Site Buddy PROFESSIONAL SERIES 30TP User manual

OWNER’S MANUAL

DIESEL POWERED TRASH PUMP

IMPORTANT ─Please make certain that persons who are to use this equipment thoroughly

read and understand this user’s manual prior to operation

PREFACE

Thank you for purchasing our products. We appreciate your business. The following manual

is only a guide to assist you and is not a complete of comprehensive manual of all aspects of

your water pump unit. Some of the illustrations and photos will differ slightly then your

model and only serve as an illustration. The equipment you have purchased is a complex

piece of machinery. We recommend that that you consult with a dealer if you have doubts or

concerns as to your experience or ability to properly maintain or repair your equipment. You

will save time and the inconvenience of having to go back to the store if you choose to write

or call us concerning missing parts, service questions, operating advice, and/or assembly

questions. Our diesel powered water pumps have some of the following features:

●Lightweight construction

●Hard working four-stroke diesel internal combustion engine

●Large fuel tank

●High quality mechanical seals

●Self-priming structure

The air-cooled diesel semi trash pumps are self-priming single-stage centrifugal water pumps.

The bodies of the water pumps are constructed of high quality die-cast aluminum alloy. The

internal rotating rings arc constructed of ceramics and the stationary rings are constructed of

graphite. The water pumps are widely used in fieldwork and on construction sites. Our water

pumps provide a portable mobile solution in pumping liquids from one place to another.

This manual will explain how to operate and service your semi-trash pump unit.

TABLE OF CONTENTS

Page number

OVERVIEW OR VARTOUS MODELS OF WATER PUMPS ………………….…...….….1

TECHNICAL SPECIFICATIONS ……………………………………………………………2

WATER PUMP SAFETY PRECAUTIONS …………… ……………………….……4

KNOWING YOUR SEMI-TRASH PUMP …………………………………………………..5

PRE-OPERATTON PREPARATION ………………………………………………………..6

STARTING THE ENGINE ………………………………………………………………….10

OPERATION ………………………………………………………………………………...14

STOPPING THE ENGINE …………………………………………………………………..15

MAINTENANCE …………………………………………………………………………...16

IRAN SPORTING AND STORAGE …………………………………………………….….20

TROUBLESHOOTING……………………………………………………………………...21

PUMP DIAGRAMS AND PARTS LISTINGS ……………………………………………..23

OVERVIEW OF VARIOUS MODELS OF WATER PUMPS

Figure 1.Overall view of the diesel water pump unit

PROFESSIONAL SERIES MODEL

TECHNICAL SPECIFICATIONS

Table 1. Specifications in Metric units

Model No. 30TP

Suction port diameter(mm) 80

Discharge port diameter(mm) 80

Suction height(m) 7

Pump lift (m) 25

Pump

Displacement (m3) 55

Engine TP178E

Speed(rpm) 3600

Displacement(cc) 296

Max.Output(kw) 4.0

Cooling system Forced air cooling by flywheel

Ignition Direct fuel injection

Engine

Shaft rotation Clockwise from flywheel end

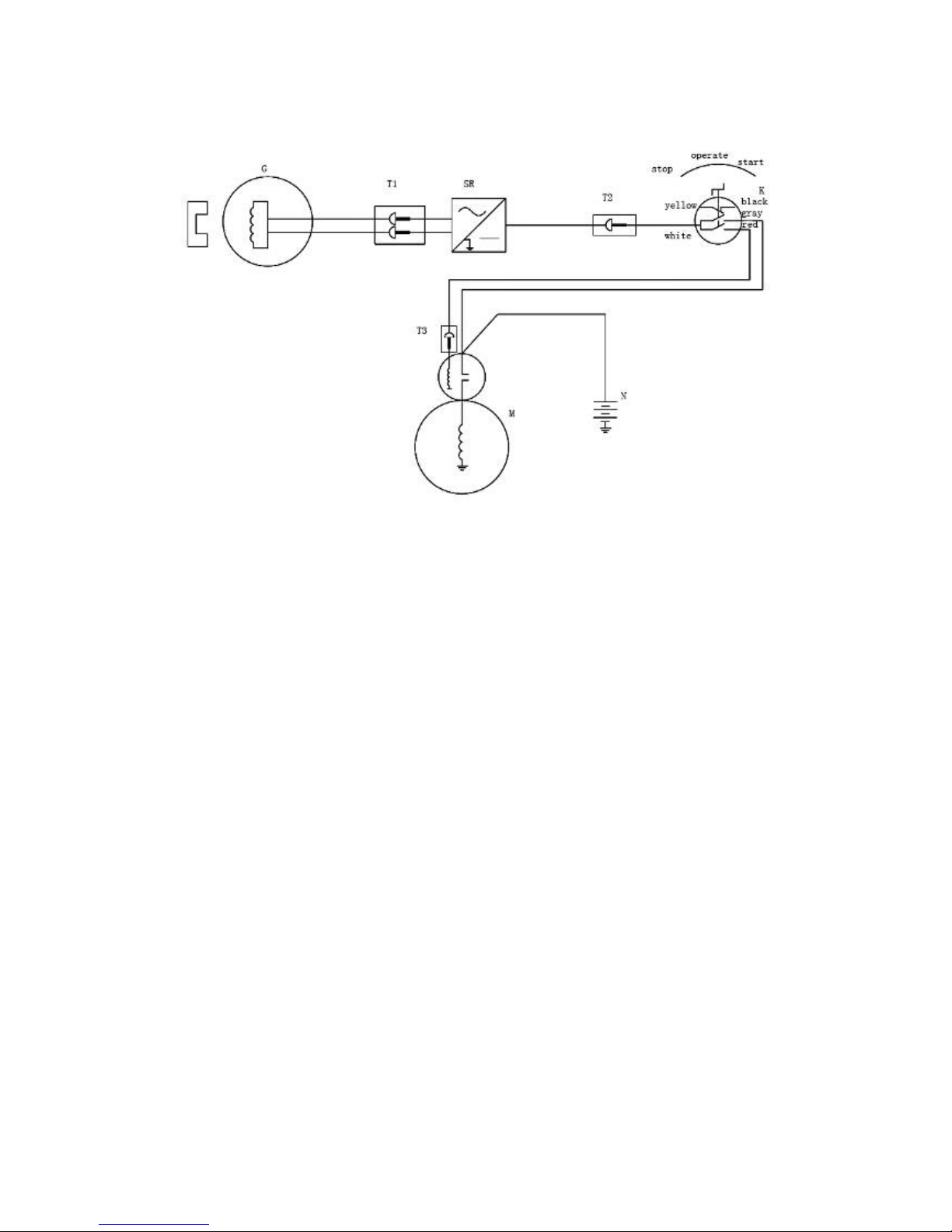

Wiring Diagram (optional for electric start models only)

SEMI-TRASH PUMP SAFETY PRECAUTIONS

●Do not smoke or allow flames or sparks to

get near fuel. Always refuel your engine in a

well-ventilated place. Do not overfill the tank

and always close the filler cap securely.

●Never run the pump indoors as the engine

emits poisonous carbon monoxide.

●Do not touch the muffler during or just after

operation, as the engine and muffler get hot

Always let the engine fully cool before touching

and storing the pump indoors.

●Always keep the pump at least 1 meter (3

feet) away from buildings and other equipment

during operation. Do not place flammable

objects or liquids close to the pump.

●Before operating your semi-trash pump,

please check your local laws and regulations

before operating your pump. It is illegal in some

areas to operate an engine without a spark

arrester.

●Know all the pumps controls and know how

to stop the pump quickly in the event of an

emergency. Do not let anyone without proper

instructions operate the pump.

●Always keep children and pets away from

the pump.

●Do not pump flammable or corrosive liquids

such as gasoline or acid. In order to prolong the

life of your pump, avoid pumping corrosive

1iquds such as sea-water, chemical solutions,

used oil, or acidic liquids.

●Always operate your pump on a level surface.

If the pump is tilted, fuel may spill and rapid

wear might occur as a result of inadequate

lubrication.

KNOWING YOUR WATER PUMP

STANDARD MODEL

Fuel cap

Muffler

Cleaner

Recoil Starter

Oil drain plug

Oil

D

epth

Gauge

a

nd Inlet

P

ort

Suctio

n Port

Priming water filler cap

Outlet

PRE-OPERATION PREPARATION

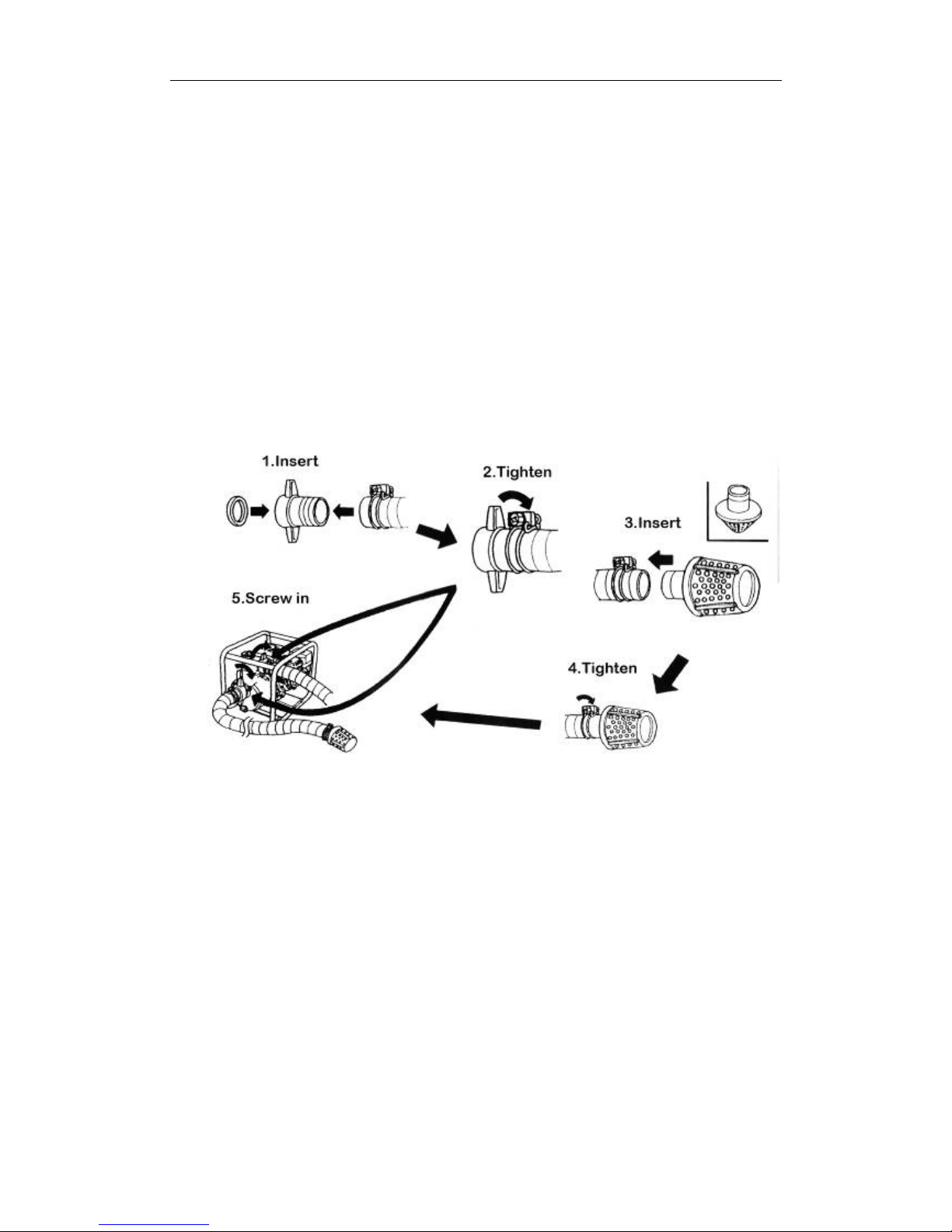

Suction Hose

The first step in preparing the pump for operation is to install the suction hose. For the suction hose,

use a reinforced-wall or wire braided hose to prevent suction collapse. A short hose is recommended

over a long hose. The pumps have standard National Pipe Threads on them; therefore, any standard

hose set will fit with the pump. If your hoses arc metric threads or any other standard, please give our

company a call and we may carry a full line of adapters or provide you with a possible solution.

NOTE: Always install the provided strainer on the end of the suction hose before pumping. If gravel or

debris enters the pump, the impeller can he seriously damaged.

Shown below is the pump hose utilizing a barbed connection and hose clamp. If you already

have specialized hose, disregard the following diagram. When using the barbed connection

setup, make sure to use a hose clamp to properly secure the hose to the barb connector.

Discharge hose

The second step is to install the discharge hose. The discharge hose can be fabric, just make

sure to use a hose clamp to secure the hose to the barb. This will prevent the hose from

disconnecting under high pressure.

Note: A short and large-diameter hose is preferred over any other. A short and large diameter

will provide lower fluid friction and improve efficiency.

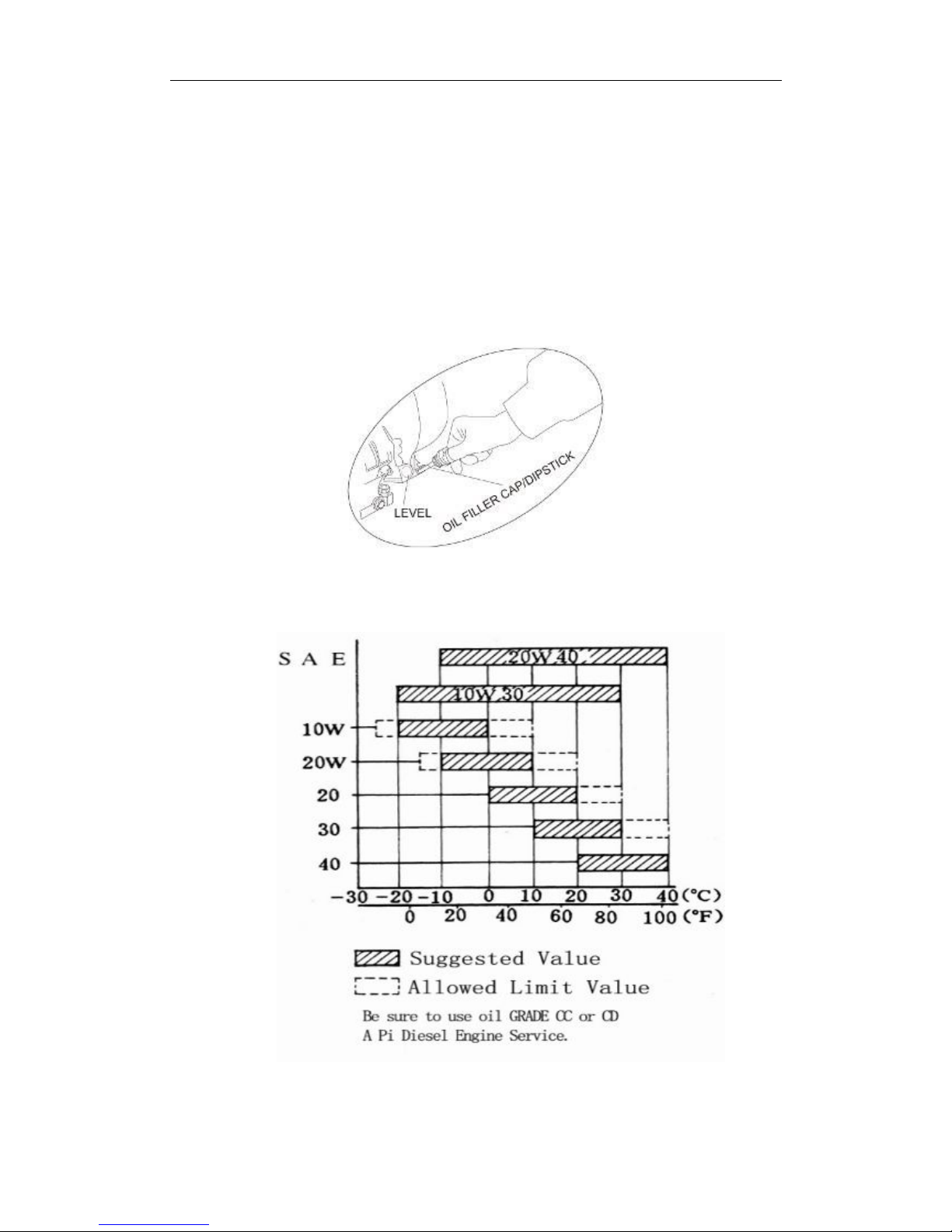

Engine oil

Engine oil is an important factor in determining the performance and life of your engine. Always

make sure the oil level is within the upper and lower limits specified on the oil dipstick. Make

sure to check the engine oil on a level surface or incorrect readings will result.

●To check the engine oil, first, remove the oil dipstick by turning counterclockwise.

●

Wipe the dipstick clean and insert the dipstick back into the oil filler neck. Do not screw it in.

Please refer to Fig 2-1.

●If the level is low, fill engine oil to the top of the oil filler neck with the recommended oil

below.

Fig 2-1. Illustration of checking the engine oil

Below is a table of recommended oil grades for the engine in various weather conditions.

Please use the proper oil according to the Table 2-1.

Table 2-1. Ambient temperature versus oil grades

Note: For diesel engines, we highly recommend the use of 15W-40 engine oil. Some other grades

are comparable, but 15W-40 is the preferred oil grade.

Fuel

Remove the fuel cap and fill the fuel tank with diesel fuel. The preferred fuel for

diesel engines is diesel number 2, which can be easily obtained from a gas station. Do not

use other fuels until consulting with your local dealer or our company.

Do not smoke or allow flames or sparks to get near fuel. Always refuel your engine in a

well-ventilated place. Do not overfill the tank and always close the filler cap securely.

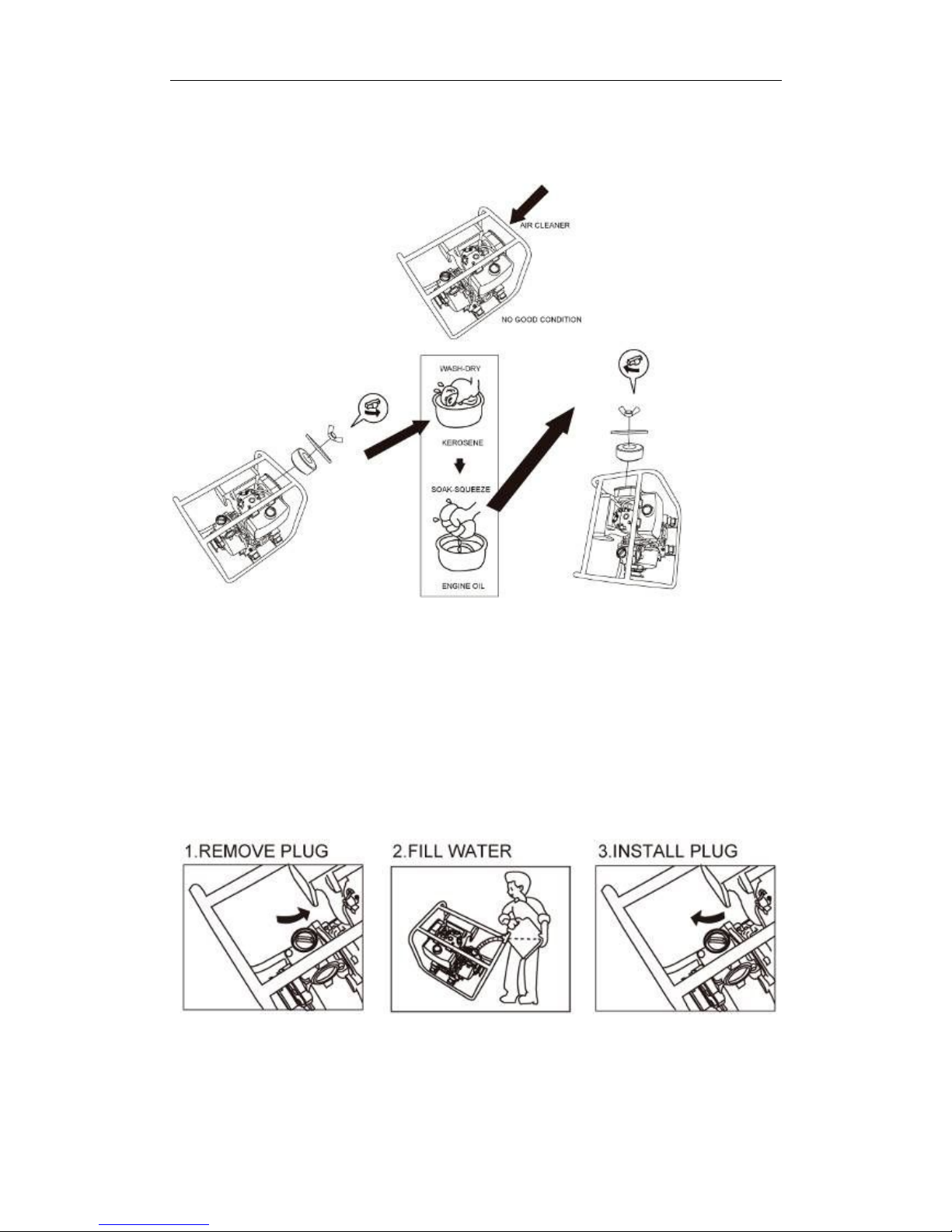

Air Cleaner

Before starting your water pump, remove your air cleaner cover and verify that the air filter is

clean and free of debris. Clean the air filter if necessary.

Priming water

The pump chamber should be completely filled before operating.

Note: Never operate the pump without priming water or the pump will overheat. Prolonged

operation of the pump under these dry conditions will damage and destroy the seal.

Follow these guidelines to fill the pump with priming water.

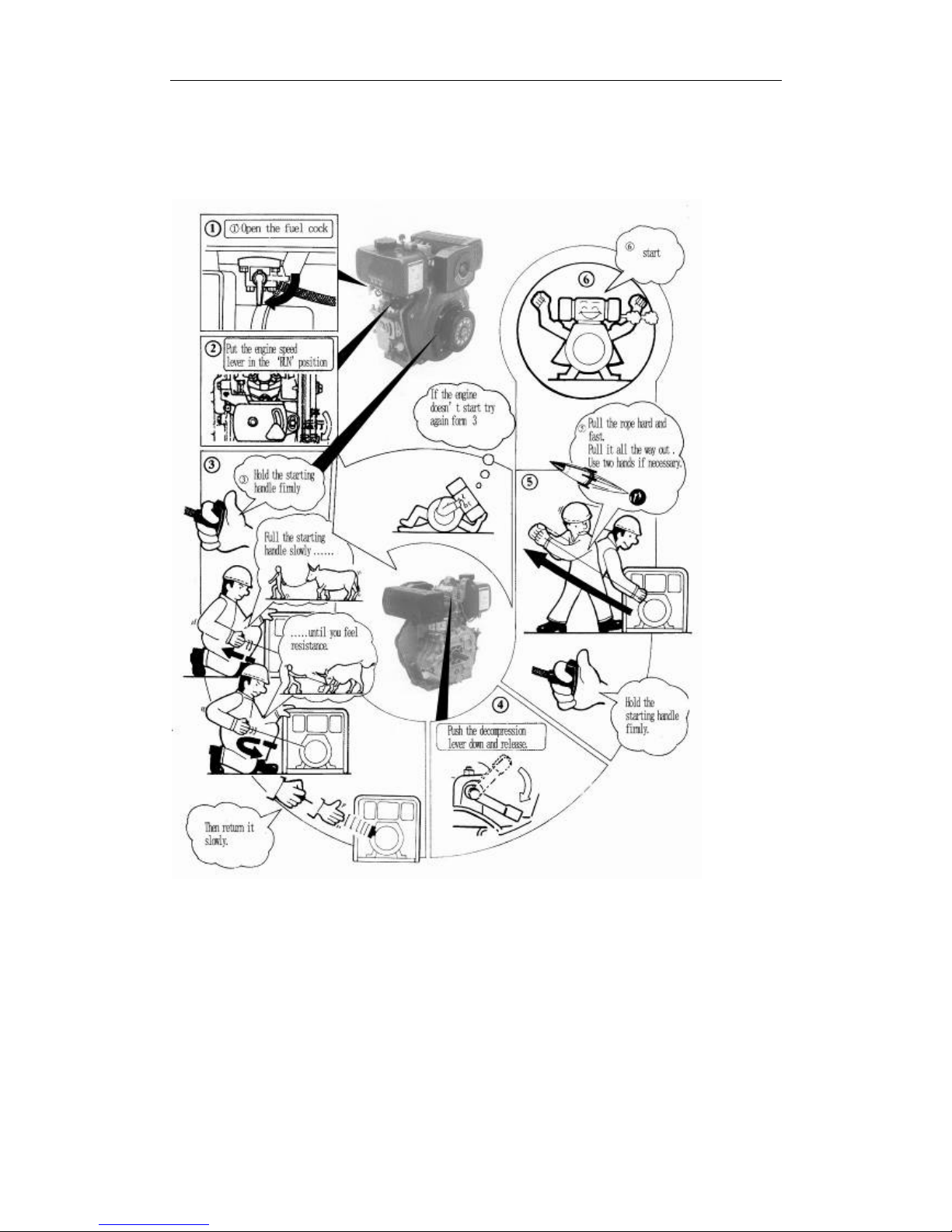

STARTING THE ENGINE

Recoil Starting

Note: When the engine is running, do not pull the recoil handle, otherwise the engine

may be damaged.

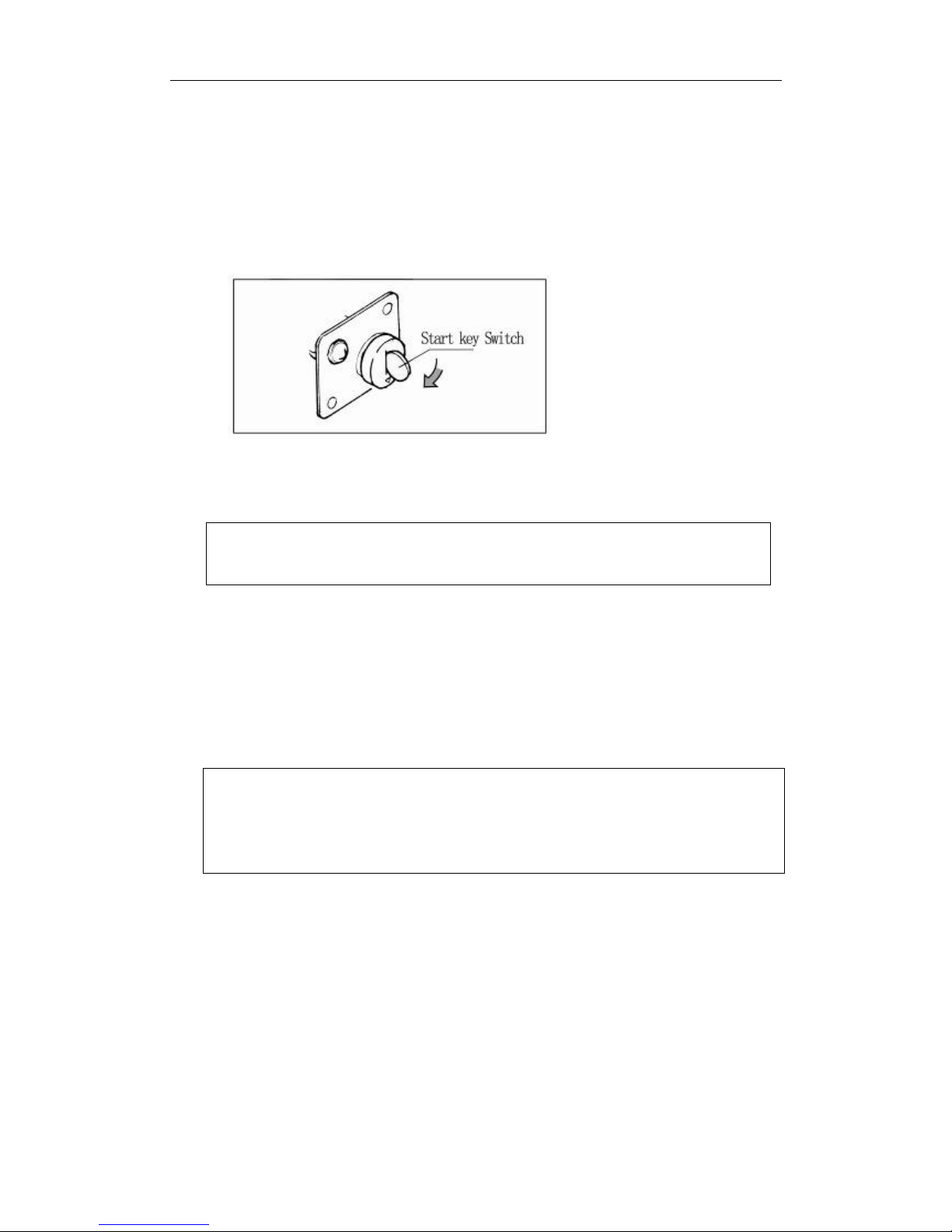

Diesel Engine with Electric Starter System

Starting

The preparation of the diesel engine for the electric starting system is the same as the manual

recoil type.

a. Open the fuel cock.

h. Set the speed governor lever to the start position.

c. Turn the start switch clockwise to the “Start”position.

d. If the engine is started, immediately remove your hand away from the key switch.

e. If the engine does not start after 10 seconds, wait a while about 15 second before trying

to start the engine again.

(1) Battery

a. Always check the liquid level of the battery every month, if the level is lower than the low

limit mark, refill the battery with distilled water till you reach the upper limit mark.

If the liquid level in the battery is to low, the electric stater will not function to its best

potential. Always keep the level of the liquid in the battery between the upper and lower

limits. If there is too much liquid, the liquid will splash onto other nearby parts there by

ruining the battery.

If you run the starter motor to long, the voltage of the accumulator will drop and the

motor may be damaged. Keep the key switch in the “ON” position.

Cold starting

If the engine is difficult to start in winter, take off the rubber seal plug and put 2cc of machine oil

into the hole.

Notice: Engines supplied to the Torrid Zone will not contain the rubber plug. A solid plug is

provided instead.

Warning:

Never use flammable liquids as fuel, such as gasoline etc. Also, never take away the air

cleaner for easy starting of the engine, doing so may cause explosions from the intake gases.

Never take the oil plug unless you’re planning on filling the oil. If the plug is not in place,

rain, dust, and other impurities may be sucked into the engine causing serious damage to the

engine parts.

OPERATION

Operating condition

The water pumps operating range should be based upon the NPSH (net positive suction head).

A more precise definition of available NPSH is “the difference between the total suction head

and the vapor pressure of the liquid, in feet of liquid, at the suction flange”. We can measure

the total suction head of the pump and we can find vapor pressure from the liquid temperature.

The difference between these two values is the available NPSH. The following equation is the

mathematical expression of the definition for available NPSH:

hsv = has - hvpa where:

hsv = available net positive suction head, in feel of liquid

hsa = total suction head, in feet of liquid, absolute

hspa = vapor pressure of liquid at suction nozzle, in feet of liquid, absolute

The approximation will be based at an altitude less than 250 meters or 820 feet. Subtracting

10 meters or 32.8 feet from the net positive suction head can approximate the suction head of

the pump. When increasing the altitude of operation, the atmosphere should be decreased as

well as the suction head of the pump. The amount of decrease can be estimated by subtracting

10 meters from the local atmosphere value. If you are using sour pump at high altitudes and

having difficulty obtaining NPSH values, please consult your local power equipment dealer.

It is better to use a straight and short pipeline when operating the water pump. A short and

straight pipeline will minimize the frictional loses in the pipeline. The pipeline should be

fixed to something to avoid vibrations. Before operating the pump, you must check the

connections between the pump and pipelines to verify that everything is installed properly and

that there are no leaks of any kinds.

The filter net should be kept at a certain distance between the river surface, river bottom, and

riverbank. The net must also be submerged at least 0.3 meters or 1 foot below the water

surface to avoid sucking air into the pipeline. The net must also be 0.2 meters or 0.7 feet

above the river bottom or riverbank to avoid sucking stones or weeds into the pipeline.

If the gap between the impeller and flow guidance surface is over 1 mm, an adjustment shim

can be added on the shaft shoulder to reduce the gap. This will permit continuous use of the

water pump. Please refer to figure 2-2 for a diagram of the water pump and a listing of the

components.

STOPPING THE ENGINE

First, bring down the speed of the engine by using the speed governor. Let it run for 3 minutes

at no load before stopping it.

Then stop the engine.

Sudden stops to the engine will cause abnormal temperature

increases in the block of the engine. Decrease the load

gradually when stopping the engine. Also, never stop the

engine with the decompression lever.

Set the fuel cock at “S” (stop position)

If the engine comes with an electric starter, turn the starting switch to the “Off”position.

Pull the recoil handle slowly until pressure is felt by your hand, this means the piston is on the

compression stroke; where the intake and exhaust valves arc closed and then let the handle

recoil back into the engine. This natural position will prevent rust from occurring when the

engine is being stored for long periods of time. Perform these steps only when the engine is

off; doing so otherwise will damage the engine.

MAINTENANCE

Oil check

During operation, it is a good idea to check the oil every morning to ensure the engine has

sufficient oil.

CHECK OIL EVERY MORNIING

Oil change

Engine oil is a critical factor in determining the life of your engine. Change the engine oil on

time. Change the engine oil more frequently if the engine is used in dusty areas.

Changing the oil while the engine is still warm will yield best results for the engine. When the

oil is still warm, you get rapid and complete draining of the oil.

Oil change procedures

● Remove the oil filler cap and drain plug to drain the oil

● Install the drain plug, and tighten it securely.

● Refill with the recommended oil and check the oil level.

● Install the oil filler cap.

Note: Do not touch motor oil for long periods of time. Used motor oil can cause skin cancer if

it comes in contact with the skin for prolonged periods of time. Getting cancer from used

motor oil is unlikely unless you handle used motor oil on a daily basis. To be safe always

wash your hands thoroughly with soap and water as soon as possible after handling used oil.

Below a maintenance schedule table is provided.

Time

Item Daily

After 20 hours

or 1 month

100 Hours or Every

3 month

500 Hours or

Every 6 month

1000 Hours or

Every year

Check and tighten the nut and screw ○

Check and fill machine oil ○

Change machine oil ○

(First time)

○

(Second time and later)

Clean and change oil filter ○●

(Change)

Check oil-leakage ○

Change the core of air filter Cycle of check and main-tenance will

be shortened at dusty place. ○

Clean fuel tank Every month

Clean or chane fuel filter ○

(Clean)

○

(Change)

Check nozzle ●

Check injection pump ●

Check pipeline of fuel

○

(Change if

necessary)

Adjust value clearance of inlet and

exhaust ●

(First time)

●

Grind value holder of inlet and exhaust ●

Change piston ring ●

Check accumulator liquid each month

Clean the core of air filter

○

(Clean)

Every month or 50 hours

Air filter service

A dirty or clogged air filter will prevent air from flowing freely into the carburetor assembly.

Always keep the air filter clean or replace if necessary. Also, if the air filter is dirty or

clogged, the performance of the engine goes down. If operating the engine in a dusty area,

service the air filter more frequently as dust particles will clog the filter at a faster rate. Never

run the engine without an air filter, dust particles may get into the intake system and damage

the engine. Rapid engine wear will occur if the engine is run without the air filter.

Table of contents

Popular Water Pump manuals by other brands

Grundfos

Grundfos seg autoadapt Installation and operating instructions

Pfeiffer Vacuum

Pfeiffer Vacuum Pascal Series Maintenance Instruction

Alcatel Vacuum Technology

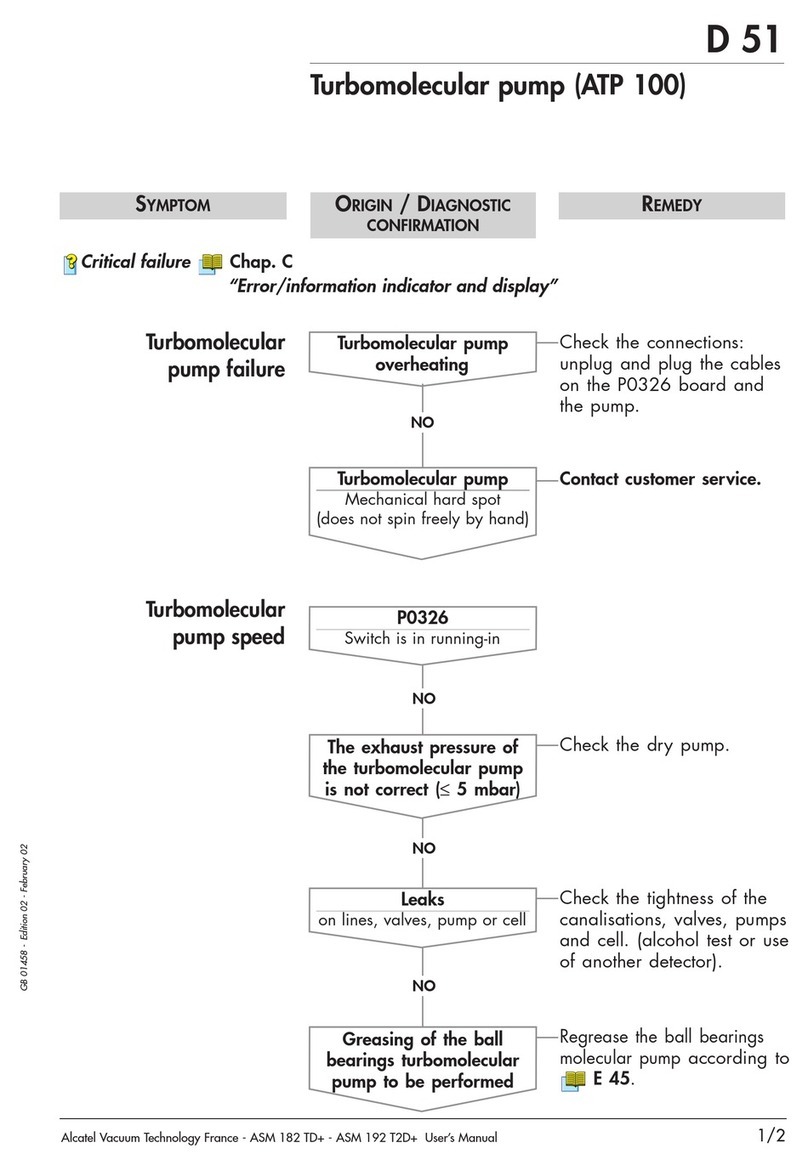

Alcatel Vacuum Technology ATP 100 Service manual & troubleshooting guide

T.I.P.

T.I.P. WPZ 450 R operating instructions

Trotec

Trotec TDP 370 E Original instructions

Pentair

Pentair Myers AWS-1 Installation and service manual

PSG Dover

PSG Dover All-Flo S050 Installation operation & maintenance

Profi-pumpe

Profi-pumpe INVERT-TECH 2 operating instructions

Pentair

Pentair VERSAILLES 160/8 instruction manual

Burcam

Burcam 506518SS installation instructions

Varian

Varian Turbo-V 1000HT instruction manual

IMER

IMER PRESTIGE Operating, maintenance, spare parts manual