SKANDIA ELEVATOR – SEH 50/18, 50/23 & 63/30

Contents

Thank you for choosing Skandia Elevator!

Your conveyor system must be assembled correctly and maintained

thoroughly if it is to operate satisfactorily. These assembly instructions and

the separate maintenance instructions must be followed for the warranty to

apply.

We hope you will be pleased with your Skandia conveyor equipment for a long

time.

Machine overview..................................................................................................................6

Safety information...................................................................................................................7

General safety information...............................................................................................................................7

Electrical safety .............................................................................................................................................................8

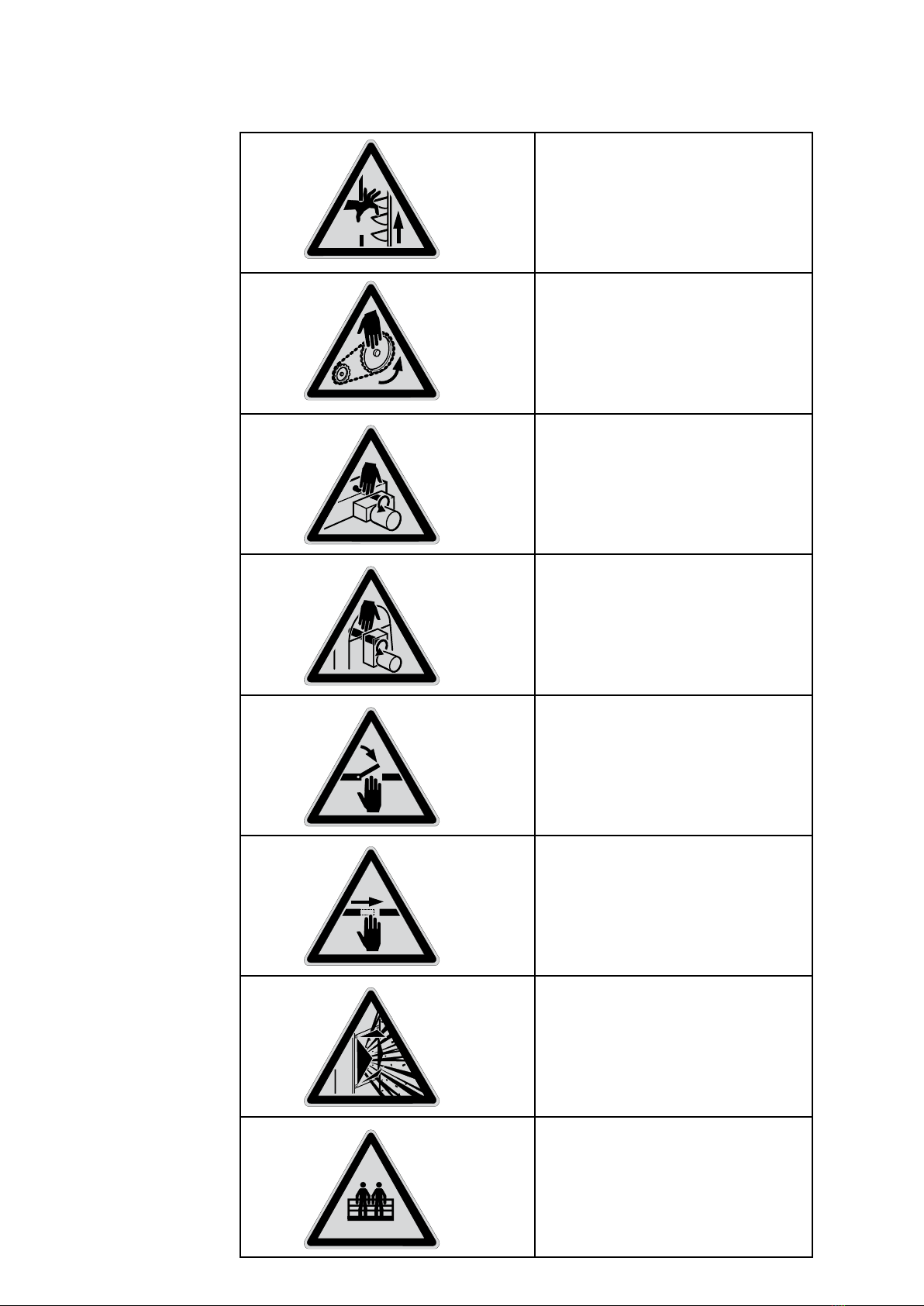

Safety decals....................................................................................................................................................................9

Before assembly.................................................................................................................... 11

Connection of the machine.................................................................................... 13

Location of inlet.........................................................................................................................................................13

Connecting another machine to the elevator...........................................................................14

Connecting the elevator to the conveyor....................................................................................... 14

Assembling the machine............................................................................................ 15

Belt alignment switch.........................................................................................................................................15

Elevator legs.................................................................................................................................................................. 16

Explosion relief panels....................................................................................................................................... 17

Elevator head...............................................................................................................................................................18

Back stop..........................................................................................................................................................................19

Bucket belt......................................................................................................................................................................20

Buckets...............................................................................................................................................................................22

Centring of bucket belt......................................................................................................................................23

Adjusting the splash guard........................................................................................................................... 24

Elevator hood...............................................................................................................................................................25

Speed monitor ............................................................................................................................................................26

Inlet......................................................................................................................................................................................... 27

Water seal........................................................................................................................................................................ 27