SJE Rhombus VARIOspeed Micro User manual

VARIOspeed Micro®

User Manual

22650 County Highway 6

n

PO Box 1708

n

Detroit Lakes, MN 56502

Phone 218-847-1317

n

Fax: 218-847-4617

www.sjerhombus.com

WARNINGS

Failure to read and understand the information provided in this manual may result in personal injury or

death, damage to the product or product failure. Please read each section in its entirety and be sure

you understand the information provided in the section and related sections before attempting any of

the procedures or operations given.

Failure to follow these precautions could result in serious injury or death. Keep these

instructions with warranty after installation. This product must be installed in accor-

dance with National Electrical Code, ANSI/NFPA 70 so as to prevent moisture from

entering or accumulating within the controller housing.

See additional specifications on page 6 of this manual.

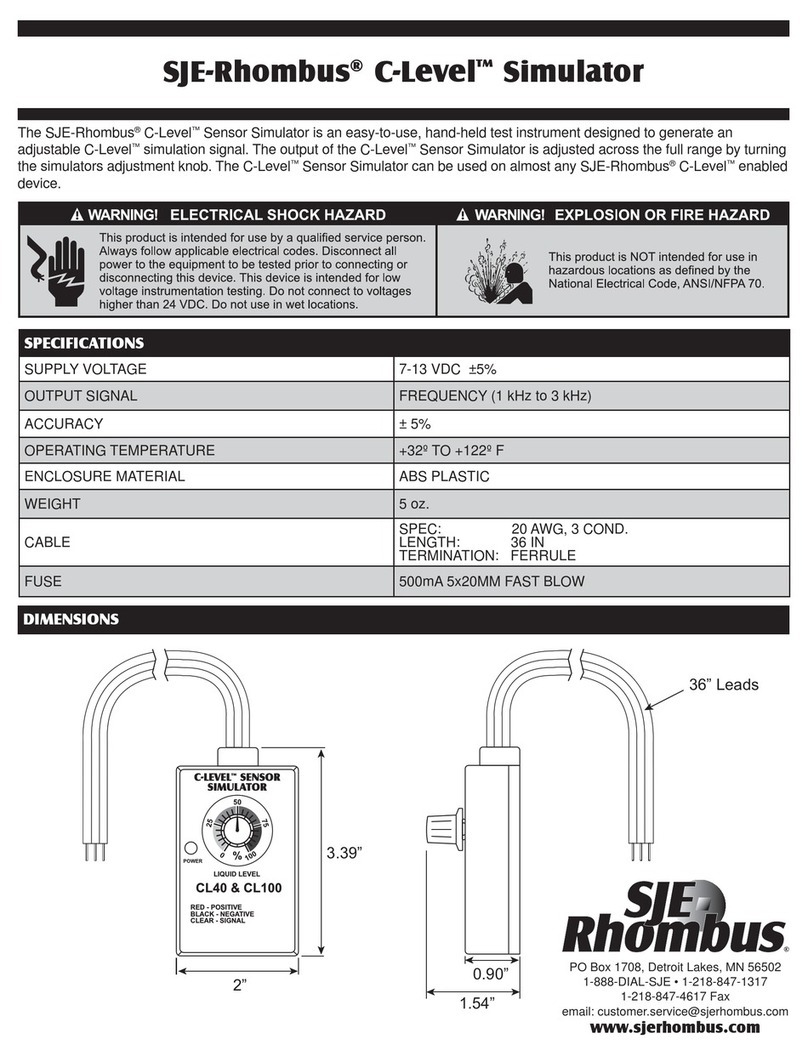

ELECTRICAL SHOCK HAZARD

Disconnect power to the VARIOspeed®MICRO VFD drive and wait 10

minutes before removing the terminal cover.

A qualified service person must install and service this product according

to applicable codes and electrical schematics.

EXPLOSION OR FIRE HAZARD

Do not use this product with flammable liquids. Do not install in

hazardous locations as defined by National Electrical Code,

ANSI/NFPA 70.

• Lethal voltages are still present inside the VARIOspeed®MICRO VFD drive after power

is disconnected. Wait 10 minutes to allow internal capacitors to fully discharge before

attempting to connect or disconnect wire or to service this equipment.

• Do not connect incoming power to motor terminals U, V, W. doing so will result in

irreversible damage to the drive.

• Do not connect power to this equipment if it has been damaged or has any missing parts.

• Do not apply power to the VARIOspeed®MICRO VFD drive with the terminal cover

removed.

• Verify that the incoming voltage supply is 230 VAC before applying power to the unit.

• The VARIOspeed®MICRO VFD drive contains no serviceable parts, do not attempt to repair

this equipment.

• The VARIOspeed®MICRO VFD drive must be grounded at the grounding terminal according

to N.E.C. Refer to the electrical connection on page 12.

• The VARIOspeed®MICRO VFD drive has been designed for indoor mounting only. Use the

optional NEMA 3R model for outdoor installations.

• Do not install in ares with: excessive or conductive dust, corrosive or flammable gas,

moisture or rain, excessive heat, regular impact shocks or excessive vibration.

• Do into install in areas where ambient temperature exceeds 40ºC (104ºF).

• HOT! Heat sink temperature may rise to 90ºC (194ºF). Do NOT touch heat sink.

Table of Contents

Introduction .................................................................................................2

Receiving and Preliminary Inspection ........................................................3

Specifications..............................................................................................4

System Setup Diagram for Deep Well Submersible .................................5

System Setup Diagram for Pressure Booster ............................................6

Pressure Tank/Pressure Relief Valve/Low Pressure..................................7

Outline Dimensions.....................................................................................8

Removing the cover to access the terminal blocks....................................8

Mounting .....................................................................................................9

Terminal Wiring Description......................................................................10

Grounding Method....................................................................................11

Filter Options ............................................................................................11

Display and Function Keys Overview.......................................................12

Display Description ...................................................................................12

Function Keys Operation ..........................................................................13

Changing the Set Pressure ......................................................................14

Changing Parameters...............................................................................14

Parameter List ..........................................................................................15

Detailed Parameter Functions ..................................................................16

Fault and Alarm Display & Solutions........................................................18

Causes of Malfunction/Troubleshooting ...................................................18

Warranty Information ................................................................................19

SJE-Rhombus®VARIOspeed®Micro Controller User Manual 1

Introduction

Congratulations, and thank you for your purchase of a VARIOspeed®MICRO series VFD. These

drives are indoor wall-mountable units designed for controlling water pumps in either deep well

applications, or pressure boosting centrifugal pump applications.

Product range

The VARIOspeed®MICRO D & D PLUS in either the 1hp or 2hp size are designed for deep well

submersible pumps and centrifugal pressure booster pumps using 230V single phase incoming

power, and are capable of controlling either single phase or three phase pumps by setting the

appropriate parameters.

Product Features

All VARIOspeed®MICRO series drives have a built-in PID function (non-adjustable) that varies

the speed (Hz) of the pump and provide optimal control for maintaining a constant pressure in a

variety of pumping applications. The information included in this manual will help you maximize the

performance of your VARIOspeed®MICRO VFD, and ensure safe operation of your pump system.

Please keep this manual for future reference.

2SJE-Rhombus®VARIOspeed®Micro Controller User Manual

Receiving and Preliminary Inspection

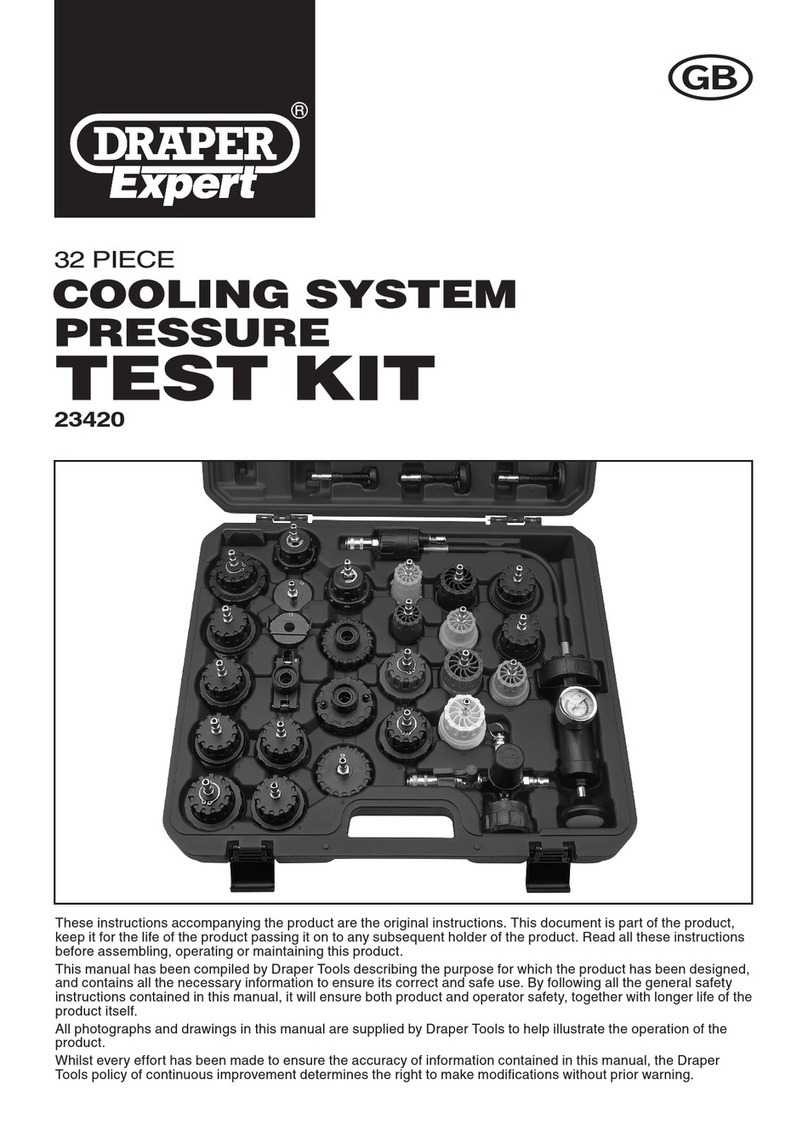

Included in the box:

1. The VARIOspeed®MICRO VFD

2. Pressure transducer (0-145 PSI range – ¼” NPTM) with 20 ft. of cable

3. Transducer cable

4. Strain reliefs (1 x 0.5”, 2 x 0.75”)

5. User manual

6. Wall mounting bracket (4 screws included)

7. Quick start manual

Verify that all components are included and the VARIOspeed®MICRO VFD model number is

correct.

WARNING: Do not connect power to this equipment if it’s been damaged or has any missing parts.

SJE-Rhombus®VARIOspeed®Micro Controller User Manual 3

4SJE-Rhombus®VARIOspeed®Micro Controller User Manual

Specifications

VARIOspeed®MICRO D (1HP) MICRO D PLUS (2HP)

Input rating

Voltage (V) 1Φ, 200V - 240V, 50/60 Hz

Power (W) 4,300W 5,400W

Current (A) Max. 19.5A Max. 24.5A

Minimum Size

Circuit Breaker 30A (2 Pole) 30A (2 Pole)

Output rating

*Voltage (V) 1Φ, 220V 3Φ, 220V 1Φ, 220V 3Φ, 220V

Power (kW/HP) 0.75kW

(1 HP)

1.5 kW

(2HP)

1.5 kW

(2HP)

2.2 kW

(3HP)

Max. Rated Current (A) Max. 11A Max. 14A

Max. Pump FLA 0-9A 0-12A

Frequency (Hz) 20~80Hz 20~60Hz

Operation

Pressure Range 1-69 PSI

Control Method PID control (Proportional + Integral + Derivative)

Environment

IP Rating IEC-529 IP31

Pollution Degree Pollution Degree 2

Operating Temperature 0ºC ~ +50ºC

Storage Temperature -10ºC ~ +60ºC

Ambient Humidity Less than 95%, Non-condensing

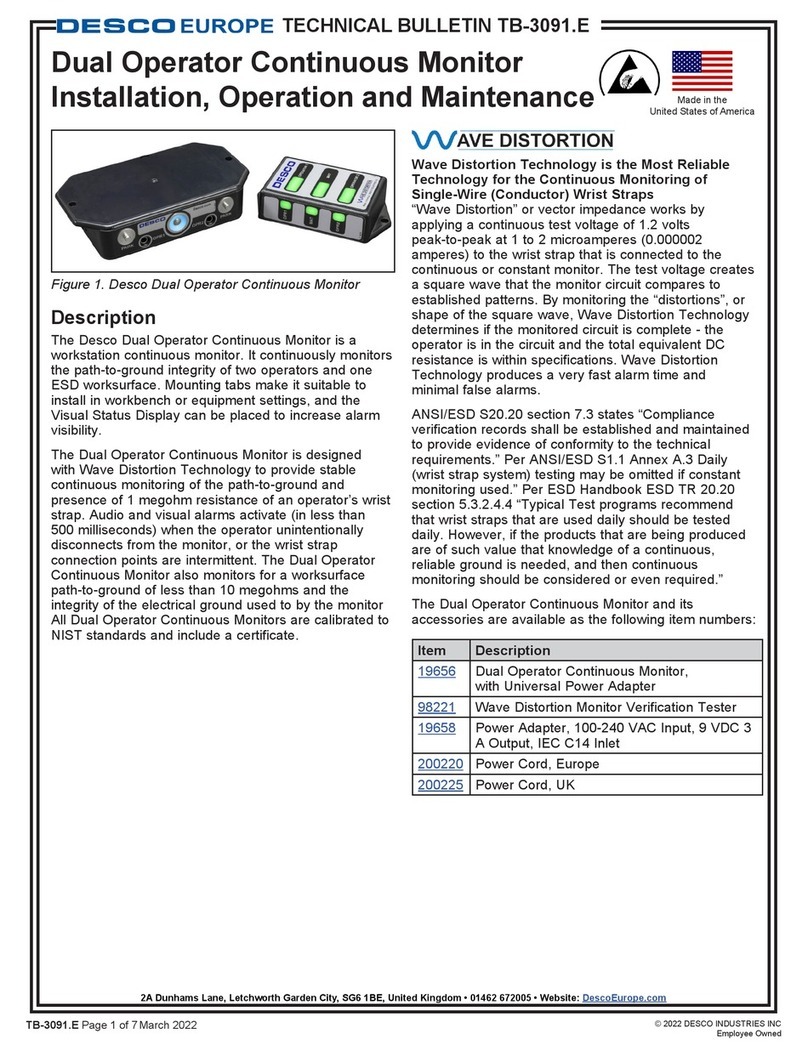

System Setup Diagram for Deep Well Submersible

SJE-Rhombus®VARIOspeed®Micro Controller User Manual 5

System Setup Diagram for Pressure Booster

6SJE-Rhombus®VARIOspeed®Micro Controller User Manual

Pressure Tank/Pressure Relief Valve/Low Pressure

To maintain constant pressure and prevent frequent startup, a small-capacity pressure tank is need-

ed in the system (refer to the minimum capacity of pressure tank table below). The VARIOspeed®

MICRO VFD may use a pressure tank of a larger capacity than listed on the table blow.

Minimum Capacity of Pressure Tank

Flow Rate (GPM) Tank Size

(Total Capacity)

Less than 12.0 4 Gallons

More than 12.0 8 Gallons

Pre-Charge Pressure

1. Initial charge pressure should be at least 70% of the system pressure (Set pressure).

2. To maintain the optimum pressure level, check the air pressure in the tank regularly.

Set Pressure (PSI) Initial Charging

Pressure (PSI)

50 (default) 35

55 39

60 42

65 46

A Pressure Relief Valve Must be Installed.

A pressure relief valve MUST be installed as close as possible to the pump discharge and plumbed

to a drain able to handle the full flow of the pump in the event of a malfunction.

WARNING!

Failure to use a pressure relief valve could result in burst pipes and flooding if a system failure should occur.

Low Pressure Switch Shutdown (optional)

A pressure switch may be used to shut down the pump on low pressure. This switch will open on low

pressure and stop the pump from operating with insufficient water supply. (See pg 12 for electrical

connections.)

SJE-Rhombus®VARIOspeed®Micro Controller User Manual 7

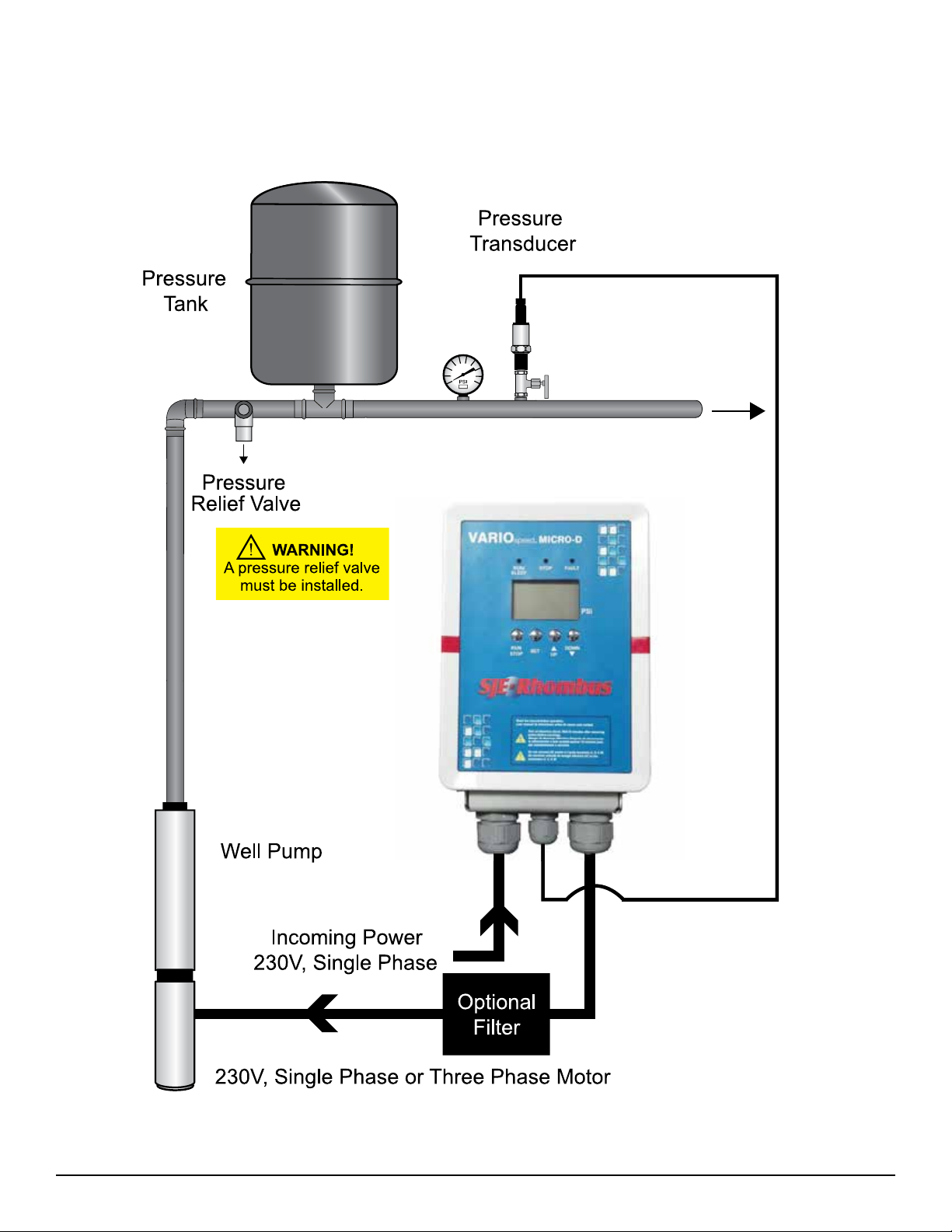

Outline Dimensions

Removing the cover to access terminal blocks

8SJE-Rhombus®VARIOspeed®Micro Controller User Manual

WARNING!

Risk of electrical shock. Wait 10 minutes after disconnecting

the incoming power before removing the cover.

Mounting

The VARIOspeed®MICRO VFD is designed for wall mounting in a clean, cool, and dry location.

First, mount the supplied wall support bracket to the wall. Mark the hole locations and secure with

screws rated for the wall material. The use of the wall support bracket is required to allow air flow

through cooking fins. Do NOT mount outdoors or expose to water, high humidity, corrosive or explo-

sive gasses. Must be mounted vertically and requires a minimum of 100mm (4”) clearance on all

sides for adequate ventilation.

Mount the VARIOspeed®MICRO VFD on the support plate using supplied screws.

HOT!

Heat sink temperature may

rise to 90ºC (194ºF).

Do NOT touch heat sink.

SJE-Rhombus®VARIOspeed®Micro Controller User Manual 9

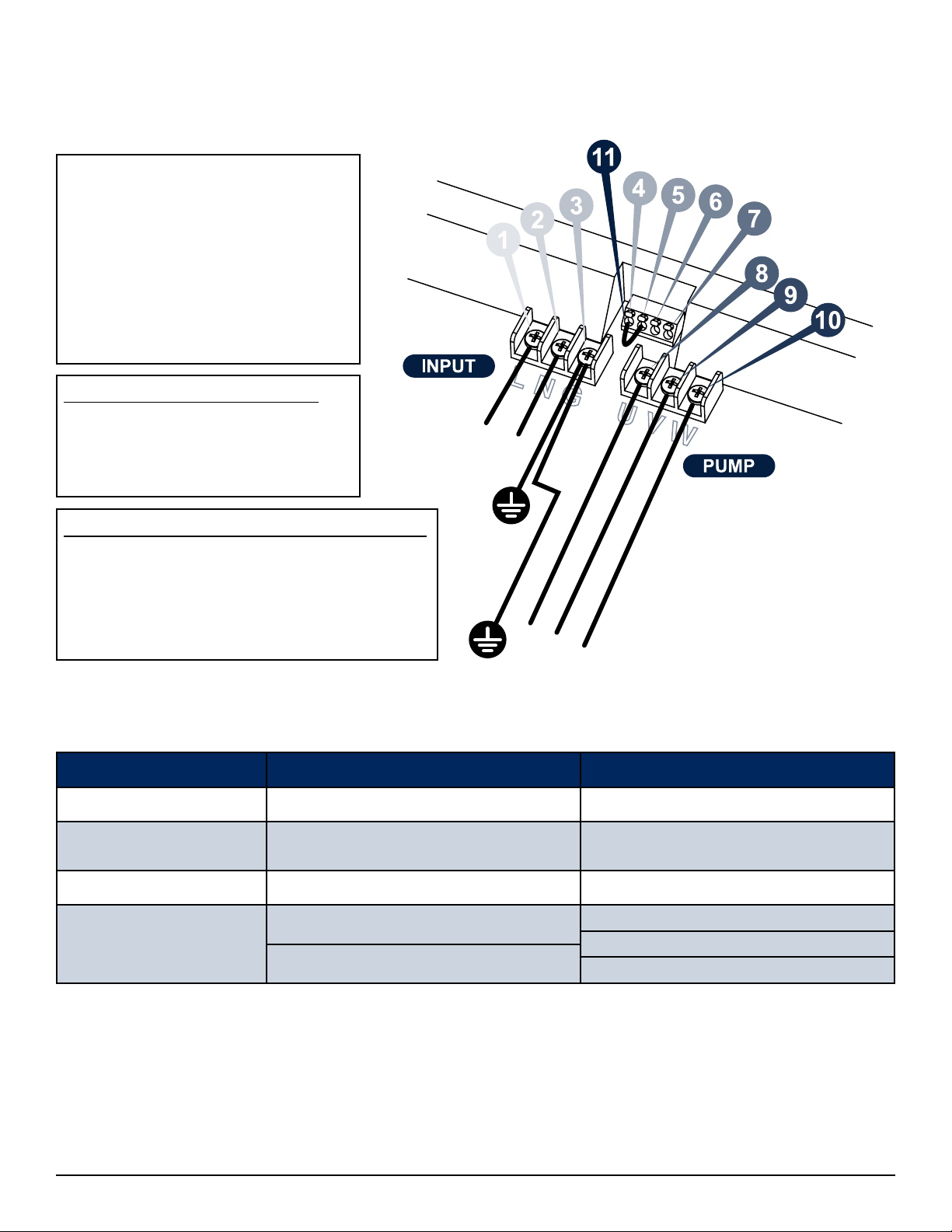

Terminal Wiring Description

1 - (L) Incoming Voltage (L or L1)

2 - (N) Incoming Voltage (N or L2)

3 - (G) Ground Connection

4 - Low Pressure Switch

5 - Low Pressure Switch

6 - Transducer +

7 - Transducer signal

Connect wiring per local code requirements using chart below.

Three Phase motor connection

8 - (U)

9 - (V)

10 - (W)

Single Phase submersible pump connection

8 - (U) start winding - Red (R)

9 - (V) motor winding - Yellow (Y)

10 - (W) motor winding - Black (B)

11 - Factory Jumper

Incoming voltage must be 200V-240 VAC, 50/60 Hz, Single Phase

A 2 pole circuit breaker must be used to protect the VFD. see the table below for correct sizing:

VARIOspeed®MICRO D (1HP) MICRO D PLUS (2 HP)

Input Current Max. 19.5A Max. 24.5A

Minimum Size

Circuit Breaker 30A 30A

Minimum Wire Size 10 AWG 10 AWG

*Motor Cable Size &

Maximum Cable Length

1Φ 14 AWG, 200 ft. 1Φ 14 AWG, 200 ft.

1Φ 14 AWG, 250 ft.

3Φ 14 AWG, 300 ft. 3Φ 14 AWG, 400 ft.

If a pressure switch or level switch is not used, a jumper must be placed between terminal 4 & 5.

If a pressure switch or level switch is used, it must be selected and connected as to open on a fault

condition (low pressure or low water).

10 SJE-Rhombus®VARIOspeed®Micro Controller User Manual

*A filter is recommended for cable lengths over 125ft. See Filter Options on page 11.

Grounding Method

Filter Options

Output noise filters.

These devices are available for 3-phase output applications only.

They are not suitable for single phase pump applications.

These filters can reduce the electrical noise generated by the Variable Frequency Drive.

Variospeed®Micro D (3-phase motor only: Model RLW-001413)

Variospeed®Micro D Plus (3-phase motor only: Model RLW-002113)

SJE-Rhombus®VARIOspeed®Micro Controller User Manual 11

Display Description

Function Keys Operation

Start or stop auto run operation.

(Warning! This will start the pump.)

Escape out of the current parameter.

Accept the changed set pressure by holding for 3 seconds.

Accept the changed value in parameters.

Navigate through parameters and menu.

Change parameter values.

12 SJE-Rhombus®VARIOspeed®Micro Controller User Manual

Viewing Motor Current (A), Frequency (Hz)

and other parameters during automatic operation.

PSI (Pressure Reading)

Hz (Output Frequency)

A (Motor Current)

C (VFD heat sink temperature)

V (Voltage X 100)

V (Voltage)

PSI (Pressure Reading)

Press

Press

Press

Press

Press

Press

Enter manual operation mode

In case of transmitter open or shorted; press DOWN for 3 seconds to go into manual operation mode.

SJE-Rhombus®VARIOspeed®Micro Controller User Manual 13

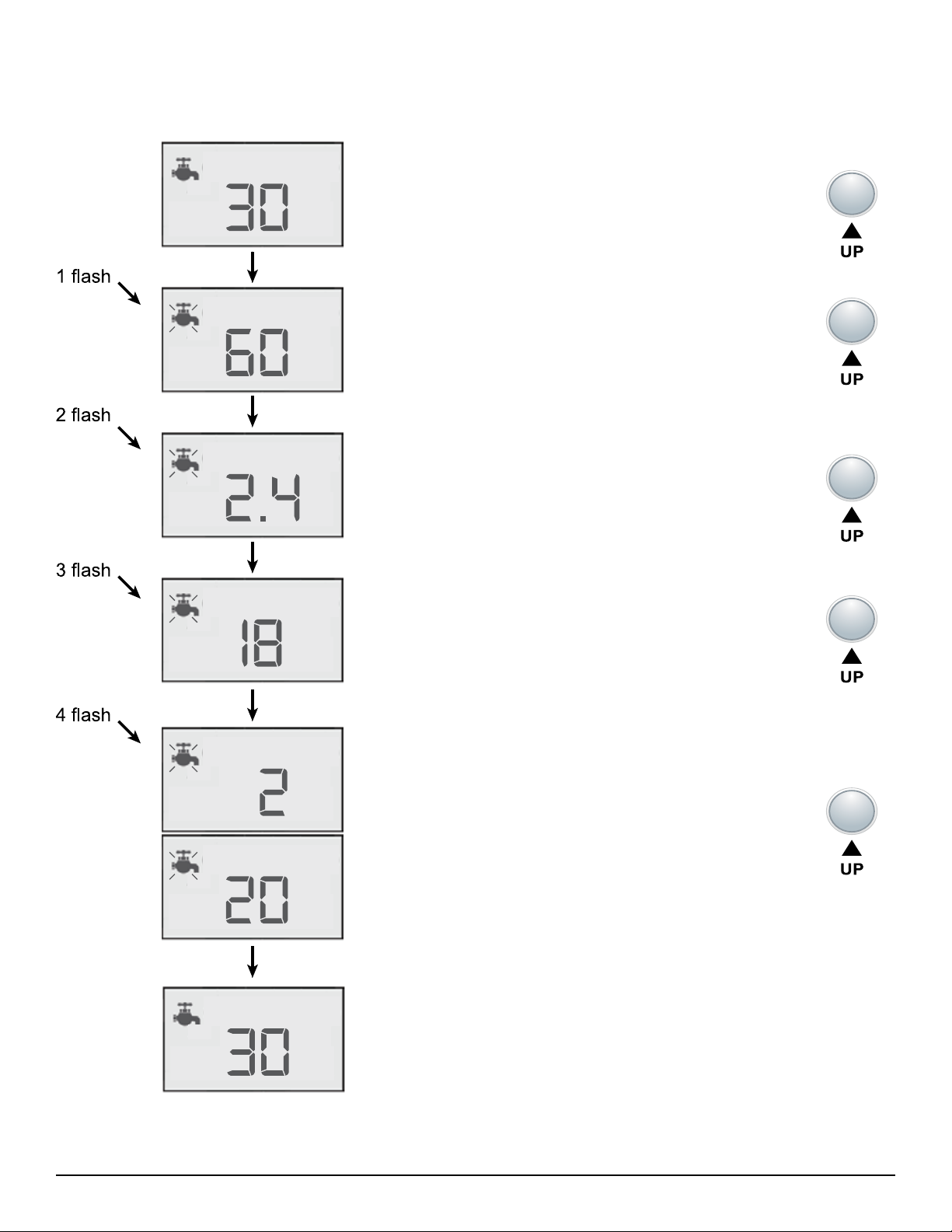

Changing the Set Pressure

Operation screen – Press SET button for 3 seconds until the word ‘Data’ appears. Now, the set

pressure can be changed. Refer to parameter table on page 15 for values.

Press UP or DOWN button to change the set pressure

Press SET button again for 3 seconds to accept the new set pressure. The display blinks twice, and

then the data disappears.

Caution:

1. Ensure the set pressure is always set above the “deadhead” pint of the pump. If not, the

pumps may keep running even though the user does not use water. It can cause damage

to the pump.

2. Set pressure shall be lower than the high-pressure alarm and higher than the low-pressure

alarm.

3. Changing pump overload protection value may result in damage if set incorrectly.

Changing Parameters

Press both the UP / DOWN buttons for 3 seconds until ‘BR-01’ appears. Now the parameter

can be changed.

Press the UP / DOWN button to move to the BR parameter wanted.

Press the SET button, and the word ‘data’ will appear. Now the data of the parameter can be

changed.

Press the UP / DOWN button to change the data.

Press the SET button to accept the new value. The data value will blink twice then the BR

parameter list mode is displayed.

Press the RUN / STOP button to exit the BR parameter mode. The system will operate under

the set value.

Caution:

Certain parameters cannot be changed when in auto run mode. Press the run / stop button to stop

the VFD before entering the parameter change mode to change these parameters.

14 SJE-Rhombus®VARIOspeed®Micro Controller User Manual

SJE-Rhombus®VARIOspeed®Micro Controller User Manual 15

Parameter List

No. Content of parameter Min.

Value

Max.

Value

Default

Value

Unit Remarks Change

during

operation

Set

Press Operating Pressure 11 69 50 PSI Target operating pressure O

BR-01 Base frequency 50 60 60 Hz X

BR-02 Max. Output

Frequency 35 80 60 Hz X

BR-03 Min. Output

Frequency 20 50 30 Hz O

BR-04 Rotating direction 0 1 0 Hz 0: Forward

1: Reverse X

BR-05 Overload Auto Reset 0 99 1 Min. 0: Manual Reset

1-99: Auto Reset Time

BR-06 Transducer Offset -5 5 0 PSI O

BR-07 Restart after sleep

pressure difference 1 15 5 PSI O

BR-08 High pressure alarm 51 99 70 PSI O

BR-09 Low pressure alarm 0 15 10 PSI O

BR-10 Frost Protection 0 99 0 Min. 0: unused

1-99: Time used O

BR-11 Lock parameters 0 2 0

0: Changeable

1: Change N/A

2: Factory Default

X

BR-12 Firmware Revision X

BR-13 Alarm Information Able to record total 10 data X

BR-14 Single or three phase

otor 131 1: 1 Phase

3: 3 Phase X

BR-15 Sleep stop delay time 5 3.0 10 Sec.

Min. X

BR-16 Low pressure restart time 0 30 0 Min. X

BR-17 Pump FLA - MICRO D 0.0 9.0 7.2 Amps Set to match motor max.

amperage X

Pump FLA - MICRO D Plus 12.0 9.6

Caution:

Setting BR-14 & BR-17 incorrectly may result in permanent motor or VFD damage.

Detailed Parameter Functions

BR-01 Base frequency

Base frequency is the frequency that the rated voltage of the inverter can output. Set according to

the rated frequency of the motor.

BR-02 Max. output frequency

Max. output frequency is the max. frequency that the inverter can operate. This value must not

exceed the frequency allowed by the motor.

BR-03 Min. output frequency

When the set pressure is reached and the demand for water stops, the pump will slow down to the

min. output frequency for a certain time and then will go to “sleep”. When this frequency is too high,

frequent ON/OFF cycling will occur. If this frequency is too low, the pump will not shut off and will

cause damage to the pump. During installation, please ensure the sleep function operates correctly

by opening and closing the valves several times and observing correct operation prior to leaving the

site. The default value is recommended for this setup.

BR-04 Rotating direction

When the wire connection of the motor is incorrect, the pump rotation is reversed. Reverse rotation

may cause lower pressure, stop water pumping and noise and vibration. If this occurs change the

setup for the rotating direction in lieu of changing the wire connection.

0: Forward rotation

1: Reverse rotation

BR-05 Auto Reset Time (OL)

0: Manual Reset

1-5: Auto Reset Time (mins.)

BR-06 Transducer offset

In case of a pressure deviation occurring in the system, or the pressure of the gauge is different from

the pressure displayed on the screen, this parameter can offset for this difference.

Before changing this parameter, ensure the pressure gauge is accurate.

BR-07 Restart after sleep pressure differential

After entering “sleep” mode the system will allow the pressure to drop this amount before starting the

pump. If this value is set too small, the pump may operate with frequent Start/Stop cycles. On the

other hand, if this value is set too high, the large pressure drop may be an inconvenient to the user.

BR-08 High pressure alarm

If the current pressure is higher than the high-pressure alarm, the high pressure alarm icon is shown

on screen and the pump stops immediately. If the current pressure drops lower than the high-

pressure alarm, the icon disappears and the pump operates normally again.

BR-09 Low pressure alarm

Note: On initial start up, the low pressure fault will not be activated for 3 minutes to allow for the

piping system to fill.

If the pressure drops for more than 15 seconds below this point, the low pressure alarm is set. The

pump stops and the low pressure alarm icon will appear on the screen. After 15 seconds, the system

automatically restarts, If the pressure returns to normal operating range within 15 seconds, the sys-

tem will continue running. If not, the system will repeat this cycle. If the low pressure alarm remains

after the second time, the pump will stop for the time entered in BR-16 and then attempt to restart.

If the low pressure fault remains, the system will shut down and not restart. The system will need to

be reset by cycling the power and removing the source of the problem.

16 SJE-Rhombus®VARIOspeed®Micro Controller User Manual

BR-10 Frost Protection

Frost protection protects the pump against the cold weather during winter. When the set time is

elapsed, the pump operates under the maximum frequency for 5 seconds, and then stops.

BR-11 Lock parameters

This function locks and initializes the program.

0: Change of parameters is allowed

1: Change of parameters is not allowed

2: Initializes the parameters to factory default values.

BR-12 Firmware version

This displays the firmware version of the program. To improve the performance of the inverter or

solve technical problems, the version is subject to change without prior notice.

BR-13 Alarm information

This parameter captures the history of the 10 most recent alarms. Check the alarm information by

using the UP / DOWN buttons.

BR-14 Setting 1 or 3 phase of the motor

Check the ‘Phase’ on the motor nameplate and set phase as follows;

1: 1 phase

3: 3 phase

Caution:

Applies only to VARIOspeed MICRO D. Setting BR-14 incorrectly may result in permanent motor or

VFD damage

BR-15 Sleep stop delay time

When the drive slows to the minimum output frequency, it delays this amount of time before going to

“sleep”.

BR-16 Low pressure re-start time

After the low pressure alarm, the drive waits this amount of time, then restarts operation. The low

pressure icon starts blinking after the low pressure alarm faults 3 times.

BR-17 Motor FLA

This parameter is to be set to the maximum amperage allowed for the pump motor. If service factor

is needed, this must also be included. The VFD will fault and display drive error if this value is

exceeded for a long period of time.

Caution:

Setting BR-14 & BR-17 incorrectly may result in permanent motor or VFD damage.

SJE-Rhombus®VARIOspeed®Micro Controller User Manual 17

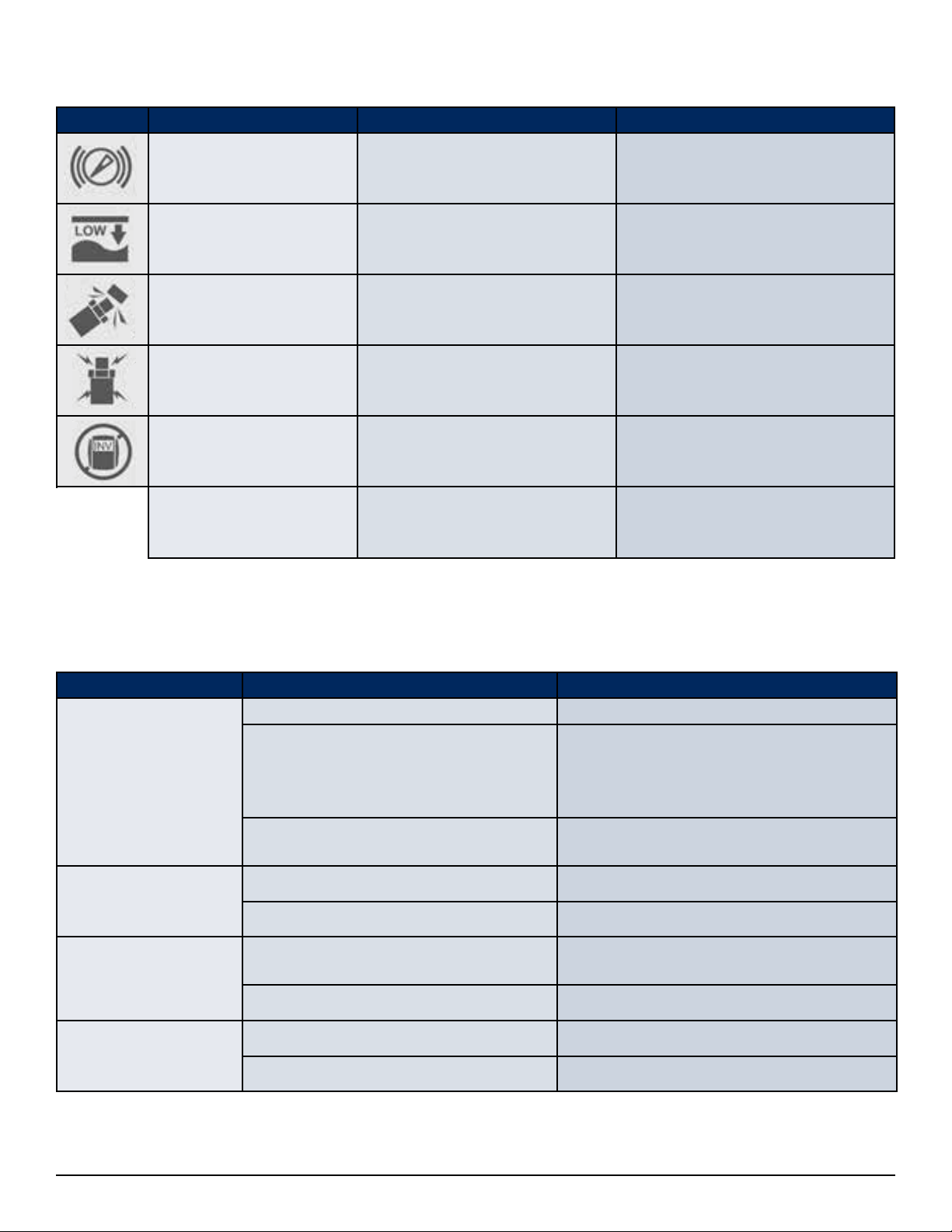

Fault and Alarm Display & Solutions

SYMBOL ALARM STATUS SOLUTION

High pressure warning Exceeding the set pressure Check the system.

Low pressure level

warning Low pressure / water level Check the connection part of

the transmitter.

Transducer open Transmitter disconnect Check the connection of the

transmitter.

Transmitter short Transmitter short-circuit Transmitter is not operating nor-

mally. Replace the sensor.

Drive error Inverter error

Inverter is faulty. Disconnect the

supply power and contact the

distributor.

Over-temperature Heat sink temperature over

90°C (194°F) Ensure proper ventilation.

Causes of Malfunction/Troubleshooting

FAULTS CAUSE ACTIONS

Motor does not run

Motor Fault Repair or replace the motor.

Low input voltage

If the input voltage is lower than the

rated by measurement, please contact

your electric power supply company to

change it to the rated voltage.

Transducer fault Conrm the cable connection

correction of transducer.

Lack of pump ow or

pressure

Inltration of air into the suction pipe

Solid material locked up the pump

Pump noise /

vibration

Mounting bracket loose or broken Tighten or replace the bolts, nuts, and

pipe supports

Reverse rotation direction Check the rotation direction again.

Pump doesn’t stop Min. frequency set too high Adjust parameter

Wrong pump selection Replace it with correct pump

18 SJE-Rhombus®VARIOspeed®Micro Controller User Manual

Table of contents

Other SJE Rhombus Test Equipment manuals