22687 23 2022

-

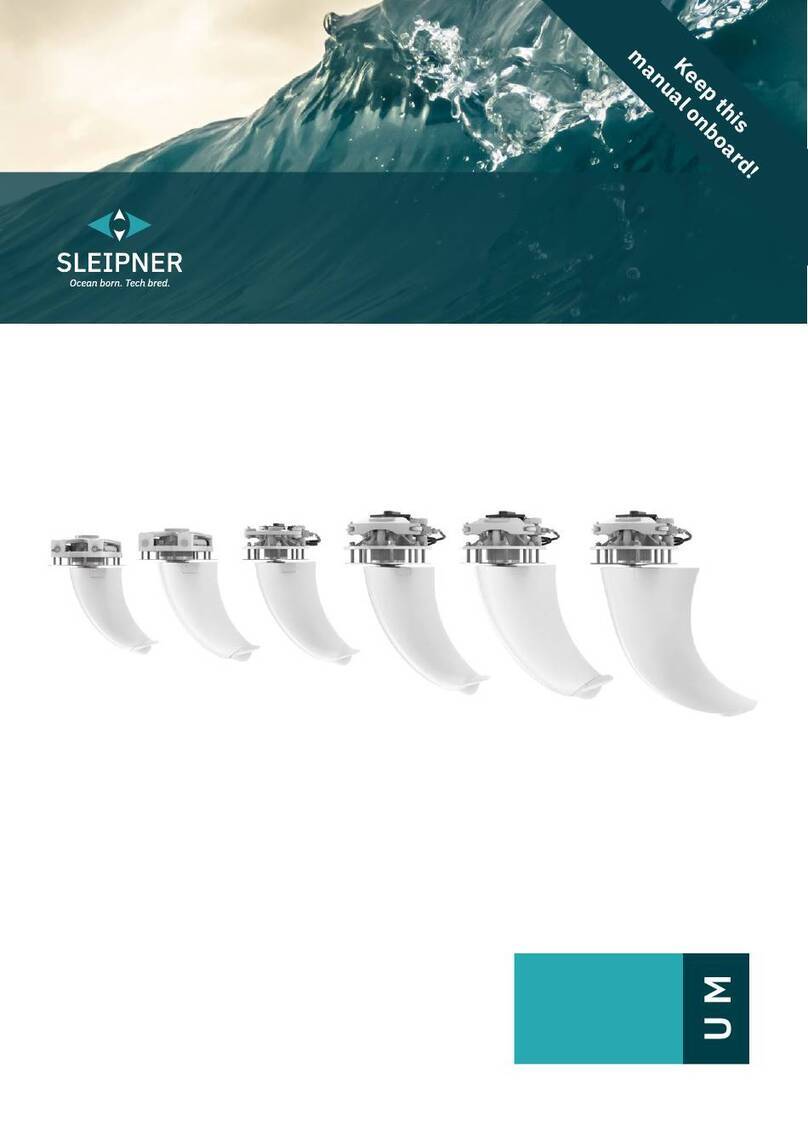

SE80 & SE100 & SE120 & SE130 & SE150

Sleipner Motor AS

P.O. Box 519, Arne Svendsensgt. 6-8

N-1612 Fredrikstad, Norway

MC_0020

Contents

Products

SE150/215T-24V - SE150 Tunnel thruster, 24V

SE150/215T-24 - SE150 Tunnel thruster, 24V

SE130/250T-24V - SE130 Tunnel thruster, 24V

SE130/250T-12V - SE130 Tunnel thruster, 12V

SE120/215T-24 - SE120 Tunnel thruster, 24V

SE120/215T-24V - SE120 Tunnel thruster, 24V

SE100/185T-24V - SE100 Tunnel thruster, 24V

SE100/185T-12V - SE100 Tunnel thruster, 12V

SE80/185T-24V - SE80 Tunnel thruster, 24V

SE80/185T-12V - SE80 Tunnel thruster, 12V

MC_0031

For electric motor thrusters

• The thruster must NOT be installed in compartments that require ignition proof electric equipment. If necessary, make a separate compartment.

(NB: Ignition Protected systems are tested to be installed in areas with possible explosive gases in accordance with ISO 8846)

• When installing the thruster electric motor in small compartments, ensure the compartment is well ventilated to allow for cooling of the electro

motor.

• If the height of the room you are installing the thruster is limited, the thruster can be installed horizontally or at any angle in-between.

- If the electro motor is positioned more than 30 degrees off vertical, it must be supported separately.

- Beware of keeping installation within advised measurements. No part of the propeller or gear house must be outside the tunnel.

• The electric motor, components and cables must be mounted so they remain dry at all times.

• Do not nish the inside of the tunnel with a layer of gel-coat/ topcoat or similar. There is only room for a thin coat of primer and two layers of anti-

fouling between the tunnel and the props.

• Don’t install the electric motor close to easily flammable objects or equipment as it will reach over 100°C before the temperature switch is

activated.

• Do not store items close to the thruster motor. Any loose items near the thruster motor is a potential re hazard and can cause undesired short-

circuiting.

• Do not lift it by internal cable connections, main terminals.

• The thruster power supply circuit must include the recommended sized fuse and a battery isolation switch.

• The electric/ hydraulic motor must be handled with care. Do not rest the thruster motor on its drive shaft as its weight can damage the shaft.

MC_0425

For thruster systems

• Do not install the thruster in a position where you need to cut a stiffener/ stringer/ support that may jeopardise the hull integrity without checking

with the boat builder this can be done safely.

• We advise painting the gear house and propellers with anti-fouling. (NB: Do not paint the anodes, sealing, rubber fi ttings or propeller shafts)

• There is only room for a thin coat of primer and two layers of anti-fouling between the tunnel and the props.

• Never run the thruster out of water.

MC_0501

Lithium Batteries for on/off thrusters models SE and SE-IP

• High capacity lithium batteries are capable of supplying a higher operating voltage to the thruster than SE and SE-IP thrusters are rated for.

Running thrusters at higher than rated voltage will reduce operating time, increase wear and damage the thruster. Operating the thruster

outside speci ed ratings will void warranty.

Installation Manual

Responsibility of the Installer .................................................................................................................................................................... 3

General Installation Considerations and Precautions Guidelines ............................................................................................................ 3

Product Measurements ............................................................................................................................................................................ 4

Product Specications................................................................................................................................................................................ 5

Positioning of the tunnel / thruster ............................................................................................................................................................ 6

Tunnel Length ............................................................................................................................................................................................. 7

Tunnel Installation in Sailboats.................................................................................................................................................................. 8

Water Deflection......................................................................................................................................................................................... 9

Tunnel Ends ............................................................................................................................................................................................. 10

Tunnel Installation............................................................................................................................................................................ 11 - 12

Stern Tunnel Installation......................................................................................................................................................................... 13

Gear Leg & Motor Bracket Installation.................................................................................................................................................... 14

Propeller Installation............................................................................................................................................................................... 15

Motor Installation .................................................................................................................................................................................... 16

Electrical Installation .............................................................................................................................................................................. 17

Product Lug Connection Conguration .................................................................................................................................................. 17

Electrical Reference Guide....................................................................................................................................................................... 18

Wiring Diagram 12V Thruster ................................................................................................................................................................. 19

Wiring Diagram 24V Thruster................................................................................................................................................................... 20

Control Panel Installation ....................................................................................................................................................................... 21

Pre-delivery Checklist ........................................................................................................................................................... 22

Service and Support ............................................................................................................................................................... 23

Product Spare Parts and Additional Resources ....................................................................................................................... 23

Warranty Statement ............................................................................................................................................................... 23