SkyAzúl qSCALE maestro User manual

qSCALE maestro

Service Manual

qSCALE maestro Service Manual

SkyAzúl, Equipment Solutions www.skyazul.com 301-371-6126

NOTICE

SkyAzúl makes no warranty of any kind with regard to this material, including, but not limited to, the

implied warranties of merchantability and/or its fitness for a particular purpose.

SkyAzúl will not be liable for errors contained in this manual or for incidental or consequential

damages in connection with the furnishing, performance, or use of this manual. This document

contains proprietary information, which is protected by copyright, and all rights are reserved.

No part of this document may be photocopied, reproduced, or translated to another language without

the prior written consent of SkyAzúl.

SkyAzúl reserves proprietary rights to all drawings, photos and the data contained therein. The

drawings, photos and data are confidential and cannot be used or reproduced without the written

consent of SkyAzúl. The drawings and/or photos are subject to technical modification without prior

notice.

All information in this document is subject to change without notice.

SkyAzúl, Inc.

16 Walnut Street

Middletown, MD 21769

Fax 301-371-0029

TABLE OF CONTENTS

1Safety Instructions ...........................................................................................8

2Components......................................................................................................9

2.1 Base Kit with vScale D2 (102125).............................................................9

2.1.1 Junction Box, qSCALE maestro (062003).............................................9

2.1.2 Pressure Sensor Kit (102121) .............................................................10

2.2 Boom Upgrade (102124).........................................................................10

2.2.1 Sensor Assembly Length Angle WGX/CAN (061185).........................10

2.3 Boom Kit, New Cable Reel (102126).......................................................10

2.4 Indicator Kit, Light Tower (102127) .........................................................10

3Description of the System.............................................................................11

3.1 Product Identification ...............................................................................12

3.2 General Information.................................................................................12

3.3 EC Conformity Declaration......................................................................12

3.4 Overview of Console Elements ...............................................................13

3.5 Overview Feedback Elements.................................................................14

4Service Menus ................................................................................................15

4.1.1 Password Entry....................................................................................15

4.1.2 Obtaining the Daily Password..............................................................17

4.2 System Settings.......................................................................................17

4.2.1 System Settings Breakdown................................................................19

4.2.2 New Password Entry ...........................................................................21

4.3 Sensor Calibration ...................................................................................22

4.3.1 Calibrate Angle Sensors......................................................................23

4.3.2 Calibrate Length Sensors....................................................................25

4.3.3 Luffing Cylinder Tuning........................................................................27

4.4 Entering Measurements...........................................................................30

4.5 Alarm Volume ..........................................................................................31

5Service and Maintenance ..............................................................................32

5.1 Download Application Data......................................................................32

5.2 Reading the Event Recorder ...................................................................33

5.3 Reset Hour meter ....................................................................................34

5.4 Change Date and Time............................................................................35

5.5 Rotate Display .........................................................................................36

5.6 Screen Capture........................................................................................37

5.6.1 Taking Screen Captures......................................................................37

5.6.2 Saving Screen Captures......................................................................37

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

5.7 Mismatched DA4 .....................................................................................38

5.8 Maintenance and Repair..........................................................................39

6Troubleshooting .............................................................................................40

6.1 Identify the Problem.................................................................................40

6.2 Initial System Inspection..........................................................................42

6.3 Indicator Definitions .................................................................................43

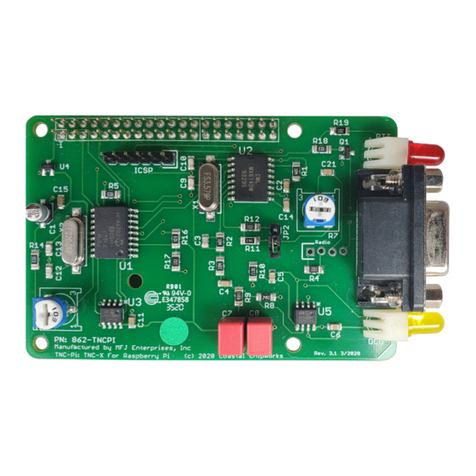

6.3.1 Indicators on Central Control Unit........................................................43

6.3.2 Indicators on Console..........................................................................43

6.4 Boom Angle Sensing ...............................................................................44

6.5 Boom Length Sensing .............................................................................46

6.5.1 Cable Reel Length Cable Replacement Procedure ............................47

6.6 Pressure Sensing ....................................................................................48

6.7 Load Sensing...........................................................................................49

6.8 Anti-Two Block Switch (A2B)...................................................................50

6.8.1 A2B Problem –Flow Chart..................................................................51

6.9 No Console Display.................................................................................52

6.10 CAN Bus Communications......................................................................53

6.11 Troubleshooting Sensors With Display....................................................56

6.11.1 Readings of CAN Bus Sensors........................................................56

6.11.2 Readings of Digital Inputs................................................................57

6.11.3 Readings of Digital Outputs.............................................................58

7Appendix .........................................................................................................59

7.1 Technical Data.........................................................................................59

7.1 Version 1 System Drawings.....................................................................60

7.1.1 061179 Junction Box Wiring Diagram .................................................60

7.1.2 Controller to 061179 Junction Box Harness Pinout.............................61

7.1.3 X1 Controller Plug to 061179 Junction Box Pinout Detail ...................62

7.2 Version 2 System Drawings.....................................................................63

7.2.1 System Layout.....................................................................................64

7.2.2 Cable Reel Upgrade (102124).............................................................65

7.2.3 062003 Junction Box Wiring Diagram .................................................66

7.2.4 Controller to 062003 Junction Box Harness Pinout.............................67

7.2.5 X1 Controller Plug to 062003 Junction Box Pinout Detail ...................68

7.2.6 Wind Speed Kit Wiring Detail...............................................................69

7.3 Boom Kit (102126)...................................................................................70

7.4 Boom Kit Wiring Detail (102126) .............................................................71

7.5 Cable Reel Wiring Detail..........................................................................72

7.6 vSCALE D2 Diagram...............................................................................74

7.7 Error Codes Table ...................................................................................75

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

301-371-6126

1 Safety Instructions

WARNING

Imminent threat of personal injury and damage to property due to incorrect sys-

tem settings!

The correct adjustment of the RCL to the current set-up status is essential for the

correct function of the system and of the machine.

The RCL can only operate correctly if all settings are entered correctly according

to the current set-up status during the SETUP procedure.

The settings can only be carried out by operators who are completely familiar with

the operation and functions of the machine and the RCL.

The correctness of these settings must be guaranteed before starting the machine

operations!

IMPORTANT

Connection to the wrong power supply will cause damage to the device.

The device may only be connected to a DC voltage source of 10 V to 30 V!

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 8

301-371-6126

2 Components

Kit Name

Kit Number

QTY

Section

BASE UPGRADE KIT W/ VSCALE D2

102125

1

Section 2.1

BOOM UPGRADE (FROM EXISTING 200/208/209 REEL)

102124

1

Section 2.2

BOOM KIT, NEW CABLE REEL

102126

1

Section 2.3

INDICATOR, LIGHT TOWER, MAESTRO, 10M, 3 COLOR (RGY)

102127

1

Section 2.4

2.1 Base Kit with vScale D2 (102125)

Component Name

Part Number

QTY

Notes

SMC, POWER HARNESS, VSCALE CONSOLE, PWR ONLY, 12'

061106

1

SMC, CONSOLE, VSCALE, D2 - C1, 4.3" DISPLAY

062010

1

SMC, QSCALE MAESTRO S6, IP66/67

623029

1

JUNCTION BOX, QSCALE MAESTRO

062003

1

Section 2.1.1

ETHERNET CABLE - 10 METER - 90 DEG BEND

900004191

1

M12 CAN CABLE - 3 METER

10967

1

CONSOLE ACCY, KIT 2-1" BALL W/ 4.75" MTG. ARM

031-300-060-382

1

SMC, CONSOLE ACCY, RAM MOUNT ADAPTER, iSCOUT D2

608460

1

SMC, DUMMY PLUG ASSY, 48-PIN

060980

1

KIT, QSCALE IX, LOAD, PSENS, DAVS, 300 BAR, SAE 6, ID 60/61

102121

1

Section 2.1.2

2.1.1 Junction Box, qSCALE maestro (062003)

Component Name

Part Number

QTY

RELAY, 30A, 12VDC, W/ DIODE, MOUNTING TAB

051355

1

RELAY, 40A, 24VDC, W/ DIODE, MOUNTING TAB

501362

1

CAUTION

Ensure that if the junction box is installed external to the cabin that the junction

box is oriented so that the connectors and strain reliefs are pointing down to

prevent water ingress.

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 9

301-371-6126

2.1.2 Pressure Sensor Kit (102121)

Component Name

Part Number

QTY

SENSOR,PRESS,SINGLE,CAN,ID 60

061091

1

SENSOR, PRESS TRANS, CAN,ID 61

061092

1

2.2 Boom Upgrade (102124)

Component Name

Part Number

QTY

Notes

SENSOR ASSY, LENGTH/ANGLE, WGX/CAN

061185

1

Section 2.2.1

2.2.1 Sensor Assembly Length Angle WGX/CAN (061185)

Component Name

Part Number

QTY

SENSOR, ANGLE, WGX 360/3510, ACTIVATED RESISTOR, 125KBPS, CA

061194

1

BOARD, LENGTH & A2B CAN -120

535950

1

2.3 Boom Kit, New Cable Reel (102126)

Component Name

Part Number

QTY

Notes

CABLE REEL, KT200, STANDARD

006-820-006-002

1.00

SENSOR ASSY, LENGTH/ANGLE, WGX/CAN

061185

1.00

Section 2.2.1

2.4 Indicator Kit, Light Tower (102127)

Component Name

Part Number

QTY

INDICATOR, LIGHT TOWER, 3 COLOR LED (GRN, YEL, RED)

051264

1.00

INDICATOR ACCY, POWER MODULE (FOR #051264 LIGHT TOWER)

051265

1.00

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 10

301-371-6126

3 Description of the System

The maestro system (also referred to as ‘RCL’) is a CAN bus system comprised of a central

microprocessor unit, operating console, angle sensor, tilt sensor, load pin, and anti-two block

switch. All components and sensors are equipped with CAN bus controllers.

When limits are reached an overload warning signal is generated at the operator’s console. At

the same time, the Function Kick Out (FKO) outputs are deactivated thus ‘locking out’ the opera-

tor and stopping aggravating machine movements. The fixed data regarding the machine (ex.

capacity charts, boom weights, centers of gravity, etc.) are stored in memory chips in the central

processor unit. This data is the reference information used to calculate the operating conditions.

NOTE

This service manual contains information about the vSCALE D2 maestro console,

mode selection, operation, sensor calibration and maintenance.

WARNING

This service manual contains information about the vSCALE D2 maestro console,

mode selection, operation, sensor calibration and maintenance.

Although the system incorporates functions for monitoring adjustable geomet-

rical limit values with visual and audible warnings and a relay output in the event

of limit values being exceeded, the system cannot be used as an operational limit

switch.

The machine driver is responsible for the safe operation of the machine.

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 11

301-371-6126

3.1 Product Identification

The type plate carries the unique identification of the operting console. It is located on the back of the

device.

Please ensure you make a note of all the information on your type plate for queries about this product.

3.2 General Information

NOTE

Knowledge of how to use a voltmeter to measure both voltage and current is as-

sumed.

HINT

For general system operation, refer to the console Operator’s Manual.

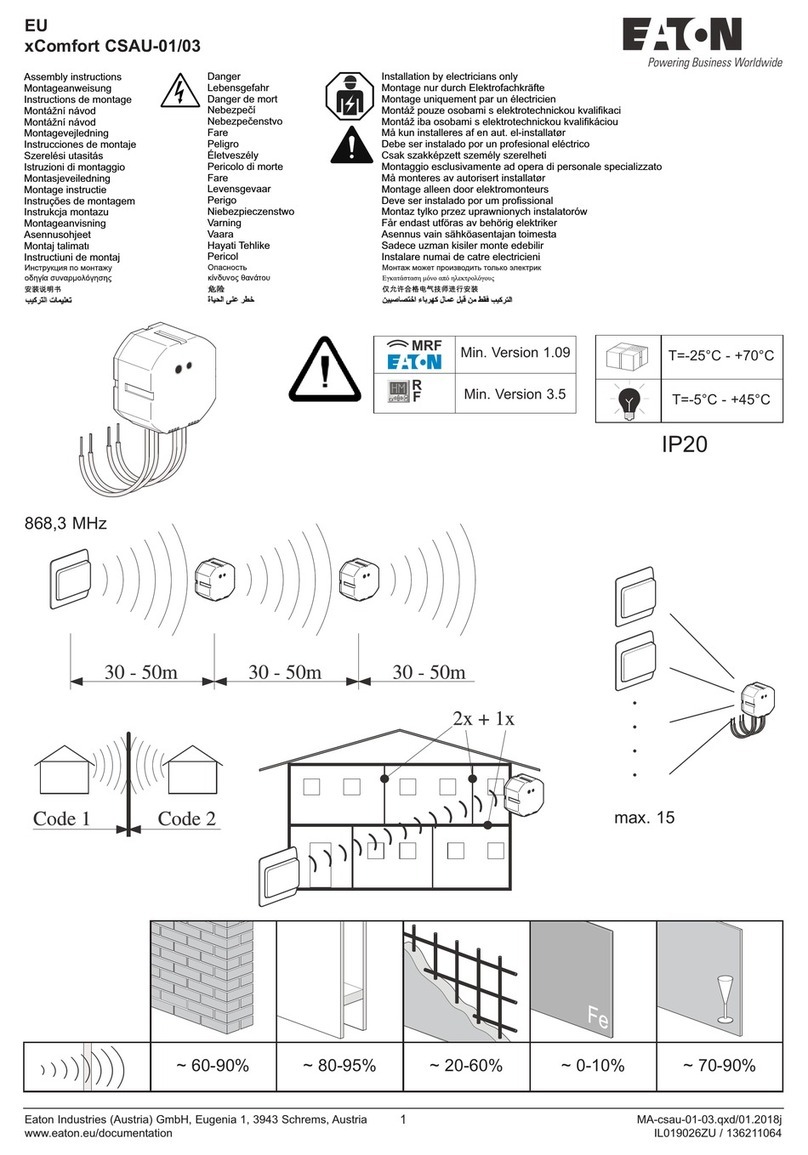

3.3 EC Conformity Declaration

The technical design and construction of the qSCALE maestro system corresponds to requirements of

the EMC directive 2004/108/EC and therefore carries the CE symbol.

The device complies with the following standards:

EN 12895:200, EN 13309:2010, EN ISO 14982: 2009

The full conformity declaration is available from the manufacturer on request.

Type plate

(Example)

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 12

301-371-6126

3.4 Overview of Console Elements

Function Keys F1 to F8: Calls Functions

Encoder With Pushbutton Function: For Selection and Confirmation

SET key: Selects Settings / Silences Alarm

HOME key: Returns to Main Working Screen

ESCAPE key: Aborts Function

Display with

RCL Main Menu

Rotary Encoder with

Pushbutton Function

For Selection and Con-

firmation

"Set" Key

Selects Settings /

Silences Alarm

"Home" Key

(Return to RCL Main

Operating Screen)

"Escape" Key

Aborts Function / Returns to

previous screeen

Feedback Elements

(See Section 3.5)

Function Keys F1-F8

Function Varies by screen

USB 2.0 interface

(used for service purposes)

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 13

301-371-6126

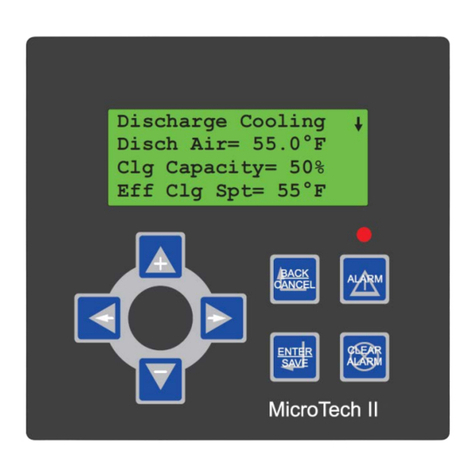

3.5 Overview Feedback Elements

Light Sensor: Not Used

Operating Display: Green While Supply Voltage is Connected

USB Data Display: Yellow During Data Exchange via Front USB Port

Wireless Indicator: Not Used

Multi-Function Light:

/

Flashes Red/White while in error state

Blue while setting the operating mode

Green while in operation

Yellow Machine nearing operational limit

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 14

301-371-6126

4 Service Menus

This chapter contains information, advice, and instructions for navigating and using the service menus.

4.1.1 Password Entry

In order to access certain menus it is necessary to enter a password. There are three password

levels:

User Level Password. The User password is 0000 and allows:

Entry to the System Settings Menu. (View only)

Setup Level Password. The Setup password is 4830 and allows:

All of the above

All Sensor Calibration routines and luffing cylinder tuning

Datalog Download

Resetting the machine runtime meter

Setting the console & controller date and time

Changing the volume of the alarm

Service Level Password. The daily password is a service level password and allows:

All of the above

Changes to System Settings

Installation of the crane model files

Rotating the display

(See Section 4.11 for information on Obtaining the daily password.)

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 15

301-371-6126

Password entry is done by the following instructions:

Use the rotary knob to select the numbers.

Pressing the knob moves to the next digit and selects right arrow.

Pressing the right arrow when the curser is to the right of the last number confirms the entry

Use the or buttons to select the number in the chosen direction. (The selected digit turns green and will be

replaced by the next selection.)

Use the button to delete the currently selected digit.

Press to confirm the password as displayed.

CAUTION

Entering the Service Password will unlock all service functions on the console until it is reset.

Always reset the console when service is complete to lock access to service menus.

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 16

301-371-6126

4.1.2 Obtaining the Daily Password

Summary

In order to obtain the Daily Password you must find the Daily Password Seed in the Settings

Menu and enter it into the excel sheet to be converted into a usable password that will last the

entire day.

Finding the Daily

Password Seed

The Daily Password Seed is located in the Settings Menu in the bottom center of the screen

above the Information Bar.

HOME

SETTINGS

Converting the

Seed into the Daily

Password

Open the DailyPassword_maestro.xls document and enter the Daily Password Seed into the field

beside the “Console” cell and then press the TAB key.

The DailyPassword_maestro.xlsx document will then generate a daily password next to the

“Password” cell.

This password will allow access to service functions until the console’s internal clock reaches

12:00am at which time a new seed is created.

4.2 System Settings

Daily Password Seed.

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 17

301-371-6126

HOME

SETTINGS

SYSTEM

SETTINGS

Function Keys

And

Choose option to adjust.

(See Section 4.2.1 for explanations of

each option.)

And

Adjust chosen option.

(See Section 4.2.1 for explanations of

each option.)

New Password Entry.

(See Section 4.2.2)

NOTE

A service level password is required to make any changes in the System Settings

Screen (See Section 4.2.2)

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 18

301-371-6126

4.2.1 System Settings Breakdown

Toggling Wind Speed Display

Use the or keys to select the Wind Speed option.

Use the or keys to set the Wind Speed display to 0 (off) or 1 (on).

Setting the Wind Speed Display to 0 (off) removes the Wind Speed Display from the Information Bar in the Main

Operating Screen.

Toggling Jib Status Display

Use the or keys to select the Jib Status option.

Use the or keys to set the Jib Status display to 0 (off) or 1 (on).

Setting the Jib Status Display to 0 (off) removes the Jib Height and Jib Angle values from the Main Operating

Screen.

Jib Status On:

Jib Status Off:

Wind Speed Display Off:

Wind Speed Display On:

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 19

301-371-6126

Toggling Cameras

Use the or keys to select the Camera option.

Use the or keys to set the Camera option to 0 (off) or select the number of cameras to activate.

Setting the Camera option to 1 or more enables the function key from the Main Operating Screen.

Toggling Camera Full-Screen Style

Use the or keys to select the Full Screen option.

Use the or keys to set the Full Screen Style to 0 (partial full screen) or 1 (complete full screen).

Setting the Full Screen Style to 1 (complete full screen) causes the function key to fully fill the screen with the se-

lected camera feed covering the function keys and Information Bar

Camera On:

Camera Off:

Full Screen 0:

Full Screen 1:

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 20

301-371-6126

4.2.2 New Password Entry

Summary

You can change the active password, for example from a the Daily Password to the Service

Password, using the New Password Entry button in the System Settings Screen

HOME

SETTINGS

SYSTEM

SETTINGS

NEW

PASSWORD

See Section 4.1.1 for instructions on entering the new password.

qSCALE maestro

Service Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

Page 21

301-371-6126

Table of contents