Sitron SP10 User manual

USER MANUAL

Installation, Operation and Maintenance Manual

Pressure Transmitters

Series: SP

02

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models & Dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Technical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Sitron-USA - Phone (516) 935-8001 / Fax (800) 516-1656

03

Introduction

Characteristics

The SP Series of pressure transmitters are designed to measure the level or pressure of

various industrial processes.

Models can be mounted with various threaded or flanged process connections. All

models are available with 4..20mA (2 wire) output (or voltage outputs). The SP/FA line

coms with an integrated Zero and Span adjustment. All units offer excellent stability,

repeatibility, accuracy and temperature compensation. HART communications protocol

is also available for many models.

Each model in this series is offered in pressure ranges that are suitable for various types

of application requirements such as for; liquids, gases, areas with limited space, food

industry, chemical industry or areas that feature aggressive mediums or waste fluids with

varying degrees of suspended solids.

Technology

The SP series utilize the principle of the alteration of resistance or capacitance. The SP

Series is available with sensing elements of either 316 Stainless Steel, ceramic

piezoresistive diaphragms or thick filmed ceramic diaphragms (for more aggressive

mediums or applications).

The external pressure of the medium induces a dislocation of electrical load that

accumulates on the opposite surface of the diaphragm, resulting in an output signal that is

proportional to the pre-calibrated pressure range of the sensor. The electronics converts

this information into either a 4...20mA(2 wire) output signal (standard) or a 1 to 5V (3 wire

optional per custom order), which is directly proportional to the applied pressure of the

process.

Small, robust and easy to install

Reliable measurement of level and pressure.

HART Communications Protocol is available (for most models)

Available in a wide range of process connections: Threaded, Flanged or Sanitary

SP Series

Pressure Transmitter

Pressure range up to 1000 Bar (14500 PSI) depending on the model

04

Models & Dimensions

SP21

103

1/4”NPT/BSP

34

Hex.15/16”

15

34

Threaded

Pressure transmitters models (unit: mm)

26.5

37

12.5

9.5

23,5

51

101

34

26.5

2” Tri-clamp

1/4” to ½”

1/4” to 1.1/2”

or 2” TC Hex. 1”

19mm

10mm

1/2”NPT/BSP

1.1/2” 50.8

2” 64

25mm

SP21 Adapter

26.5

Ø

111

SP68

NPT/BSP

NPT/BSP

SP30

SP10

05

Models & Dimensions

SP96 (unit: mm)

Standard

1 ½ or 2” TC

NPT/BSP

38

83

38

50

28

84

19

Hex.

72

93

36

35

DIN connector M12 connector

1 ½” 50.8

2” 64

1 ½” 50.8

2” 64

NPT/BSP

Standard

1 ½ or 2” TC

103

19

87

1 ½” 50.8

2” 64

35

36

M12 connector

Threaded

1 ½ or 2” TC

NPT/BSP

SP98 (unit: mm)

93

29

Hex. 1 1/2”

BSP / NPT

Hex. 1 5/8”

1” BSP / NPT

29

77

SP81

M12 connector

06

42

1 ½” 50,8

2” 64

77

89

44

19

Hex.1 5/8”

NPT/BSP

80

SP98FA with Housing

Threaded 1 ½ or 2” TC

Threaded 1 ½ or 2” TC

31

37 77

89

NPT/BSP

1 ½” 50,8

2” 64

80

SP96FA with Housing

Models & Dimensions

Threaded Connections

3/4”

1 ½”

1 ½”

1 ½”

2 ½”

2 ½”

1”

2”

2”

2”

3”

1”

1,75º

Tri-Clamp Connection Flange Connections

Process Connections

TC Connection

ANSI 150#

ANSI 300#

Rubber Seal

Process Connection

NPT BSP FF

RF

24

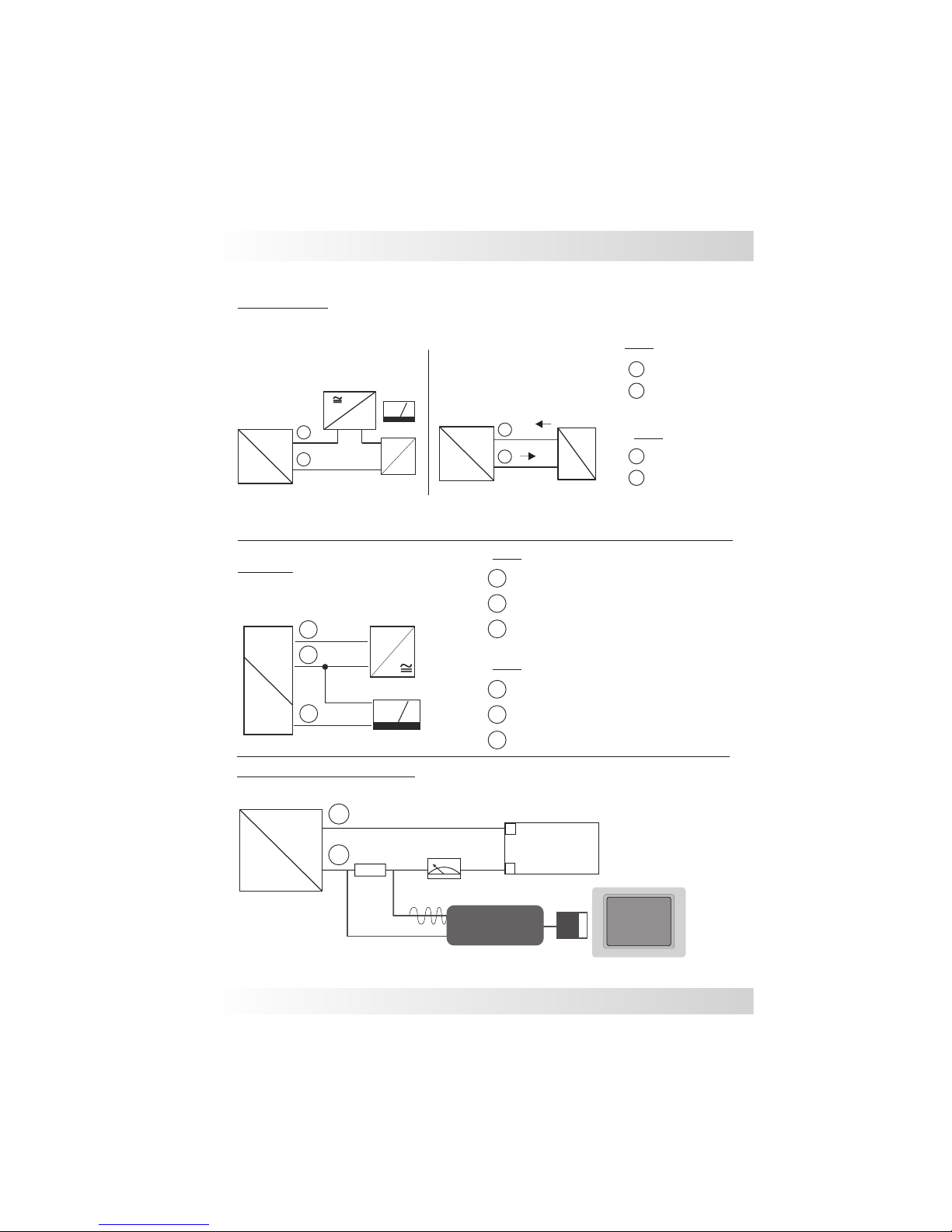

Input

Active

+-

1

4 ... 20 mA

+

_

2

24Vdc

4...20mA (2 wires)

Active

4

2

13

DIN 43650 connector

2 and 3 wires

1

3

-

+ Out

Passive

4...20mA

4...20mA (2 wires)

Passive

1

-

4...20mA

Electrical Connections

1...5Vdc

+

Supply

3

4

Supply

1...5Vdc (3 wires)

2

Out

+

-

1

243

Pressure

Transmitter

+

_

2

07

M12 connector

2 and 3 wires

1

-

+ Out

2

3

1

+

S

_

Pressure

Transmitter

Pressure

Transmitter

08

Electrical Connections

‘

2

3

1

+

S

_

+

-

1...5Vdc

Pressure

transmitter Supply

Vdc

Red (+)

Green (-)

SP10 & SP68

2

1Red (+)

Black (-)

SP10

SP68

HART Modem connection

4...20mA (2 wires)

Passive

+-

1

Supply

+

_

24...20mA

Passive Input

Active

+-

1

4 ... 20 mA

+

_

2

24Vdc

4...20mA (2 wires)

Active

2

1

3

2

1Red (+)

Black (-)

Yellow (Out) 3 wires

SP68

3

2

1Red (+)

Green (-)

Yellow (Out) 3 wires

SP10

4...20mA

Pressure

transmitter

Pressure

transmitter

PC Software

+

2

_

1

Transmitter

®

250?

Padrão Hart modem

PC

+

-

••

USB

Power

Supply

HART

Modem

4...20mA

09

SP96FA & SP98FA

-

Supply

+

+

4...20mA

12 15 18 21 24 27 30 [V]

0

Load max. [Ù]

500

400

300

200

100

SP96FA

0

1200

1000

800

600

400

200

Load max. [Ù]

12 16 20 24 28 32 36[V]

SP98FA

ZS

ZS

Zero & Span adjustment

Supply

Load impedance

4...20mA (2 wires)

Electrical Connections

10

1) Use PTFE tape or o'rings to seal the system.

2) Before installing, make sure the cable connections are

correct and that the line voltage is compatible with the

specifications of the equipment. Use reliable cables and

make sure that they are grounded. Shielded cables

prevent interference and changes in the eletronic signal,

protecting against false measurement output. Avoid

radio frequency interference as it may also cause false

signals and even create a possible malfunction of the

transmitter. When possible, keep hand held

communication equipment away from the SP transmitter.

3) Care should be taken to prevent deformities in the

membrane. You should also be careful not to touch or let

any other object touch the membrane of the sensor

during installation (this does not apply to the units with

ceramic sensing elements) . Any deformity to the surface

of the 316SS silicone filled membrane will damage the

sensor and impair its operation.

Transmitters with cable gland:

Tighten the cable gland as much as possible so that the

cable is securely in place and cannot be pulled through

the cable gland. This will help insure that no moisture is

able to infiltrate into the housing. Don´t forget to attach

the housing cover and tighten all three screws into

position so that there is no infiltration.

4) Protect the transmitter against rain and do not expose it

to excessive heat. Respect the working temperature and

the class protection specified for use.

5) Before installation, for security reasons, make sure the

tank or pipe is empty and without pressure.

6) For transmitters with sealing:

Under no circunstances should you remove the

transmitter seal. Avoid flexing the membrane with your

hands and keep it protected until the installation.

Mounting Notes

11

The transmitters can be installed in various

positions, but the following needs to be taken into

account: For level measurement the installation

should be at the base of the tank or at the point of

minimum level measurement (fig.1). This means

that the reference point for the base measurement

will become the point at which the sensor is

installed which will not necessarily be at the

bottom of the tank.

It is advisable to install a blocking valve between

the transmitter and the connection to perform

maintenance without having to stop the process.

Avoid installing in the tank outlet or near shaker

where there is pressure pulses thus preventing

rapid changes in the signal. For this case it is

necessary the use of still-pipe (Stilling tube) to

absorb the liquid surfaces (Fig. 2).

Min.

Max.

Valve

Height “h”

4...20mA

Base

atm

Pressure

Principle of Operations

The weight of the column of liquid

generates hydrostatic pressure on the

diaphragm of the sensor. When the

density of the product is constant and

the quantity of the liquid is increased

or decreases, there will be a

proportional output from the sensor .

Fig.2

Fig.1

Density

Specific Gravity

Pump

Pressure of the Liquid Column

Water Column

P(mH2O)= relative density.h(m)

System MKS

P(KPa)= density(Kg/m3). g(m/s). h(m)

System MKgfs

P(Kgf/m2)= Specific Gravity(Kg/m3). h(m)

Installation

12

Installation

In situations where the tank is suspended, the

transmitter should always be installed in a point

below the connection using the sealing system

with capillary connection. This type of installation

is required when you want to mount the

transmitter in a better position for viewing (Fig. 3) .

Note: Evaluate what type of product is to be

measured. Aggressive products can damage the

membrane of the sensor element or of the o´ring

seal. That is why it is necessary to determine the

compatability of the product before the unit is

purchased and installed. (Fig. 4).

Install the transmitter so that the electrical cable

dips below the transmitter (or makes a "U") so that

water can drain off the cable without the risk of

infiltrating into the transmitter (Fig 5).

Use a cable with vent tube for all Sitron transmitter

models so that the linearity of the output signal and

the operation of the unit is not compromised (this

special cable can also be provided by Sitron) (Fig.

7).

Avoid installing the transmitter underneath a tank

or were splashing or overflow of the product might

damage the unit. If this is unavoidable, install a

barrier to protect the unit from the product

infiltrating from the outside of the transmitter.

This may also be recommended when the

installation is in an open environment. Weather

variations can create internal condensation, so it

is best to avoid exposing the transmitter to direct

Min.

Max.

height “h”

Sealing

Cappilary

Membrane

Seal

Flange

Fig. 4

Fig. 3

Fig. 5

Fig. 7

Filter

Vent tube

Fig. 6

13

Calibration

Z(zero)

S(span)

Fig.2

Fig.1

SP98FA and SP96FA

Before the calibration of the unit is first tested,

the process should be free of pressure or (if

that is not possible) the unit should first be

tested outside of the vessel.

Make sure the muliti-meter is correctly

connected in series with the source and the

instrument. The scale should be set to mA

First confirm that the current output is at 4mA

(for SPFA units you can adjust the trimpot

"zero".) Turning the trimpot clockwise

increases the current value, and turning it

counterclockwise decreases the value

(Fig.2).

After adjusting (if necessary) the 4mA (zero)

install the unit in the process or fill the vessel

to increase the pressure of the process to the

maximum level desired. If necessary, turn the

trimpot (Span) to adjust the 20mA signal

(Fig. 3).

After calibrating the unit for the first time, it is

recommended that the you re-check the zero

and span ouput with your multimeter. This will

confirm that the unit is properly calibrated or if

further adjustment is necessary.

14

Seal the thread with Teflon tape before

installation.

(Fig. 1).

When tightening the sensor, use only use the

316S.S. hexagon fitting to achieve a seal, do not

twist with the body of the sensor.

The transmitter should not be dropped or suffer

any impact or fall, as this can damage the

electronics or the sensor (Fig.3).

Electrical connection with DIN connector:

Figure 4. Shows the steps for proper assembly of

the connector. When you tighten the threaded

part, stop once you feel that the rubber seal is at its

maximum compression point. Do not over-tighten

the thread. It is very important that the connector is

securely sealed so that the class protection is

maintained and no infiltration occurs.

Do not turn or handle by the housing

(Fig. 2).

Do not insert any object into the entry point of the

transmitter supply. This will immediately damage

the membrane.

Fig. 1

Fig. 2

Fig. 3

Handling

Rubber seal connection

Screw

Screw O’ring

Cable seal

Cable gland

Enclosure

Fig.4

Cable

Cable

Vent tube

Vent tube

15

Ceramic capacitive

Cable gland ½”NPT

4...20mA (2 wires )

-1 to 40 Bar

IP 65

22mA max.

316 SS

-10 to +80ºC

12...30Vdc

3 x F.S.

+/- 0.5%

SP98FA

ZS

Fiberglass Nylon

Zero & Span

N1

BSP or NPT - flange or sanitary

Technical Specifications

Housing

Adjustment

Application

Power supply

Consumption

Output

Accuracy

Sensor type

Range

Electrical connection

Process connection

Body material

Work temperature

Over pressure

Class protection

Pressure and Level measurement for liquids and gas

16

Technical Specifications

316 SS piezoresisitve silicon

4...20mA (2 wires )

-1 to 200 Bar

IP 65

22mA max.

316 SS

-10 to +80ºC

12...30Vdc

3 x F.S.

+/- 0.5%

SP96FA

ZS

Housing Fiberglass Nylon

Adjustment Zero & Span

N1

Cable gland ½”NPT

BSP or NPT - flange or sanitary

Application

Power supply

Consumption

Output

Accuracy

Sensor type

Range

Electrical connection

Process connection

Body material

Work temperature

Over pressure

Class protection

Pressure and Level measurement for liquids and gas

17

316 SS silicon piezoresistive

Polyethylene

4...20mA (2 wires )/ ,1...5V, 0...5V (3 wires)

0.1 to 1000 Bar

IP 68

22mA max.

304 SS

-10° to + 80°C

12...30Vdc

3 x F.S.

+/- 0.5%

SP68

M20*1.5” / 1/2”(BSP or NPT) (others)

Reverse polarity

3

2

1Red (+)

Black (-)

Yellow (Out) 3 wires

Technical Specifications

Application

Power supply

Consumption

Protection

Output

Accuracy

Sensor type

Range

Electrical connection

Process connection

Body material

Work temperature

Over pressure

Class protection

Pressure and Level measurement for liquids and gas

18

316 SS piezoresistive

Silicon or olive oil

DIN43650 or M12 connector

4...20mA (2 wires ) 0...4,5V (3 wires) upon request

0,1 to 1000 Bar

IP 65

22mA max.

304 SS

12...30Vdc

3 x F.S.

+/- 0,5%

SP30

M20*1.5 , 1/2” BSP or 2”TC

0 to +80ºC ( olive oil sensor)

-10° a + 80°C ( silicon sensor)

(-) Negativo

(+) Positivo

Out (V)

2

3

1

DIN 43650 Connector

1

3

4

2

( ) GND

4

Reversal polarity

Technical Specifications

Application

Power supply

Electrical connection

Process connection

Work temperature

Body material

Consumption

Sensor type

Protection

Accuracy

Range

Output

Class protection

Over pressure

Pressure and Level measurement for liquids and gas

19

316 SS silicon piezoresistive

Cable or M12 connector

4...20mA (2 wires ) 0...5 e 1...5V (3 wires)

0,2 to 250 Bar

IP 65

22mA max.

304 SS

-10 to +80ºC

12...30Vdc

3 x F.S.

+/- 0.5%

SP10

G1/4” / 1/4"-18 NPT / 1/8"-27 NPT / M14*1.5 /

M12*1.5 / 1/4"-19 PT / 7/16"-20 UNF (female)

3

2

1Red (+)

Green (-)

Yellow (Out) 3 wires

Reversal polarity

Technical Specifications

Application

Power supply

Electrical connection

Process connection

Work temperature

Body material

Consumption

Sensor type

Protection

Accuracy

Range

Output

Class protection

Over pressure

Pressure and Level measurement for liquids and gas

Accuracy

Range

Sensor type

Power supply

Application

Consumption

Output

Protection

4...20mA (2 wires ) 0,5...4,5/ 1...5V/ 0...5V (3 wires) upon request

Process connection

Electrical connection

BSP ou NPT - flange or sanitary

Work temperature

Class protection

Body material

Over pressure

SP21

316 SS silicon piezoresistive

DIN43650 or M12 connector

0.1 to 1000 Bar

22mA max.

12...30Vdc

2

Reverse polarity

+/- 0.25%

1

3

M12 connector

304 SS

-10° to + 80°C

DIN 43650 connector

2

Technical Specifications

IP 65 / IP66 / IP67

3 x F.S.

3

43

4

2

1

3

4

4

2

1

1

Out (V)

(-) Negative

(+) Positive

Out (V)

( ) GND

( ) GND

20

(-) Negative

(+) Positive

30mm

Ø

47mm

30mm

Ø

28mm

56mm

28mm

56mm

47mm

SP21 SP21- IP66

30mm

Ø

65mm 35mm

36mm

SP21- IP67

Hex. 1.1/16”

Pressure and Level measurement for liquids and gas

This manual suits for next models

8

Table of contents

Popular Transducer manuals by other brands

HBM

HBM U1A Mounting instructions

Daiichi Electronics

Daiichi Electronics FAETT2-92A-33 instruction manual

S+S Regeltechnik

S+S Regeltechnik PREMASGARD 111 Series Operating Instructions, Mounting & Installation

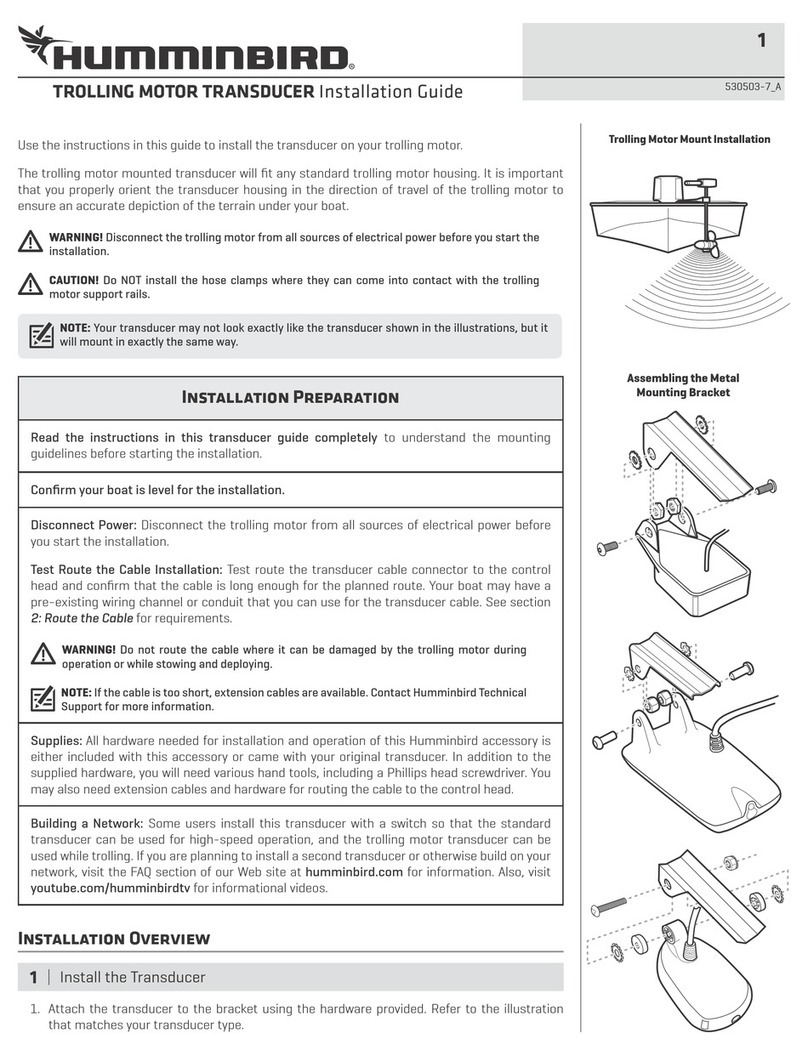

Humminbird

Humminbird TROLLING MOTOR TRANSDUCER installation guide

WIKA

WIKA F2802 operating instructions

JUMO

JUMO HC103 operating instructions