Skytron ELITE Series User manual

Page59

ELITE SERIES SURGICALTABLES

MODEL ELITE 6002

MAINTENANCE MANUAL

INCLUDING BATTERY MODELS

REV 8/05

Page52

Page53

Table of Contents

SECTION I HYDRAULIC SYSTEM ...................................................................................................... 1

1-1. General........................................................................................................................................... 1

1-2. ComponentOperation .................................................................................................................... 2

a. Motor/PumpOperation ............................................................................................................. 2

b. Pressure Relief Valve .............................................................................................................. 2

c. Mini-Valves............................................................................................................................... 3

d. Mini-valve in Neutral Position ................................................................................................... 3

e. Mini-Valve Right Port Activated................................................................................................ 4

f. Mini-Valve Left Port Activated .................................................................................................. 4

g. Hydraulic Cylinders (Slave Cylinders) ..................................................................................... 5

h. Elevation Cylinder Return Circuit ............................................................................................. 6

i. Brake System........................................................................................................................... 7

j. Emergency Brake Release ...................................................................................................... 8

k. Flex/Reflex System ................................................................................................................... 8

1-3. Hydraulic Adjustments ................................................................................................................... 9

a. Fluid Level. ............................................................................................................................... 9

b. Bleeding The Hydraulic System ............................................................................................... 9

c. Pressure Relief Valve .............................................................................................................. 9

d. Speed Controls......................................................................................................................... 9

SECTION II MECHANICAL TABLE ADJUSTMENTS........................................................................ 11

2-1. Back Section Gear Mesh Adjustment ........................................................................................... 11

2-2. Hydraulic Cylinder Adjustment...................................................................................................... 11

a. Back Section ........................................................................................................................... 11

b. Leg Section ............................................................................................................................. 11

SECTION III HYDRAULIC TROUBLESHOOTING ............................................................................. 12

3-1. Precautions ................................................................................................................................... 12

3-2. Troubleshooting Notes .................................................................................................................. 12

3-3. ELEVATION DIAGNOSIS CHART .............................................................................................. 13

3-4. TRENDELENBURG DIAGNOSIS CHART.................................................................................. 14

3-5. LATERAL - TILT DIAGNOSIS CHART ........................................................................................ 15

3-6. FLEX SYSTEM DIAGNOSIS CHART.......................................................................................... 16

3-7. BACK SECTION DIAGNOSIS CHART ....................................................................................... 17

3-8. LEG SECTION DIAGNOSIS CHART .......................................................................................... 18

3-9. BRAKE CIRCUIT DIAGNOSIS CHART ..................................................................................... 19

3-10. Flexible Hose Identification and Placement................................................................................... 20

Although current at time of publication, SKYTRON's policy of continuous development makes this manual

subject to change without notice.

REV 8/05

Page54

Table of Contents (continued)

SECTION IV ELECTRICAL SYSTEM.................................................................................................. 22

4-1. General.......................................................................................................................................... 22

4-2. Components .................................................................................................................................. 22

4-3. Battery Model Components........................................................................................................... 22

SECTION V ELECTRICAL SYSTEM TROUBLESHOOTING ............................................................. 23

5-1. Troubleshooting Notes .................................................................................................................. 23

5-2. Main Switch................................................................................................................................... 23

5-3. Pendant Control ............................................................................................................................ 24

5-4. Relay Box...................................................................................................................................... 25

5-5. Solenoids....................................................................................................................................... 27

5-6. Motor/Pump Assembly.................................................................................................................. 29

5-7. Return To Level Micro-Switches................................................................................................... 31

5-8. Troubleshooting............................................................................................................................. 31

SECTION VI -6002B- BATTERY MODEL, ELECTRICAL TROUBLESHOOTING.............................. 36

6-1. General.......................................................................................................................................... 36

6-2. Troubleshooting Notes .................................................................................................................. 36

6-3. Main Switch................................................................................................................................... 37

6-4. Batteries ........................................................................................................................................ 37

6-5. Battery Charging Box/AC120V Transformer................................................................................. 38

6-6. Switch-Over Relay........................................................................................................................ 39

6-7. Pendant Control ............................................................................................................................ 40

6-8. Auxiliary Switches......................................................................................................................... 42

6-9. Relay Box...................................................................................................................................... 43

6-10.Main Wire Harness Continuity Tests............................................................................................. 45

6-11. Solenoids....................................................................................................................................... 46

6-12. Motor/Pump Assembly.................................................................................................................. 47

SECTION VII ELECTRICAL SYSTEM ADJUSTMENTS .................................................................... 48

7-1. Relay Box Adjustments Models 6002 & 6002B............................................................................ 48

WARNING

Indicatesapossibilityofpersonalinjury.

CAUTION

Indicates a possibility of damage to

equipment.

NOTE

Indicates important facts or helpful hints.

Page55

BASIC RECOMMENDED TOOLS:

1/8". 1/4" STRAIGHT BLADE SCREWDRIVERS

#2 PHILLIPS SCREWDRIVER

HYDRAULIC PRESSURE GAUGE SKYTRON P.N. 6-050-02

METRIC ALLEN® WRENCHES 1.5mm-8mm

ADJUSTABLE CRESCENT WRENCH

DIGITAL VOLTMETER, TRUE RMS

METRIC OPEN END WRENCHES 7mm-18mm

LEVEL (CARPENTERS)

BASIC RECOMMENDED MAINTENANCE PROCEDURES

The basic items notes below should be inspected at a minimal interval period of 6 months (dependant on

usage). For optimal usage, safety and longevity of the product, have it serviced only by an authorized

Skytron representative with authentic Skytron replacement parts.

• Check Power Cord (if applicable) • Inspect Articulating Joints

• Check Pendant Control (if applicable) • Inspect Table Tops

• Check Oil Level in Reservoir • Check Operational Times and Pressure Values

• Check For Hydraulic Leaks • Check Pressure Relief Valve Setting

• Check All Table Functions • Check Side Rails

• Check Velcro • Check Lateral Tilt Housing Bolts

• Inspect Leg and Head Section detachment mechanisms for proper operation

• Lubricate Elevation Slider Assembly with SKYTRON Slider Grease P/N D6-010-89

• Tighten X-Ray Top Stand-Offs, Use Loc-tite

• Lubricate Casters

• Check brake pads for wear and inspect brake cylinders for proper operation.

Only facility-authorized SKYTRON trained, maintenance personnel should troubleshoot the

SKYTRON6002SurgicalTable.Troubleshootingby unauthorized personnel could resultin

personal injury or equipment damage.

How to contact us:

Skytron

5000 36th St. SE, Grand Rapids, MI 49512

PH: 1-800-759-8766 (SKY-TRON)

FAX: 616-957-5053

Page56

IPX4

ENCLOSURE CLASS

V

VOLTAGE RATING OF THE UNIT

A

AMPERAGE RATING OF THE UNIT

HZ

FREQUENCY OF THE UNIT

POWERED BY BATTERY

BATTERY TYPE:

SEALED

LEAD ACID 12V, VALVE REGULATED

16AH, 10HR (530W/10MIN)

FUSE:

15 AMP FAST ACTING INTERNAL FUSE

INDICATES DANGEROUS VOLTAGE, 120 V, 60 Hz

PROTECTIVE GROUNDING.

IN ORDER TO ENSURE PROPER GROUNDING RELIABILITY,

THIS TABLE MUST BE CONNECTED TO A PROPERLY GROUNDED

HOSPITAL GRADE OUTLET.

CONNECTION FOR NEUTRAL CONDUCTOR SUPPLIED

N

UNIT TO BE USED ONLY IN SPECIFIED ENVIRONMENTAL CONDITIONS

TEMPERATURE: 15˚ - 30˚ C (60˚ -85˚ F)

HUMIDITY: 30% - 60% RELATIVE HUMIDITY, NON CONDENSING

AC VOLTAGE

CLASS I DEFIBRILLATION PROOF, TYPE B EQUIPMENT- IPX4 RATED.

INTERNALLY POWERED EQUIPMENT

TYPE B

EQUIPMENT

EQUIPMENT LABELS AND SPECIFICATIONS

BATTERY MODELS

ATTENTION, CONSULT MANUAL FOR FURTHER INSTRUCTIONS.

INDICATES SPECIAL USER ATTENTION.

POWERED BY AC VOLTAGE

15A

FUSE (2) 10 AMP FAST ACTING

10A

Page57

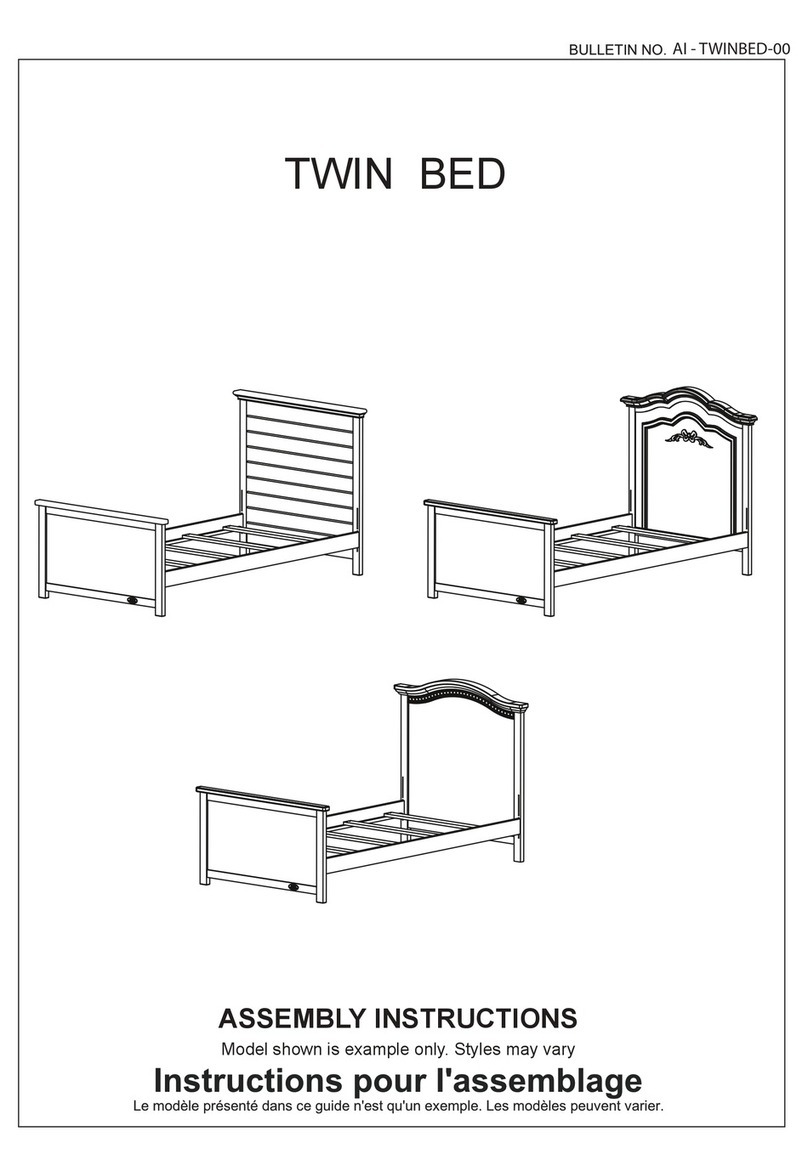

15"

10" 21-1/2" 24"

13" 20"

75"

76"

TOP VIEW

19-1/2"

60˚

90˚

5-3/4" 3"

8" 35-1/2"

5-3/4"

SIDE VIEW

22"

19"

43" MAX

.

28" MIN

.

END VIEW

®

Electrical Specifications

Power requirements

Current Leakage

Power Cord

120 VAC, 60Hz, 300 Watts

Less than 100 micro amps

15 feet w/hospital grade connector

(removeable on battery model)

6002 Series General Purpose Surgical Table Specifications

Page52

Page1

TRENDELENBURG

LATERAL TILT

BACK

SECTION LEG SECTION

BRAKE SYSTE

M

EMERGENCY

BRAKE RELEASE

PRESSURE

RELIEFVALVE

MOTOR/PUMP

ASSEMBLY

OIL

RESERVOIR

E

LEVATION

CYLINDER

MINI-VALVES

PLUMBING

TERMINAL

ELEV TREND TILT FLEX BACK LEG BRAKE

c. PressureReliefValve-Providesanalternateoil

pathwhenthehydrauliccylindersreach the end of

their stroke.

d. Electro/HydraulicMini-ValveAssemblies-These

direct the fluid to the appropriate hydraulic cylin-

ders.

e. Hydraulic Lines, Fittings, Connections - They

provide a path for the hydraulic oil.

f. HydraulicCylinders-Theyconvertthehydraulic

fluidpressureandvolumeintomechanicalmotion.

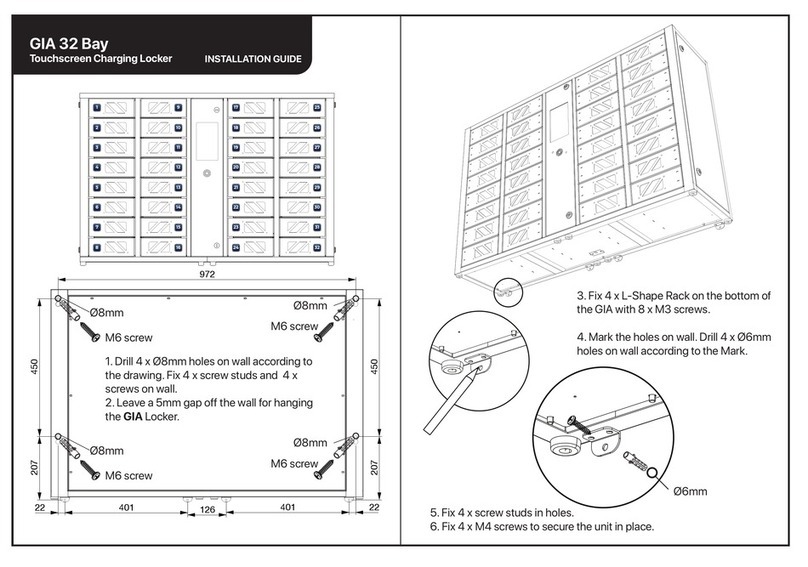

Figure 1-1. Hydraulic Block Diagram Model 6002

1-1. General

Electro-Hydraulic System

The hydraulic system (with the exception of the

hydraulic cylinders and hoses) is contained within

the base of the table. The hydraulic valves and

pump are electrically controlled by the use of a

hand-heldpushbuttonpendantcontrol. Thepower

requirementsforthetable are120VAC,5amp, 60

Hz.

The table contains the following components. Re-

fertotheblockdiagram(figure1-1)forrelationship.

a. Oil Reservoir - Main oil supply. Approximately

two quarts.

b. Motor/Pump Assembly - A positive displace-

ment gear type pump provides the necessary oil

pressure and volume.

SECTION I HYDRAULIC SYSTEM

Page2

1-2. Component Operation

a. Motor/Pump Operation

The motor/pump assembly is a gear type pump

that provides the oil pressure and volume for the

entire hydraulic system. The pump has an inlet

sideandanoutletside. Theinletsideisconnected

tothereservoirwhichprovidesthe oil supply. The

reservoir has a very fine mesh screen strainer

which prevents foreign material from entering the

oil system.

Theoutputlineofthepumpisconnectedtothemain

oil galley which is internal and common to all the

hydraulic mini-valves and pressure relief valve.

Also, common to the hydraulic mini-valves and

pressure relief valve is an oil galley that internally

connectstotheoilreservoirtoprovideareturnpath

for the hydraulic oil. See figure 1-2.

b. Pressure Relief Valve

Figure 1-4 . Pressure Relief Valve

Functioning

Figure 1-3. Pressure Relief Valve Not

Functioning

Thisdeviceprovidesanalternateoilpathwhenthe

hydraulic cylinders reach the end of their stroke

andthepumpcontinuestorun. Ifthispathwerenot

provided, the pump motor would stall because the

oil cannot be compressed. The pressure relief

valveisdirectlyconnectedtothemini-valvebodies

and shares both the common internal main pres-

sure oil galley, and the return oil galley, that inter-

nally connect to the reservoir. See figure 1-3.

Figure 1-2.

The main component of the valve is an adjustable

spring loaded plunger that is pushed off from its

seatbytheoilpressure. Theoilthenflowsbackinto

the reservoir. See figure 1-4 Turning the adjust-

ment nut clockwise increases the amount of oil

pressure required to open the valve, and turning it

counterclockwisedecreasestheamountofoilpres-

sure. (See adjustment section for specification.)

PRESSURE RELIEF

ADJUSTMENT NUT

SPRING LOADE

D

PLUNGER

P

RESSURE

G

AUGE

PRESSURE RELIEF

ADJUSTMENT NUT

SPRING LOADE

D

PLUNGER

P

RESSURE

G

AUGE

Page3

c. Mini-Valves

The operation of the mini-valves is identical for all

table functions except the elevation and Single

ActionBrakecircuits. Thesetwohydrauliccircuits

use a 3-way (single check valve) type mini-valve.

All other functions use a 4-way (dual check valve)

type mini-valve.

Either type mini-valve is controlled by two pushing

type, electrically operated solenoids. The sole-

noids push the spool valve (located in the lower

portion of the valve) one way or the other. This

motion opens the main supply galley (which has

pumppressure)allowing theoiltoflow throughthe

variouspartsofthe mini-valvetothefunction. The

spool valve also opens an oil return circuit which

allows the oil to return to the oil reservoir.

The main components of the mini-valve and their

functions are listed below:

1. Spool Valve - Opens the main oil galley

(pump pressure) to either mini-valve outlet de-

pending on which direction the spool valve is

pushed. Also it provides a return path for the oil

returning back into the reservoir.

2. Pilot Plunger - There are two plungers in a

four-way mini-valve (one in a 3-way mini-valve),

one under each check valve. The purpose of the

pilot plungers is to mechanically open the return

check valve allowing the oil to return back into the

reservoir.

3. Check Valve-Twoare providedineachfour-

way mini-valve to seal the oil in the cylinders and oil

lines and prevent any movement of the table. One

check valve is provided in a 3-way mini-valve.

4. Speed Adjustments - There are two speed

adjustments in each mini-valve. They are needle

valve type controls which restrict the volume of oil

returning back into the reservoir, thereby control-

lingthespeedofthetablesurfacemovement. A3-

way mini-valve has only one speed adjustment.

Thespeedcontrolsarealwayslocatedinthereturn

oilcircuit. Thispreventsuncontrolledmovementof

the piston in the slave cylinder due to one side of

the piston being loaded with hydraulic pressure

and the other side having no load.

Also,byusingthiscontrolmethod,itdoesn’tmatter

what size cylinder and piston is used because the

speedcanbecontrolledbyrestrictingthereturnoil.

Ifthepumpputsoutmorevolumetoacertainslave

cylinder than the speed control is allowing to go

back to the reservoir, the pressure relief valve

provides an alternate path for the pump oil.

d. Mini-Valve in Neutral Position

(No fluid flow) See figure 1-5.

1. Spool Valve Centered - This closes off both

oil pressure and oil return galleys.

2. PilotPlungersBothClosed-Thepilotplung-

ers control the opening of the check valves. If they

are closed, the check valves must be closed.

3. Check Valves - Both check valves are

closed trapping the oil in the cylinder and oil lines.

4. Speed Adjustment - When the mini-valve is

in the neutral position, the speed adjustment does

notaffectanythingbecausethereisnotanyoilflow.

Figure 1-5. Mini-Valve in Neutral Position

Page4

INLET

OUTLET

INLET OUTLET

e. Mini-Valve Right Port Activated

(See figure 1-6)

Slave Cylinder Piston Moves to Left

Right Mini-Valve Port is Supply Line

Left Mini-Valve Port is Return Line

f. Mini-Valve Left Port Activated

(See figure 1-7.)

Slave Cylinder Piston Moves to Right

Left Mini-Valve Port is Supply Line

Right Mini-Valve Port is Return Line

1. Spool Valve - Pushed to the left by electric

solenoid. This opens the internal oil pressure gal-

ley allowing the fluid to go through the check valve

andontothecylinder. Also, thespoolvalveopens

the oil return line providing an oil path through the

internal oil galley back to the reservoir.

2. PilotPlungerValve-Left pilot plungervalve

ispushedupbytheincomingoilpressuremechani-

cally opening the check valve located above it in

thereturncircuit. Thisactionallowstheoilfromthe

left side of the slave cylinder to go back into the

reservoir. The right pilot plunger valve is not

affected in this operation mode.

3. Check Valves - Both check valves are

opened in this operation mode. The right check

valveispushedopenbytheoilpressurecreatedby

thepump. Theoilthencontinuestogothrough the

lines and pushes the slave cylinder piston to the

left. At the same time, the left check valve is held

open mechanically by the pilot plunger providing a

returnpathfortheoilthroughthemini-valveback

to the reservoir.

4. SpeedAdjustment-Therightspeed control

(output side) does not have any effect in this

operation mode because the oil is routed around

thespeedadjustment throughaby-passvalve and

then to the output port. The left speed adjustment

controls the speed of the table function by restrict-

ing the amount of oil going back into the reservoir.

1. Spool Valve -Pushed to the right by electric

solenoid. This opens the internal oil pressure gal-

leyallowingthe fluidtogothrough thecheckvalve

andontothecylinder. Also, thespoolvalveopens

the oil return line providing an oil path through the

internal oil galley back to the reservoir.

2. PilotPlungerValve- Rightpilotplungervalve

ispushedupbytheincomingoilpressuremechani-

cally opening the check valve located above it in

thereturncircuit. Thisactionallowstheoilfromthe

right side of the slave cylinder to go back into the

reservoir. Theleftpilotplungervalveisnotaffected

in this operation mode.

3. Check Valves - Both check valves are

opened in this operation mode. The left valve is

pushed open by the oil pressure created by the

pump. The oil then continues to go through the

lines and pushes the slave cylinder piston to the

right. Atthesametime,therightcheckvalveis held

open mechanically by the pilot plunger providing a

returnpathfortheoilthroughthemini-valveback

to the reservoir.

4. Speed Adjustment - The left speed control

(output side) does not have any effect in this oper-

ation mode because the oil is routed around the

speed adjustment through a by-pass valve and

thentotheoutputport. Therightspeedadjustment

controls the speed of the table function by restrict-

ing the amount of oil going back to the reservoir.

Figure 1-6. Mini-Valve Right Port Activated Figure 1-7. Mini-Valve Left Port Activated

Page5

TRENDELENBURG

CYLINDER

BACK SECTIO

N

CYLINDER

E

LEVATION

C

YLINDER

LATERAL TILT

CYLINDER

LEG SECTION

CYLINDER

Figure 1-10. Trendelenburg Cylinder Assy.

In order to remove any looseness or play in the

table top, the trendelenburg pistons are made in

two pieces as shown in figure 1-11. This arrange-

ment eliminates any gear lash between the piston

teeth and the table pinion gear due to oil pressure

alwaysbeing present on both sides of the pistons.

Figure 1-11. Trendelenburg Cylinder Pistons

Figure 1-9. Back Section Cylinder

2. Trendelenburg Cylinder Assembly - This

cylinder / piston arrangement has rack teeth cut

into the top of each piston. These teeth mesh with

a pinon gear that is connected directly to the table

side frames. The pinion gear shaft and table side

frames are supported by bearings at either side.

Whenhydraulicfluidispumpedintoonesideofthe

cylinder, the pistons are pushed in one direction,

moving the pinion gear and table side frames with

them. Oil pressure can be applied to either side of

the piston, making the table tilt end for end. See

figure1-10.

g. Hydraulic Cylinders (Slave Cylinders)

Thereareseveraldifferenttypesofhydrauliccylin-

ders used in the table that activate the control

functions. With the exception of the elevation and

brake cylinders, all operate basically the same

way. The control functions are listed below: (See

figure 1-8.).

Back Section--2, double action cylinders

Leg Section--2, double action cylinders

Trendelenburg--1, double action cylinder

Lateral Tilt--1, double action cylinder

Elevation--1, single action cylinder

Brakes--4, single action cylinders

Figure 1-8. Cylinder Placement

1. Back Section and Leg Section Cylinders -

The double action cylinders are closed at one end

and have a movable piston with hydraulic fluid on

both sides. Connected to this piston is a ram or

shaft that exits out of the other end of the cylinder.

Through the use of either a gear, or clevis and pin

arrangement, this ram is connected to a movable

table surface.

The movable surface can be moved one way or

the other by pumping hydraulic fluid into the cylin-

der on either side of the piston. Obviously, if oil is

pumped into one side of the cylinder, a return path

mustbeprovided fortheoil ontheotherside. See

figure 1-9.

RAM HYDRAULIC LINE

PISTON

O-RING

O-RING

TABLE TOP

PINION GEA

R

PISTON

S

SIDEVIEW

OIL PRESSURE

SPLIT PISTONS

REMOVE GEAR LASH TOPVIEW

OIL PRESSURE

Page6

3. LateralTiltAssembly-Thelateraltiltassem-

bly consists of two cylinders, pistons and connect-

ing rods. The connecting rods attach to the lateral

tilt lever which connects to the table side frames.

When hydraulic fluid is pumped into one cylinder,

thepistonandconnectingrodpushesthelateraltilt

leverwhichtilts thetabletop tooneside. Totiltthe

table top in the opposite direction, fluid is pumped

into the opposite cylinder. See figure 1-12.

5. Brake Cylinders - The brake cylinders are

single action type similar to the elevation cylinder.

The movable piston's ram is connected to a brake

pad. Seefigure1-14. Oilpumpedintothetopofthe

cylinder pushes the piston down raising the table

baseoffitscasters. Aninternalreturnspringonthe

bottomofthepiston,pushesthepistonuptoreturn

the oil through the mini-valve to the reservoir.

Figure 1-12. Lateral Tilt Cylinder Assembly

4. ElevationCylinder-This singleactioncylin-

der does not have hydraulic fluid on both sides of

thepiston.Itdependsontheweightofthetabletop

assembly to lower it.

The cylinder is set in the center of the elevation

maincolumn. Thecylinderiselevatedbythedriven

forceoftheoilpressure. Whenlowering,theoilthat

is accumulated in the cylinder is returned to the oil

reservoirthroughthemini-valveduetothetabletop

weight.

A slider support assembly is used to support the

weightoftheuppertablesection. Astainlesssteel

shroud covers the flexible hydraulic hoses and

slider. See figure 1-13.

Figure 1-13. Elevation Cylinder Assembly

Figure 1-14. Single Action Brake Cylinder

h. Elevation Cylinder Return Circuit

Three-way (single check valve type) mini-valves

control both the elevation and return circuits. The

elevation circuit operation within the mini-valve is

identical to the operation of the four-way valves

previously described (inlet pressure opens the

check valve allowing the oil to enter the cylinder).

In the return position, inlet pressure pushes the

pilot plunger up and opens the return check valve.

See figure 1-15. The open check valve allows a

path for the oil in the elevation cylinder to return to

the reservoir. When the pilot plunger valve is

opened,thecontinuingpump pressure opens the

pressure relief valve which provides a return oil

path to the reservoir.

TABLE TOP

P

ISTON PISTON

CONNECTING

RODS

LATERAL TIL

T

LEVER

O

IL LINE

B

RAKE

P

AD RAM

RETUR

N

SPRING

PISTON

Page7

The mini-valve used in the elevation circuit con-

tains only one check valve (all four-way mini-

valves use two check valves). The check valve is

usedtotraptheoilintheelevationcylinderthereby

supporting the table top. When the top is being

loweredthecheckvalveismechanicallyheldopen

by the pilot plunger through pump pressure.

Figure 1-16. Brake System Block Diagram

Each corner of the cast-iron table base has a

hydraulic brake cylinder. These single action cyl-

indersarehydraulicallyconnectedinparalleltothe

mini-valve and all four are activated together. It is

normalforonecornerofthetabletoraisebeforethe

others due to the weight distribution of the table.

An electronic timer in the relay box is activated

when any function on the pendant control is

pushed momentarily. The pump/motorandbrake

system mini-valve are activated and the brake

cylinders are completely set. The electronic timer

runs for approx. 8-10 seconds.

The brakes are released by pushing the BRAKE

UNLOCK button momentarily. An electronic timer

in the relay box activates the brake function hy-

draulic mini-valve and pump/motor.

When activated, the return hydraulic circuit oper-

ates similar to the elevation cylinder return circuit.

Returnspringsinsidethesingleactionbrakecylin-

ders retract the brake pads and provide the pres-

suretoreturnthehydraulicoilbacktothereservoir.

The electronic timer operates the return circuit for

approximately 8-10 seconds.

Figure 1-15. Elevation Return Circuit

i. Brake System

Thebrakesystemconsistsofthefollowingcompo-

nents: (figure 1-16)

1. Single action slave cylinders (4 each).

2. 3-way (single check valve type) mini-valve.

3. Manually controlled emergency brake re-

lease.

4. Plumbing terminal, flexible hoses, copper

lines and "O" rings.

5. Portions of the electrical system.

INLET

RETURNTO

RESERVOIR

TO RESERVOIR

THROUGH

PRESSURE

RELIEFVALVE

BRAKE SYSTEM

EMERGENCY

BRAKE RELEAS

E

RELIEF

VALVE

PLUMBING

TERMINAL

BRAKE

R

ETURN TO

R

ESERVOIR

RESERVOIR PUMP/MOTOR

ASSEMBLY

Page8

figure1-18.

Figure 1-18. Flex/Reflex System

Figure 1-17.

NOTE

•The emergency brake release valve

mustbetightenedsecurelywhennotin

use.

•If the emergency brake release valve

has been operated, the UNLOCK but-

tononthependant controlmayhaveto

be pressed before brakes will lock

again.

If the emergency brake release valve is open or

loose, two conditions could occur:

The brakes will release slowly- depending on how

loosethevalveis,thiscouldtakeanywhere from a

few minutes to several hours.

k. Flex/Reflex System

TheFlex/Reflexsystemusedonthepresenttables

incorporatesanadditionalmini-valve(7total)which

connects the trendelenburg and back section hy-

draulic systems in a series. When FLEX is acti-

vatedbythependantcontrol,theFlex/Reflexmini-

valve opens the oil pressure path to the Reverse

Trendelenburgpiston. Thereturnoilpath fromthe

trendelenburg piston is routed through the back

section cylinder to the mini-valve return port. See

j. Emergency Brake Release

Theemergencybrakereleaseissimplyamanually

operatedbypassvalveconnectedin parallel tothe

brakecylindersandtheoilreservoir. Seefigure1-

17. When the valve is opened (turned counter-

clockwise) a return circuit for the brake hydraulic

fluid is opened. The return springs force the

pistons up pushing the hydraulic oil back into the

reservoir and retracting the brake pads.

BACK

DOWN

TREND REVTREND BACK UP

PLUMBING

TERMINAL

FLEX/REFLEX

MINI-VALVE

EMERGENCY BRAKE

RELEASE LEVER

Page9

c. Pressure Relief Valve

Thepressurerelief valveisadjustedby turningthe

adjustmentnutuntilthedesiredpressureisreached.

To adjust:

1. Removetheblindcapandattachahydraulic

pressuregaugetothemainoilgalleyusing a 6mm

plumbing bolt. See figure 1-20.

1-3. Hydraulic Adjustments

a. Fluid Level.

Thefluidlevelshouldbeapproximately1/2"below

thefillerholeor gasketsurface.Ifadditionalfluid is

needed, remove the filler vent cap with a phillips

screwdriver and add fluid through this opening

using a funnel. See figure 1-19.

NOTE

The elevation cylinder should be com-

pletely down and all the other control

functions in their neutral position when

checking oil level.

Figure 1-19.

ThetypeofoilthatshouldbeusedisMobilDTE#25

or equivalent. This is a very high quality hydraulic

oil. The table requires approximately two quarts of

oil to operate properly.

b. Bleeding The Hydraulic System

Topurgetheairfromthehydraulicsystem,operate

each function back and forth at least two or three

times.

NOTE

Wheneverahydrauliclineorcomponent

isreplaced,bleedtheairoutofthelines

using the pump pressure before mak-

ing the final connection. Then operate

the function until it stalls in both direc-

tions.

RESERVOIR

OPENING

FILLE

R

CAP

FILLERVENT

Figure 1-20.

2. Raisethetabletopuntilthepistonreachesthe

end of its stroke and stalls. Observe reading on

pressure gauge and turn the adjustment nut (clock-

wise to increase oil pressure, counterclockwise to

decrease)untildesiredreadingisobtained. Pressure

should be 80KG/CM† -1138 PSI.

Page10

Apressuregaugeshouldbeusedtoset the speed

of the back section, trendelenburg and flex control

functions.

To adjust:

1. Attachthepressuregaugeontothe main oil

galley as shown in figure 1-21.

2. Thegaugeshouldread the following values

when operating the various control functions in

either direction. Turn the speed controls until

desired values are obtained.

Back Section Up 65KG/CM†-925PSI

Dn 65KG/CM†-925PSI

Trendelenburg Up 65KG/CM†-925PSI

Dn 65KG/CM†-925PSI

Flex 70KG/CM†-995PSI

Reflex 70KG/CM†-995PSI

NOTE

WhenadjustingFlex/Reflexspeedcon-

trols, set Reflex last.

Elevation - There is not a speed adjustment for

raisingthetable. Thespeed controlwillonlyaffect

the rate of descent and it should equal the rate of

elevation.

d. Speed Controls

Thespeedcontrolsrestrictthevolumeofoilreturn-

ing back to the reservoir thereby controlling the

speed of each control function.

All four-way mini-valves, have two speed controls

located in the ends of each valve body. All three-

way mini-valves have only one speed control.

One speed control adjusts one direction of a

particular function and the opposite speed control

adjuststheotherdirection. Theyareadjustableby

using a small straight blade screwdriver and

turning the adjustment screw clockwise to de-

crease the speed and counterclockwise to

increase the speed. Refer to figure 1-21.

Figure 1-21.

Any control function should move in either direc-

tionatthesamerate. Iftherateofacertainfunction

is too slow, open the speed control slightly and

recheck. Usethesecondhandonawatchandtime

a particular function. Match that time in the oppo-

site direction by opening or closing the speed

control. Approximate operating times are as fol-

lows:

LateralTilt 7 seconds

Back Up 25 seconds

Back Down 15 seconds

Page11

SPANNER

WRENCH

TABLE SID

E

FRAME

BACK SECTION

CYLINDER

ECCENTRIC CAM

BACK SECTION

LEG

SECTION

TABLE SIDE FRAME

LEG CYLINDER

ECCENTRIC CAM

SPANNER WRENCH

SECTION II MECHANICAL TABLE ADJUSTMENTS

To adjust:

Loosen the cam locking nuts located inside the

table side frames. Use a spanner wrench to turn

the cylinder eccentric cams as required to shift

either cylinder fore or aft as needed so no twisting

orflexingof thebacksectionisobservedwhenit is

stalled in the full up position. See figure 2-2.

Figure 2-1. Eccentric Cam Adjustment

2-2. Hydraulic Cylinder Adjustment

Back & Foot / Leg Sections

The hydraulic cylinder rams that control both the

backandfoot/legsectionsmustmovetogetherso

thatthesesectionsarenottwistedwhenoperated.

This is accomplished by the use of eccentric cams

thatmovethecylinder bodiesforeandaftto adjust

their effective stroke.

NOTE

Adjust gear mesh before adjusting ec-

centric cams for the back section.

a. Back Section

Position the back section all the way up until it

stalls. Both sides of the back section should stop

moving at the same time and should not show any

signs of twisting.

Any twisting or flexing of the back section as it

approaches the stalled position indicates that one

of the cylinders is not reaching its fully extended

position at the same time as the other. This

condition would require an adjustment.

Figure 2-2. Back Section Adjustment

b. Leg Section

Position the leg section all the way up. Both sides

of the leg section should stop moving at the same

time and should not show any signs of twisting.

Any twisting or flexing of the leg section as it

approaches the stalled position indicates that one

of the cylinders is not reaching its fully extended

position at the same time as the other and an

adjustment is required.

To adjust:

Loosen the cam locking nuts located inside the

table side frames. Use a spanner wrench to turn

the cylinder eccentric cams as required to shift

either cylinder fore or aft as needed so no twisting

or flexing of the leg section is observed when it is

stalled in the above horizontal position. Tighten

locking nuts when proper adjustment is achieved.

See figure 2-3.

2-1. Back Section Gear Mesh Adjustment

Thegearmeshisadjusted by theuseofaneccen-

tric cam. This cam moves the gear teeth closer

together to eliminate gear lash. This adjustment

arrangement compensates for any wear between

the gears that might occur.

To adjust:

Loosen the cam locking nut and allen set screw.

Useaspanner wrenchtorotatethe eccentriccam.

Use firm pressure on the spanner wrench. See

figure 2-1. Tighten the locking nut and set screw

when adjustment is complete.

Figure 2-3. Leg Section Adjustment

ECCENTRIC

CAM

NUT

S

ET SCREW

SPANNE

R

WRENCH

Page12

SECTION III HYDRAULIC TROUBLESHOOTING

3-1. Precautions

Before attempting to troubleshoot any hydraulic

problemonthetable,pleasereadthrough the pre-

cautions and notes below.

CAUTION

Whendisconnectinganyofthehydrau-

lic lines, fittings, joints, hoses, etc., for

the following control functions, be sure

these table surfaces are in their down

position or completely supported.

•Elevation

•Back Section

•Leg Section

When working on the trendelenburgor

lateral tilt hydraulic circuits, be sure to

supportthetabletop. Whenworkingon

thebrakesystemmakesurethebrakes

are completely retracted.

CAUTION

Failuretofollowtheseprecautionsmay

result in an uncontrolled oil spray and

damage to the table or personal injury.

3-2. Troubleshooting Notes

When troubleshooting a table malfunction, first

determinethefollowing:

1. Does the problem affect all control func-

tions?

2. Does the problem affect only one control

function?

3. Iftheproblemaffectsone control function is

it in both directions?

4. Is the problem intermittent?

5. Is the problem no movement of a table

surface or does the table surface lose position?

Oncethe problem has been determined, concen-

trate on that particular hydraulic circuit or control

function.

Listed below are the hydraulic components that

are common with all hydraulic circuits. If there is a

problem with any of them, it could affect all control

functions.

1. Motor/Pump Assembly

2. Reservoir

3. Pressure Relief Valve

4. Certain Oil Lines and Galleys

Iftherewasaprobleminthefollowingcomponents,

only one control function would normally be af-

fected.

1. Mini-Valve

2. Slave Cylinder

3. Oil Lines

NOTE

Whenever a hydraulic line or compo-

nentisreplaced,bleedtheairoutofthe

lines using the pump pressure before

making the final connection. After all

connections are tight, cycle the control

function back and forth two or three

times to purge the remaining air from

the system.

CAUTION

When installing new "O" rings use hy-

draulic oil to thoroughly lubricate the

"O" rings and cylinder. Keep every-

thingclean.

Each complete oil circuit is shown on the following

pages. Whentroubleshootingaparticularfunction,

refer to the appropriate oil circuit diagram and the

list of possible problems

Other manuals for ELITE Series

2

This manual suits for next models

2

Table of contents

Popular Indoor Furnishing manuals by other brands

Multay

Multay AN03 Assembly instruction

OfficeSource

OfficeSource PL236T Assembly instructions

Peka

Peka SLIM 450 Assembly instruction

Home Decorators Collection

Home Decorators Collection SK19326Br1-B Use and care guide

MAD

MAD airfoil G28T quick start guide

Dorel

Dorel Ameriwood Industries 3595317PCOM manual