Skope BB380r-2 Owner's manual

380r-2 Door

580r-3 Door

780r-4 Door

SKOPE Backbar Remote Chillers

Horizontal Display and Storage

nstallation and Operating nstructions

MAN0706 Rev. 1.0 Dec. 2003 edition

Model: BB380r-2SW

BB380r-2, BB580r-3, BB780r-4

SKOPEBackbarRemote Chillers

Designed and Manufactured by

New Zealand

SKOPE INDUSTRIES LIMITED

PO Box 1091,Christchurch

NewZealand

Freephone: 0800 947 5673

Fax: (03) 983 3896

E-mail: enquiry@skope.co.nz

Website: www.skope.co.nz

Australia

SKOPE AUSTRALIA PTY LTD

A.C.N. 000 384 270

PO Box 7543,Baulkham Hills B.C.

NSW 2153, Australia

Freephone: 1800 121 535

Fax: 1800 121533

E-mail: enquiry@skope.com.au

Website: www.skope.com.au

Middle East

SKOPE INDUSTRIES MIDDLE EAST

PO Box 37663, Dubai

UnitedArab Emirates

E-mail: skopeme@emirates.net.ae

CONTACT ADDRESSES

i

BB380r-2, BB580r-3, BB780r-4

SKOPE Backbar Remote Chillers

BB380r-2, BB580r-3, BB780r-4

SKOPE Backbar RemoteChiller

Installation and OperatingInstructions

MAN0706

Rev. 1.0 Dec. 2003 edition.

Published by

SKOPE IndustriesLimited,

Christchurch, New Zealand.

Copyright© 2003

SKOPE IndustriesLimited.

All rights reserved.

SKOPE and CYCLONE are

registered trademarks of

SKOPE IndustriesLimited.

SKOPE IndustriesLimitedreserve the

right toalter specifications without

notice.

ii

BB380r-2, BB580r-3, BB780r-4

SKOPEBackbarRemote Chillers

1SPEC F CAT ONS

1.1Cabinet and Refrigeration Unit. . . . . . . . . . . . . . . . . . . . . . .6

2NSTALLAT ON

2.1Positioning of Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2Refrigeration System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3OPERAT ON

3.1Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2Operation of Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3Loading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.4Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.5Servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4ELECTRONC CONTROLLER

4.1Controller Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2Controller Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.3Programming Controller . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.4Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.5Display Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

TABLE OF CONTENTS

iii

6BB380r-2, BB580r-3, BB780r-4

SKOPE Backbar Remote Chillers

1.1Cabinet and Refrigeration Unit

* Height excludescastors orlegs

Cabinet Construction

Finish: Stainless steel orpowdercoatedgalvanised steel

Insulation: 50mmthick, polyurethanefoam

Cyclo-isoPentane blowingagent: C5H10/C5H12

Dimensions

Models: BB380r-2 BB580r-3 BB780r-4

Doors: 2 Door 3Door 4 Door

Height: 920mm* 920mm* 920mm*

Width: 1355mm 1915mm 2475mm

Depth (Solid Back): 590 - 600mm(with bench top)

Depth (Pass-Thru): 655 - 670mm(with bench top)

Floor area: 0.81m21.14m21.48m2

Internal volume: 380 litres 580 litres 780 litres

Electrical

Power supply: 220-240V a.c. 50Hz, single phasepowersupply

Run Amps: See rating label insidecabinet

Interior light: 1 x 36 Watt 1x 58 Watt 1 x 58 Watt

Refrigeration Unit

Product temp: +1°Cto +4°C

Rated ambient: 32°C at 65% RH

Evap. capacity 480 Watts 615 Watts 850 Watts

Evaporator: CLS9902R

TX valve - R134a VAL7923

TX valve - R404A VAL9641

TX valve - R22 VAL9643

Orifice: ‘0X’ REF9761 ‘00’ REF7596 ‘00’ REF7596

Refrigeration tail Ø: Liquid line: 1/4” Suction line: 3/8”

Drain Ø: 19mmO.D.

SPECF CAT ONS

1

7

BB380r-2, BB580r-3, BB780r-4

SKOPEBackbarRemote Chillers

2.1Positioning of Machine

Castors / Legs

If your SKOPE Backbar chiller has been supplied with either the

optional adjustable height castors or adjustable legs (packed with

the cabinet), they should be fitted to the base of the cabinet before

final positioning of the chiller.

Siting chiller

When installing the chiller it is important to consider the location and

physical environment where the chiller is to be positioned. When

siting the chiller, avoid direct sunlight and warm draughts etc.

Maximumrecommended operating ambient temperature is 32°Cat

65% RH, and for tropical machines is 40°C at 75%RH.

Adequate allowance should be made for door opening. The chiller

must be positioned on alevel surface for the doors to shut and seal

correctly, and to prevent the condensate tray from overflowing.

Shelves

Remove all packaging material from the shelves. Clip the shelf

support brackets into the shelf support strips, at the desired heights,

and fit the shelves.

Shelves may be positioned at different heights to suit various

products. Always ensure that the shelf clips are securely engaged in

each of the shelf support strips. Shelf support strips are marked ‘+’

for easy location of shelf clips.

NSTALLAT ON

2

8BB380r-2, BB580r-3, BB780r-4

SKOPE Backbar Remote Chillers

Mains flex

The mains flex exits below the refrigeration unit front cover. Initial

retrieval of the mains flex is from inside the refrigeration unit

compartment, behind the unit front cover. To retrieve the mains flex:

1.Open the unit front cover: firstly undo the fixing screw at bottom

of cover, then lift the cover up from the bottomand swing open.

2.Pull the mains flex fully out from the unit compartment, and

remove the rubber band.

3.Push the unit end of flex into the grey plastic clip beside the

front cover bottom hinge, and close the plastic clip over the

flex, ensuring it is held firmly in place.

4.The mains flex can now be run under the cabinet, and plugged

into a power socket

5.Close the unit front cover: by lifting the cover up from the

bottom and pushing firmly closed. Remember to refit the

bottom fixing screw.

NSTALLAT ON

2

Figure1: Mains Flex

Flex Clip

Unit Front Cover

MainsFlex

Bottom Hinge

Cabinet Base

9

BB380r-2, BB580r-3, BB780r-4

SKOPEBackbarRemote Chillers

2.2Refrigeration System

Drain

A500mm long, 19mm O.D. PVC drain hose is supplied. All drainage

is to conform to local regulations, covering removal of condensate to

waste water. Ensure drain is trapped with adequate fall. Venting the

drain may be required for a restrictive run.

Refrigeration lines

A 1/4” liquid line, and 3/8” suction line are provided to attach pipe

lines to. The suction lines must be insulated.

NOTE:The electronic controller supplied with the cabinet can switch

a solenoid. No solenoid is supplied with the remote unit.

Refrigeration Practice

Installation must be performed by arefrigeration tradesperson, to an

appropriate standard complying with all local regulations.

Performance depends on the overall installation (including

condensing unit). Cabinet suitability must always be quantified for

the application. The final responsibility for condensing unit

performance and component selection rest with the installer. The

installer must check matters such as:

•Heat load

•Refrigeration load

•Variable operating conditions (usage, ambient, humidity)

•Refrigeration pipe sizing

•Refrigeration pipe length (distance, elevation, pressure drop)

•Location and ventilation (cabinet and condensing unit)

•Drainage

NSTALLAT ON

2

10 BB380r-2, BB580r-3, BB780r-4

SKOPE Backbar Remote Chillers

•Power supply

•Unit is fully evacuated prior to charging

•All cabinet penetrations are sealed

Electrical

The cabinet is supplied with a 3-core 10 Amp mains flex and plug.

The cabinet lighting and centre pillar heater elements are protected

by a 3 Amp fuse, located in the unit junction box.

If a solenoid is fitted and controlled by the electronic controller, the

solenoid will need connected to the connector block inside the unit

junction box.

NSTALLAT ON

2

Figure 2:Refrigeration Pipework

Unit Pipework Cover Refrigeration Unit Compartment

Drain Tube

Suction Line

Liquid Line

Rear of Cabinet

11

BB380r-2, BB580r-3, BB780r-4

SKOPEBackbarRemote Chillers

3.1Safety nformation

When using any electrical appliance, safety precautions should

always be observed. Read these instructions carefully, and retain for

future reference.

•Do not use this appliance for other than its intended use.

•Only use this appliance with voltage specified on the rating label.

•Ensure adequate ventilation of SKOPE refrigeration unit.

•Be careful not to touch moving parts and hot surfaces.

•Do NOT cover the grilles or block the entry or exhaust of airflow

by placing objects up against the refrigeration unit.

•Do NOT probe any opening.

•Regulations require that all electrical work be carried out by

authorised persons. For your own safety and that of others,

ensure this is done.

•If the refrigeration unit is required to be installed or removed

from the cabinet, ensure all necessary safety precautions are

observed.

Warning:

Do NOT overload power supply.

Caution:

Disconnect machine mainspower supply before attempting to

perform any electrical service or maintenance.

OPERAT ON

3

12 BB380r-2, BB580r-3, BB780r-4

SKOPE Backbar Remote Chillers

3.2Operation of Machine

Plug in machine and check operation of the refrigeration unit and

lights. The electronic controller and evaporator fan motor should

operate initially. Note: If the solenoid valve is fitted, and operated by

electronic control, then the solenoid should open when compressor

indicator is shown.

Checking operation

•The solenoid / compressor relay should switch off when cabinet

internal temperature reaches approximately +1°C, and on again

at approximately +4°C. The internal cabinet air will continue to

circulate at all times.

•The light switch, located next to the electronic controller on the

refrigeration unit front cover, activates the cabinet interior

lighting and can be switched on or off as required.

•For efficient operation, ensure the door gaskets form a good

seal with the cabinet.

3.3Loading

For even cooling and efficient operation, allow air space around

packages etc. Do not allow products to overhang the front of shelf

as this could prevent the door fromshutting or cause glass

breakage.

mportant:

Leave air space above product on the top shelf, as well as a

gap of approximately 50mm next to the return air grille

between the cabinet interior and the refrigeration unit

compartment.

OPERAT ON

3

13

BB380r-2, BB580r-3, BB780r-4

SKOPEBackbarRemote Chillers

3.4Cleaning

When necessary, wash both interior and exterior of cabinet with

soapy water. Exterior of cabinet may be waxed with automobile

polish for extra protection. Ensure the machine is disconnected from

the mains power supply before washing the cabinet with water.

Do not wipe the sealant off the swing door gaskets, as the sealant

ensures the door gaskets forma good seal with the cabinet.

Caution:

Disconnect machine from mains power supply before washing

the cabinet with water.

3.5Servicing

Servicing should be carried out by an authorised service agent.

Detailed service and spares information is available in the SKOPE

Backbar Remote Operating and Service Manual - P/No: MAN0707.

OPERAT ON

3

14 BB380r-2, BB580r-3, BB780r-4

SKOPE Backbar Remote Chillers

4.1Controller Display

Table1: Controller Operation

In normal operating conditions the controller can permanently

display one of the following:

tem KeyFunction

1SET: Pressto displaytarget set point. In programming mode it selects

a parameter or confirms an operation

2DEFROST: Press to start a manual defrost

3UP: Pressto see the maximum stored temperature. In programming

mode it browses the parameter codes,orincreasesthe displayed value

4DOWN: Press to see theminimum stored temp. Inprogrammingmode

it browses the parameter codes, or decreasesdisplayed value

5Compressor ON indicator

6Defrost cycle ON indicator

7Set Point displayed indicator

8Decimal point indicator

Key Combinations:

+ Press to lock and unlock the keypad

+ Press to enter the programming mode

+ Press to return to the roomtemperature display

ELECTRONC CONTROLLER

4

1

35

2

4

6

7

8

Figure3: ControllerDisplay

15

BB380r-2, BB580r-3, BB780r-4

SKOPEBackbarRemote Chillers

1.Internal cabinet temperature (standard parameter ‘Lod’ =P1)

2.Setpoint (parameter ‘Lod’ = SP)

3.Condensing temperature (parameter ‘Lod’ =P2)

Meaning of LEDs

Each LED function is described in the following table:

Table 2: LED Functions

4.2Controller Operation

The SKOPE electronic controller controls and displays the cabinet

temperature. The preset temperature setting controls internal air

temperature between 1°C and 4°C. For compressor protection the

control has built in minimumoff cycle time of 3minutes, and features

regular timed defrost cycles (compressor off, evaporator fans on).

Probe One is fitted to abracket in the return evaporator airflow. This

probe is used for both temperature control and display.

Probe Twois cable tied in place with an insulated cover. This probe

is not active.

LEDModeFunction

ONCompressor enabled

Flashing Programmingphase(flashingwith)

Anti-short cycle delay enabled

ONDefrost enabled

Flashing Programmingphase(flashingwith)

Drip time in progress

ONThe Set Point is displayed

ELECTRONC CONTROLLER

4

16 BB380r-2, BB580r-3, BB780r-4

SKOPE Backbar Remote Chillers

4.3Programming Controller

The controller keypad must always be locked, to prevent unauthor-

ised modification.

To unlock the keypad (to modify parameters)

Press both the UP and DOWN keys until ‘Pon’

is displayed.

How to lock the keypad

1.Press and hold both the UP and DOWN

keys for more than 3 seconds.

2.The ‘PoF’ message will be displayed and

the keypad will be locked. At this point it will be possible only to

see the Set Point or maximum or minimum temperature stored.

3.If akey is pressed for more than 3seconds, the ‘PoF’ message

will be displayed.

To display the Set Point

Press, and immediately release the SET key. The

display will show the Set Point value, and the Set Point

LED will be highlighted.

To change the Set Point

1.Push and hold the SET key for

more than 2 seconds.

2.The value of the Set Point will be

displayed, and the LED will start blinking.

3.To change the Set value, push the UP or DOWN keys.

4.To memorise the new Set Point value, push the SET key again

or wait 15 seconds.

ELECTRONC CONTROLLER

4

17

BB380r-2, BB580r-3, BB780r-4

SKOPEBackbarRemote Chillers

To start a manual defrost

Push and hold the DEFROST key for more than 2

seconds.

To change a parameter value

1.Enter the programming mode by

pressing and holding both the

SET and DOWN keys for 3 sec.

( and start flashing).

2.Select the required parameter.

3.Press the SET key to display the Set value (now only the

LED is flashing).

4.Press the UP or DOWN keys to change the Set value.

5.Press the SET key to store the new value and move to the

following parameter.

6.To exit: Press both the SET and UP keys, or wait 15 seconds

without pressing any keys.

7.To lock in new parameter value: after one minute operation,

disconnect and reconnect cabinet into the mains power supply.

NOTES:

1.The Set value is stored even when the procedure is exited by

waiting for the time-out to expire.

2.Dependent on customer requirements, the SKOPE electronic

controller has different parameter configurations.

Parameter configuration 160 = Beverage, and 170 = Food.

To establish correct controller parameter configuration, see

label on controller housing.

ELECTRON C CONTROLLER

4

18 BB380r-2, BB580r-3, BB780r-4

SKOPE Backbar Remote Chillers

4.4Parameters

Table 3: Controller Parameters

Parameters

Display Beverage

160

Food

170

Range Description of Parameter

SET PO NT PARAMETERS

Set 2 1 LS to US Set Point

Hy 2 2 0.1°C to 25.5°C Differential

LS +1 -1 DO NOT ADJUST

US 15 5

PROBE PARAMETERS

Ot -0.7 0 DO NOT ADJUST

OE 0 0

CONTROL PARAMETERS

OdS 0 0 DO NOT ADJUST

AC 3 3

D SPLAY PARAMETERS

CF °C °C

DO NOT ADJUSTrES dE in

LoD P1 P1

DEFROST PARAMETERS

IdF 6 6 1 to 120 hours Interval between defrost cycles

MdF 12 12 0 to 255 minutes Maximum length for defrost

dFd dEF dEF DO NOT ADJUST

dAd 20 20

ALARM PARAMETERS

ALc Ab Ab DO NOT ADJUST

ALU 12 7 ALL to 150°C Maximum temperature alarm

ALL -2 -2 -50°C to ALU Minimum temperature alarm

AtH 1 1

DO NOT ADJUST

ALd 240 120

dAO 24 24

tbA n n

PA2 58 58

AU2 65 65

ACH 5 5

dL2 2 2

dA2 0 0

AOP CL CL

OTHER PARAMETERS

dP1 - -

DO NOT ADJUST

dP2 - -

rEL - -

Ptb - -

ELECTRONC CONTROLLER

4

19

BB380r-2, BB580r-3, BB780r-4

SKOPEBackbarRemote Chillers

4.5Display Alarms

Aflashing LED indicates an alarm.The following is alist of the alarm

displays:

Table 4: Controller Display Alarms

Note: Refrigeration systemand cabinet lighting shut down with ‘P1’,

‘P2’ and ‘CSd’ alarms.

Alarm Recovery

•Condenser over temperature alarm ‘COH’ recovers when the

condenser is either cleaned or cools down.

•Condenser alarm ‘CSd’ temperature recovers by replugging the

cabinet power supply (or isolation switch). In this case, all the

alarms are reset.

AlarmDescription

Stage ONE - Maintenancerequired:

Immediately attend condenser (for auto alarmreset).

Stage TWO - Refrigeration Shut-Down:

Condenser over-temperaturehas shut-down system and

cabinetlighting.Attendcondenser.To reset alarm, cabinet

must bereplugged intopower supply.For repeat alarms,

contact anauthorisedserviceagent.

Faulty Ambient probe (internal cabinet - return air)

Faulty HighTemperatureprobe(condenser)

Internal cabinet - LOW temperature alarm

Internal cabinet - HIGH temperature alarm

ELECTRON C CONTROLLER

4

This manual suits for next models

2

Table of contents

Popular Storage manuals by other brands

QNAP

QNAP TS-h1886XU-RP-R2 user guide

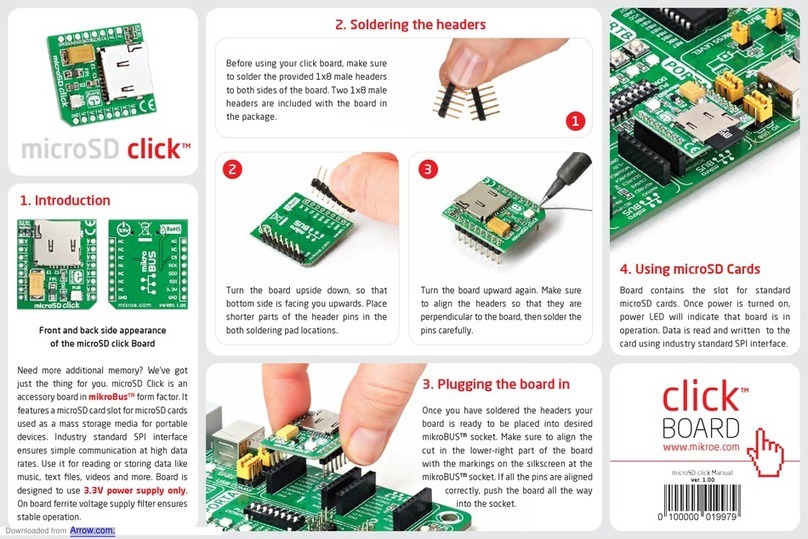

mikroElektronika

mikroElektronika microSD Click quick start guide

Verbatim

Verbatim 2-Disk RAID USB and eSATA External Hard... user guide

Glyph

Glyph GT050Q1F-1000 quick guide

G-Technology

G-Technology G Drive Pro product manual

Synology

Synology CS-406 Quick installation guide