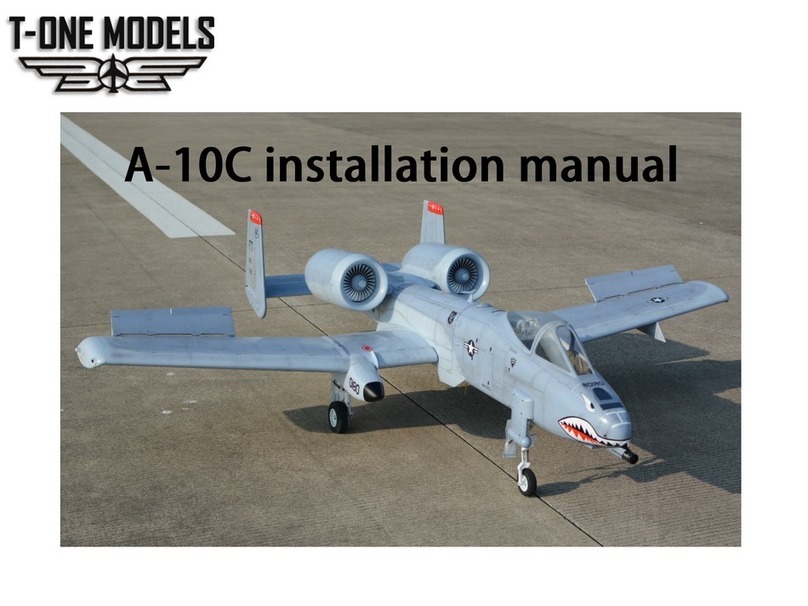

Skyshark Focke-Wulf 190A-8 User manual

Considered a highly risky and unnecessary venture

by urt Tank of Focke-Wulf, the Fw190 eventually

proved to be probably the best fighter produced by

Germany in WWII. Design work was started in 1938

with the idea of using the BMW radial engine

wrapped by the smallest possible airframe. Initial

testing showed that, with the exception of engine

cooling problems, the Fw190 was a superb handling

aircraft, and production variants started rolling off the

assembly line in June 1941. Squadron use quickly

showed that the 190 was more than a match for the

British Spitfires and Hurricanes, and the 190 was well

suited to many other uses, such as dive bombing.

Several variants were introduced in succession, with

the A-8 version being the last of the fighter variants

to be powered by the radial engine. Later versions

switched to an in-line engine, thus the “short nose”

and “long nose” Focke-Wulfs. The A-8 version was

used until the war’s end, side by side with most other

variants, and was a comparable match to the

Mustangs and later Spitfires.

The Fw190 A-8 variant was powered by the BMW

801D-2 radial engine, with a horsepower rating of

1700 hp. Water injection was used to boost takeoff

and combat performance. The Wingspan of the 190

was 34 ft. 5 ½ in, with a length of 29 ft. 5 in. Gross

weight was over 7,600 pounds. Armament varied

greatly, but the standard included two Mg131s in the

fuselage, and four Mg151s in the wing. A variety of

cannons, rocket pods, and bombs could also be car-

ried. Standard crew was one pilot, though there was

room in the aft fuselage to carry another person,

usually a downed pilot picked up during an emer-

gency. A two seat trainer was introduced in the latter

stages of the war.

Skyshark R/C Corporation

75 Mid Cape Terrace, Ste 7

Cape Coral, FL 33991, U.S.A.

Web ite: www. ky harkrc.com

email: c ervice@ ky harkrc.com

Thank you for purchasing the FW 190 from Skyshark R/C

Corporation. For the first time, R/C enthusiasts have a

choice in scale aircraft designs. Our goal, through comput-

er technology and state-of-the-art production techniques, is

to offer aircraft which in the past have not been modeled

simply because they weren’t popular enough to justify mass

production. Our production techniques allow us to produce

aircraft which, though not as popular and well known as P-

51s and P-47s, still offer historical significance (good or

bad!), Good looks and flying characteristics, and a unique-

ness that is sure to turn heads wherever you take your air-

plane!

Your airplane has many unique features

in its design:

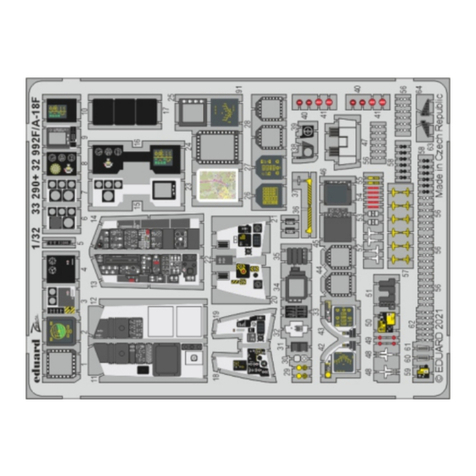

CAD Design

CAD design allows strength to be built into the airplane

without sacrificing weight. Accurate parts design and place-

ment ensures a perfect fit.

CAD Drawn Plans

The plans in this kit are not copied from a master set! They

are originals drawn directly from the CAD program where

the airplane was designed. We do this because it allows us

to use color, which helps you better visualize the various

components of the airplane, and we can use better quality

paper, which greatly reduces the possibility of shrinkage.

Since you’re going to build directly on the plans, they ought

to be the proper size! Also, parts placement is guaranteed

to be accurate, so you can build a better, straighter model.

Laser Cut Parts

The same program that generates the design and plans

also drives the laser, so every part is reproduced exactly as

it was designed. Laser cutting also allows us to fit more

parts on each sheet of wood, reducing the waste, and low-

ering the cost to you. Since laser cutting does not have the

same limitations that mechanical cutters do, small and

hard-to-produce parts are simply a computer file away, so

you get a more accurate airplane.

Plastics and Fiberglass

The cowl is accurately reproduced high quality fiberglass.

The canopy is accurately reproduced in clear plastic, and is

molded in two pieces. The wing fillets and other accessories

are molded in plastic to ease the building and finishing

chores!

A Word About the Building Options

Engine Options

Engine choices range from .60 to .68 2-strokes, or .60 to .90

4-strokes. There’s plenty of room in the cowl to mount the

engine in any direction you desire, and you can, with a little

extra thought, completely cowl in the engine; the extra

thought is needed for adequate engine cooling.

Electric Options

Electric conversion on a kit this size is very easy and

straightforward. ou will simply need to plan for a battery

hatch in order to save having to remove the wing for bat-

tery changes. The gun hood on the FW190 makes this very

easy!

Retract Options

Retract installation is shown on the plans and explained in

these instructions for Spring Air or Robart 85 degree

retracts. Of course, you are free to use any retract you wish.

The 85 degree units will not truly reproduce the “canted in”

look of the FW, but will Come very close. Actually, with the

gear canted in scale, the ground handling characteristics

are not as good as if the gear legs are closer to vertical.

Flaps

Flaps on an aircraft this size add more weight and complex-

ity than are offset by any aerodynamic gain, so we elected

to not incorporate flaps into the design of the Focke-Wulf.

Flaps can be added if you wish, but the design and engi-

neering is up to you!

1

General Building Information

The FW190 can be built by a person with average building

skills. It is designed for someone who has built a trainer or

low wing sport plane. No unusual building techniques are

required, although more difficult areas are explained in

detail where necessary. Certain steps in the building

process must be followed as depicted, or you might find

yourself digging back into the structure to redo something.

These areas are outlined when necessary.

Occasionally hints will be included at certain building steps.

These are not required for completion, rather they are tips

intended to ease a particular process.

The laser does not cut through the wood, it burns its way

through. As a result of this, occasionally there will be

scorching on the surface of the wood. This is normal, and is

only a surface discoloration, and does not affect the wood

in any other way. Similarly, the laser settings are optimized

for wood density averages, so occasionally, due to varia-

tions even in individual sheets, some areas might not cut

through completely. This is apparent mainly with the ply-

wood. Simply use care in removing the parts from the

sheets; most of the time, the parts will literally fall out of the

sheets!

The Wing Section building steps are shown for both Fixed

Gear and Retract installation. Decide which gear installation

you want to go with, and use the appropriate building sec-

tion.

Hardware and a motor mount are not included in the kit.

There are so many choices for quality hardware that these

choices are left to the individual preferences of the builder,

rather than include something in the kit that you’ll probably

throw away anyway. A vibration-dampening motor mount is

recommended for use regardless of engine choice, so

select a mount suited to your particular engine.

This aircraft is not a toy. It must be flown in a responsible

manner according to the rules set forth by the Academy of

Model Aeronautics. The builder assumes the responsibility

for the proper assembly and operation of this product.

Skyshark R/C Corporation shall have no liability whatsoev-

er, implied or expressed, arising out of the intentional or

unintentional neglect, misuse, abuse, or abnormal usage of

this product. Skyshark R/C Corporation shall have no liabil-

ity whatsoever arising from the improper or wrongful

assembly of the product nor shall it have any liability due to

the improper or wrongful use of the assembled product.

Skyshark R/C Corporation shall have no liability for any and

all additions, alterations, and modifications of this product.

Having said that mouthful, turn the page and start building

the best airplane on the market!

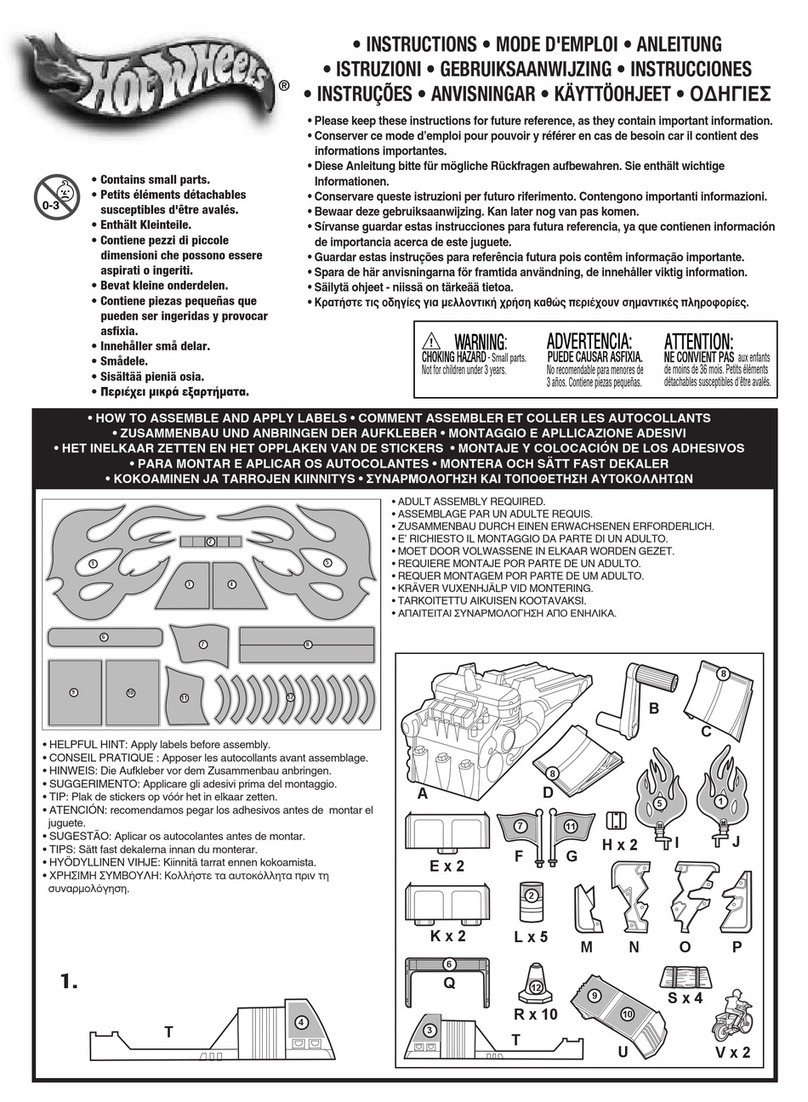

Accessor es needed to f n sh the FW190:

Sullivan Gold-N-Rods, 48" (Part no. 504) or other appro-

priate pushrods

Sullivan RST-10 or -12 Fuel Tank or other 10 - 12 ounce

fuel tank

Motor mount for appropriate engine

Skyshark FW190A-8 Spinner

3-1/4" Main Wheels (Robart #134)

1-1/2" Tailwheel (Dubro 150TW)

3/16” Gear Straps for gear covers (Dubro #811)

Hinges - We normally use CA hinges for ease.

Control Horns, Clevises, Bolts, Nuts, Screws, etc. (consult

our website)

1/7th Scale Pilot Full or Bust Figure

Engine, Muffler, Radio, Covering, Paint, etc.

Electr c Convers on:

Brushless Outrunner Motor 400-500 v

Skyshark Lightning 75 or E-flite Power 60

ESC: OS70, Cobra 80 or E-flite 80

Battery: Ulti-Power 6-8 cell 5200mAh

Rare Earth Magnets for battery hatch.

Notes:

2

Hor zontal Stab l zer Assembly

1. Slide H1 thru H8 into the slots in H10. Turn this

assembly over (carefully!) And pin to the board. Glue

all the pieces.

2. Glue H9 to the ends of H10.

3. Cut a piece of ¼ x ¼ balsa stock to size and slide it

into the slots in the aft end of the rib jigs to for the

trailing edge. Glue in place.

4. Cut additional ¼ x ¼ balsa pieces to fit between H8

and H9.

5. Slide H11 into the slots in the leading edge and glue.

Slide H12s into place and glue.

6. Carefully remove the tabs on the rib jigs forward of

H11 and H12, and aft of the trailing edge.

7. Use a 1/16” x 4” x 36” balsa sheet to sheet the stab

upper surface.

8. Remove the stab from the board, remove the jigs,

and sand the ribs smooth. Sheet the bottom of the

stab. Trim and sand the sheeting at the trailing edge,

leading edge, and at H9 and the notches.

1. Glue E2s into the slots in E1. Notice that the inside

edge of the stab is angled slightly, while the outside

edge is straight.

2. Fill the inside bay of the elevator with scrap balsa, to

add support for the control arm and elevator joiner

wire. Sand to match the rib contour.

3. Bevel the trailing edge of E1 to match the rib contour.

4. From a 1/16 x 3 x 36 balsa sheet, cut a piece to

serve as the upper sheet. Glue this piece in place,

matching the edge with the ribs.

5. Cut a piece of 3/8 x ¼ balsa stock to size and glue

to the leading edge. Sand the elevator at the leading

edge, trailing edge, and sides.

6. Glue two E3s together, and glue to the outer end of

the elevator. Remember that the elevator has an

inner and outer end!. Sand to match the taper, and

match the forward portion (control horn) to the stabi-

lizer. Repeat for the other elevator.

Elevator Assembly

9. Cut 3/8 x ¼ balsa stock to fit the leading edge, and

glue in place. Sand the leading edges to match the

rib contour and sand to an airfoil shape.

10. Glue two H13s together and glue to the end of the

stab at H9. Sand to shape. Repeat for the other

side.

3

1. Glue R3 thru R7 into the slots in R2.

2. Glue R1 to this assembly, aligning R1 to the top at

R7.

Rudder Assembly

3. Using the same technique as with the elevators,

sheet the remaining side of the rudder. Sand the

leading edges, sides, and trailing edge of the rudder.

4. Glue two R8s together, then center and glue into the

notch between R1 and R3. Add small pieces of 1/16

balsa to the sides of R8 for fill, and sand to match the

rudder taper.

5. Glue two R9s together, and glue to the top of the rud-

der, aligning the trailing edges. Sand to match the

taper, but do not sand the control horn yet. This will

be matched to the vertical when it is built.

A leron Assembly

1. Glue A2 thru A10 into the slots in A1.

2. Fill in the third bay (between A4 and A5) with scrap

balsa for support for the control arm. Sand to match

the rib taper.

3. Cut a piece of ¼ x ¾ balsa stock approximately 2”

longer than the aileron assembly and place the

aileron assembly on this piece. Align the assembly

so that most of the extra length is toward the portion

of the aileron with the rounded end. Also center the

aileron to allow for the additional sheeting to be

added. Glue in place.

4. Cut the opposite side sheeting from 1/16 x 3 x 36

balsa sheet, and glue in place. Sand the trailing

edge, leading edge, and sides.

5. Glue two A11s together, and glue in place to the

aileron assembly. Sand to shape.

Left W ng F xed Gear Assembly

1. Glue W1A to W1, aligning the slot in both pieces.

Glue W1B to W1A. Make a left and right side.

2. Epoxy W3A to W3, aligning the edges. Make a left

and right side. Double-check yourself here - it’s easy

to make two left sides!

3. Epoxy W6A to W6, aligning the edges. Make a left

and right side. Repeat the double-check procedure!

4

4. Glue a ¼ x ¼ balsa spar to W15 Ply spar, aligning

with the bottom edge. For the left side, the balsa spar

will glue to the front of W15.

5. Slide W1 into the center slot in W15. Temporarily

slide the other W1 into the slot as well, but do not

glue. Glue only the left side W1 in place.

6. Align and glue W2, W3, W4, W5, and W6 in place.

7. Glue W7, W8, and W9 in place. Use slight upward

pressure on the balsa spar to fully seat it in the rib

while gluing.

8. Bevel the side of W9A to fit and glue in place.

9. Glue W16 and W17 in place in the notches in the

trailing edges of the ribs.

10. Glue W10 in place.

11. If using the single servo aileron setup, do the follow-

ing: Locate and drill the hole for the bellcrank bolt in

W19. Install the bellcrank on W19. Cut the plastic

pushrod housing to 18 1/2” and slide the housing

through the holes in the ribs to W10. Open up the

holes at W10 and W2 slightly to allow for pushrod

movement and glue the housing to all the ribs

except W10 and W2. Install W19 with the bellcrank

side down, and glue W11 in place. Cut two inner

pushrods to 20”, assemble them with the aileron

connector, and slide the pushrod through the hous-

ing. Cut the pushrod at the bellcrank to allow for the

clevis, install the clevis, and connect to the bell-

crank.

12. Glue W12, W13, and W14 in place.

13. Cut a piece of ¼ x ¾ balsa stock to length and glue

to W9 thru W14 as the aileron spar.

5

14. Cut a piece of 3/8 x 1 balsa stock to fit between W1

and W2 for the leading edge. Glue in place. Sand

the leading edge flush with W2.

15. Cut another piece of 3/8 x 1 balsa to fit between the

leading edge at W2 and W4. Sand to fit and glue in

place.

16. Fit the remaining 3/8 x 1 balsa to the leading edge

and glue in place. See Figure 17.

17. Glue the top ¼ x ¼ balsa spar in place.

18. Cut shear webs to fit from W6 to W14 from scrap

3/32” balsa. Sand as needed for a tight fit between

the ribs. Glue between the top and bottm 1/4”

spars as indicated on the plans. The grain in the

shear webs should run vertical.

19. Sand the aileron spar flush with the ribs. Lightly

sand the spar to remove any high spots.

20. Cut two 1/16 x 4 x 36 and two 1/16 x 3 x 36 balsa

sheets to 29”. Edge glue these sheets. Trim the

sheet to match the leading edge.

21. Sheet the top of the wing. Start at the leading edge

and glue except at W1, W2 and W3 - leave this free

until you’ve glued to the spar, then glue.

22. Trim the trailing edge to 0.7 aft of W16 and W17.

Trim and sand the sheeting at W14, W1, and the

aileron.

23. Epoxy the Maple Gear Block to ribs W3, W4, W5,

and W6.

24. Epoxy the Maple Gear Block Anchor to the Gear

Block and W3A. Align so that the Gear Block

Anchor is flush with W3A and perpendicular to the

Gear Block.

25. Add balsa tri-stock to the sides of the Gear Block

Anchor for added support.

26. Carefully drill the Gear Block using a 3/16” bit to

open up the hole for the gear wire. Use caution to

prevent drilling through the top sheeting!

27. Remove the tabs from the bottom of the ribs.

Remove the tab on the bottom aft of W1 and W2

and glue W20 Ply Holddown Plate in place. Trial fit

W18 Servo Tray in place in the slots in W1 and W2,

centering the hole with W1. Do not glue at th s

t me.

28. Sand the aileron spar flush with the ribs. Bevel the

trailing edge sheeting to match the rib contours.

Sand off the tabs on the ply spar, and lightly sand

any high spots on the bottom of the wing.

29. Bend and install the pushrod onto the bellcrank.

Make alignment marks on the aileron spar and the

leading edge for the opening in the bottom sheet-

ing.

6

30. Cut two 1/16 x 4 x 36 and two 1/16 x 3 x 36 balsa

sheets to 29”. Edge glue these sheets. Using the

same techniques as with the top of the wing, sheet

the bottom of the left wing.

31. Trim and sand the sheeting at W1, W14, the trailing

edge, and the aileron opening.

32. Open up the hole in the sheeting for the pushrod,

using the marks made previously as a guide.

33. Glue a ¼ x ¼ balsa spar to W15 Ply spar, aligning

with the bottom edge.

34. Slide W1 into the center slot in W15. Glue to the

other W1. Make a mark on the leading edge for the

dowel opening.

35. Align and glue W2. Slide W18 servo tray in place

and glue. Align and glue W3, W4, W5, and W6 in

place.

R ght W ng F xed Gear Assembly

36. Glue W7, W8, and W9 in place. Use slight upward

pressure on the balsa spar to fully seat it in the rib

while gluing.

37. Bevel the side of W9A to fit and glue in place.

38. Glue W16 and W17 in place in the notches in the

trailing edges of the ribs.

39. Glue W10 in place.

40. If using the single servo aileron setup, do the fol-

lowing: Locate and drill the hole for the bellcrank

bolt in W19. Install the bellcrank on W19. Cut the

plastic pushrod housing to 18 1/2” and slide the

housing through the holes in the ribs to W10. Open

up the holes at W10 and W2 slightly to allow for

pushrod movement and glue the housing to all the

ribs except W10 and W2. Install W19 with the bell-

crank side down, and glue W11 in place. Cut the

pushrod at the bellcrank to allow for the clevis,

install the clevis, and connect to the bellcrank.

7

41. Glue W12, W13, and W14 in place.

42. Cut a piece of ¼ x ¾ balsa stock to length and glue

to W9 thru W14 as the aileron spar.

43. Cut a piece of 3/8 x 1 balsa stock to fit between W1

and W2 for the leading edge. Glue in place. Sand

the leading edge flush with W2.

44. Cut another piece of 3/8 x 1 balsa to fit between the

leading edge at W2 and W4. Sand to fit and glue in

place.

45. Fit the remaining 3/8 x 1 balsa to the leading edge

and glue in place.

46. Glue the top ¼ x ¼ balsa spar in place.

47. Cut shear webs to fit from W6 to W14 from scrap

3/32” balsa. Sand as needed for a tight fit between

the ribs. Glue between the top and bottm 1/4”

spars as indicated on the plans. The grain in the

shear webs should run vertical.

48. Sand the aileron spar flush with the ribs. Lightly

sand the spar to remove any high spots.

49. Cut two 1/16 x 4 x 36 and two 1/16 x 3 x 36 balsa

sheets to 29”. Edge glue these sheets. Trim the

sheet to match the leading edge and the left wing

sheeting.

50. Sheet the top of the wing. Start at the leading edge

and glue except at W1, W2 and W3 - leave this free

until you’ve glued to the spar, then glue.

51. Trim the trailing edge to 0.7 aft of W16 and W17.

Trim and sand the sheeting at W14, W1, and the

52. Epoxy the Maple Gear Block to ribs W3, W4, W5,

and W6.

53. Epoxy the Maple Gear Block Anchor to the Gear

Block and W3A. Align so that the Gear Block

Anchor is flush with W3A and perpendicular to the

Gear Block.

54. Add balsa tri-stock to the sides of the Gear Block

Anchor for added support.

55. Carefully drill the Gear Block using a 5/32” bit to

open up the hole for the gear wire. Use caution to

prevent drilling through the top sheeting!

8

56. Remove the tabs from the bottom of the ribs.

Remove the tab on the bottom aft of W1 and W2

and glue W20 Ply Holddown Plate in place.

57. Sand the aileron spar flush with the ribs. Bevel the

trailing edge sheeting to match the rib contours.

Sand off the tabs on the ply spar, and lightly sand

any high spots on the bottom of the wing.

58. Bend and install the pushrod onto the bellcrank.

Make alignment marks on the aileron spar and the

leading edge for the opening in the bottom sheet-

ing.

59. Cut two 1/16 x 4 x 36 and two 1/16 x 3 x 36 balsa

sheets to 29”. Edge glue these sheets. Using the

same techniques as with the top of the wing, sheet

the bottom of the left wing.

60. Trim and sand the sheeting at W1, W14, the trailing

edge, and the aileron opening.

61. Open up the hole in the sheeting for the pushrod,

using the marks made previously as a guide.

62. Cut the opening in the top sheeting for the servo.

Cut away the excess material at W1 and install the

servo.

63. Trim the sheeting away from the gear wire slots.

64. Using the mark made previously, open up the hole

in the leading edge for the dowel and epoxy the

dowel in place.

65. Glue the wingtips in place. Sand the wingtips to

shape. Sand the leading edge to shape.

Left W ng Retract Assembly

1. Glue W1A to W1, aligning the slot in both pieces.

Glue W1B to W1A. Make a left and right side.

2. Epoxy W5R1 to W5. Epoxy W5R2 to W5R1, aligning

along the upper edge. Make a right and left side.

Double-check yourself here, it’s easy to make two

left sides!!

3. Epoxy W6R1 to W6. Epoxy W6R2 to W6R1, aligning

along the upper edge. Make a right and left side.

Repeat the double-check procedure!

9

4. Glue a ¼ x ¼ balsa spar to W15 Ply spar, aligning

with the bottom edge. For the left side, the balsa spar

will glue to the front of W15.

5. Slide W1 into the center slot in W15. Temporarily

slide the other W1 into the slot as well, but do not

glue. Glue only the left side W1 in place.

6. Align and glue W2, W3, W4, W5, and W6 in place.

Note that W5 and W6 will be installed so that the ply

plates face each other.

7. Glue W7, W8, and W9 in place. Use slight upward

pressure on the balsa spar to fully seat it in the rib

while gluing.

8. Bevel the side of W9A to fit and glue in place.

9. Glue W16 and W17 in place in the notches in the

trailing edges of the ribs.

10. Glue W10 in place.

11. If using the single servo aileron setup, do the follow-

ing: Locate and drill the hole for the bellcrank bolt in

W19. Install the bellcrank on W19. Cut the plastic

pushrod housing to 18 1/2” and slide the housing

through the holes in the ribs to W10. Open up the

holes at W10 and W2 slightly to allow for pushrod

movement and glue the housing to all the ribs

except W10 and W2. Install W19 with the bellcrank

side down, and glue W11 in place. Cut two inner

pushrods to 20”,assemble them with the aileron

connector, and slide the pushrod through the hous-

ing. Cut the pushrod at the bellcrank to allow for the

clevis, install the clevis, and connect to the bell-

crank.

12. Glue W12, W13, and W14 in place.

13. Cut a piece of ¼ x ¾ balsa stock to length and glue

to W9 thru W14 as the aileron spar.

10

14. Cut a piece of 3/8 x 1 balsa stock to fit between W1

and W2 for the leading edge. Glue in place. Sand

the leading edge flush with W2.

15. Cut another piece of 3/8 x 1 balsa to fit between the

leading edge at W2 and W4. Sand to fit and glue in

place.

16. Fit the remaining 3/8 x 1 balsa to the leading edge

and glue in place. See Figure 40.

17. Glue the top ¼ x ¼ balsa spar in place.

18. Cut shear webs to fit from W6 to W14 from scrap

3/32” balsa. Sand as needed for a tight fit between

the ribs. Glue between the top and bottm 1/4”

spars as indicated on the plans. The grain in the

shear webs should run vertical.

19. Sand the aileron spar flush with the ribs. Lightly

sand the spar to remove any high spots.

20. Cut two 1/16 x 4 x 36 and two 1/16 x 3 x 36 balsa

sheets to 29”. Edge glue these sheets. Trim the

sheet to match the leading edge.

21. Sheet the top of the wing. Start at the leading edge

and glue except at W1, W2 and W3 - leave this free

until you’ve glued to the spar, then glue.

22. Trim the trailing edge to 0.7 aft of W16 and W17.

Trim and sand the sheeting at W14, W1, and the

aileron.

23. Epoxy W22 Ply Retract Plate in place in the slots

between W5 and W6.

24. Wheel wells may be added by inserting scrap 1/16”

balsa sheeting using the blue gear door outline as

a guide. Place the wheel wells about 1/8” to 3/16”

inside the outline.

25. Install the retract unit and run the air lines. Install

the retract unit per the instructions with your specif-

ic retract.

26. Install the wheel and strut. Test for fit. Remove the

retract and wheel.

27. Remove the tabs from the bottom of the ribs.

Remove the tab on the bottom aft of W1 and W2

and glue W20 Ply Holddown Plate in place. Glue

W18 Servo Tray in place in the slots in W1 and W2,

centering the hole with W1.

28. Sand the aileron spar flush with the ribs. Bevel the

trailing edge sheeting to match the rib contours.

Sand off the tabs on the ply spar, and lightly sand

any high spots on the bottom of the wing.

29. Bend and install the pushrod onto the bellcrank.

Make alignment marks on the aileron spar and the

leading edge for the opening in the bottom sheet-

ing.

11

30. Cut two 1/16 x 4 x 36 and two 1/16 x 3 x 36 balsa

sheets to 29”. Edge glue these sheets. Using the

same techniques as with the top of the wing, sheet

the bottom of the left wing.

31. Trim and sand the sheeting at W1, W14, the trailing

edge, and the aileron opening.

32. Open up the hole in the sheeting for the pushrod,

using the marks made previously as a guide.cut out

the opening for the retract and wheel.

33. Glue a ¼ x ¼ balsa spar to W15 Ply spar, aligning

with the bottom edge.

34. Slide W1 into the center slot in W15. Glue to the

other W1. Make a mark on the leading edge for the

dowel opening.

35. Align and glue W2, W3, W4, W5, and W6 in place.

Note that the ply plates on W5 and W6 face each

other.

R ght W ng Retract Assembly

36. Glue W7, W8, and W9 in place. Use slight upward

pressure on the balsa spar to fully seat it in the rib

while gluing.

37. Bevel the side of W9A to fit and glue in place.

38. Glue W16 and W17 in place in the notches in the

trailing edges of the ribs.

39. Glue W10 in place.

40. If using the single servo aileron setup, do the fol-

lowing: Locate and drill the hole for the bellcrank

bolt in W19. Install the bellcrank on W19. Cut the

plastic pushrod housing to 18 1/2” and slide the

housing through the holes in the ribs to W10. Open

up the holes at W10 and W2 slightly to allow for

pushrod movement and glue the housing to all the

ribs except W10 and W2. Install W19 with the bell-

crank side down, and glue W11 in place. Cut the

pushrod at the bellcrank to allow for the clevis,

install the clevis, and connect to the bellcrank.

12

41. Glue W12, W13, and W14 in place.

42. Cut a piece of ¼ x ¾ balsa stock to length and glue

to W9 thru W14 as the aileron spar.

43. Cut a piece of 3/8 x 1 balsa stock to fit between W1

and W2 for the leading edge. Glue in place. Sand

the leading edge flush with W2.

44. Cut another piece of 3/8 x 1 balsa to fit between the

leading edge at W2 and W4. Sand to fit and glue in

place.

45. Fit the remaining 3/8 x 1 balsa to the leading edge

and glue in place.

46. Glue the top ¼ x ¼ balsa spar in place.

47. Cut shear webs to fit from W6 to W14 from scrap

3/32” balsa. Sand as needed for a tight fit between the

ribs. Glue between the top and bottm 1/4” spars as

indicated on the plans. The grain in the shear webs

should run vertical.

48. Sand the aileron spar flush with the ribs. Lightly

sand the spar to remove any high spots.

49. Cut two 1/16 x 4 x 36 and two 1/16 x 3 x 36 balsa

sheets to 29”. Edge glue these sheets. Trim the

sheet to match the leading edge and the left wing

sheeting.

50. Sheet the top of the wing. Start at the leading edge

and glue except at W1, W2 and W3 - leave this free

until you’ve glued to the spar, then glue.

51. Trim the trailing edge to 0.7 aft of W16 and W17.

Trim and sand the sheeting at W14, W1, and the

aileron.

52. Epoxy W22 Ply Retract Plate in place in the slots

between W5 and W6.

53. Wheel wells may be added by inserting scrap 1/16”

balsa sheeting using the blue gear door outline as

a guide. Place the wheel wells about 1/8” to 3/16”

inside the outline.

54. Install the retract unit and run the air lines. Install

the retract unit per the instructions with your specif-

ic retract.

55. Install the wheel and strut. Test for fit. Remove the

retract and wheel.

13

56. Remove the tabs from the bottom of the ribs.

Remove the tab on the bottom aft of W1 and W2

and glue W20 Ply Holddown Plate in place.

57. Sand the aileron spar flush with the ribs. Bevel the

trailing edge sheeting to match the rib contours.

Sand off the tabs on the ply spar, and lightly sand

any high spots on the bottom of the wing.

58. Bend and install the pushrod onto the bellcrank.

Make alignment marks on the aileron spar and the

leading edge for the opening in the bottom sheet-

ing.

59. Cut two 1/16 x 4 x 36 and two 1/16 x 3 x 36 balsa

sheets to 29”. Edge glue these sheets. Using the

same techniques as with the top of the wing, sheet

the bottom of the left wing.

60. Trim and sand the sheeting at W1, W14, the trailing

edge, and the aileron opening.

61. Open up the hole in the sheeting for the pushrod,

using the marks made previously as a guide. Cut

out the opening for the retract and wheel.

62. Cut the opening in the top sheeting for the servo.

Cut away the excess material at W1 and install the

servo.

63. Trim the sheeting away from the gear wire slots.

64. Using the mark made previously, open up the hole

in the leading edge for the dowel and epoxy the

dowel in place.

65. Glue the wingtips in place. Sand the wingtips to

shape. Sand the leading edge to shape.

Fuselage Assembly

1. Make two ¼ x ¼ balsa crutches by splicing pieces of

36” balsa stock to length.

2. Pin the ¼ x ¼ crutches in place on the plans.

3. Glue F1A, F2A, and F3C in place, aligning with the

bulkhead layout on the plans. Note that F1A is offset

to allow for engine right thrust.

4. Glue F4A thru F12A in place.

5. Glue F13 and F14A in place.

14

See the Coc pit installation instructions at the end of

this manual now for instructions on installing the

optional coc pit that is included with this it. If you do

not wish to install the coc pit, continue with the stan-

dard instructions.

6. Glue F16 cockpit floor in place.

7. Glue F18 in place.

8. Glue F19 in place. Remove the openings for the

cockpit, match the ends of F18 and F19 together and

glue.

9. Glue pieces of ¼ x ¼ balsa stock into the slots in the

bulkheads, starting at F10A. This piece will extend to

F19, and will need to be beveled where it meets F19.

10. A short section of ¼ x ¼ will run between F3C and

F1A. Glue in place.

11. Add 1/8 x ¼ stringers to the fuselage assembly. Add

the bottom stringer first - it runs from F14A to F1A.

12. A short stringer section will then run from F14A thru

F12A and butt against F11A.

13. The second stringer will run from F12A to F1A.

14. The third stringer will run from F12A, and butt

against F8A. The other section will run from F3C to

F1A.

15. Glue F20 Stab Saddle in place between F12A and

F14A. Bevel the ends of F20 as necessary to fit at

F14A.

16. Sheet the upper fuselage using 1/16” x 4” x 36” balsa

sheets Edge glue the sheets as necessary. Pin small

pieces of 1/8 x ¼ scrap against the sides of the crutch.

This will raise the sheeting up 1/8”, so the lower sheeting

will attach to the crutch when it is added. A small piece will

need to be edge glued to the upper portion of the sheet

between F7A and F10A. Add this section, and use the fol-

lowing as a guide: The best way to assure a straight fuse

(that I’ve found) is to match the left and right sheets for

density, then start the sheeting on both sides of the fuse

at the same time. Slowly work the sheet up the fuselage

sides, one stringer section at a time, starting in the mid-

dle and working alternately to both ends. Do one stringer

row, then move to the opposite side and do that stringer

row, and so forth. When you have difficulty making the

sheet conform to the fuse sides, wet the sheet with an

ammonia solution (Windex with Ammonia in the spray

bottle works great and doesn’t stain the wood!) And con-

tinue. As you get close to the top, pick one side and sheet

to the ¼ x ¼ keel. Then work the other side to the same

point.

15

17. Add sheeting to the upper forward fuse to complete

that section. Trim and sand the sheeting at F3C to

F19. Try to achieve a level surface across F19 - you

may have 1/32” to 1/16” of sheeting not flush at the

rear of F19 - this is O .

18. Trim the sheeting to within ¼” of F1A. Leave the

extra hanging in front to allow for the F15 Firewall.

19. Trim and sand the sheeting between F10A and

F12A, down to the stringer.

20. Trim and sand the sheeting even with F20.

21. Remove the upper fuse from the board. Glue F1B,

F2B, F3B, F4B, F5B, and F6B in place.

22. Epoxy F15 Firewall to F1A and F1B.

23. Glue F21 Ply Wing Saddle in place. The forward

portion has to make a radical curve, so the best

way to achieve this is to break the outer plies where

F21 meets F2B to make it conform. This area is not

a structural load bearer, so it’s O to do this.

24. Epoxy F22 Ply Holddown Plate in place in the slots

in F21.

25. Cut and glue the rudder and elevator pushrod

housings in place. Cut the openings in the aft fuse

between F12 and F13 for pushrod exits.

26. Glue F7B thru F12B in place.

27. Cut a ¼ x ¼ balsa keel to fit and glue in place.

28. Add 1/8 x ¼ balsa stringers to F1B and F2B, and to

the aft lower fuselage between F6B and F12B. .

29. Add an additional short stringer between F6B and

F7B, right at the sharp corner.

30. Sheet the lower fuselage. As you work up the fuse

sides, cut the sheeting lengthwise between F6B

and F7B. When making the corner, this area will

lay flat. Wet the sheeting while working around the

corner, and continue sheeting to F12B.

16

31. Continue the sheeting forward, but leave an open-

ing as shown. You will need access to this area

when mounting the wing.

32. Trim and sand the sheeting at F15, F12B, and the

wing saddle.

33. Lay the wing in the saddle and align. Trim the sad-

dle as necessary for a good fit.

34. With the wing aligned, slide F23 over the wing

dowel and epoxy to F2B.

35. Sheet the remainder of the forward fuselage.

36. Align the wing and drill and install the wing hold-

down bolts.

37. With the wing in place, fit and glue F2C to the lead-

ing edge of the wing.

38. Glue two W21s together. Fit and glue to F2C and

the bottom of the wing. Trim and sand to match the

fuselage.

1. Glue S1 and S2 together.

2. Trail fit this assembly to the tail section - trim as nec-

essary.

3. With the S1/S2 assembly flat, glue the S3 spar, and

S4, S5, and S6 ribs.

4. Align and glue S3 thru S6 to the opposite side of the

vertical.

5. Glue S6 to the top of S1/S2.

Vert cal Stab l zer Assembly

17

6. Glue short pieces of tri-stock to the inside of F20 for

added horizontal stabilizer support.

7. Align and glue the horizontal stabilizer in place.

8. Align and glue the vertical stab assembly to F12, F14

and the horizontal stab.

9. Cut the vertical stab leading edge from ¼ x ¼ balsa

and glue in place.

10. Fit the upper fuselage block in place, trim and glue.

Sand to a rough shape to conform to the fuselage

and F12A.

11. Glue F24 to the vertical and horizontal. The front

edge will wrap up F12A.

12. Cut and edge glue sheeting for the stab. The lower

aft edge will follow F24, but the lower forward edge

will have to be trimmed to fit along F24, F12, and

the leading edge. Sheet the vertical stab.

13. Glue two S8s together and glue to the top of the

vertical stabilizer. Sand to shape.

14. The area shown by the arrow should be filled with

lightweight filler and sanded to shape. Sand the

fuse block and tail area to shape.

Fuselage F nal Assembly

1. Cut the gun hood out and fit to the upper fuselage.

Cut the cockpit glare shield to fit as shown on the

plans and in the photo.

2. Cut the instrument panel from the 3-view drawing

and glue to the back of the laser-cut instrument

panel. Glue the instrument panel in place.

3. Epoxy the gun hood in place. Fill and sand the joint

along the fuse as necessary.

4. Glue F27 Headrest in place.

5. Trim and fit the canopy in place. Finish the cockpit as

desired, and glue the canopy in place.

6. Trim and fit the aft canopy shell. Glue to the canopy

and the fuselage.

18

7. With the wing in place, glue F24 balsa fillets in place

to the lower fuse, aligning with the trailing edge of

the wing. Do not glue F24 to the wing.

8. Cut and trim the plastic wing fillets to shape, and

glue in place.

9. Trim and fit the cowl to the fuse. As an added

strengthener, glue small (1”) squares of sheet alu-

minum or carbon fiber to the inside of the cowl at the

screw holes, then add the fiberglass over these. This

will prevent the screw holes from cracking.

The remainder of the construction consists of attaching

the rest of the components to the airplane. Most of this is

builder’s choice, and individual tastes, styles, and compo-

nent selection, so any detailed descriptions would be

impossible. The remainder of assembly is described in

general terms only.

Engine Installation:

The engine centerline is marked on F15. Locate and drill

the holes for your motor mount. Install the motor mount

and engine of your choice.

Fuel Tan and Throttle Cable:

After deciding which direction the engine will point (up,

down, or sideways) drill holes for and install the throttle

cable. Mount the fuel tank of your choice, and connect the

lines.

Servo and receiver installation:

3/8” maple blocks are provided for servo rails.. Mount

these as shown on the plans and mount the servos.

Mount the receiver and connect the components. The bat-

tery pack may be located anywhere in the fuselage for

balance purposes.

Covering:

Cover the airplane with the covering of your choice. The

covering choices are too numerous to mention, but the

airplane shown on the box was covered with film, painted,

and clear-coated. It is recommended that the airplane and

control surfaces be covered separately.

Control surfaces:

Locate the control horn positions. Final sand the control

surfaces. Locate the hinge points (hinges and other hard-

ware are not provided in the kit because everyone has his

own preferences. Rather than put in stuff that most of you

will throw away, we left it out to keep the kit price down)

and install the hinges and control surfaces. Use at least

three hinges per control surface for best results. Connect

and adjust the pushrods.

Landing Gear (Fixed):

Insert the main gear wire legs into the slots in the wings,

secure with straps, and mount the wheels of your choice.

Landing gear (Retracts): Bend the gear wire to match the

angle shown on the plans, and install the gear legs and

wheels. Install the remainder of the retract components

per the retract instructions.

Center of Gravity:

The CG is measured with the aircraft UPSIDE DOWN 4-

13/16” back for the wing leading edge, where the wing

meets the fuselage.

Control Throws:

Ailerons: 7/16” up & down

Elevator: 1/2” up & 3/8”down

Rudder: 1” left & right

The rest is up to you! Fly and enjoy!

F nal Assembly

19

This manual suits for next models

1

Table of contents

Other Skyshark Toy manuals