SKYSHL SS413F Series User manual

Shenzhen SKYSHL Technology Co.,Ltd.

Version:V2020.08

CATALOGUE

1.

Overview

……………………………………………… 1

2.Product specifications ………………………………… 1

3.Main components of fusion splicer……………………… 3

4.Common Operating Interface Description ……………… 5

5.Power supply ………………………………………… 6

6.Cleaning operation before splicing ……………………… 8

7.Regular maintenance…………………………………… 9

8.Basic Splicing Procedures …………………………… 11

9.

ARC Calibration

…………………………………… 14

10.

Manually adjust the fiber position

……………………15

11.Cutting Length of Optical Fiber……………………… 18

12.

Common troubleshooting

…………………………… 18

Appendix A:Warranty period and conditions ……………20

Overview

1.

Thank you for choosing our products. This operation outline mainly

introduces the product performance, basic operation steps and maintenance of

optical fiber fusion machine, which is newly produced by our company.

The machine adopts a high-speed image processing technology and special

precision positioning technology. The whole processes of fiber fusion splicing

can be automatically completed within 9 seconds. Provided with TFT color

LCD display, the screen is protected by high strength protective

panel. User-friendly graphical interface is convenient for efficient and

quick operation by the user. High performance battery can realize online

charging continuously in the work, to get a longer battery life. No manual arc

calibration operation is needed.

The machine has real time splice arc control and correction functions. In

extreme environment, the machine can also effectively ensure the splice

quality of optical fiber. The machine is featured with fast splice speed, less

splice loss, light weight, portable, applicable to backbone network,

metropolitan network and FTTH project. In order to complete accurately the

splice operation, please read carefully this user's manual.

(SS413F Video: youtu.be/llfhWtie48c)

2.

Product specifications

1

Applicable optical

fibers

SM (G.652 & G.657), MM (G.651), DS (G.653), NZDS (G.655) and

user-defined optical fibers

Splice loss

0.02dB (SM),0.01dB (MM),0.04dB(DS/NZDS)

Return loss

Better than 60dB

Control

technology

Real time splice arc control and correction; Self adaptive in working

environment scope; Electrode oxidation self adaptive.

Splicing time

≤9 seconds (standard SM).

Heat time★

≤25 seconds (The Heat time can be set and the heater temperature can be

adjusted.); Fast heat

function, functions of automatic or manual heating selection.

Splicing function

Step-by-step splicing or automatic splicing optional

Fiber alignment

Fine alignment, fiber core alignment, clad alignment, manual alignment

Fiber diameter

Cladding diameter 80 ~ 150μm,

Coating diameter 100 ~ 1000μm

Cleave length

Coating less than 250μm: 5 ~ 16 mm; Coating 250 ~ 1000μm: 16 mm.

Tension test

Standard 2N (optional)

Magnification

times★

320 times (X-axis or Y-axis);

160 times (X-axis and Y-axis).

2

Remarks:

①The technical data in the above table“★”are different for different

types of products.

②Detailed technical indicators of the product should be consulted and

obtained with the sales staff of the company.

Fiber clamp

Multifunctional clamp is applicable to bare fiber, tail fiber, jumper,

covered fiber and stealth fiber. The clamp meets the requirement of

industry standard FTTH fusion quick splicer.

Heat-shrink sleeve

60mm/40mm/20mm and a series of micro- shrink sleeves (some

features are optional)

Display

★

Provided with TFT color 4.3 LCD display. The screen is protected by

high strength protective panel. Contents (image) can be flipped, easy

for two-way operation.

External Interface

USB2.0 Interface: convenient data download, USB flash disk

upgrade software.

Splicing mode

100 groups user mode, 53 groups factory mode.

Heater mode

40 groups user mode, 11 groups factory mode.

Connection storage

Built-in memory is capable to save latest 10000 splices.

Store 100 groups of splice images (X, Y fiber splicing images).

Electrode life

> 5500 times (times of arc).

Lithium battery

★

Continuous splicing, heating more than 350 times (typical

environment).

Power saving

function

In “Power Save Mode" Under typical

circumstances can save 15% battery power

Power supply

★

Lithium battery provides 12.5V power (charging in 10.8V) and can

be charged continuously when the splicer works. When the charging

time 3.5, the battery charging times are not less than 300 times.

(Charging) Power adapter: Input AC100-240V 50/60HZ, Output

DC13.5V/4.8A. The present power mode can be identified, real-time

monitoring the present battery capacity.

Work environment

Operating environment: -10~+50℃; Storage temperature:- 40 ~ +

60℃;Humidity: <95% RH

(non-condensing); Operating altitude: 0 ~5000m

Maximum wind speed: 15m / s.

External

dimension★

133(Length)*163(Width)*140(Height)

Weight ★

1.6 kg (Batteries not included)

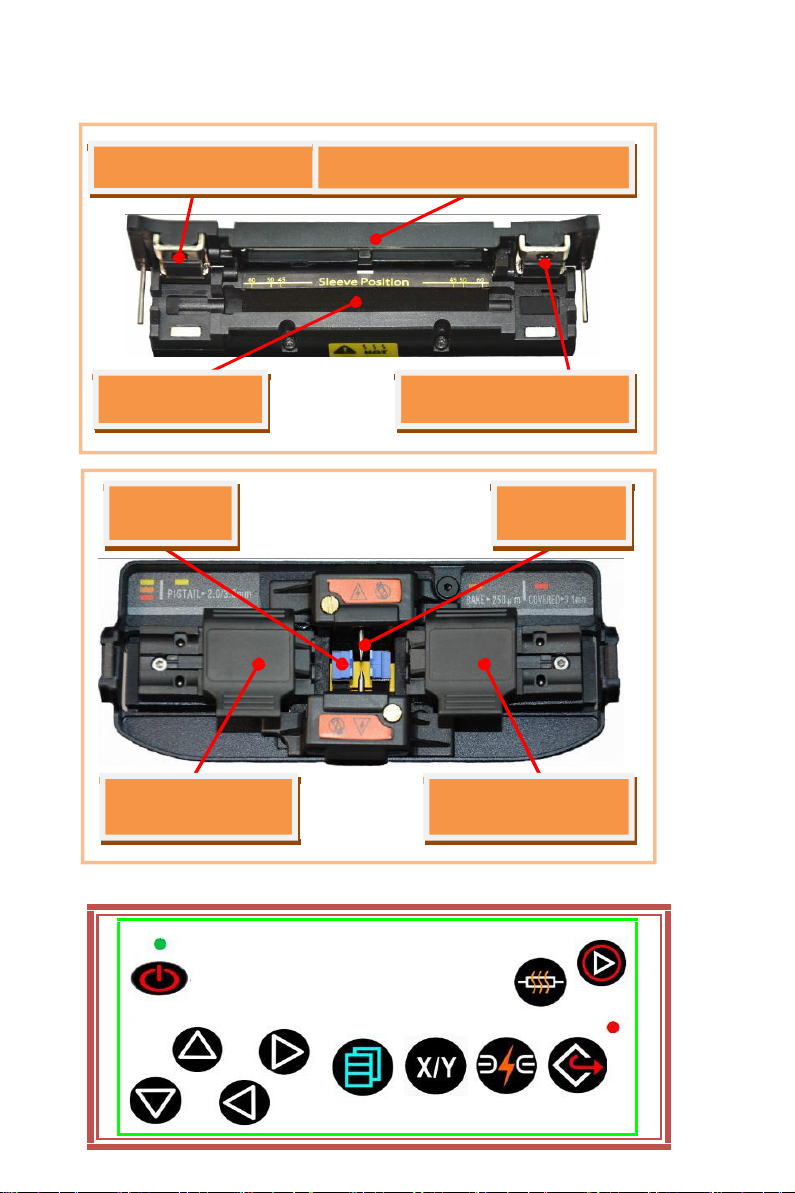

3.Main components of fusion splicer

3.1 Name of main components of fusion splicer

Left fiber clamp

Heating groove

Heater right press plate

Heater transparent window cover

Heater left press plate

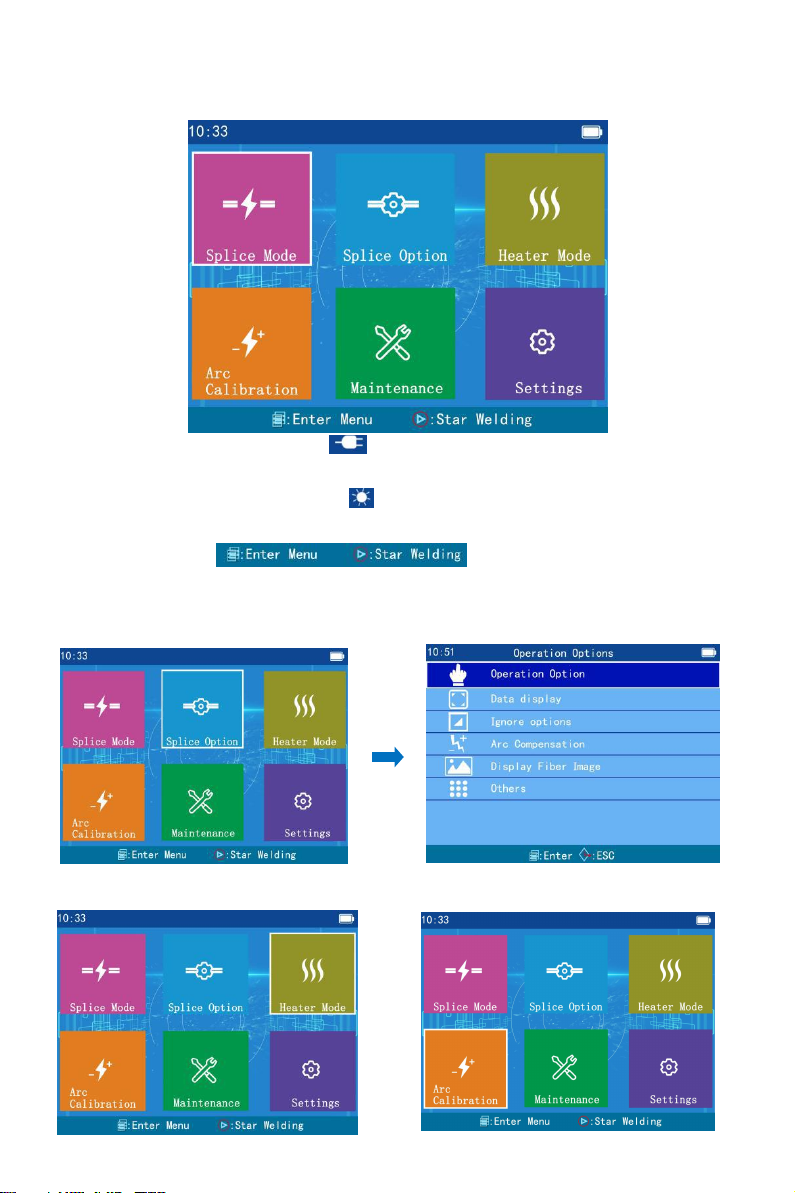

3.2 Descriptions of the keypad of fusion splicer

Right fiber clamp

V-groove

Electrode

3

Buttons of keypad I Buttons of keypad II

Remarks:

①Keypad layout is different for different model fusion splicer of this series, each

button mark and their functions are listed in the table above.

②The "blue" text on the table above is the button functional description of

keyboard Ⅱ.

Boutton

Readiness

Manual mode

Automatic

mode

Parameters menu

Power switch

Power switch

Power switch

Power switch

Moving cursor

Upward movement of fiber

Invalid

Increasing the amount of

parameters/moving cursor

Downward movement of

fiber

Invalid

Reducing the amount of

parameters/moving cursor

Leftward movement of fiber

Invalid

Reducing the amount of

parameters/moving cursor

Rightward movement of

fiber

Invalid

Increasing the amount of

parameters/moving cursor

Invalid

Return to readiness screen

Return to

readiness

screen

Return to higher level menu

screen

Invalid

Invalid

Invalid

Confirming option

function/Parameter modification

Enter splice

mode menu

Open the function to move

motor by buttons at pause

Invalid

Enter lower level menu

/operation screen

Start splicing

Continue forward

/Start splicing

Start splicing

Invalid

Start splicing

Continue forward

/Start splicinge

Start splicing

Confirming option

function/Parameter modification

Invalid

Motor reset

Motor reset

Invalid

Invalid

Motor reset/Return to higher

level menu

Motor

reset/Return to

higher level

menu

Return to standby screen/Higher

level menu

Heater Switch

Heater Switch

Heater Switch

Heater Switch

Invalid

Next step / arc

Invalid

Invalid

4

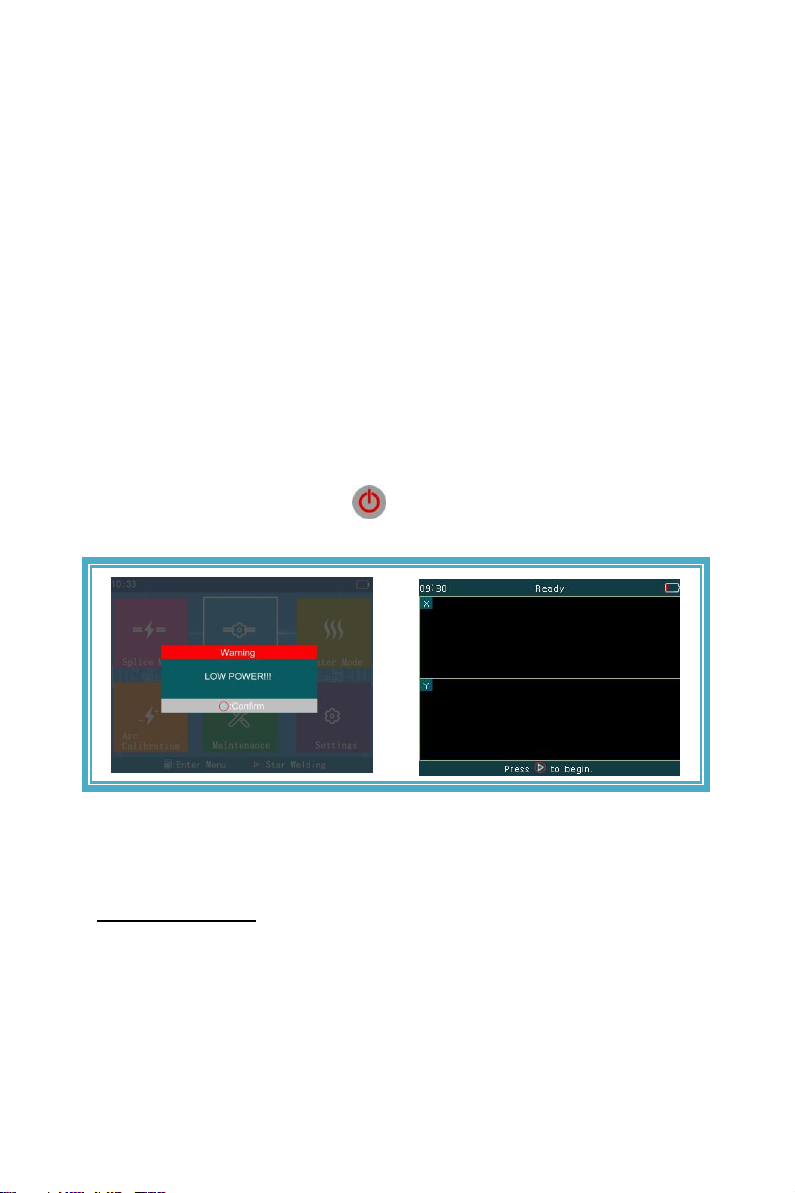

4. Common Operating Interface Description

●Top right corner of the screen :Indicating "Heater" is "warming up" at

current.

●Bottom of screen :Indicating "Keypad operation"

on current screen.

4.3【Heater mode】 4.4【Arc Calibration】

4.2【Splice options】4.2.1【Operation Options】

●Top right corner of the screen :Indicating the present power supply mode of

"power adapter".

4.1 Standby Interface of fusion splicer (Level 1 Menu)

5

5.1 Starting up:

Hold down button;

When the LED indicator on the keypad is changed to green,release button.

5.2 Shutdown:

Hold down button. After the LED indicator on the keypad is changed

from green to red, release button.

5.3. Power supply

5.3.1 Power adapter power supply(no need to install lithium batteries)

Adapter AC input

●Only AC power cord attached to the adapter is used, and

the input voltage is AC100-240V 50-60HZ.

●The grounding terminal of AC power line input must be grounded

effectively。

Adapter DC output

●Use only the DC power cord attached to the adapter.

●Output voltage: DC13.5V 4.8A

●Insert DC power cord into the "POWER INPUT" port at the bottom of

splicer. The splicer supplies power to the adapter.

4.5【Maintenance】 4.6【Settings】

5. Power supply

6

②Different battery configurations correspond to different charging modes.

●Use only AC power cord attached to the adapter, input voltage:AC100-

240V 50/60HZ.

●The grounding terminal of AC power line input must be grounded

effectively.

●Insert DC power cord attached to adapter "POWER INPUT" at the

bottom of splicer Input port, the splicer will start one charging process of

secondary lithium batteries.

Charging of batteries

●Charging indicator lamp is red; after charging, Charging indicator Lamp

Turn green.

●When the power is off, the charging time is up to 3hours, 30minutes,

40minutes and the battery is surplus. The amount of capacity determines

the length of charging time.

Battery maintenance

●Please store lithium batteries in a cool, dry and safe environment.

●Do not place the lithium battery near high temperature, flammable and

explosive gases or liquids.

●If the lithium battery needs to be stored for a long time (more than one

month), it is recommended to charge it to 40%-60%, and the storage time

should be charged 1 to 2 times a month.

5.3.2 Lithium battery power supply

①The random lithium batteries are correctly connected to the bottom of the

splicer (power module), that is to realize the power supply of lithium

batteries in the splicer.

7

●Please use the special charger provided by our company for the lithium

battery.

●Do not short circuit the positive and negative electrodes of the lithium

battery, otherwise it will cause burns and explosion.

●Please use the standard lithium battery supplied by SKYSHL for the fusion

splicer, please do not use other lithium batteries not supplied by our

company.

●Do not disassemble the lithium battery privately.

●Do not hit the lithium battery strongly.

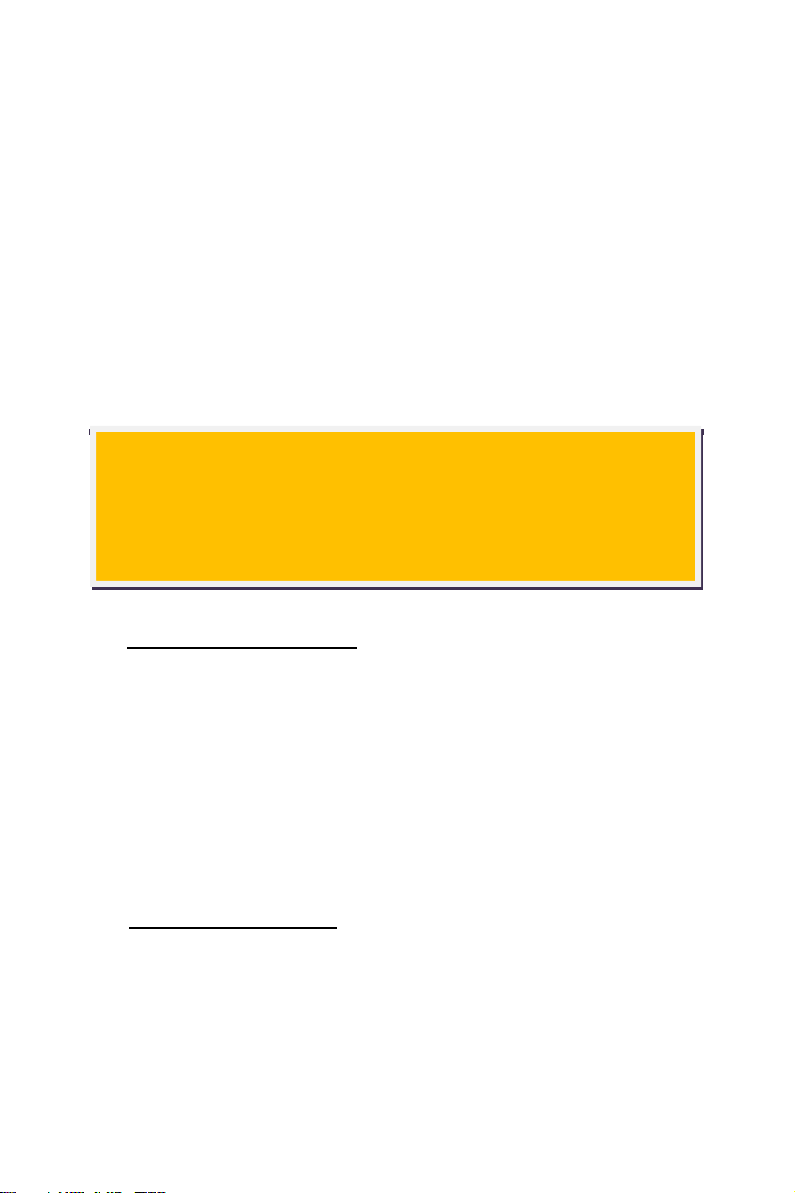

5.3.3 Low voltage alarm (battery-powered)

This model fusion splicer has "low voltage alarm" function.When the

lithium battery (group) power is below a certain value,the fusion splicer

screen will show "low battery!!!" warning window as shown below. At

this point, the user should promptly use the power adapter or charge the

lithium battery, or hold down button to turn off the fusion splicer.

Otherwise, it will shut down automatically after about 30 seconds.

6. Cleaning operation before fusion

Cleaning V-groove(Youtube Video:https://youtu.be/P6qsIM3S-D4)

Clean the bottom of the V-groove with a wet cotton swab dipped in

absolute ethanol. Use a dry cotton swab to absorb the residual anhydrous ethanol

in the V-shaped tank. Use a clean, cut, fiber-optic end to remove dirt.

8

The mirror and objective lens are dusty after a long time without routine

maintenance, resulting in whitening and fuzzy black-clad of fiber image.

<1> Before cleaning the lens, first turn off the power of the fusion

splicer.

<2> Roll specific lens paper into a stick, fold and tear out, then clean the

mirror, objective lens surface with the rough edge of the stick.

7. Regular maintenance

Cleaning objective lens(SS413F has no mirror, only camera)

In routine maintenance, the ear syringe may be used for blowing off the

dust from the surface of the mirror and the objective lens of the fusion splicer.

●When cleaning, be careful not to bump into or touch the electrode rod.

9

<3> When the lens paper cleaning is invalid and the objective lens surface

is free of visible dust particles, try to use a thin cotton swab dipped in a

little pure alcohol (99% and above) and wipe gently the lens surface. It

is recommended in principle not to use alcohol to clean the mirror

surface.

<4> Wipe the lens with a cotton swab from the middle of the lens and

make a circular motion up to the edges of the lens. Then wipe with a

clean dry swab the remaining alcohol. The objective lens surface

should be clean and free of dirt.

Replacement of electrode

Electrodes will be worn-out after long-term use, plus silicic

oxide accumulates on the tip, it also requires regular cleaning. It is

recommend to replace the electrode when the electrode rod exceeds its

service life. If the machine continues in service without changing the

electrode, it will increase splice loss and reduce the strength after fusion

splicing.

Use of lithium batteries

Lithium batteries must be charged in the ambient temperature range of

0~+40℃. The storage environment of lithium batteries for a long time

is: temperature -5 ~+35℃. humidity 65+20% RH, clean, dry and

ventilated.

●Incorrect use methods or undesirable chemical substances cleaning

objective lens can cause optical fiber imaging fuzzy damage the

equipment.

10

6.Use a fiber cleaver to cut the fiber

(make sure the end face after the cut is

flat)

5.Remove the fiber sheath and coating

and use alcohol to clean the fiber

11.Place the heat shrinkable sleeve in

the middle of the heater

10.Take out optical fiber

3.Cleaning coating or tight sleeve of

optical fibers

8.Close the windproof cover and begin

to fuse the optical fibers

2.Confrimation of splice and heater

mode

9.LCD screen observation of optical

fiber welding

11

7.Place optical fibers in V-groove of the

SS413F

8. Basic Fusion Procedures

(Youtube Video:https://youtu.be/A6uZtgps8Ok)

The end of the optical fiber is placed

between the V-groove edge and the center

of the electrode.

Electrode center

V groove edge

"Auto SM" fusion mode is

Recommended for SM(G.652&

G.657)." Standard 60mm ” heater

mode is recommended for the length

of protective casing is 60mm.

4.Putting Optical Fiber into thermal

shrinkage protection casing

1.Turn on the power of the SS413F

Because the fiber is very fragile, do not

touch other objects with the end face of

the cut fiber.

15.Complete

13.Move the fiber to place the weld point in the

middle of the heat shrink tube.

14.Close the heater cover and start heating

12.Place the weld point of the fiber in the

center of the heat shrink tube.

The 900um tail

fiber is connected

with the leather

cable.

250μm bare fiber is

connected with 250

μm bare fiber.

①Open the wind cover and wait for the automatic reset of the fusion

splicer until the machine is at readiness status.

②Put respectively the prepared fibers into The bottom of left and

right V grooves of the fusion splicer.

③When the windproof cover is closed, the splicer will

automatically complete fusion between the following different kinds of

optical fibers.

●The application of different types of fibers in FTTH projects:

12

Splicing point

13

SOC hot splicing:

The clamp must meet the industry standard

FTTH hot melt quick connector. 【Need a

SOC fiber fixing clip (optional)】

the leather cable is connected with

the leather cable.

250μm bare fiber is connected

with the leather cable.

14

<2>Place two optical fibers in the fusion splicer.

Both Arc Calibration Fibers and Splicing Fibers are made in exactly the same

way.

9. ARC Calibration ( Video: youtu.be/lBO6tsaLN5k)

Why do we need to do Arc Calibration?

When the fiber optic material, altitude, climate, temperature, humidity,

electrode condition and other factors change greatly, it may lead to increased

splicing loss of the l splicer; Arc calibration can effectively reduce the splicing

loss.It is recommended to do an ARC calibration before the first use after getting

the machine.

<1>Select “Arc Calibration” from the main menu page

<3>Closing the cover will automatically start the arc calibration.

<4>If “Step1: Arc Calibration Not Finished”or “Step2: Arc Calibration

Not Finished ”is displayed at the bottom of the screen, it indicates that the

calibration has failed. Please make two fibers again, then start Arc Calibration

again.

15

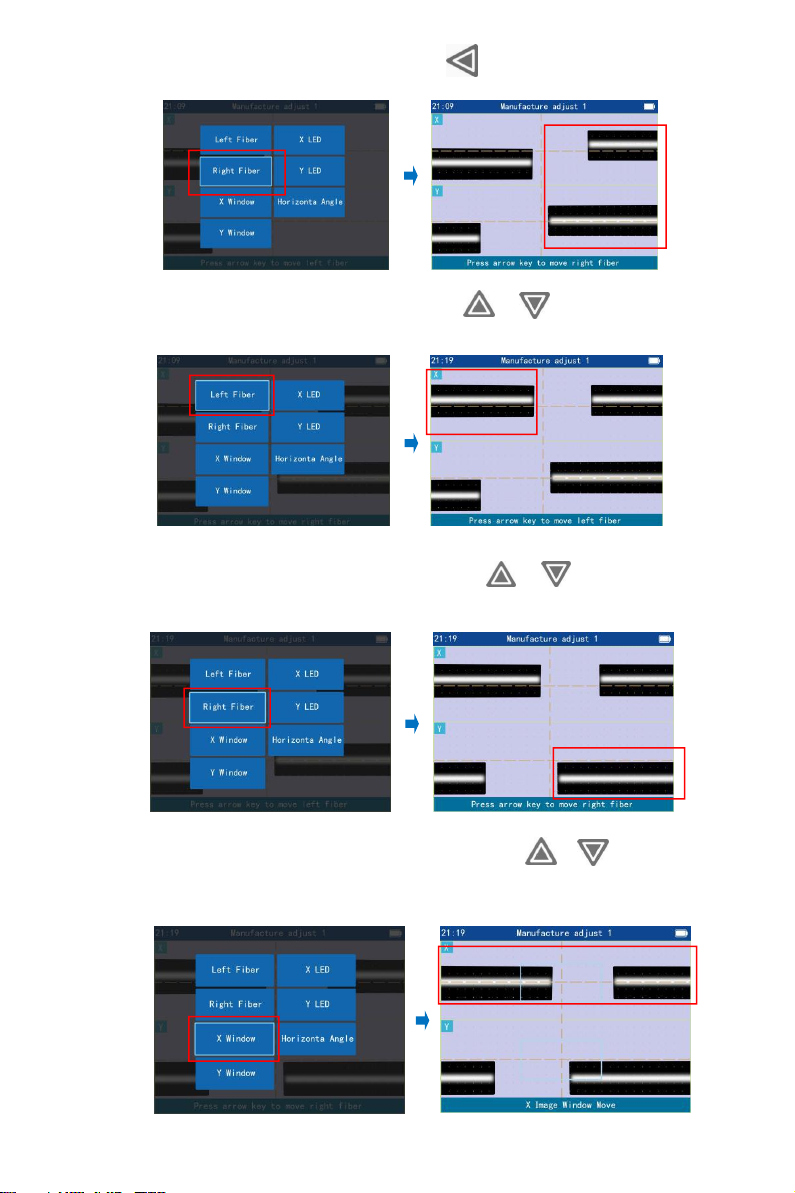

<2>Select 【Left Fiber】(Press and hold key to display positioning grid, hold

key to display menu, press and hold key to confirm selection); Press and hold

the button to move the fiber to the left position of the screen(As shown in figure

10.2.2).

<5>If it displays “Complete”, it means the calibration was successful.

Figure 10.2.1 Figure 10.2.2

9. Manually adjust the fiber position / Motor Calibration

(Video: youtu.be/u0oUbqNg77A)

Why do we need to adjust the position of the fiber?

Due to the dust on the construction site, the initial position of the motor

changed. When the fiber is welded, the motor stroke cannot reach the alignment

position, which leads to the wrong position of the fiber and welding cannot be

performed. After cleaning the dust in the V-groove, the fusion splicer still can not

be welded, so we need to manually adjust the position of the fiber to restore the

original position of the motor.

<1>Select 【Maintenance】-> 【Manufacture adjust 1】-> Enter the

password "1" (The button selects the characters and the button confirms

the entry).

Figure 10.1.1 Figure 10.1.2 Figure 10.1.3

16

<3>Select 【Right Fiber】, Press and hold the button to move the fiber to the right

screen position(As shown in Figure10.3.2 ).

Figure 10.6.1 Figure 10.6.2

Figure 10.5.1 Figure 10.5.2

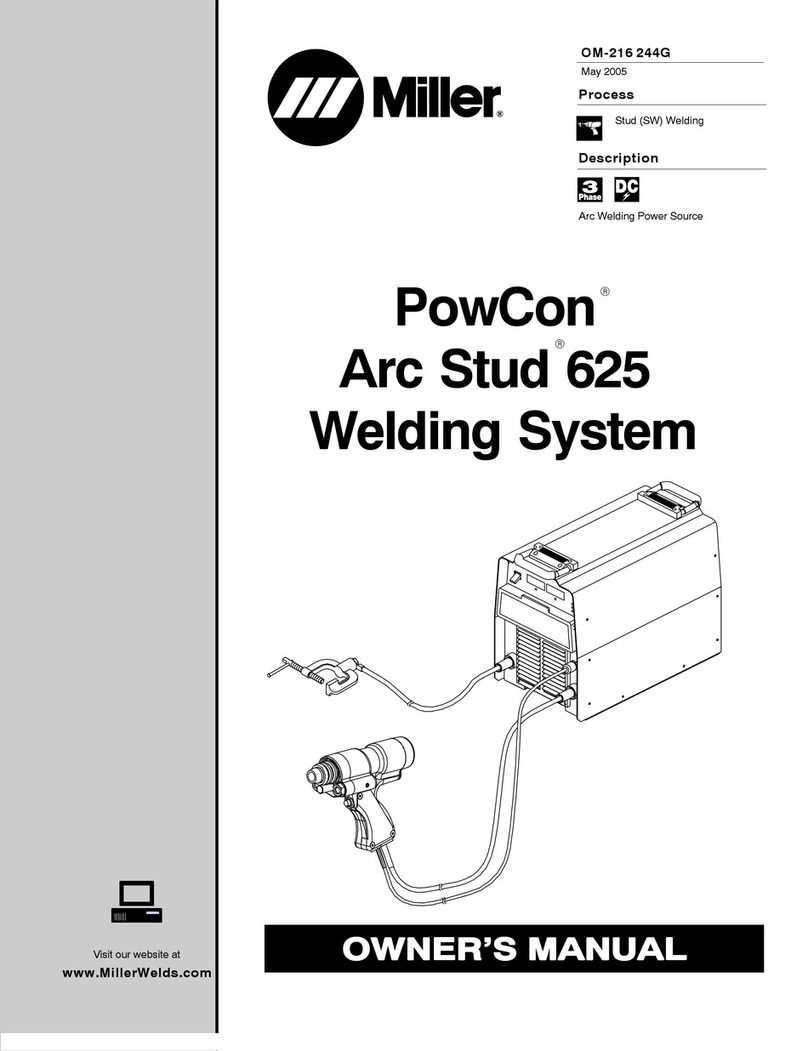

<6>Select【X Window】,and then press and hold the or to make the center

line of the fiber in the X window overlap the horizontal auxiliary line in the X

window(As shown in Figure10.6.2).

Figure 10.4.1 Figure 10.4.2

<5>Select 【Right fiber】and press and hold the or to align the left and right

fibers displayed in the Y window horizontally(As shown in Figure10.5.2 ).

<4>Select 【Left fiber】and press and hold the or to align the left and right

fibers displayed in the X window horizontally(As shown in Figure10.4.2 ).

Figure 10.3.1 Figure 10.3.2

<10>Press the button twice to exit calibration after calibration is complete.

17

Figure 10.8.1 Figure 10.8.2

<8>Select【X Window】, and then press the or key to overlap the center of

the gap between the left fiber and the right fiber in X Window with the vertical

auxiliary line(As shown in Figure10.8.2).

Figure 10.7.1 Figure 10.7.2

<7>Select【Y Window】,and then press and hold the or to make the center

line of the fiber in the Y window overlap the horizontal auxiliary line in the Y

window(As shown in Figure10.7.2).

Figure 10.9.1 Figure 10.9.2

<9>Select【Y Window】, and then press the or key to overlap the center of

the gap between the left fiber and the right fiber in Y Window with the vertical

auxiliary line(As shown in Figure10.9.2).

11. Cutting Length of Optical Fiber

optique

12. Common troubleshooting

Phenomenon

Defect

Reason

Measures

Bubble

1.Dust on the end

of optical fibe. 2.

Condensation.

3.Poor end face

ofoptical fiber.

4.Arc intensity is

too low.

1.Clean the fiber.

2.Cut the end face of the fiber

again and make sure the end face

of the fiber is flat.

3.Replace with new electrodes.

4.Stable electrode.

(【Maintenance】->【Electrode】->【Stabilize

Electrode】)

Unfused

1.Too high

pre-arc intensity

2.Propulsion

speed is too slow

3.Advance

blocked

1.Do"arc calibration".

2. Stable electrode.

(【Maintenance】->【Electrode】->【Stabilize

Electrode】)

3. Clean V-groove.

Variable

diameter

18

Other manuals for SS413F Series

1

Table of contents

Popular Welding System manuals by other brands

Miller

Miller PowCon Arc Stud 625 owner's manual

Lincoln Electric

Lincoln Electric RANGER 405D operating manual

SAF

SAF SAFEX M 253 Safety instruction for use and maintenance

Jackle

Jackle maxiMIG 250 operating manual

Lincoln Electric

Lincoln Electric POWER MIG210S Operation manual

ESAB

ESAB CUTMASTER A60 operating manual