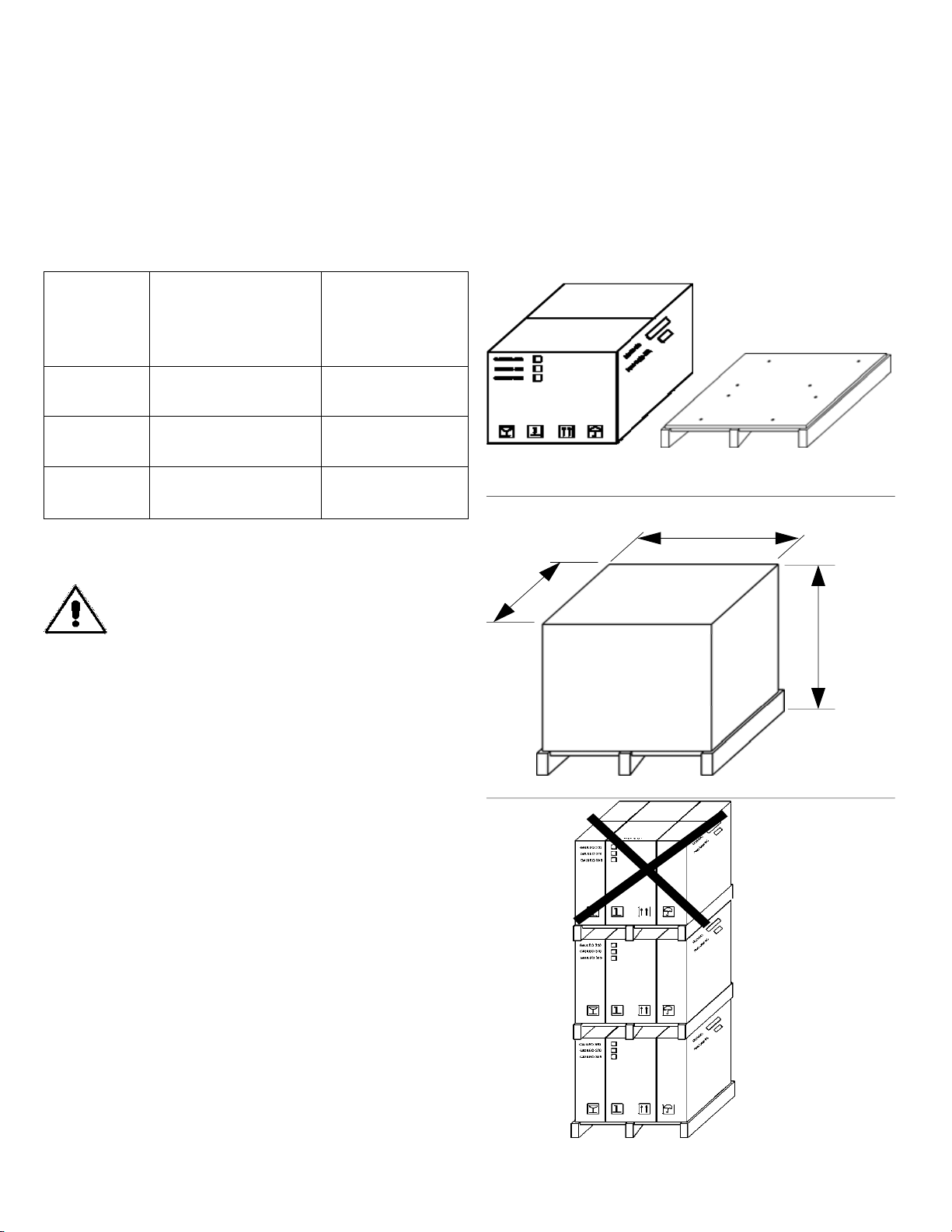

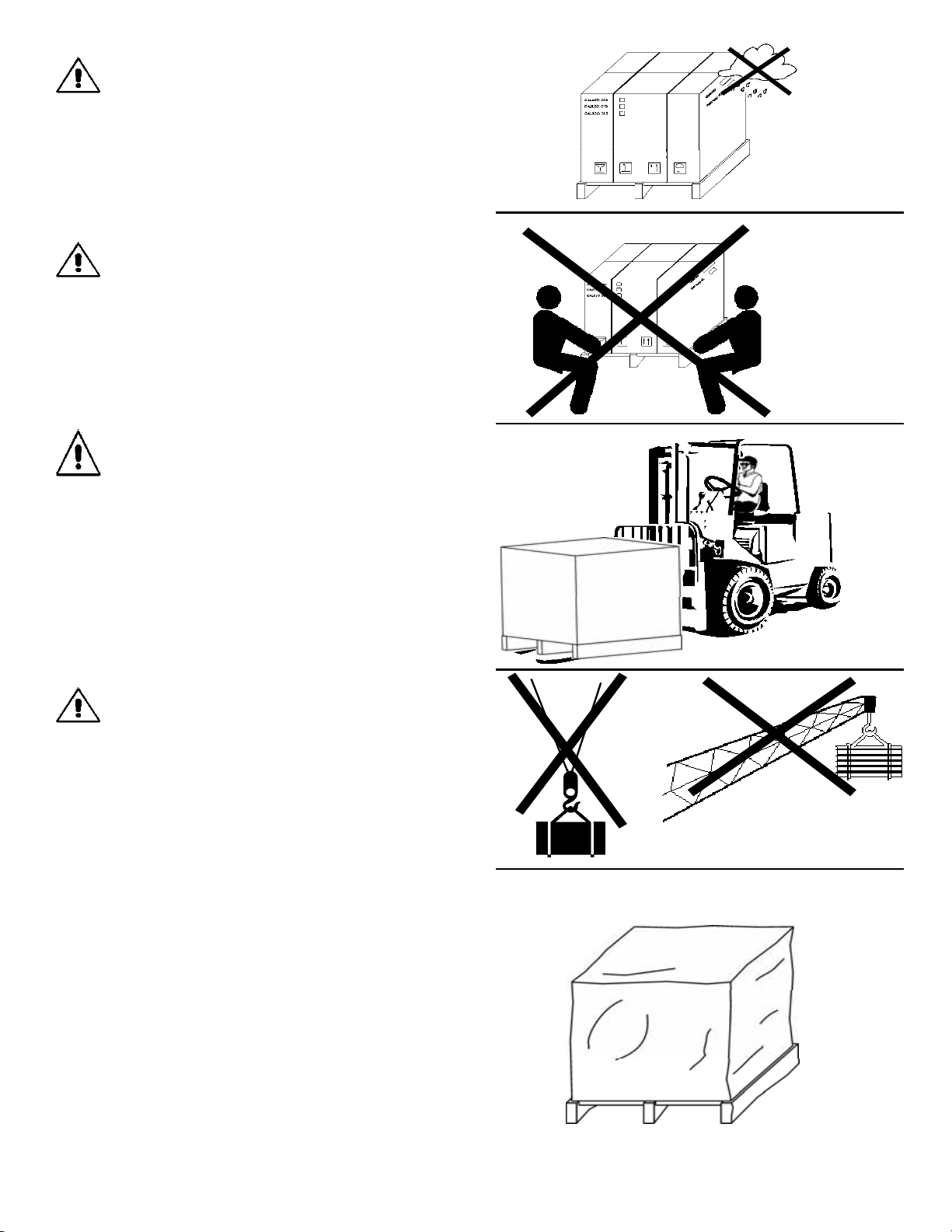

1.1 -PACKAGING

1.2 -PACKAGING UPON DELIVERY

CHAP. 2 - INSTALLATION page 6

2.1 UNPACKING

2.2 POSITIONING

2.3 -ELECTRICAL CONNECTION

2.3.1 - Slicer with single-phase motor

2.3.2 - Slicer with 400 V. three-phase motor

2.3.3 - Slicer with 230 V. three-phase motor

2.3.4 - Blade rotation direction

2.4 - WIRING DIAGRAM

2.5 CONTROL PANEL

2.6 -PRELIMINARY CHECK

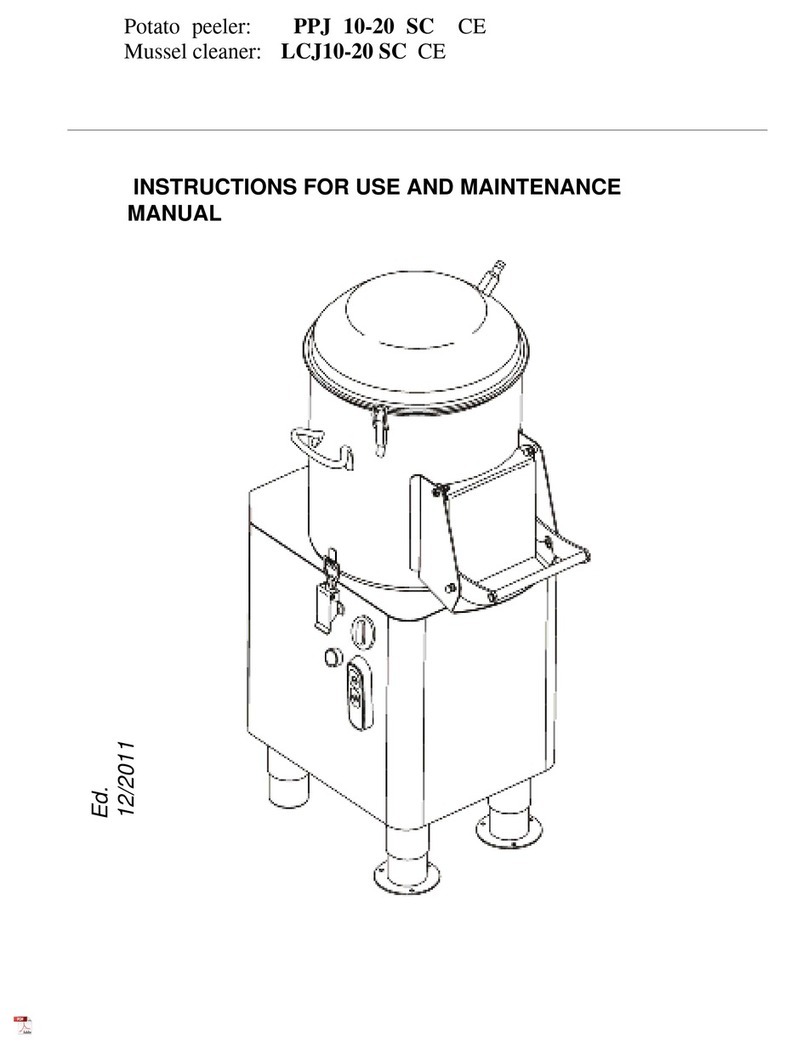

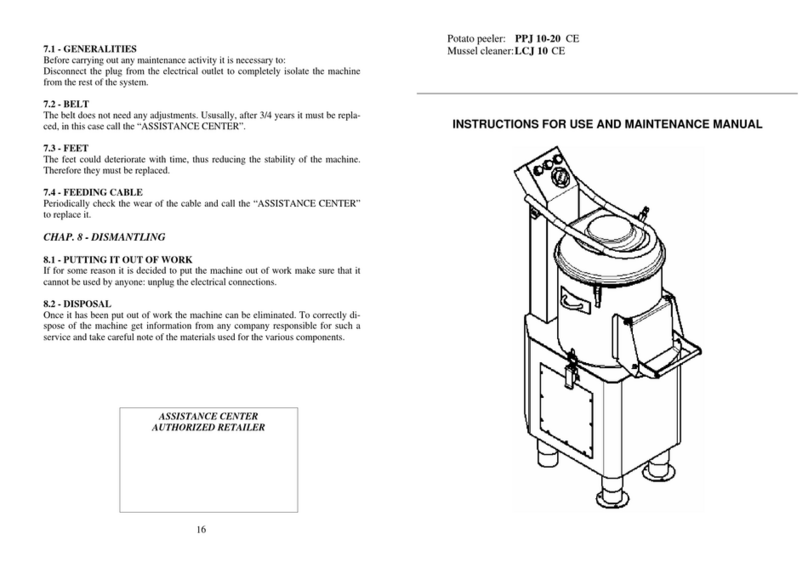

CHAP. 3 - INFORMATION ON THE MACHINE page 11

3.1 -GENERAL SAFETY PRECAUTIONS

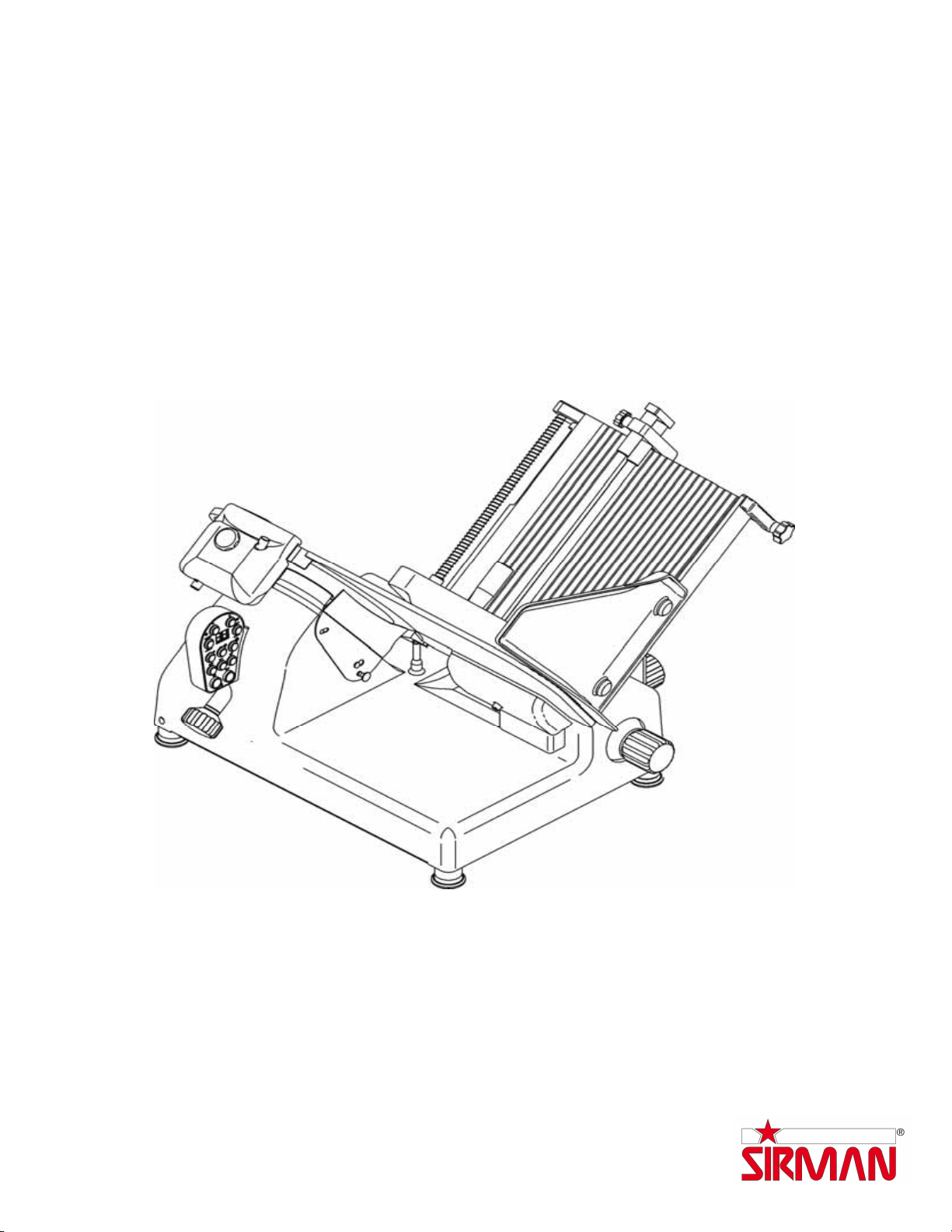

CHAP. 4 - GETTING FAMILIAR WITH THE SLICER page 13

4.1 CONSTRUCTION FEATURES

4.2 -SAFETY DEVICES INSTALLED ON THE MACHINE

4.2.1 -Mechanical safety

4.2.2 -Electrical safety

4.3 - DESCRIPTION OF THE MACHINE

4.4 - OVERALL DIMENSIONS, WEIGHT, FEATURES….

CHAP. 5 - USING THE MACHINE page 18

5.1 - OPERATIONAL CHECK

5.1.1 - Using the controls

5.2 - LOADING AND CUTTING THE PRODUCT

5.3 -SHARPENING THE BLADE