SITECNA 04 Series Manual

Flow Regulator

Series 04, 06, 08, 12, 16

1/4”, 3/8”, 1/2”, 3/4”, 1”NPT

Installation, Regulation and

Maintenance Instructions

Sitecna Srl a Socio Unico

Via G. Di Vittorio, 22

20068 Peschira Borromeo

Milano - ITALY

Tel. +39 025475482

Fax +39 0255303713

E-mail [email protected]

Web www.sitecna.eu

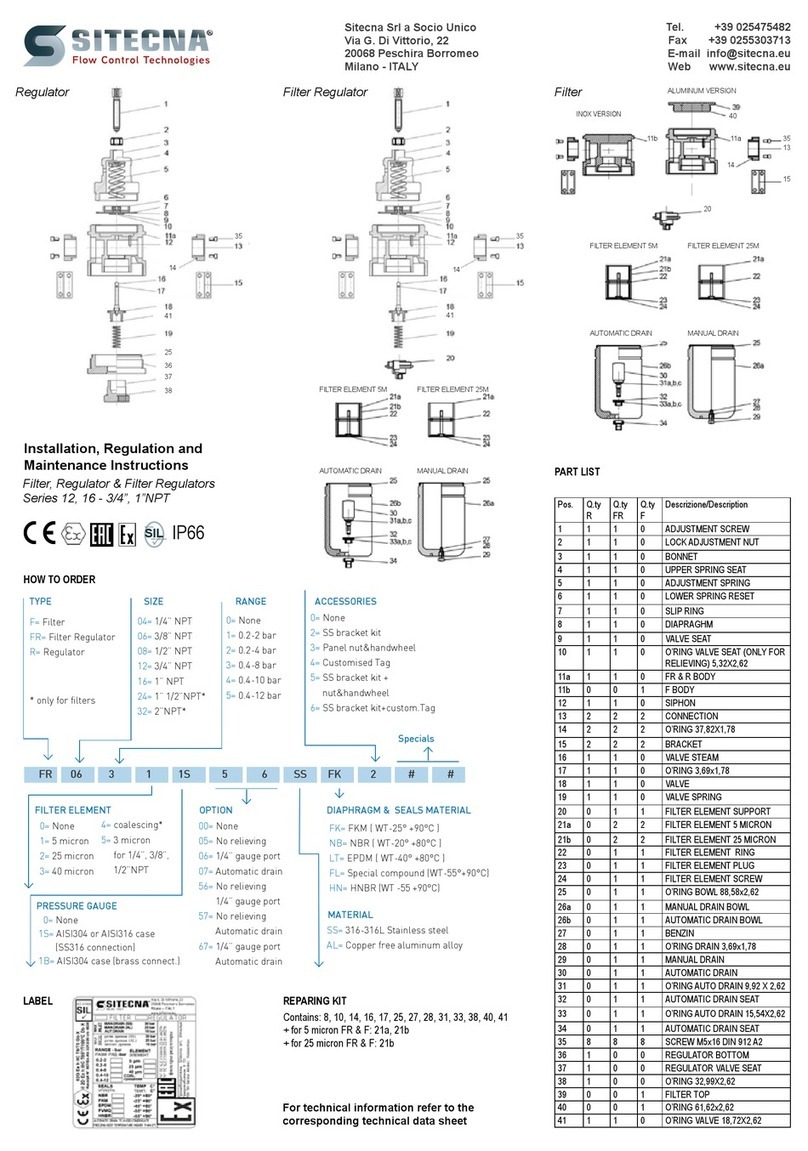

PART LIST

HOW TO ORDER

For technical info refer

to the corresponding

technical data sheet

Unidirectional Bidirectional Bidirectional + vent

1

2

3

5

6

8

4

7

14 15

Pos. Q.ty

RFU

Q.TY

RFB

Q.TY

RFB/V

Descrizione/Description

1 1 1 1 ADJUSTING KNOB

2 1 1 1 LOCKING RING

3 1 1 1 ADJ. SCREW SEAT

4 1 1 1 O’RING 12,42 X 1,78

5 1 1 1 NEEDLE

6 1 1 1 O’RING 6,07 X 1,78

7 1 1 1 O’RING 3,69 X 1,78

8a 1 0 0 BODY UNIDIRECTIONAL

8b 0 1 0 BODY BIDIRECTIONAL

8c 0 0 1 BODY VENT VERSION

9 1 0 0 VALVE

10 1 0 0 O-RING 4,48 X 1,78

11 1 0 0 VALVE SPRING

12 1 0 0 O-RING 12,42 X 1,78

13 1 0 0 PLUG

14 1 0 1 PLUG VENT VERSION

15 1 0 1 O-RING 4,48 X 1,78

Unidirectional Unidirectional

Bidirectional Bidirectional

Pos. Q.ty

RFU

Q.TY

RFB

Descrizione/Description

1 1 1 ADJ. SCREW SEAT

2 1 1 O’RING 23,47 X 2,62

3 1 1 NEEDLE

4 1 1 O’RING 12,42 X 1,78

5 1 1 O’RING 9,25X1,78

6a 1 0 BODY UNIDIR. 3/8”N

6b 0 1 BODY BIDIR. 3/8”N

7 1 0 DIAPHRAGM

8 1 0 SHUTTER

9 1 0 VALVE SPRING

10 1 0 PLUG

11 1 0 O’RING 23,47 X 2,62

1

2

3

4

5

6

7

1

2

3

4

5

7

8

9

10

11

12

Pos. Q.ty RFU Q.TY RFB Descrizione/Description

1 1 1 NUT M10

2 1 1 ADJ. SCREW SEAT

3 1 1 O’ RING 36,17 X 2,62

4 1 1 NEEDLE

5 1 1 O’RING 21,95 X 1,78

6 1 1 DIAPHRAGM

7a 1 0 BODY UNIDIR.

7b 0 1 BODY BIDIR.

8 1 0 DIAPHRAGM

9 1 0 SHUTTER

10 1 0 VALVE SPRING

11 1 0 PLUG

12 1 0 O’ RING 36,17 X 2,62

MODEL 04 - SIZE 1/4”NPTMODEL 06, 08 - SIZE 3/8”, 1/2”NPT

MODEL 12, 16 - SIZE 3/4”, 1”NPT

PART LIST PART LIST

RFU 04N SS FK

02N= 1/8” NPT

04N= 1/4” NPT

06N= 3/8” NPT

08N= 1/2” NPT

12N= 3/4” NPT

16N= 1” NPT

MATERIAL DIAPHRAGM & SEALS MATERIAL

SIZE

SS= 316-316L

Stainless steel

AL= Copper free

aluminum alloy

FK= FKM ( WT-25° +90°C )

NB= NBR ( WT-20° +80°C )

LT= EPDM ( WT-40° +80°C )

FL= FVMQ (WT-55°+90°C)

HN= HNBR (WT -55° +90°C)

RFU = uni-directional flow

regulator

RFB = bi-directional flow

regulator

TYPE

K-RF-04-SS-**

for RF 1/4”NPT

contains:

4, 6, 7, 10, 12, 15

K-RF-08-SS-**

for RF 3/8, 1/2”NPT

contains:

2, 4, 5, 11

K-RF-16-SS-**

for RF 3/4, 1”NPT

contains:

3, 5, 12

** Refers to seals type:

FK>FKM NB>NBR

LT>EPDM FL>FVMQ

HN>HNBR

** Refers to seals type:

FK>FKM NB>NBR

LT>EPDM FL>FVMQ

HN>HNBR

** Refers to seals type:

FK>FKM NB>NBR

LT>EPDM FL>FVMQ

HN>HNBR

6

REPAIR KIT 1/4”NPT

REPAIR KIT 3/8”, 1/2”NPT

REPAIR KIT 3/4”, 1”NPT

1

2

3

4

5

6

7

1

2

3

4

5

7

8

9

10

11

12

1.INTRODUCTION

Throughout this manual there are a number of HAZARD

WARNINGS that must be read and adhered to in order to

prevent possible personal injury and/or damage to equi-

pment. Three signal work “DANGER”, “WARNING” and

“CAUTION” are used to indicate the severity of a hazard,

and are preceded by the safety alert symbol.

Danger Denotes the most serious hazard and is

used when serious injury or death WILL result from misuse

or failure to follow specic instructions.

Warning Used when serious injury or death MAY

result from misuse or failure to follow specic instructions.

Caution Used when injury or product/equipment

damage may result from misuse or failure to follow specic

instructions.

Caution It is the responsibility and duty of

Warning all personnel involved in the installation,

Danger operation and maintenance of the equi-

pment on which this device is used, to fully understand the

procedures by which hazards can be avoided.

The compatibility of the product is the responsibility of

the person who designs the equipment or decides its

specications.

Only personnel with appropriate training should operate

machinery and equipment.

Do not service or attempt to remove the machinery or

equipment until safety is conrmed.

2.DESCRIPTION

The Flow regulators are generally used to control the

outow of a media. A typical application is the speed control

of an actuator. A complete range of needle valves and ow

regulators provides a variety of choices between uni or

bidirectional versions and different precision features.

3. OPERATION

Adjusting the speed of actuator by opening the needle

slowly after having closed it completely. Loose of needle

valve may cause unexpected sudden actuator extension.

Turning clockwise the adjustment knob the quantity of ow

passing through the regulator decreases. Turning the adju-

sting knob counter clockwise, you increase the quantity of

ow through the ow regulator.

When needle valve is turned counter‐clockwise it is open

and cylinder speed increase.

The ow rate is adjusted in the direction indicated by the

arrow. In the direction opposite the ow, typically to cylinder

supply, is free and not adjusted.

If the cylinder pressure falls below the inlet pressure, the

pressure differential on the diaphragm will close the exhaust

Port 3, preventing further exhaust.

Fig.2 Bidirectional RF

4. PNEUMATIC DIAGHRAM

Fig.1 Unidirectional RF

5. TECHNICAL FEATURES

Medium: compressed air or inert gases, ltered, lubricated

and not lubricated

Port thread: 1/8”, 1/4”, 3/8”, 1/2, 3/4”, 1” NPT

Max pressure: 12bar

Materials: Body - SS316L or Aluminum alloy

Internal parts: SS316 or galvanized steel (all vers)

6.TRANSPORTATION & STORAGE

The preferred storage location is a clean, dry and protected

warehouse. If the components have to be stored outside,

precautions should be taken to keep valves clean and dry.

For storage temperatures, refer to the table in paragraph

“TECHNICAL FEATURS”.

To avoid contamination of impurities during the storage period,

don’t remove thread protection caps; remove them just before

the installation phase.

7. INSTALLATION

Warning Before performing any work, read this ma-

nual and study all gures. Assure yourself that you understand

and you can do what is required in each step. Failure to follow

these instructions may affect quick release valve operation and

may result in exposure to personal injury.

Before installing the valve, set and block the machine or equi-

pment in a secure position; close the air shutoff valve and

exhaust air from air lines and disconnect all electrical power.

• Please operate within the range of specied capacity in the

manual. If exceeded, the product can be damaged and may

result in serious damages and accidents.

• Make sure to use pressure reading device when setting pres-

sure level.

• Install in correct order when other devices are being operated.

8. MOUNTING

• Any direction

• With air ow in direction of arrow according to label.

• Connect piping to proper ports using pipe thread sealant on

male threads only. Do not allow sealant to enter interior of

unit.

9. TESTING

• Apply inlet pressure, then turn adjustment (1) clockwise to

decrease and counterclockwise to increase outlet pressure

setting.

• Once required pressure is achieved tighten locknut (2) to

lock setting.

NOTE

Warning In option has a “Anti-tamper system” to

avoid the un-authorized modication of the setting. This option

is mandatory for safety related applications.

10. MAINTENANCE

Warning Before performing any work, read this ma-

nual and study all gures. Assure yourself that you understand

and can do what is required in each step. Failure to follow these

instructions may affect quick release valve operation and may

result in exposure to personal injury.

Before uninstalling the valve, set and block the machine or

equipment in a secure position; close the air shutoff valve and

exhaust air from air lines; disconnect all electrical power.

• Shut off inlet pressure. Reduce pressure in inlet and outlet

lines to zero.

• Turn adjustment screw fully counter clockwise.

• Disassemble in general accordance with the item numbers

on exploded view.

A.Ordinary maintenance

Caution The RF should be periodically checked for

proper functioning:

• Clean the RF from impurities and dirt;

• Visually check of the integrity of the body of RF;

• Check that there aren’t leakages;

• Check the correct functionality of the RF.

C. Assembly/Disassembly

• Assemble/disassamble the unit as shown on the exploded

view.

D. Repair Kit

K-RF-*-SS-**

* Refers to size: 04>for RF 1/4”NPT;

08> for RF 3/8”, 1/2”NPT; 16> Rfor F 3/4”, 1”NPT

** Refers to seals type: FK>FKM NB>NBR

LT>EPDM FL>FVMQ HN>HNBR

Too see part included see other page.

11. MARKING ACORDING TO 2014/34/UEAtex

For using these equipment in potentially explosive

atmospheres, it is recommended - for the installation and the

maintenance operation - to use tools and instruments that

can produce only a single spark (for instance: screwdrivers,

spanners). Avoid use of tools that can produce sparks like

disk saw or grinder

Action must be taken to put to earth the units through a

suitable connection, checking that all the metal components

(ttings and pipe line) have to be equitable potential.

Equipment have to be installed in the corresponding zone

according to the marking.

II 2G Ex h IIC T6/T5 Gb X

II 2D Ex h IIIC T85°C/T100°C Db X

AISI316 and Aluminium Flow Regulator - 04, 06, 08, 12,16

INSTALLATION, REGULATION & MAINTENANCE INSTRUCTIONS

NOTE: special conditions for safe use

Before performing any work, read this manual and assure

yourself you understand. X at the end of ATEX sobstitutes

T amb for series VB, DP, VSR, RF, LK, SCLP, TF, FLGSS, VP,

SLHF, SLVP, SLSC, PV. T amb depends on used seals,

based on the following correspondance:

NBR=-20°C...+80°C, FMK=-25°C...+90°C,

EPDM= -40°C...+80°C, FVMQ & HNBR= -55°C...+90°C

MATERIAL TEMPERATURE

DIAPHRAGM SEALS TRANSPORT STORAGE OPERATING

NBR NBR -20°C...+80°C -20°C...+80°C -20°C...+80°C

FKM FKM -25°C...+90°C -25°C...+90°C -25°C...+90°C

EPDM EPDM -40°C...+80°C -40°C...+80°C -40°C...+80°C

FVMQ FVMQ -55°C...+90°C -55°C...+90°C -55°C...+90°C

HNBR HNBR -55°C...+90°C -55°C...+90°C -55°C...+90°C

FRONT

FRONT

BACK

BACK

Unidirectional

Unidirectional

Bidirectional

Bidirectional

1/4”NPT Unidirectional

1/4”NPT Bidirectional

3/8”,1/2”NPT

3/4”,1”NPT

20

LABELS

Sitecna Srl a socio unico

Via G. Di Vittorio, 22

20068 Peschiera Borromeo

Milano - Italy ( Europe)

Milano –Italy ( Europe)

P.IVA/C.FISC. 08973090155

NR MECC. MI253803

C.C.I.A.A. 1259759

Dichiarazione di conformità UE

In accordo con la Direttiva Europea 2014/34/UE

EU-Declaration of Conformity

In accordance with Directive 2014/34/EU

Noi, Sitecna Srl, dichiariamo che i seguenti prodotti / Sitecna Srl declares that the following equipment:

Product

mod.

Product

mod.

Product

mod.

Filter

F…

Volume Booster

VB…

Flow regulator

RFB…, RFU…

Regulator

R…

Control spool valve

DP…

Glass tube flowmeter

FLGSS…

Filter Regulator

FR…

Quick exhaust valve

VSR…

Vacuum pump

ST-VP…

Back Pressure valve

BP

Lock-up valve

LK…

Silencer

SLHF…, SLVP…, SLSC…

2 ways switching valve

SV…

Overload protector

SCLP…

Dust excluder

PV…, PVSL…

3 ways switching valve

S3…

Tee Filter

TF

Pressure gauge

MBSS…, MBS6…, MBSN…

Sono conformi alla normativa di armonizzazione dell’Unione / They comply with the Union harmonization legislation:

Direttiva 2014/34/UE ATEX

Direttiva 2014/34/UE del Parlamento europeo e del Consiglio, del 26 febbraio 2014,

concernente l’armonizzazione delle legislazioni degli Stati membri relative agli

apparecchi e sistemi di protezione destinati a essere utilizzati in atmosfera

potenzialmente esplosiva (rifusione) Testo rilevante ai fini del SEE.

Directive 2014/34/EU of the European Parliament and of the Council of 26 February

2014 on the harmonisation of the laws of the Member States relating to equipment and

protective systems intended for use in potentially explosive atmospheres (recast) Text

with EEA relevance.

Secondo le seguenti Norme di riferimento / As per folowing reference Normative Documents:

EN ISO 80079-36:2016

Atmosfere esplosive - Apparecchi non elettrici per atmosfere esplosive -

Metodo di base e requisiti

Explosive atmospheres - Non-Electrical equipment for explosive atmospheres - Basic

method and requirements

EN ISO 80079-37:2016

Atmosfere esplosive - Apparecchi non elettrici per atmosfere esplosive –

Tipo di protezione non elettrica per sicurezza costruttiva "c", per controllo della sorgente

di accensione "b", per immersione in liquido "k"

Explosive atmospheres - Non-Electrical equipment for explosive atmospheres - Non-

electrical type of protection constructional safety ''c'', control of ignition sources ''b'', liquid

immersion ''k''

N 1127-1:2011

Atmosfere esplosive - Prevenzione dell’esplosione e protezione contro l’esplosione -

Concetti fondamentali e metodologia

Explosive atmospheres - Explosion prevention and protection - Basic concepts and

methodology

Ai sensi della Direttiva 2014/34/EU, i prodotti sopra indicati riportano la seguente marcatura / According to the Directive 2014/34/EU,

above mentioned products reports the following marking:

II 2G Ex h IIC T6/T5 Gb X

II 2D Ex h IIIC T85°C/T100°C Db X

Inoltre, ai sensi della direttiva 2014/34/UE, i prodotti sopra menzionati sono oggetto, per gli aspetti relativi sia alla progettazione sia alla fabbrica-

zione, al controllo interno di fabbricazione (Allegato VIII –Modulo A). Ref 557/Ex-Ab 3213/20 c/o N° 0035 TÜV Rheinland.

In conformity to Directive 2014/34/EU, the afore mentioned equipment, regarding their design and production, are object to internal manufacturing

check (Attachment VIII –Module A). Ref 557/Ex-Ab 3213/20 c/o N° 0035 TÜV Rheinland.

La presente dichiarazione di conformità è rilasciata sotto

la responsabilità esclusiva del fabbricante.

This declaration of conformity is issued under exclusive

responsibility of the manufacturer.

Milan, 20/05/2020

Davide Matteo De Corrado

Managing Director

Trace No: xxxx

This manual suits for next models

4

Other SITECNA Controllers manuals

Popular Controllers manuals by other brands

Regada

Regada SO 2 Installation, service and maintenance instructions

Votronic

Votronic VPC Terra Installation and operating manual

B+B Sensors

B+B Sensors WLS-GEH230V Operation manual

Ecojay

Ecojay SmartZone ZS4X-2.0 Installation & operation

JOSTechnik

JOSTechnik HK2.0-R Series Original operating instructions

Sun Yeh Electrical

Sun Yeh Electrical S Series Operation manual