VICTORY VSPH Models

8

VENTING INSTALLATION

Follow the vent material manufacturer’s instructions in

conjunction with these instructions for venting system

installation.

I. Non-Direct Vent Installation

The air for combustion is taken from the ambient air

surrounding the boiler; therefore, ample supply of air is

required for combustion and ventilation (see page 5.)

DO NOT use this installation method if the surrounding of

the boiler is contaminated. The harmful corrosive

contamination may be from the chlorine-type detergents,

cleaners, bleaches, and fabric softeners used in laundry or

chlorine-based swimming pool chemicals.

A. SIDEWALL VENTING - NON-DIRECT VENT

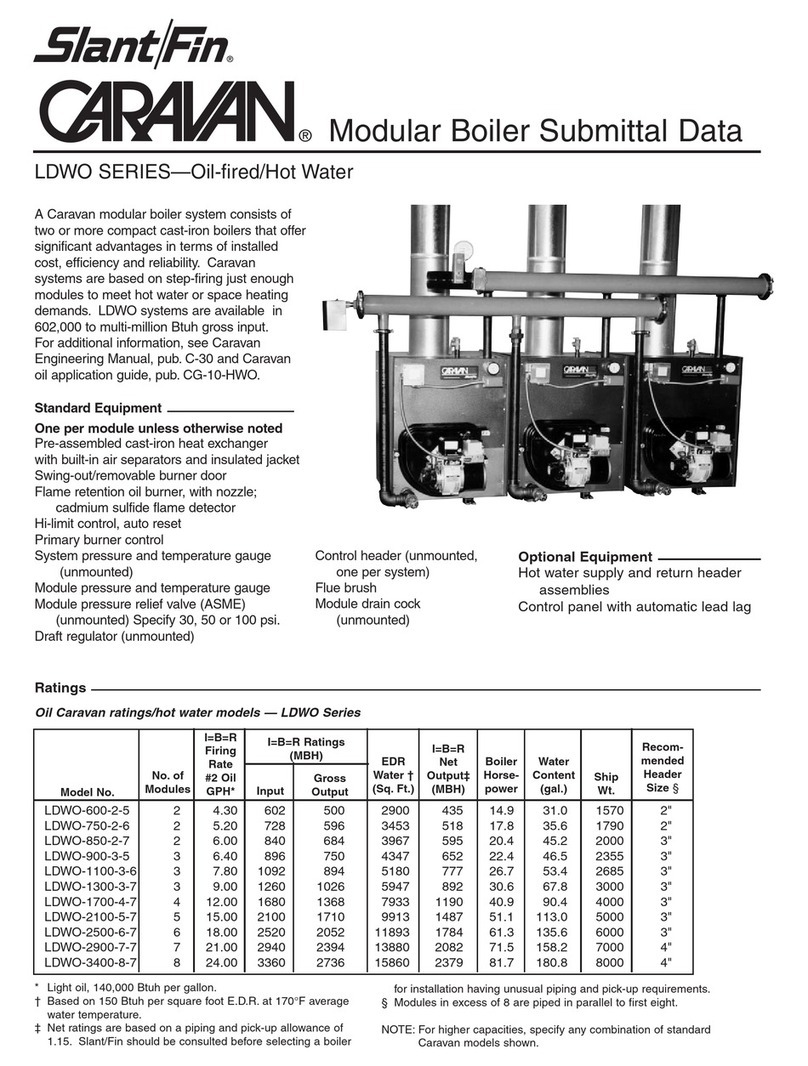

Figures 5 and 6 show typical horizontal sidewall venting. For

combustible wall passage of vent piping, a UL or CSA listed

thimble must be used, providing the wall thickness from 76

mm (3") minimum up to 305 mm (12") maximum. The vent

piping must terminate with a screened tee or elbow

termination facing down.

CAUTION: Flue gasses existing from the vent terminal will

condense. Building materials in the area of the vent terminal

should be protected from discoloration and degradation.

VENT TERMINATION LOCATION AND CLEARANCES

1. The venting system shall terminate at least 914 mm (36")

above any forced air inlet located within 3048 mm (120").

2. The venting system shall terminate at least 1219 mm

(48") below, 1219 mm (48") horizontally from, or 305 mm

(12") above any door, window or gravity air inlet into any

building. The bottom of the vent terminal or air intake ter-

minal shall be at least 305 mm (12") above grade or the

normal snow level whichever is greater.

3. Through the wall vents shall not terminate over public

walkways or over areas where condensate or vapor

could create a nuisance or hazard or could be detrimen-

tal to the operation of regulators, relief valves or other

equipment. Minimum clearance of 1219 mm (48") hori-

zontal distance is maintained, from electric meters, gas

meters, regulators and relief equipment.

4. Vent termination must not be located in any confined

space (i.e. window wells, alcoves, narrow alleys) or under

any overhang or deck. Vent termination should not allow

flue gas discharge towards neighbor’s windows or where

personal injury or property damages can occur.

B. NON-DIRECT VENT - VERTICAL VENTING

Figure 7 shows typical venting through the roof. The vent

pipe must pass through the ceiling, floor and the roof verti-

cally through a 178 mm (7") minimum diameter cutout. A fire

stop is required for each ceiling and floor penetration. For

roof passage, an appropriate UL listed roof flashing must be

used.

An existing chimney (see Figure 8) may be used as a chase

for vertical venting. Other appliances CANNOT be vented

into the same chimney or vent pipe with in the chimney.

The vertical vent piping must terminate with a screened tee,

or combination of 45° elbow and a 90° screened elbow

termination or a rain cap termination.

II. Direct Vent Installation

Air intake piping from outside to the boiler air intake collar

provides the air for combustion. The boiler surrounding may

be contaminated with chlorine-based products such as laun-

dry detergents.

A. SIDEWALL DIRECT VENTING

Figures 9 and 10 show typical sidewall direct venting.

Slant/Fin vent/air intake termination MUST be used for this

method of installation.

CAUTION: Flue gasses existing from the vent terminal will

condense. Building materials in the area of the terminal

should be protected from discoloration and degradation.

See page 4 for vent termination location and required

clearances.

VENT/AIR INTAKE TERMINATION INSTALLATION

1. Termination must be installed horizontally.

2 Refer to Figure 11 for installation details.

3. Wall thickness should be 76 to305 mm (3" to12") thick

4. Follow instruction for "vent termination location and

clearances" explained on this page.

5. Cut a rectangular opening with following dimensions in the

wall.

Height: 133 mm (51/4")

Width: 324 mm (1213/44")

6. From outside of the wall, install outside termination plate

using 4 screws. Make sure the louvers are at left side.

7. For combustible wall a 4" galvanized pipe must be used as

a wall thimble.

The length of the 4" galvanized pipe should be

approximately 25 mm (1") shorterthan the wall thickness.

8. From inside the building, fit galvanized pipe over4" collar

of the outside plate.

9. From inside, fit 3” diameterair intake pipe over3" collar

located on the air box of the outside plate.

(text continued p.13)