www.skyrc.com - 10 -

WATT METER

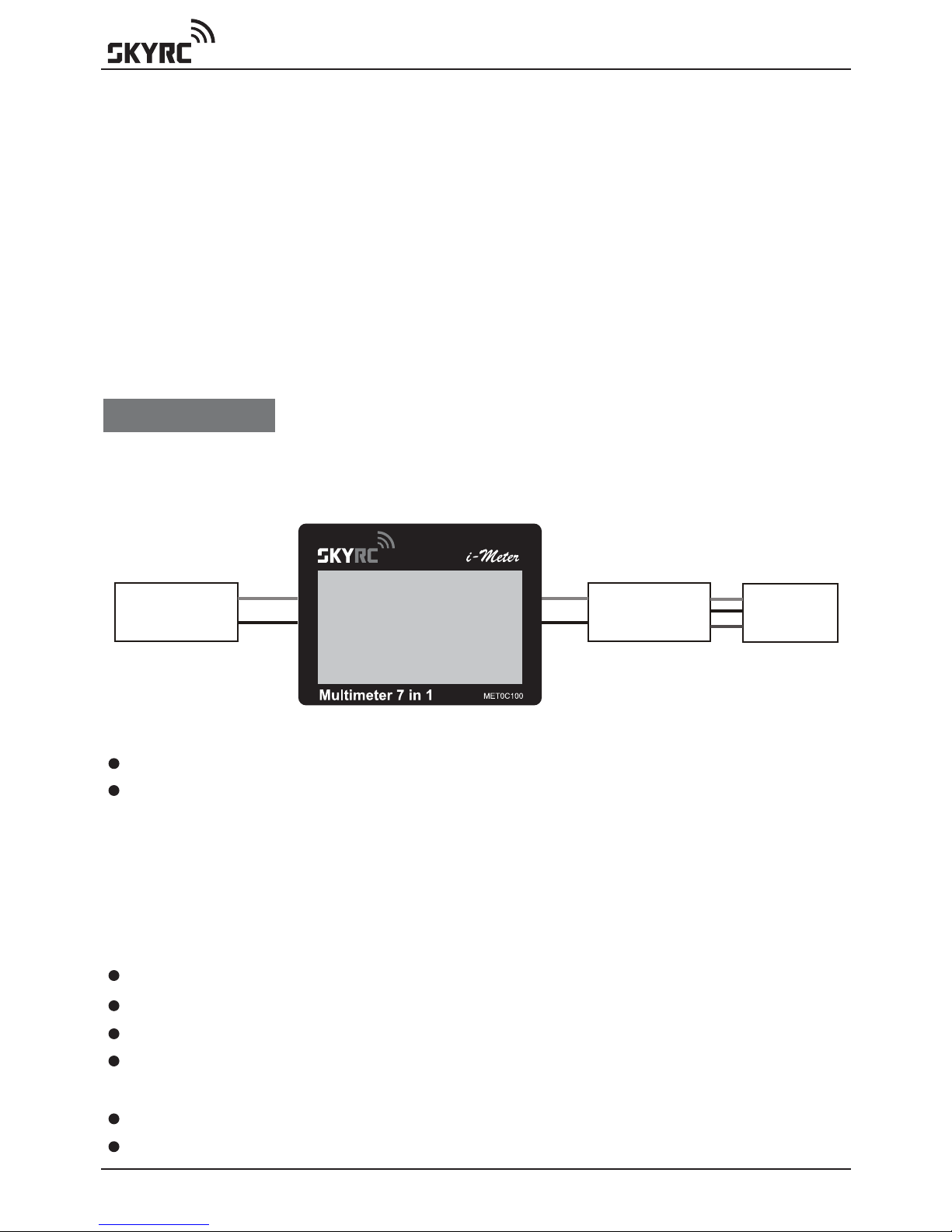

WATT METER

This function measures Current (Amps), Peak current, Voltage (Volts),

Power (Watts), Energy(Watt-Hours) and Charge(Amp-Hours) values for

you, in real-time, for the circuit in which you connect it.

Now you can stop wondering what's going on with your electric model

and get answers that allow you to apply science to your hobby. The

precise measurements you collect will help you fine tune your model

to get all the performance that you paid for.

With watt meter function, it is now easy to determine things like:

Flight time

Current through an ESC and motor

ESC, BEC and motor efficiencies

Charge put into and removed from a battery and the performance of

battery chargers

Battery health

Why power is lost during acrobatics or extreme conditions

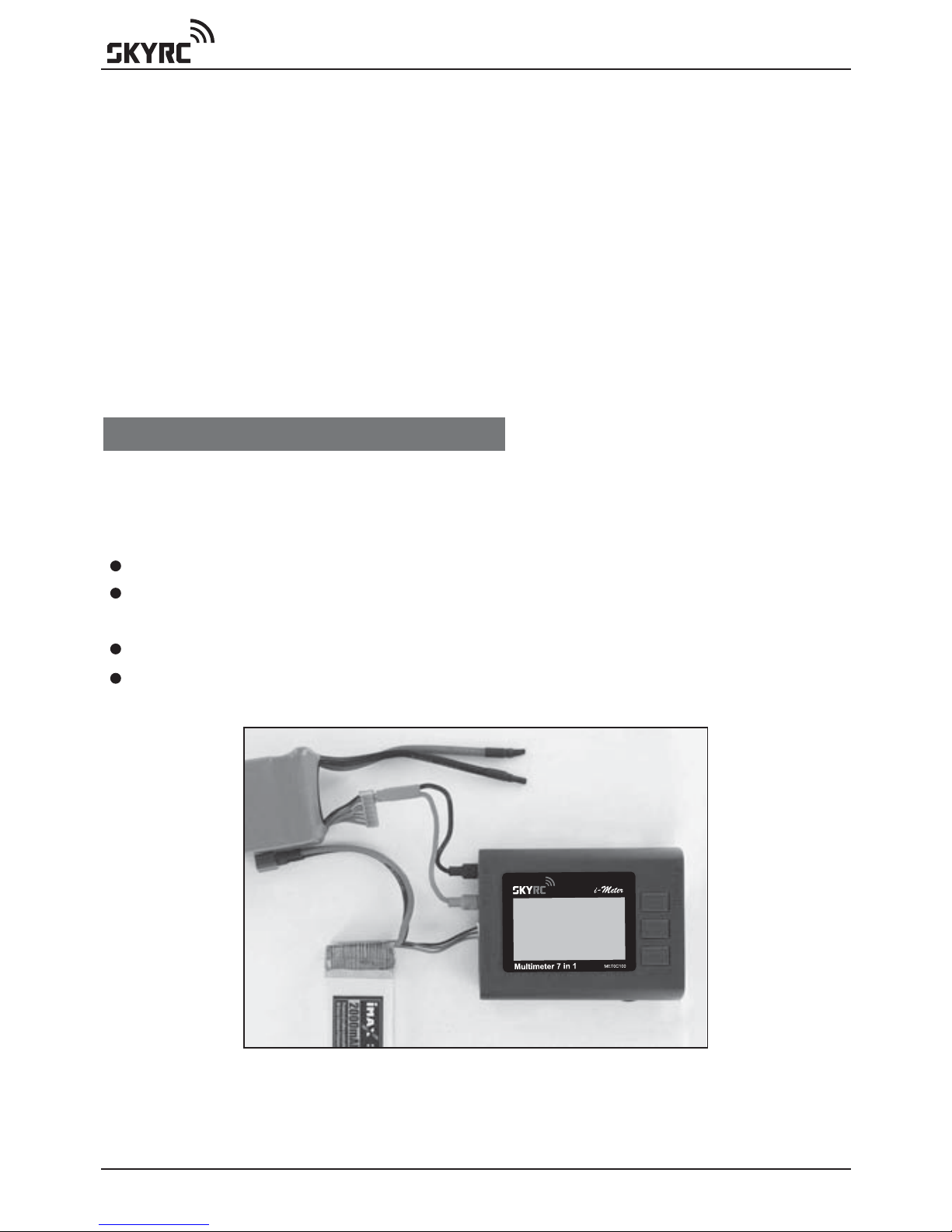

i-Meter is activated when the battery is connected to the unit.

Press ‘MODE’ to select ‘WATT METER’ function

Press ‘ENTER’ to confirm selection

PRECAUTIONS

1. Do not leave a cell connected to the i-Meter for more than five

minutes.

2. Be aware that although the i-Meter only takes small samples from

the battery pack, the voltage will be reduced. Make sure you check

your pack balance.

3. Avoid plugging the cell in reverse polarity. The i-Meter can cope with

a reversed connection for a few seconds but it’s still better not to do

it in the first place.

4. Do not connect more than 5V to the cell inputs, again, the IRM can

cope for a few seconds but it’s best not to do it!

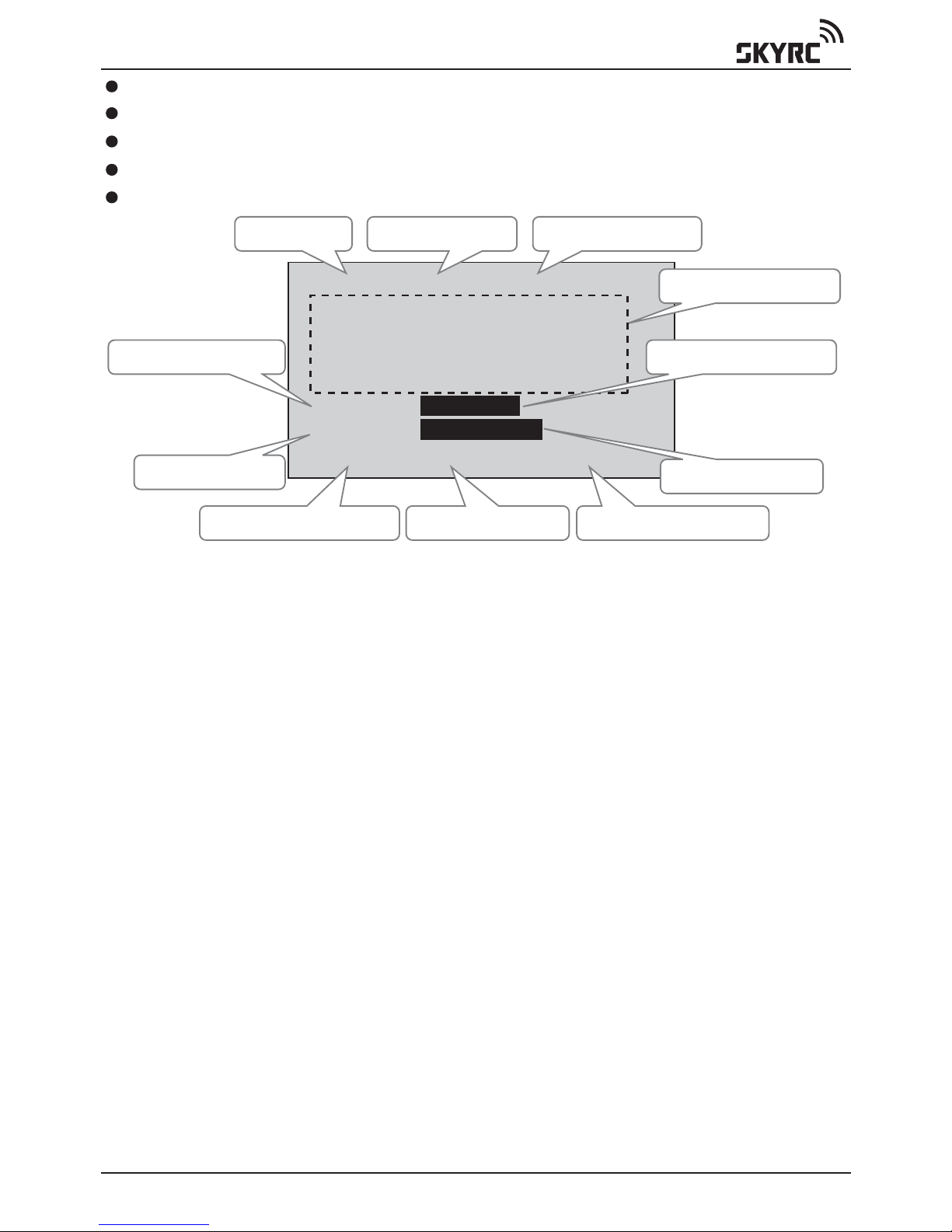

Battery

Pack

Speed

Controller

Motor

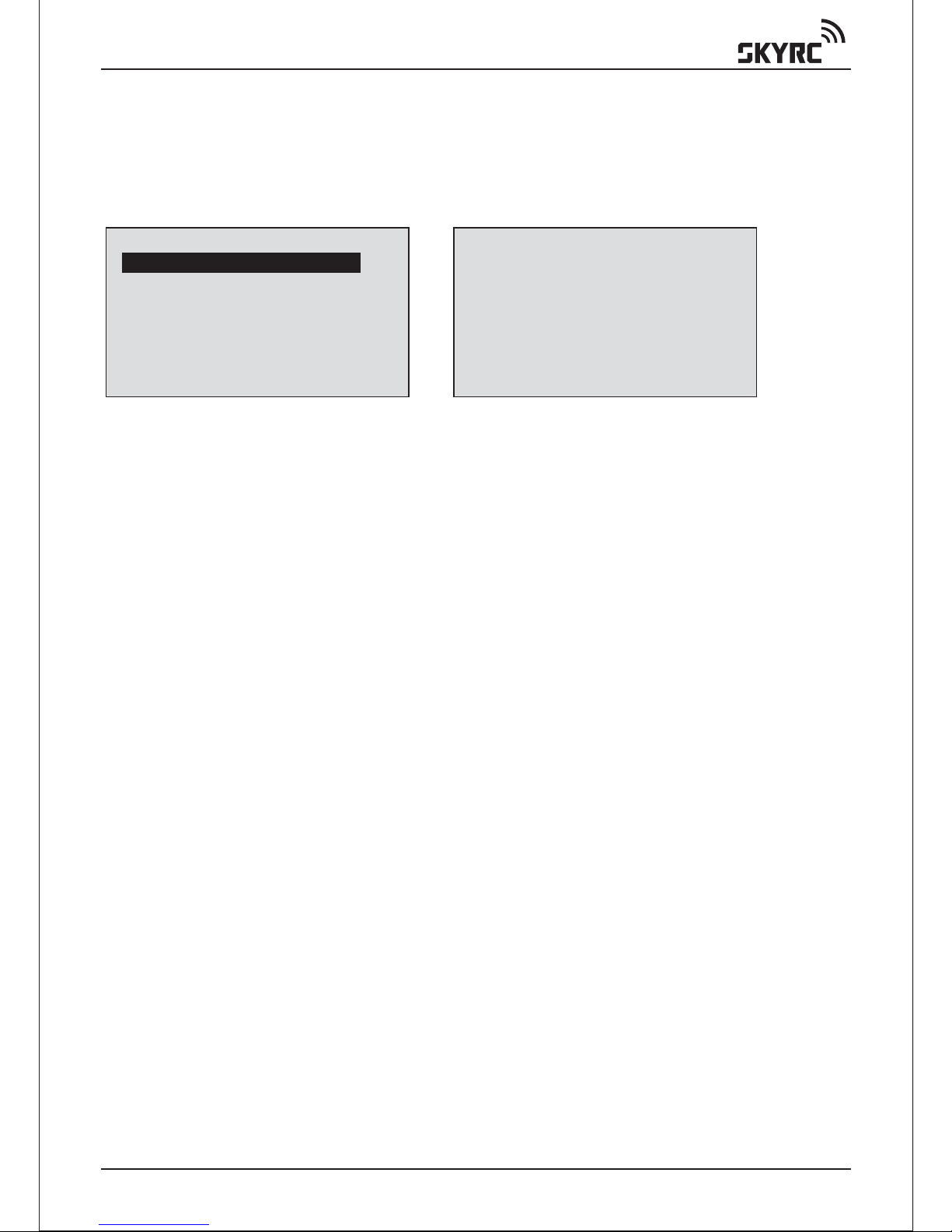

WATT METER

CURRENT: 35.11A

PEAK(C): 52.11A

VOLTAGE: 25.13V

WATTAGE: 882.31W

PEAK(W): 1309.2W

Energy: 82Wh

Charge: 3.2Ah