HP

85148/8512A

Opera ting

and

Servic e

Ma nual

TABLE

OF

CONTENTS

SECTI ON 1 . GEN ERAL IN FORM AT ION

...........

1-l

Introduction

............................... l-l

Verifying the Test Set

.......................l-l

Instruments Covered by Manual

..............l-2

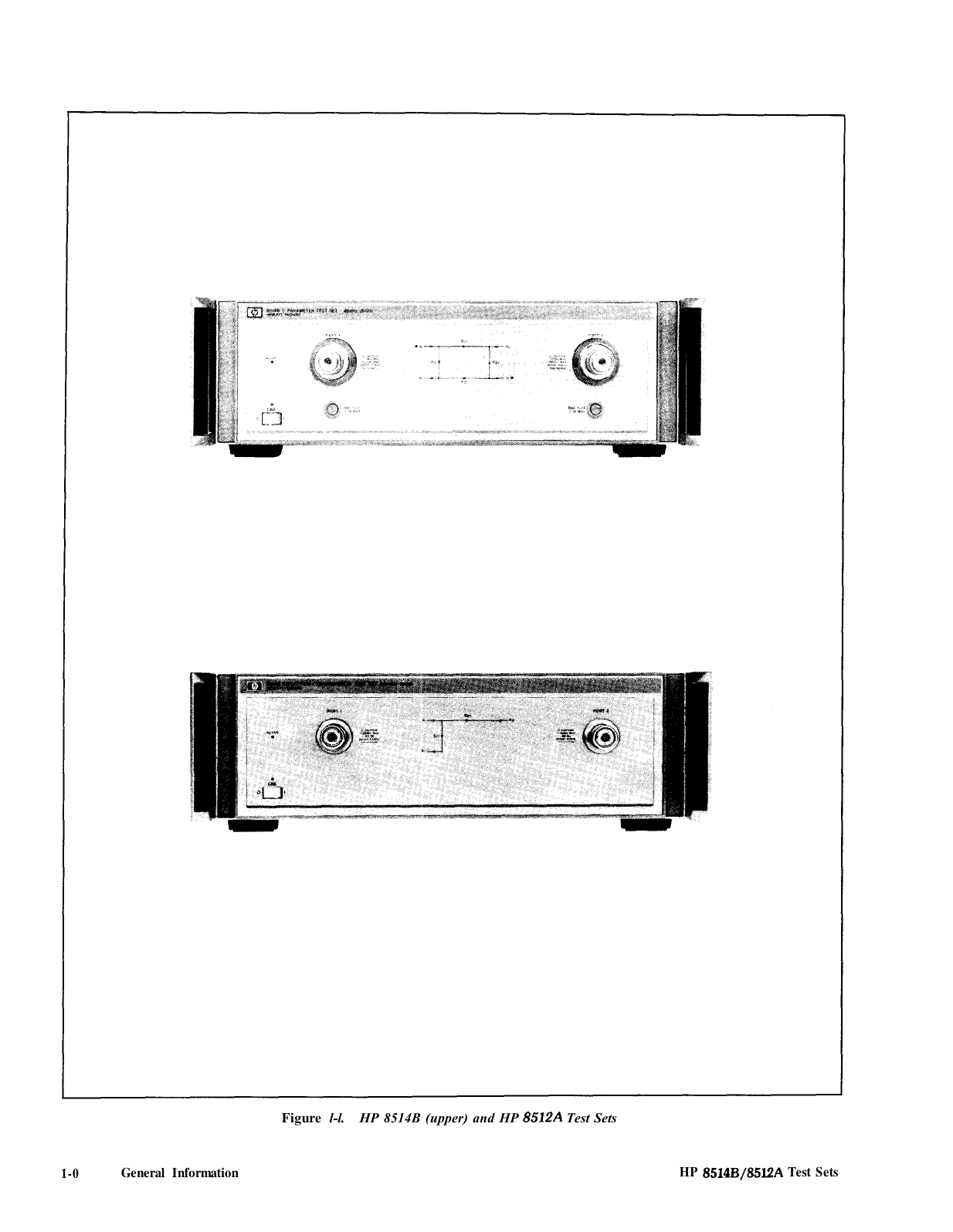

Description and Operating Characteristics

of the Instrument

.......................l-2

Options

.................................. l-4

Option 001

.............................

1-4

Option 002 (HP 8514B only)

................l-4

Option 003 (HP 8514B only)

................l-4

Option

002/003

(HP 85148 only)

............l-4

Option908

............................. l-4

Option 910

............................. l-4

Option913

............................. l-4

Option W03, Warranty Conversion

..........l-4

Option

W30,

Extended Service

.............l-4

Accessories

...............................

1-5

Accessories Supplied

....................

l-5

Accessories Available

....................

l-5

Operating and Safety Precautions

.............l-6

Operating

.............................. l-6

Service

................................ l-6

Additional Equipment Required

...............l-6

SECTI ON 2. I N STALLAT I ON . . . .

Introduction . . . . . . . . . . . .

Initial Inspection

. . . . . . . . . . .

Environmental Considerations

Operation and Storage

. . .

Preparation for Use . . . . . . . .

Positioning the Test Set . . .

Connecting the Test Set

. .

Packaging . . . . . . . . . . . . . . . .

SECTI ON 3 . OPERAT ION ......

Introduction

................

Front Panel Features

........

Rear Panel Features

.........

Operator’s Check

...........

Equipment

..............

Procedure

.................

HP 85148 Operator’s Check

. .

Sampler Test

............

b1 Thru Test

.............

b2 Thru Test

.............

.

.

.

.

.

.

.

..........

2-l

..........2-l

..........2-l

..........

2-1

..........2-l

..........2-l

..........2-l

..........

2-2

..........

2-5

..............

3-l

..............3-l

..............

3-2

..............

3-3

..............

3-4

..............

3-4

..............

3-4

..............

3-4

..............

3-4

..............

3-5

..............

3-5

HP

8512A

Operator’s Check

.................

3-6

a1 Test...............................

3-6

b1 Reflection Test

.......................

3-6

b2 Thru Test

...........................

3-6

Controlling Multiple Test Sets

................

3-7

Installation

...............................

3-7

Operation

................................

3-7

Initialization at Power-up

.................

3-7

Selecting a Test Set

.....................

3-9

Measurement Calibration

.................

3-9

Operational Checks

.....................

3-9

Performance Verification

.................

3-9

Cable and Anti-Rotation Clamp Installation

.....

3-11

Procedure

...............................

3-11

SECTI ON 4 . SPECI FICATI ON S ................

4-1

Mechanical Specifications

..................

4-1

Supplemental Characteristics

................

4-2

SECTI ON 5 . TEST SET TROU BLESH OOTI N G

..... 5-l

Test Set Temperature

......................

5-2

Check all Connections

.....................

5-2

Check Power Supply/Regulator, Fuses,

and Switches

.........................

5-2

A15 Regulator Board Assembly

............

5-2

Fuses

................................

5-2

Address Switches

.......................

5-3

Test Set Self-Test Indicators

................

5-3

If Self-test Fails to Run

...................

5-3

Configuration Switch

.......................

5-4

Check VTO/Driver (LO)

.....................

5-5

Test Set Self-Test Indicators

................

5-5

Test Set Troubleshooting Using Time Domain

. .

5-6

Test Set Assembly Replacement Procedures

...

5-7

(1) Bias Tee

..............................

5-9

(2) Coupler

...............................

5-l 0

(3) Switch/Splitter

.........................510

(4) Frequency Converter

....................

5-10

(5) Sampler

..............................

5-l 1

(6)

VT0

Assembly

.........................

5-11

(7) Regulator Board Assembly

...............

5-l 1

(8) Step Attenuator Assembly

................

5-l 2

(9) Capacitor

.............................

5-l 2

(10) 3.5 mm RF Connector Repair

............

5-12

Disassembly

...........................

5-12

HP

8514B/85l2A

Test Sets Table of Contents

i