I

SECTION PAGE

SAFETY NOTICE ...................................................................................................................................... III

INTRODUCTION Abbreviations list ......................................................................... IV

Serial numbers ............................................................................ IV

LUBRICATION

AND MAINTENANCE .................................................................................................... *

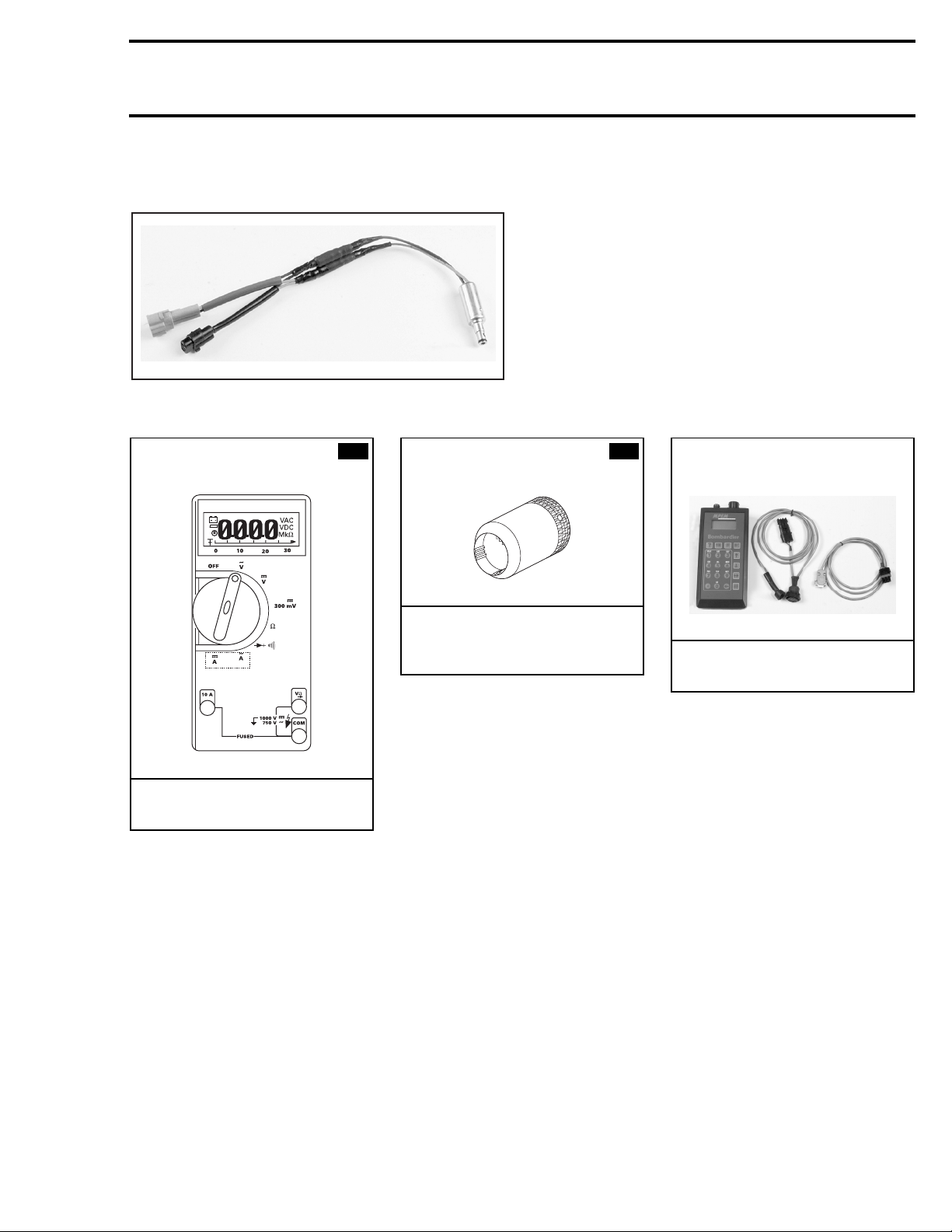

01 TOOLS .................................................................................................... 01-1

02 TROUBLESHOOTING .................................................................................................... 02-1

ENGINE Table of contents......................................................................... *

699 Engine ................................................................................. *

Leak test and engine dimension measurement .......................... *

CDI system (220-watt magneto system)..................................... 03-1

Oil injection system..................................................................... 04-1

Liquid cooling system.................................................................. *

Rewind starter............................................................................. *

Carburetor and fuel pump............................................................ *

Fuel tank and throttle cable......................................................... *

TRANSMISSION Table of contents......................................................................... *

Drive belt ..................................................................................... *

Drive pulley.................................................................................. *

Driven pulley................................................................................ *

Pulley distance and alignment..................................................... *

Brake ........................................................................................... *

Gearbox ....................................................................................... *

Drive chain................................................................................... *

03 ELECTRICAL SYSTEM Table of contents......................................................................... *

Wiring diagrams........................................................................... 08-1

Ignition timing.............................................................................. *

Spark plugs.................................................................................. *

220-watt magneto system .......................................................... 03-2

Theory and operation................................................................... 03-2

Testing procedure ....................................................................... 03-2

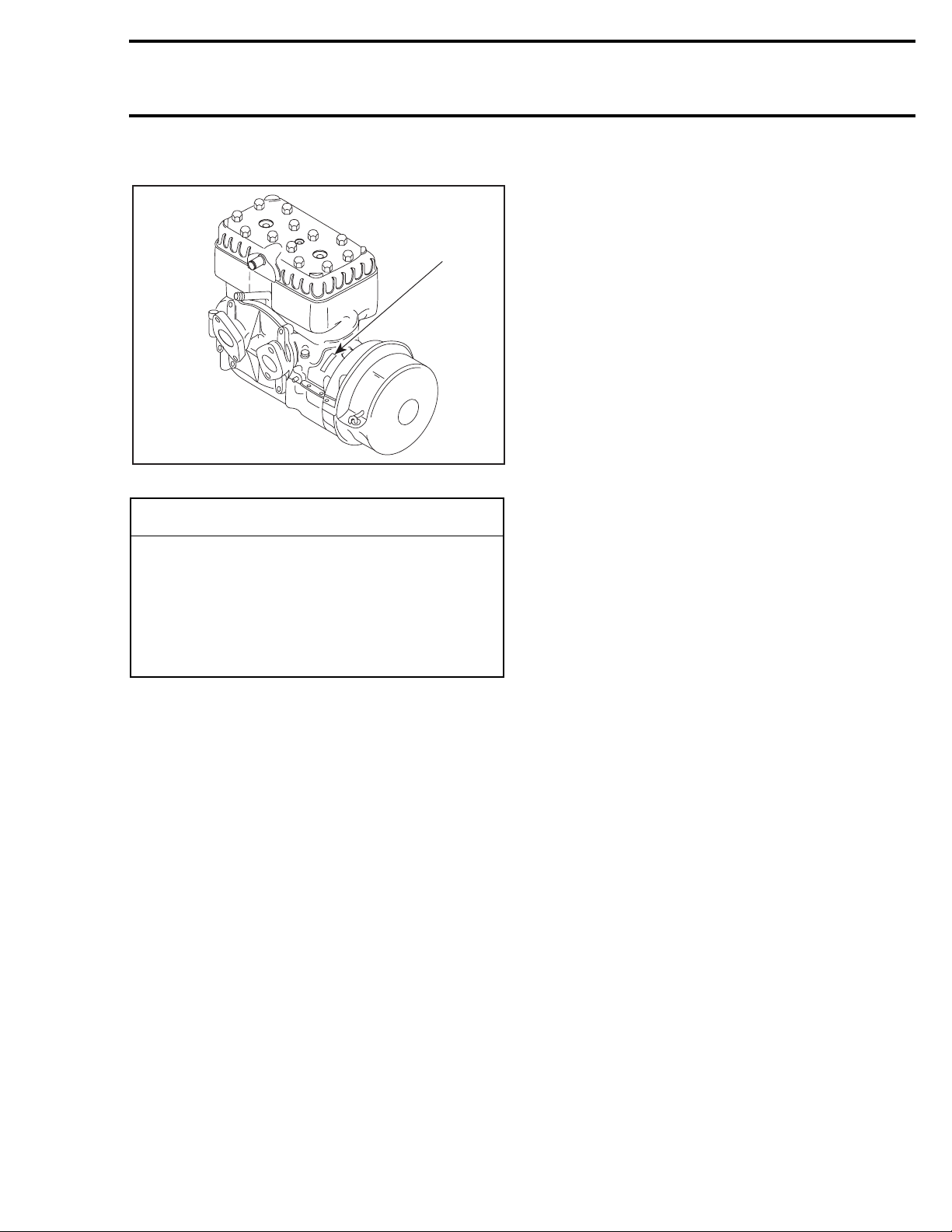

04 OIL INJECTION SYSTEM Oil injection pump ....................................................................... 04-2

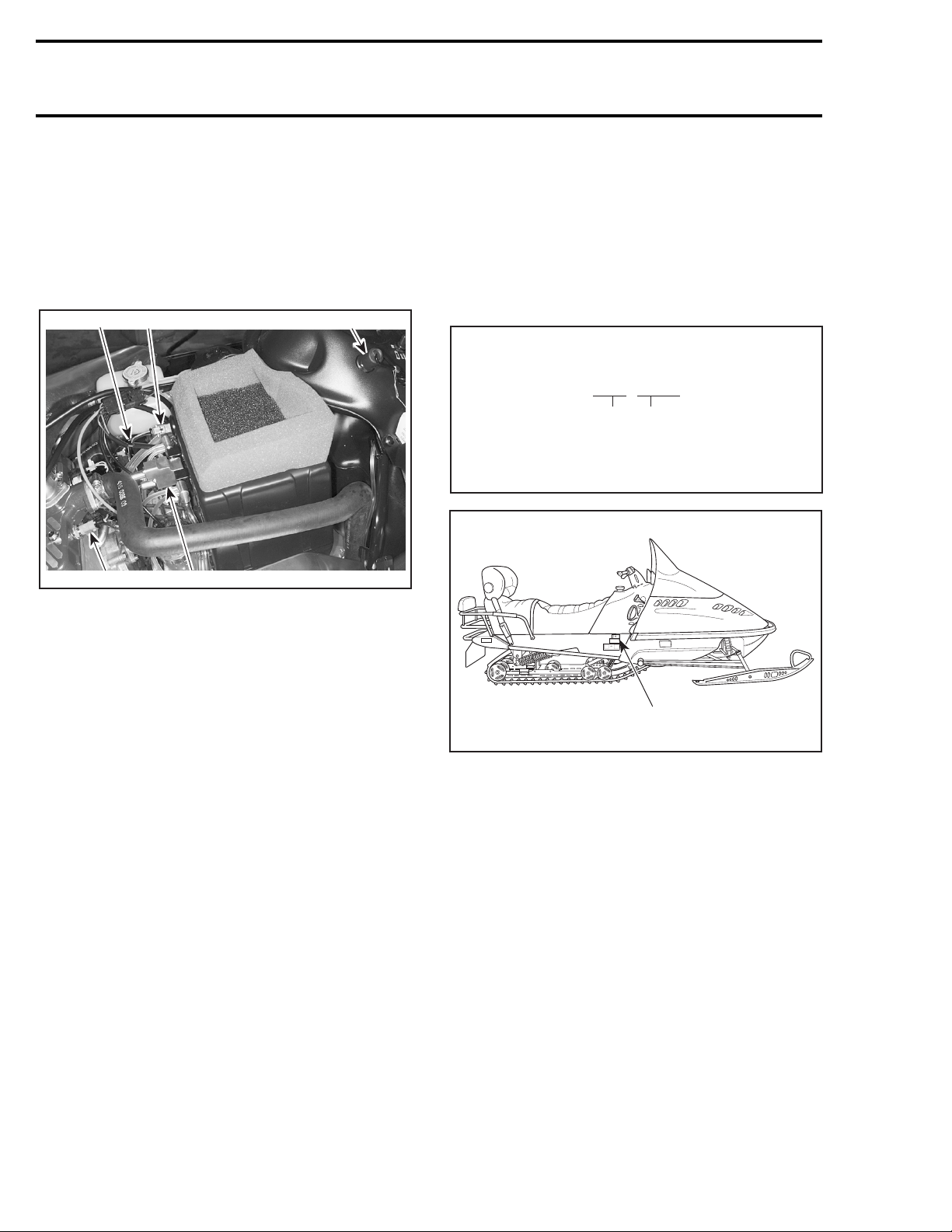

05 DESS SYSTEM Component location .................................................................... 05-1

Theory and operation................................................................... 05-1

Ignition system testing................................................................ 05-3

Lighting system testing............................................................... 05-4

06 DIGITAL PERFORMANCE

MANAGEMENT (DPM)

SYSTEM

Component location .................................................................... 06-2

Theory and operation................................................................... 06-2

Testing procedure ....................................................................... 06-11

Starting procedure....................................................................... 06-12

* Refer to

1998 Shop Manual volume 2

(P/N 484 0682 00)

TABLE OF CONTENTS