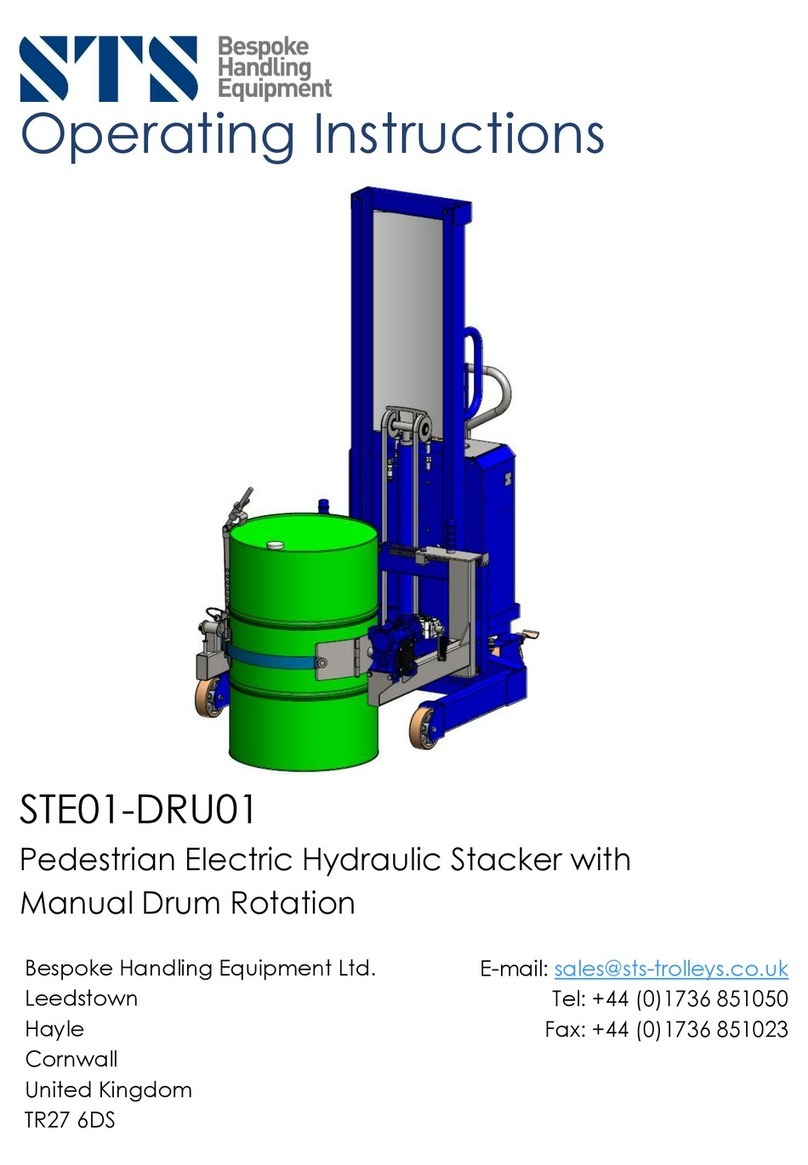

STS DTP05 User manual

Operating Instructions

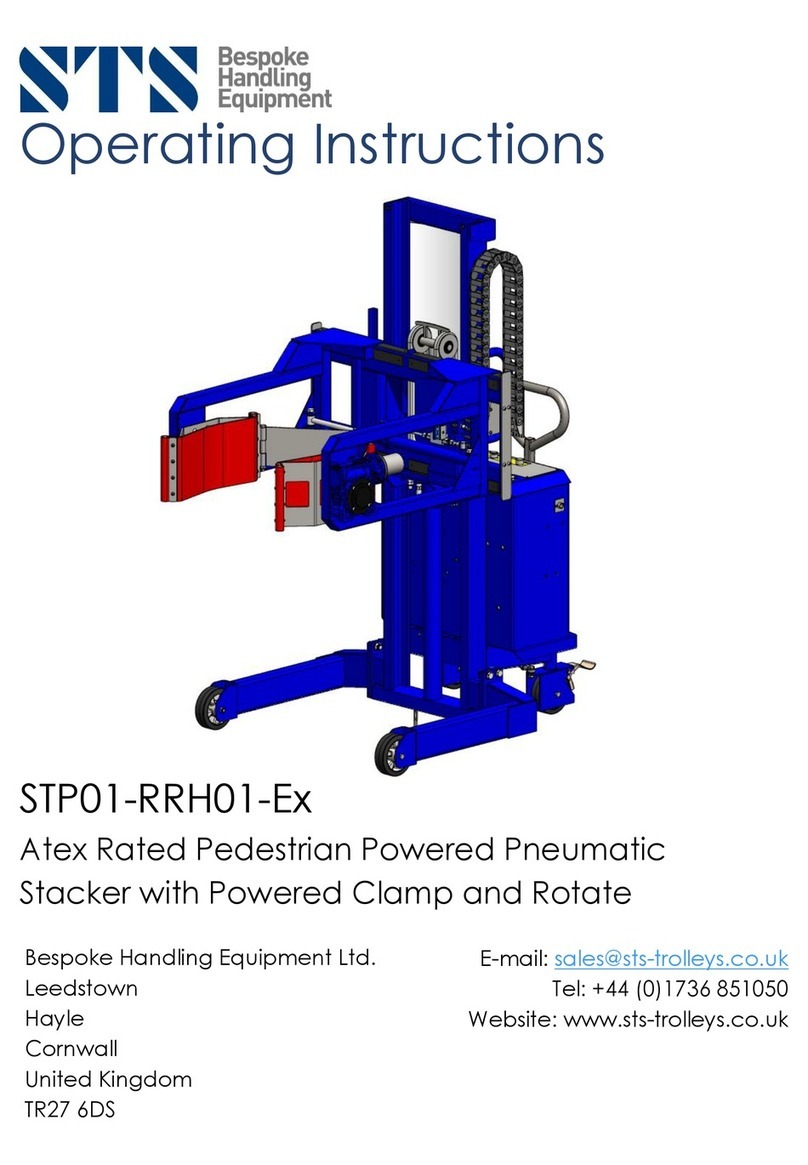

DTP05 (Ex)

Corner Drum Depalletiser

Operation and maintenance manual

Product code: DTP05 (Ex)

Product description: Corner Drum Depalletiser

BESPOKE HANDLING EQUIPMENT LTD

Technical Support Line: +44 (0)1736 851050

Key safety requirements

1. Do not use the unit unless you have read and fully understood the

operation and maintenance manual.

2. This equipment is designed for use on level ground.

3. Only handle drums that are in a good condition. Should the lip or any

other part of the drum be damaged, these should not be handled.

4. When not in use the equipment should be parked in a safe location; if the

unit has brakes these should be applied.

5. This product is to be used by one operator at a time and they must be

behind the unit at all times.

6. For equipment which lifts drums, do not transport the drum at

unnecessary heights; the drum should be as close to the floor as possible

at all times.

7. Do not allow other personnel to be in front of the unit when in use.

8. The safe working load (SWL)/rated capacity should not be exceeded in

any circumstances.

9. The equipment should be inspected at regular intervals, decided by the

operator’s company, for signs of damage or defects.

10.The unit must be inspected at least annually or after any unusual event by

a suitably competent person.

11.Ensure damaged or missing safety notices are replaced; these are

available from STS.

12.The manual forces relating to the use of this equipment are relatively low;

any doubts in this should be reported to STS.

13.If any operator is in any doubt of the correct suitability of the equipment

or has any problem understanding the instruction manual then they

should contact STS for technical support.

14.Installation of third-party equipment which affects the performance of the

equipment requires the written permission of the manufacturer.

15.Upon delivery equipment should be inspected for transit damage. Any

damage should be reported to STS and the equipment should be

quarantined and not used.

16.If the unit supplied is the ATEX model, ensure earthing chains are securely

fitted and are in contact with the ground at all times; also wheels should

be kept clean and free from debris.

17.The manufacturer shall not be held liable in case of faults or accidents due

to negligence, incapacity, installation by unqualified personnel or improper

use.

Operation and maintenance manual

Product code: DTP05 (Ex)

Product description: Corner Drum Depalletiser

BESPOKE HANDLING EQUIPMENT LTD

Technical Support Line: +44 (0)1736 851050

Initial setup and connecting to drums:

•Ensure the rack is lowered fully so that all the vertical lift stroke is available;

this is done by turning the lowering lever anticlockwise.

•There are five rungs at which you can secure the drum catch, removing the

lowest R-pin allows you to remove the catch from the rack and relocate it so

that the catch is positioned below the drum lip you wish to connect to.

•Manoeuvre the depalletiser using the handle being sure to keep good

posture; operators should move gently while manoeuvring, planning ahead

in good time.

•Line up the lifter with the centreline of the drum.

•Lift the rack using the pump handle so the catch rises above the top lip of

the drum.

•Push the unit forward so the top catch engages the drum.

•Lower the rack slowly using the lowering lever ensuring the top hook

engages over the top lip of the drum and that the bottom toggle secures

beneath the drum lip.

Removing drums from pallet:

•Pump the hydraulic handle to raise the drum to the desired height.

•Remove drum from the pallet by gently pulling the depalletiser away.

•When clear of the pallet and transporting the drum, keep the drum as low to

the ground as is practical.

•To place the drum down, simply turn the control lever anticlockwise locates

on the top of the lifter. The rate at which the drum lowers is controlled by

the amount that the lever is pulled.

•Once the drum is placed on the floor (or another pallet), continue to lower

the rack until the catch goes slack, the operator can then reach forward and

manually remove the hook from the drum.

•If the catch is lowered too much it is not possible to unhook the catch, in

this instance raise the rack slightly by pumping the handle, the catch will go

slack ready for unhooking.

Operation and maintenance manual

Product code: DTP05 (Ex)

Product description: Corner Drum Depalletiser

BESPOKE HANDLING EQUIPMENT LTD

Technical Support Line: +44 (0)1736 851050

Removing drums from pallets:

•Pump the hydraulic handle to raise the drum to the desired height.

•Remove drum from the pallet by gently pulling the depalletiser away.

•When clear of the pallet and transporting the drum, keep the drum as low to

the ground as is practical.

•To place the drum down, simply turn the control lever anticlockwise locates

on the top of the lifter. The rate at which the drum lowers is controlled by the

amount that the lever is pulled.

•Once the drum is placed on the floor (or another pallet), continue to lower

the rack until the catch goes slack, the operator can then reach forward and

manually remove the hook from the drum.

•If the catch is lowered too much it is not possible to unhook the catch, in this

instance raise the rack slightly by pumping the handle, the catch will go slack

ready for unhooking.

Operation and maintenance manual

Product code: DTP05 (Ex)

Product description: Corner Drum Depalletiser

BESPOKE HANDLING EQUIPMENT LTD

Technical Support Line: +44 (0)1736 851050

Universal drum catch variations

WARNING –Due to variations in the manufacture of drums it is important that

the correct hook position is selected. Failure to do so could result in the catch

disconnecting from the drum.

The universal drum catch has been designed so that a various number of

positions can be used to fit different sized drums. By removing the top R-clip,

the top hook can be turned over so that the sticker is upside down. This gives

the top hook a further 5mm of reach. Changing the hole that the top catch is

located in increases the reach by a further 10mm by each hole placement. The

top hook must always be placed in the shortest possible position.

The following examples are for guidance only:

Effect of changing top hook position and orientation

Catch (Original)

Catch (Flipped)

Back hole (4th)

0mm (200 litre steel

setting)

+5mm

3rd hole

+10mm

+15mm

2nd hole

+20mm

+25mm

Front hole (1st)

+30mm

+35mm

Most Drum Types

The top hook should

be mounted the

correct way up and

in the bottom hole.

Steel Open-Top

The top hook should

be mounted with

the labels inverted

and in the bottom

hole.

MAUSER Open-Top

The top hook should

be mounted the

correct way up and in

the third hole.

Thrust Pad

This pad is located

at the bottom of the

stainless rack and is

designed for varying

shaped drums.

Folding out the pad

keeps the drum

more vertical.

Operation and maintenance manual

Product code: DTP05 (Ex)

Product description: Corner Drum Depalletiser

BESPOKE HANDLING EQUIPMENT LTD

Technical Support Line: +44 (0)1736 851050

Maintenance

Any maintenance needs to be carried out by a competent individual. The unit is

designed to be low maintenance.

Schedule

Weekly

3

Monthly

Annually

Brakes and Toggle

Test brakes and adjust if required

●

●

●

Check orange side-shift toggle grips cross beam

(DTP04 only)

●

●

Chassis and Superstructure

Inspect labels are legible and complete

●

●

●

Inspect all components for wear and damage

●

●

●

Inspect chassis for damage and visually inspect all

welds for cracks

●

●

If the unit is ATEX rated ensure that the earthing

chains are in contact with the floor and that the

wheels are clean, free from debris

●

●

●

Hydraulic Operations

Test hydraulic lift and lower function for correct

operation

●

●

●

Check hydraulic oil level via sight glass, top up if

below half sight glass

●

●

Inspect hydraulic seals for damage and leaks

●

●

Replace hydraulic oil (Shell Tellus 22 or equivalent)

●

Agreed Performance Level

Carry out a load test with rated load, or if necessary

with customer specified load

●

Cleaning

Steam jets, degreasing agents and high-pressure

cleaners should be employed with great caution to

avoid degreasing components

●

●

Hydraulics troubleshooting

Unit does not lift

Unit overloaded

Unit does not lift to full stroke

Pump is short of oil. Ensure rod is at bottom

of stroke and top-up/refill with hydraulic oil.

Shell Tellus 22 or equivalent, half sight glass.

Oil leaking from top of ram around

chromed rod

Replace ram seals

Oil leaking from tank filler point

Filler bung damaged or unit over filled with

oil

Operation and maintenance manual

Product code: DTP05 (Ex)

Product description: Corner Drum Depalletiser

BESPOKE HANDLING EQUIPMENT LTD

Technical Support Line: +44 (0)1736 851050

Decommissioning and disposal

Final de-commissioning or disposal of the unit must be performed in accordance

with the regulations of the country of use, meeting the countries regulations for

disposal of hazardous materials. In particular, regulations governing the disposal

of batteries, fuels and electronic and electrical systems must be observed.

Maintenance

Any maintenance needs to be carried out by a competent individual.

The unit is designed to be maintenance free.

•Before use inspect unit thoroughly for signs of damage.

•For cleaning it is recommended that if any degreasing agents or high

pressure cleaners are to be used then they should be used with great caution

as to avoid the degreasing of any mechanical components.

If you do not understand any part of this manual and/or need assistance, please

contact us: Technical Support Line: +44 (0)1736 851050

Bespoke Handling Equipment Ltd.

Leedstown

Hayle

Penzance

TR27 6DS

Other manuals for DTP05

1

This manual suits for next models

1

Table of contents

Other STS Lifting System manuals