Sentinel 7

GAS PIPING

A. Local installation codes apply. The pipe joint compound

used on threads must be resistant to the action of liquefied

petroleum gases.

B. The gas supply line to the boiler should be run directly from

the meter for natural gas or from the fuel tank for L.P.

propane gas. See page 2 for location of union and manual

main shutoff valve that may be specified locally.

Selecting pipe size for natural gas:

1. Measure or estimate the length of piping from the meter

to the installation site.

2. Consult gas supplier for heating value of gas-W/m3

(BTU/cu. ft.).

3. Divide boiler rated input by heating value to find gas flow

in piping (m3/hr) (cu. ft. per hour).

4. Use table below to select proper pipe size.

Example: Boiler model SE-175 is to be installed. Distance

from gas meter to the boiler is 6.1m (20 ft). Heating value of

natural gas is 10560 W/m3(1020 BTU/cu. ft.) Select proper

pipe size.

At 6.1m (20 ft.) length of pipe, match required capacity from

table below (choose higher capacity, in this case is 5.4 m3

[190 cu. ft.] per hour). Required pipe size is 19mm (3/4").

Improper gas pipe sizing will result in pilot flame outages,

insufficient heat and other installation difficulties. For more

information and also if other appliances are to be attached

to the piping system, see Appendix C of National Fuel Gas

Code ANSI Z223.1-latest edition or CSA B149.1-00 for nat-

ural gas and propane.

C. The boiler and its gas connection must be leak tested before

placing the boiler in operation. Use liquid soap solution for

all gas leak testing. Do not use open flame.

This boiler and its individual shutoff valve must be discon-

nected from the gas supply piping system during any pres-

sure testing of that system at test pressures in excess of

3.5 kPa (1/2 PSIG). This boiler must be isolated from the gas

supply piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 3.5 kPa (1/2

PSIG).

D. All gas piping used should be inspected thoroughly for

cleanliness before makeup. A sediment trap must be pro-

vided, as illustrated on page 2.

E. The minimum and maximum gas supply pressure (at the

inlet of gas valve) are shown on the boiler rating plate for the

type of gas used. Gas supply pressure should never be less

than minimum or more than maximum pressure when the

boiler or any other appliance is turned on or off.

ELECTRICAL CONTROLS AND WIRING

A. The electrical power to the boiler must be on a separately

fused and live circuit.

B. If an external electrical source is utilized, the boiler, when

installed, must be electrically grounded in accordance with

the requirements of the authority having jurisdiction or, in

absence of such requirements, with the Canadian Electric

Code – CSA-C22.1, Part 1 – latest edition.

C. Basic control wiring diagrams are supplied. Other control

systems may be factory supplied, see User's Information

Manual and Instructions packed with control system sup-

plied.

D. After placing the boiler in operation, the safety shutoff device

must be tested. See page 12 safety check.

BOILER ROOM AIR SUPPLY AND VENTILATION

An ample supply of air is required to obtain combustion and

ventilation. ALL AIR COMES FROM OUTSIDE, directly through

wall openings to the boiler or through unsealed openings

around windows, doors, etc. in the whole building. When build-

ings are insulated, caulked and weather stripped, now or later

on, direct openings to outside may be required and should be

provided. If the boiler is not near an outside wall, air may be

ducted to it from outside wall openings.

Provisions for combustion and ventilation air must be made in

accordance with section 5.3, Air for Combustion and Ventila-

tion, of the National Fuel Gas Code, ANSI Z223.1-latest edition

or CSA B149.1-00 for natural gas and propane, or applicable

provisions of the local building codes. The following recom-

mendation applies to buildings of energy-saving construction,

fully caulked and weather stripped:

INSTALLATION IN ENCLOSED BOILER ROOM REQUIRES

TWO UNOBSTRUCTED OPENINGS FOR PASSAGE OF AIR

INTO THE BOILER ROOM:

1. Air drawn horizontally from outdoors DIRECTLY through an out-

side wall; one louvered opening near the floor and one louvered

opening near the ceiling, each opening with a minimum FREE air

passage area of 550 mm2 per kW (1 square inch per 4000 BTUH)

of total appliances’ input.

2. Air drawn horizontally through HORIZONTAL DUCTS; one open-

ing near the floor and one opening near the ceiling, each opening

with a minimum FREE air passage area of 1100 mm2 per kW (1

square inch per 2000 BTUH) of total appliances’ input.

3. Air drawn VERTICALLY from outdoors; one opening at the floor

and one opening at the ceiling, each opening with a minimum

FREE air passage area of 550 mm2 per kW (1 square inch per

4000 BTUH) of total appliances’ input.

4. Air drawn from inside the building; one opening near the floor and

one opening near the ceiling, each opening with a minimum

FREE air passage area of 2200 mm2 per kW (1 square inch per

1000 BTUH) of total appliances’ input.

Gas flow = = 4.9 m3/hr

51 290 W/hr

10 560 W/m3

(Gas flow = = 171.5 cu. ft. per hour)

175,000 BTU/hour

1020 BTU/cu. ft.

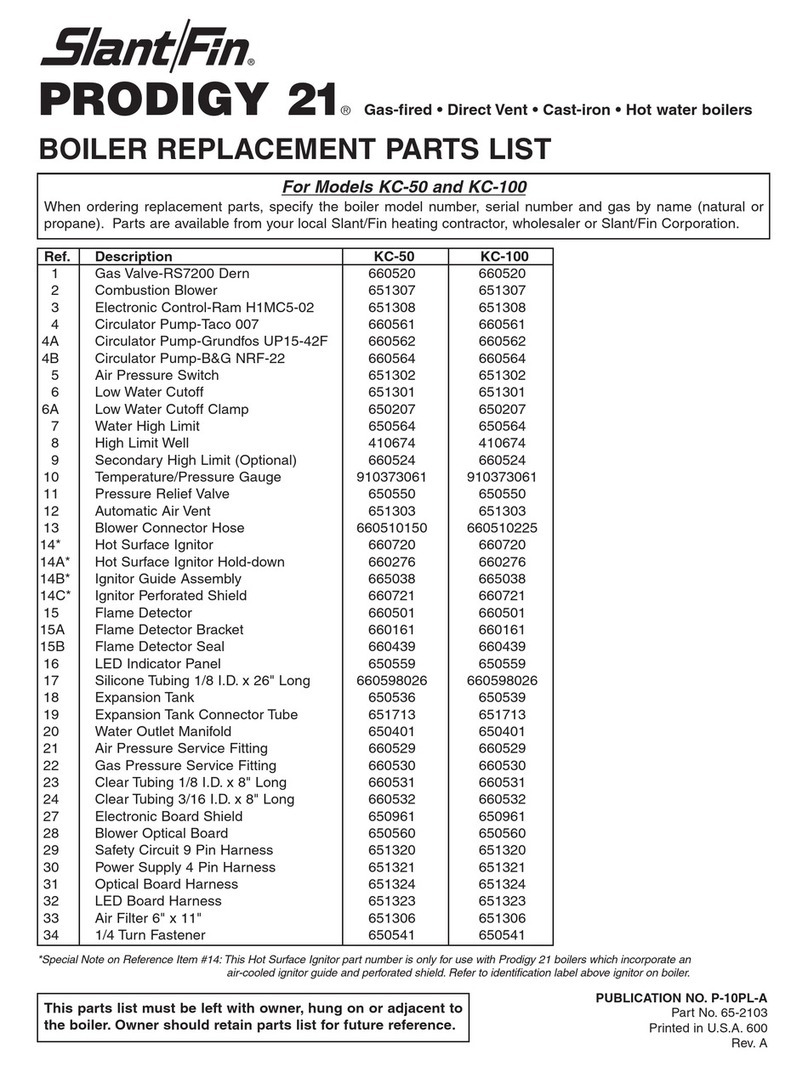

13mm (1/2”) 19mm (3/4”) 25mm (1”) 32mm (1-1/4”) 38mm (1-1/2”)

mft

m3/hr cu.ft./ hr. m3/hr cu.ft./hr. m3/ hr cu.ft./hr. m3/ hr cu.ft./ hr. m3/ hr

cu.ft./ hr

.

3.0 10 3.7 132 7.9 278 14.7 520 29.7 1050 45.3 1600

6.1 20 2.6 92 5.4 190 9.9 350 20.7 730 31.1 1100

9.1 30 2.1 73 4.3 152 8.1 285 16.7 590 25.2 890

12.2 40 1.8 63 3.7 130 6.9 245 14.2 500 21.5 760

15.2 50 1.6 56 3.3 115 6.1 215 12.5 440 19.0 670

18.3 60 1.4 50 3.0 105 5.5 195 11.3 400 17.3 610

21.3 70 1.3 46 2.7 96 5.1 180 10.5 370 15.9 560

24.3 80 1.2 43 2.5 90 4.8 170 9.9 350 15.0 530

27.4 90 1.1 40 2.4 84 4.5 160 9.1 320 13.9 490

30.5 100 1.1 38 2.2 79 4.2 150 8.6 305 13.0 460

Length

of Pipe

Gas Flow In Piping

Pressure Drop = 8mm (.3”) in water Specific Gravity = 0.60

Iron Pipe Size (Ips)—inches

At pressure drop of 0.3 in. water, specific gravity = 0.60.