SLG SD55 User manual

1

Manual Balanced Crane

Model: SD55

Instruction Manual

Note: Operator must read this instruction manual before using the product and follow

the requirements during operating.

VERSION ONE 11/2015

2

Contents

1. Product Main Components……………………….. 3

2. Specification ……………………………………….. 3

3. Assemble and adjustment ……………………… 4

4. Safety Operation ………………………………… ..5

5. Warning …………………………………………. .. 6

6. Operating Instructions………………………………6

7. Daily Inspections ……………………………………..6

3

PLEASE READ THIS INSTRUCTION MANUAL COMPLETELY BEFORE USING.

THOROUGHLY UNDERSTAND AND FOLLOW ALL SAFE OPERATION &

WARNING INSTRUCTIONS. IF THIS MANUAL IS LOST, PLEASE CONTACT YOUR

LOCAL SUPPLIER FOR ANEW COPY. IF THE WARNING/CAUTION STICKERS ON

THE PRODUCT IS LOST, PLEASE CONTACT YOUR LOCAL SUPPLIER FOR NEW

ONES.

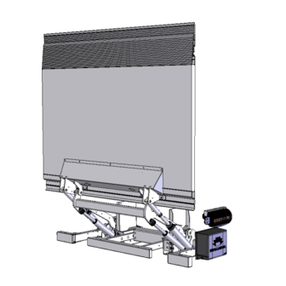

1. Product Main Components

1

2

3

4

5

10

6

9 8 7

Drawing 1

1.extension arms 2.hooks.3.cylinders 4.stands 5.front wheels 6.base chassis 7.brake

8.countbalance case 9.steering wheels 10.handle

2、Specification

Drawing 2

MODEL

DSD55

RATED

CAPACITY

P1

550kg

P2

400kg

P3

300kg

P4

220kg

P5

150kg

Motor Power/

Voltage (KW/V)

0.8Kw/12V

Battery Capacity

(Ah)

60Ah

Operating

System

S3=3.0%

NET WEIGHT

(KG)

530kg

P1 P2 P3 P4 P5

4

3、Assembly and Adjustment

3.1 Remove the package carefully, avoiding severe vibration and significant tilt.

3.2 Turn the stands To the upright position , insert the pin to fix both parts, then lock them with

the spring pin(as drawing 3-1);

3.3 Carry the counterbalance case on the base chassis, fix them with 4PCSBolts((in the spare

parts bag)(as drawing 3-2).

3.4 Connect the handles and the steering wheels with 2 PCS bolts .Tighten the bolts at both

sides firmly.(as drawing 3-3).

3.5 Check if all fasteners of the parts are tightened firmly.

Products could be used only if finishing all above mentioned inspections without abnormal.

1 2 3 4 1 2 3

Drawing 3-1 drawing 3-2

1

2

3

4

drawing 3-3

1、stands 2、pin、3. Spring pin

4、base chassis

1、.weight box

2、base chassis 3、bolt

1、handle2、bolt 3、supporting seat

4、steering wheels

5

4、Safe Operation

4.1 The Operator Requirements

The lifter must be operated by professionals who can demonstrate the product lifting operation to

users and can instruct vividly how to operate.

Operator must be trained and fully understand the operation of product lifting and self-propelling,

as well as all safety requirements.

4.2 Forbidden Use by Unauthorized Person

During operations, the operator has responsibility to prevent unauthorized person using the

product. The product is strictly forbidden to carry or lift people.

4.3 Failure and Fault

In case of any failure or fault (e.g. wheel worn-out or brake fault and etc.), please stop using the

product immediately.

4.4 Repair

Without professional training and specific authorization, the operator is forbidden to repair or

replace any spare parts of the product. Any change of installation position of switches and

safety devices is strictly forbidden.

All spare parts from original manufacturer are strictly inspected and completely qualified. They

are safe and reliable for product operation. The replaced parts including oil must be disposed

according to local related environmental protection regulations.

4.5 The product will bring potential dangerous to people or the area during

lifting and lowering, unauthorized person should be away from the danger area.

4.6 Working in Hazardous Environments

When the product be used in high risk area, it should be added protective device.

4.7 Safety Warning Signs

The safety warning signs and precautions mentioned in the manual are very important.

4.8 Keep Distance

During operating the product, unauthorized person should keep an appropriate distance away

from it.

4.9 Ground Checking

Carefully check whether the ground is flat and solid enough for moving before using the

product.

4.10 Loads Requirement

In case the load has to be removed, lower the load and jib extension to the lowest possible

point before moving. Caution:moving should be slowly and steadily

4.11 Do not load the crane beyond the rated capacity for each specified lift arm position as indicated in the

label.

4.12 Before operating the crane ensure the lift arm is securely positioned by the pin.The load hook

is provided with a latching mechanism. Ensure it works properly.

4.13 To lift the load in a well balanced and stable way make sure the center of gravity remains

always inside the crane base

4.14 Screw on the brake(NO. 7 ),before operating.

4.15 Do not allow the load to swing or drop violently when moving.

6

5.Warning

5.1DO NOT overload;

5.2 When moving with load, the hook should be at the lowest position.

5.3 U-turning or lifting loads is prohibited on a slope.

5.4 DO NOT load people;

5.5 DO NOT operation under the extension arm.

5.6 STOP operation immediately once the cargo is unstable.

5.7 STOP operation when the hydraulic oil temperature is too high.

5.8 DO NOT adjust the safety valves in the power pack.

5.9 Reducing the balancing weight is prohibited.

6. Use and operation

6.1 Before using the crane, it is necessary to purge air from the valve system of the hydraulic unit.

6.2 This can be done by releasing the valve, then pumping the hydraulic jack several times.

6.3 Closing the valve, the crane is now ready to be used, pump the hydraulic unit to raise the load,.

6.4 Lowering the load, release the valve. Counterclockwise slowly, the load can be lowered

smoothly. Quick-releasing is strictly prohibited.

7. Daily Inspections

7.1 Lubricate all moving parts at regular intervals.

7.2 Always keep the crane clean and protected from aggressive conditions.

7.3 Check the oil level of the hydraulic unit with the piston fully retracted. Top up if necessary.

IMPORTANT : An excess of oil will render the crane inoperative.

7.4 Use only hydraulic oil, HL or HM types, with an ISO grade of cinematic viscosity of 30 cst at 40

ºC or an Engler viscosity of 3 at 50ºC.

VERY IMPORTANT : never use brake fluid.

7.5 When ordering spare parts, please state the series number and the capacity of the crane.

Table of contents

Popular Lifting System manuals by other brands

Dhollandia

Dhollandia DH-L Series Operation manual

Challenger Lifts

Challenger Lifts EnviroLift EV1020 Installation, operation & maintenance manual

Bishamon

Bishamon NSP3500N Operation and service manual

Blue Giant

Blue Giant EPT-55 Operator's manual

WITTUR

WITTUR WSG-SF Series operating instructions

JLG

JLG EcoLift50 Service and maintenance manual