Table of Contents

Splice Menu .................................................................. 48

Composition of Splice Menu ........................................................................... 48

Splice Mode ................................................................................................... 49

Select Splice Mode ........................................................................................ 50

Manual Splice Mode ....................................................................................... 59

ECF Splice ..................................................................................................... 60

Splice Settings ............................................................................................... 62

Memory .......................................................................................................... 63

Camera Image ............................................................................................... 65

Splice Memory Comment ............................................................................... 66

Heater Menu ................................................................. 67

Select Heater Mode ....................................................................................... 6

About heating of a connector splice part ........................................................ 0

Maintenance ................................................................. 71

Maintenance Menu information ...................................................................... 1

Replace Electrodes ........................................................................................ 2

Stabilize Electrodes ........................................................................................ 3

Clear Arc Count .............................................................................................. 3

Clear Cleaver Counter ................................................................................... 4

Motor Drive .................................................................................................... 4

Diagnostic Test ............................................................................................... 5

Dust Check .................................................................................................... 6

Arc Calibration ...............................................................................................

Motor Calibration ............................................................................................ 9

Maintenance Info............................................................................................ 9

Machine Settings............................................................................................ 80

Supervisor Menu ............................................................................................ 81

Error Message List ........................................................ 82

Questions and Troubleshooting .................................... 88

Power Supply ................................................................................................. 88

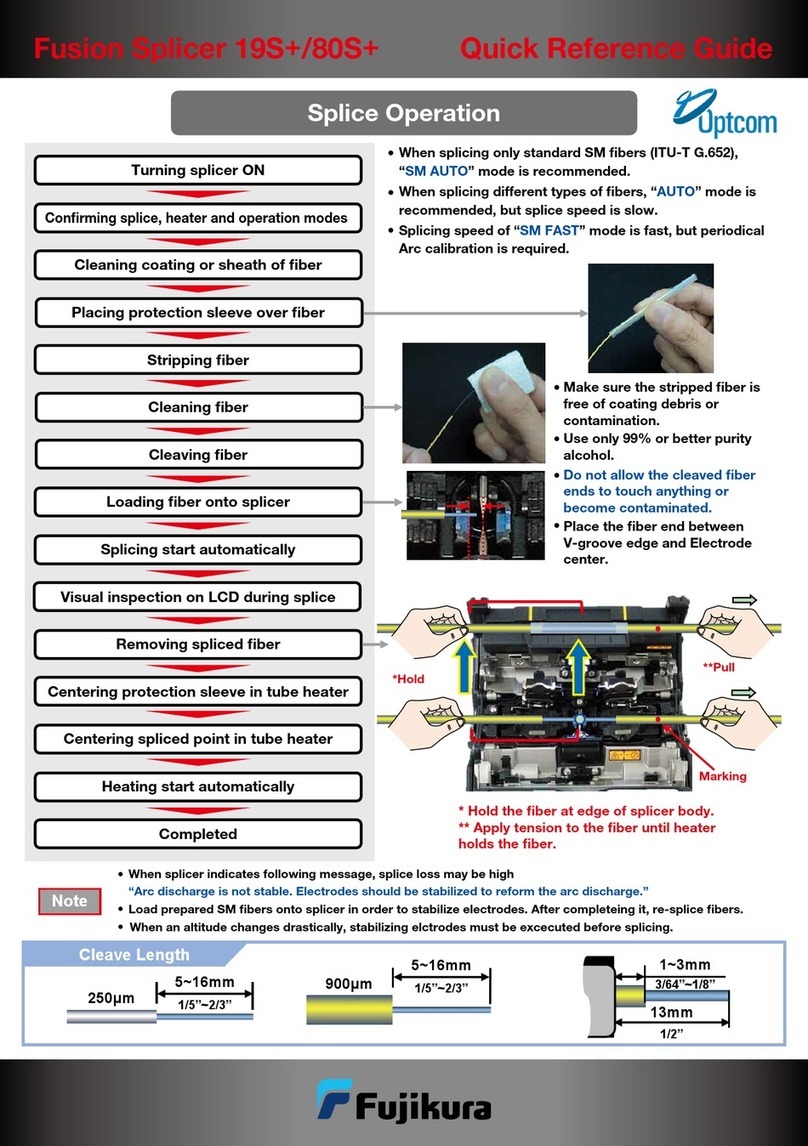

Splicing Operation .......................................................................................... 89

Tube-heating Operation ................................................................................. 91

Supervising .................................................................................................... 91

Other Functions ............................................................................................. 92

Guarantee and Contact Address .................................. 93

Guarantee ...................................................................................................... 93

Contact Address ............................................................................................. 94