Quick start manual - F5200

MR-F5200B-U Quick start manual ATEQ F5200 Page 1/17

Quick start manual

TABLE OF CONTENTS

TABLE OF CONTENTS..................................................................................................1

PREAMBLE ....................................................................................................................2

1. DEFINITION OF THE ATEQ F5200 ....................................................................................................2

2. MEASUREMENT CHARACTERISTICS..............................................................................................2

3. THE MAIN TYPES OF MEASUREMENT............................................................................................3

4. THE THREE TYPES OF TEST ............................................................................................................3

5. MEASUREMENT CYCLE ....................................................................................................................3

INSTALLATION ..............................................................................................................4

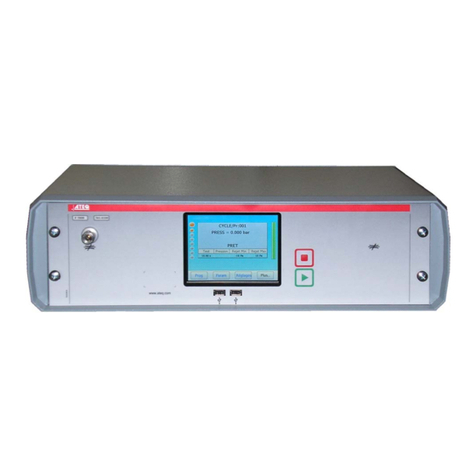

1. APPEARANCE OF THE ATEQ F5200................................................................................................4

2. ELECTRICS CONNECTORS ..............................................................................................................4

3. PNEUMATICS CONNECTORS...........................................................................................................7

4. PNEUMATIC SUPPLY.........................................................................................................................7

USER INTERFACES.......................................................................................................8

1. LCD DISPLAY AND NAVIGATION.....................................................................................................8

2. CYCLE KEYS ......................................................................................................................................8

3. QUICK CONNECTORS .......................................................................................................................8

STARTING UP AND ADJUSTMENTS............................................................................9

1. MAIN MENU.........................................................................................................................................9

2. TEST MENU.........................................................................................................................................9

3. TEST TYPE........................................................................................................................................10

4. PROGRAMS MANAGEMENT...........................................................................................................10

5. PARAMETERS ..................................................................................................................................11

6. START AND STOP A MEASUREMENT CYCLE..............................................................................12

7. PASSWORD ......................................................................................................................................12

CONFIGURATION MENU.............................................................................................13

1. EXTENDED MENUS..........................................................................................................................13

2. SPECIAL CYCLES ............................................................................................................................14

3. OTHERS MENUS ..............................................................................................................................14

ACCESSORIES AND CHARACTERISTICS.................................................................15

1. ACCESSORIES FITTED WITH THE DEVICE...................................................................................15

2. ACCESSORIES IN OPTION..............................................................................................................15

3. TECHNICAL CHARACTERISTIC OF THE F5200............................................................................15

ERRORS AND FAULTS ...............................................................................................16

1. ERROR MESSAGES .........................................................................................................................16

2. IN CASE OF OPERATION DOUBT ..................................................................................................16

INDEX ...........................................................................................................................17

Due to continuing improvements, the information contained in this user manual,

the features and design of this device are subject to be changed without prior

notice.