Slycma ARIANE 3.1 Quick start guide

Ref : 26702 1 07/01/15

LINEAR OPERATOR CARD

ARIANE 3.1

180W Asynchronous – Brushless Motors

COMMISSIONING MANUAL

Parc d’Activités Lyon Sud Ouest – 4 route du Dôme – F - 69630 CHAPONOST

Tel : (0033) 04 78 86 81 00 / Fax : (0033) 04 78 86 81 08

Ref : 26702 2 07/01/15

!! DISCLAIMERS !!

Your ARIANE 3.1 operator card was pre-adjusted in the factory.

After wiring according to the electrical schematic diagram attached to the

manual’s backpage, switch on the card. Then simply proceed with:

- its configuration with respect to the controller (direction of the limit

switches signals, shock, master or slave mode, car cell management by

the card, etc.),

- the learning of the travel (CMD1 mode) with an associated landing door

- the adjustment of the test door operating parameters (speeds,

slowdowns, torques, closing and opening sensitivities) with the commands

CMD3, 5 and 7,

The card has many parameters to allow it to adapt to all renovation

solutions, but it is not necessary to intervene on all these values. The

factory parameter setting allows an immediate correct operation of the

door.

A few particularities :

-Driving the Asynchronous or Brushless motor

The ARIANE 3.1 card allows driving both of these types of motors with a 230V voltage

and a 180W maximum power rating.

-Taking into account the Inspection mode

Inspection signal input to be mandatorily wired to prohibit automatic door movements

during technical services.

-Managing glazed doors (VITR and DURF parameters)

This option controls finger jammings when the door opens.

Standard EN81 – 1/2 articles 7.2.36 and 8.6.7.5

-Master 2 mode

The door opens when the cell beam is passed through and closes when the cell beam

is no longer hidden.

-Necessity of connecting the Close limit switch signal

As long as the close limit switch signal is not given, the door can re-open in case of a

skate closing problem. Therefore, the controller must wait for this signal to move the

car.

.

-Driving the auxiliary functions

Two programmable relays allow triggering a buzzer, an electro-cam, an electromagnetic

suction disc or an intermediate end stop.

Ref : 26702 3 07/01/15

ARIANE 3 OPERATING GUIDE

When the card is switched on, it executes the controller orders.

To intervene on ARIANE, you may choose from among 3 display modes, a

parameter setting mode and a manual commands mode :

Scroll the menu by successively pressing the key and make your

choice by pressing the key (If you do not validate within 3 seconds,

the default value "Fr00" is displayed).

Display modes:

- "Fr00" →display of the motor output frequency (Hz)

- "0000" →display of the position (encoder points)

- " _ _ " →display of the card Input / Output state

Parameter setting mode : - PARA →Changing the parameters

In the PARA mode, you can access all the door configuration

parameters and operating values.

Scroll the configuration parameters : successively press

Scroll the operating values : successively press

To read the value, press

To change the value, press or

To save the new value, press

To quit the mode, simultaneously press and

.

Manual commands mode : - CMD Commands CMD1 to CMD8

In the CMD mode (CMD for command), you can operate the door

independently from the controller orders

Scroll the commands mode : successively press or

To select a command, press (the display flashes)

To quit the mode, press

Ref : 26702 4 07/01/15

CONTENTS

PART 1 : Connection of the ARIANE 3.1 card

Mains power connection ........................................................... Page 5

Asynchronous motor connection ............................................... Page 5

Brushless motor connection ..................................................... Page 5

Encoder connection ................................................................. Page 6

Safety chain connection ........................................................... Page 6

Controller orders connection...................................................... Page 6

Car input cell connection .......................................................... Page 7

Controller signals connection .................................................... Page 7

Multifunction relay connection .................................................. Page 8

Wire function terminals list ...................................................... Page 8

PART 2 : Configuration according to the controller

Setting of mandatory parameters .............................................. Page 9

Details about the configuration parameters ...............................Page 10

PART 3 : Commissioning the ARIANE 3.1 card

Mechanical efficiency checking .................................................Page 13

Travel learning ......................................................................Page 13

PART 4 : Adjustment of the door operation

Operating diagrams ...............................................................Page 14

Changing a parameter ............................................................Page 14

Operating values ................................................................... Page 15

Value range table ..................................................................Page 16

PART 5 : Saving the parameters

Saving the parameters ...........................................................Page 17

Recording your own parameters ...............................................Page 18

PART 6 : Details about the command modes (CMD)

The command modes (CMD) ...................................................Page 19

Special case of a double opening travel .....................................Page 20

PART 7 : Details about the ARIANE 3.1 operations

Basic operation .................................................................... Page 21

Reset operation .....................................................................Page 22

Inspection operation ..............................................................Page 22

Parameterizable relays operation ..............................................Page 23

Fail soft operation ..................................................................Page 24

Operation with Car door locking device .....................................Page 24

Energy save operation ............................................................Page 24

PART 8 : Maintenance operations

Card Inputs/Outputs display ....................................................Page 25

Operating faults display ..........................................................Page 26

Details about operating faults ..................................................Page 27

Encoder position display .........................................................Page 28

Numbers of cycles display .......................................................Page 28

Ref : 26702 5 07/01/15

Part 1 : The Ariane 3 card connections

The card efficiency is first subjected to a mechanical

setting in conformity with the door.

Necessary connectors are supplied in a bag.

MAINS POWER CONNECTION – 3x7.62 – 230V 50Hz – 2A connector

The 230 V power supply must not come

from the primary of a 110/230/400V

transformer because a damaging

overvoltage can occur if the transformer

is not loaded.

The connector must not be handled with power switched on

If the voltage between neutral and ground is very different from 0 volts,

power the card via an insulating transformer (example : case of connection

in TI state).

ASYNCHRONOUS MOTOR CONNECTION : 4x minifit (made in

factory)

Make sure that the motor cable shielding

is properly connected to the Ariane card

package.

Make sure that the motor’s ground is

connected to the connector (EMC

requirement).

BRUSHLESS MOTOR CONNECTION : 4x motor minifit and 6x hall

effect sensors microfit (made in factory)

Make sure that the motor cable shielding is

properly connected to the package and that

the 3 phase wires are properly installed on

the minifit connector.

Make sure that the 6x hall effect sensors microfit

connector of the Brushless motor is properly

connected to the right side of the ARIANE body.

Ref : 26702 6 07/01/15

ENCODER CONNECTION – 4x microfit connector (made in factory)

For an Asynchronous motor

Connection of the counting cells.

Make sure that the encoder’s 6 wires are

properly connected, that the crimpings are in

good condition, and that the wire is

immobilized

For a Brushless motor

Connection of the encoder integrated with the

motor

Make sure that the 4 wires are crimped

correctly and that the cable is immobilized

SAFETY CHAIN CONNECTION – 2 x 5.08 connector

Connect the safety chain to the 2 x 5.08 connector. Check

the factory wiring of the door contacts on the 4 x 5.08

connector is conformity with the electrical drawing regarding

there is one or two contacts. (One in lateral opening, 2 in

central opening)

There is no interaction between the card’s operation and the

safety contacts.

CONTROLLER COMMANDS CONNECTION – 6 x 5.08 connector

All the orders must come from dry contacts which switch

the 0V common supplied by the card.

It is not necessary to apply voltages to these inputs.

Warning : When an operator driven by contactors is

replaced, do not use the old contactors flakes as

command contacts, but use relays which switch low

currents (20 mA at 12 VDC).

Ref : 26702 7 07/01/15

The required standards are the open order, the close order and the inspection

information signal.

If only the close order is available, the open order must

be bypassed. The close and nudging orders have priority

over the open order.

The inspection connection is mandatory

to inhibit any untimely door movement

during a technical service. (Standard

EN81 – 1/2 article 14.2.1.3 a)

CAR CELL CONNECTION – 3 x 5.08 connector

If the car cell is controlled by the card, a NC (normally closed) dry

contact must be connected between the card’s OV common and

the Cell information signal input.

This input may also be used for a ’ReOpening pushbutton in the

carequipped with a NC contact. It may be connected in series

with the cabin cell’s NC signal input.

If necessary for the cell, a +12V power supply is provided.

The use of this input is conditioned by the CELLand MODE

parameters.

CONTROLLER SIGNALS CONNECTION – 6 x 5.08 connector

Connect the Limit switch and Shock signal returns to

the controller.

These signals are dry contact relay outputs which

require minimum switching currents of 10mA.

The direction of the NO (normally open) or NC

(normally closed) limit switches is selected with the

FDC(Limit switch) parameter.

The shock signal also restores the car cell signal if

the car cell is connected to the card.

The direction of the NO or NC Shock signal is

selected by the CHOC(SHOCK) parameter.

Warning : the closing limit switch connection is mandatory so that

the car starts moving only when the close cycle is totally complete

(skate closed, for example) and not as soon as the door contact

closes.

Ref : 26702 8 07/01/15

MULTIFUNCTION RELAY CONNECTION – 4 x 5.08 connector

Two programmable commands may be

connected to the RMF1 and RMF2 outputs, which

are two dry contact relays.

The driven device type is selected with the

RMF1and RMF2parameters, namely :

- A buzzer, which will be activated during the

learning, reset, nudging and fail soft operation.

- An electromagnetic suction disc, which will keep

the door panels closed

- An electro-cam, which will unlock swinging

doors or articulated sliding doors

- An electromagnetic intermediate open end stop

External power supplies must be provided for the

devices

The maximum interrupting capacity of the relays is

6A for 250 VDC and 15A for 400 VAC

WIRE FUNCTION ASSIGNMENTS LIST

Ref : 26702 9 07/01/15

Terminal n° Assignment

Ph, N, T Mains power supply

L1, L2, L3, T Motor connection

5, 6 Safety chain connection

7, 8, 9, 10 Door contacts connection

14, 15 Shock signal

16, 17 Closing limit switch stop signal

18, 19 Opening limit switch stop signal

25 + 12 VDC

26, 27 NC (normally closed) Cell input

28 Inspection NO (normally opened) command input

29 Nudging NO Command input (forced closing)

30 Closing NO command input

31 Intermediate Opening NO command input

32 Complete opening NO command input

33 Common 0V of the commands

PART 2 : Configuration according to the controller

Scroll the menus by successively pressing ,

and select PARAby pressing .

Scroll the parameters with

To read the value, press

To change the value, press

To save the new value, press

SETTING OF THE MANDATORY PARAMETERS

Display order of the parameters :

→MSTF Hold under voltage closing OUI(YES) /NON(NO)/DEPL Set in Factory

→MSTO Hold under voltage opening OUI (YES)/NON(NO) Set in Factory

→MODE Operating mode : ESCL/MAI1/MAI2

→CHOC Shock contact direction / Controller : NO or NF

→FdC Limit switch contact direction / Controller : NO or NF

→SMOT Motor rotating direction DIR/INV Set in Factory

Ref : 26702 10 07/01/15

→VITR Glazing option OUI/NON Set in Factory

→CELL Cell management : NON/OUI/LIMI

→TYPE Door type: Mobile (MOBI), Swinging (BATT), Fixed (FI) Set in Factory

MOBI or FI are the type of skate on automatic doors

→rMF2 MULTIFUNCTION RELAY 2 : buZZ/butE/Vent/CAME

→rMF1 MULTIFUNCTION RELAY 1 : buZZ/butE/Vent/CAME

→PINI Factory parameters INI, SAVE, IN01, ..., IN30 Set in Factory

→CYCL No. of cycles performed x 1000 Information

→ERR Last 10 recorded errors, Errx/EFFA Information

→MOTR ASYN/BRUS motor type selection Set in Factory

→BAUD CAN parameter Not used

→PRTE CAN parameter Not used

END of CONFIGURATION

To exit the parametersmenu, simultaneously press and .

If the card has never been started, it displays APPr

Ref : 26702 11 07/01/15

CONFIGURATION PARAMETERS DETAILS

MSTF Hold closed under voltage OUI, NON or DEPL (YES,

NO, or DISPL)

DEPL = Moving : The motor is held under voltage if the

closing input is activated. Generally, non(no) for

automatic doors and oui(yes) for swinging doors.

If there is a mechanical holding hook to keep the

door in closed position, select NON (NO).

MSTO Hold opened under voltage OUI, NON (YES, NO).

Generally, oui(yes) for automatic doors and non

(no) for swinging doors.

In case a mechanical retaining hook is present to

keep the door in the open position, select NON (NO).

MODE Behaviour choice in case door blocking in closing

ESCL : Slave mode. Door not opened, but the Obstacle

relay activated. The controller time out reversalmust

be set to 0.

MA-1: Master mode 1. Door completely opened with

time out in case blocking

or cell detection with the Obstacle relay activated.

MA-2: Master mode 2. Door opens as long as the cell

signal lasts in case of cell detection. Otherwise, door

immediately closed.

The Obstacle relay is activated in case of a shock, or in

case of complete reopening driven by the cell.

CHOC The OBSTACLE relay operating direction : NO, NF

(Normally Open, Normally Closed)

FDC Operating direction of the relays FdC-O (OLS)/FdC-F

(CLS):

NO, NF (Normally Open, Normally Closed)

SMOT Motor direction software reversal : DIR or INV

VITR Glazed door option : OUI, NON (YES, NO) allows

preventing finger jamming as door opens.

Ref : 26702 12 07/01/15

CELL Cell input management option : OUI, NON, LIMI

(YES, NO, LIMI)

The cell must be a normally closed (NF) and must

be connected to ARIANE

The cell is automatically viewed during learning and filled

in. The CELL parameter allows eliminating it, if

necessary.

With the LIMI option : The cell is inhibited as the door is

reset after a mains power failure (230 VAC).

TYPE Door type selection :

BATT : Operator installed in front of a swinging door

FI : Operator with fixed blade

MOBI : Operator with mobile skate

Warning ! In case of a door type change, a new

learning procedure must be performed (CMD1).

RMF2 Choice of multifunction output relays use

BUZZ : a buzzer sounds when the door moves

RMF1 Learning, reset, nudging movements or fail stop.

BUTE : intermediate end stop control when two open

travel ranges are to be used.

CAME : driving of an electro-cam for swinging door type

BATTor MOBI, or for shutter door type FI.

VENT : an electromagnetic suction disc is driven to

keep the door locked if the close order is maintained.

Pini Allows loading the pre-programmed or saved adjustment

values after the Asynchronous or Brushless motor

type (MOTR) is selected.

INIT allows restoring the last saved parameter setting.

SAVE allows saving the current adjustment.

In01, In02, In03 etc. … allows loading the factory

parameter range tables corresponding to the various

door types.

Ref : 26702 13 07/01/15

List of the PINI value tables :

IN 01 IN 02 IN 03 IN 04 IN 05 IN 06

IN 07 IN 08 IN 09 IN 10 IN 11 IN 12

IN 13 IN 14 IN 15 IN 16 IN 17 IN 18

SHEET METAL GLAZED SHEET METAL

2VOT / 3VOT

CO … 850 CO 900 … 1200 Co and CH very large

SHEET METAL GLAZED SHEET METAL GLAZED SHEET METAL GLAZED

2VOC

CO … 850 CO 900 … 1200 Co and CH very large

GLAZED

4VOC - 6VOC

CO … 850 CO 900 … 1200 Co and CH very large

SHEET METAL GLAZED SHEET METAL GLAZED SHEET METAL

SHEET METAL GLAZED

GLAZED

To confirm the selected parameters, quit parameter

setting by simultaneously pressing and when all

the parameter settings are made.

CYCL Informative display : Indicates the number of cycles

in thousands performed by the card since its

commissioning.

This number cannot be reset to 0.

Err Informative display : Indicates the last 10 errors

detected by the card.

Motr Choice of the type of motor to be driven :

asynchronous ASYnor brushless bruS

bAud PrtE CAN parameters not used currently

Ref : 26702 14 07/01/15

PART 3 : Starting the ARIANE 3 card

When the parameter setting of the door configuration with respect to

the controller is confirmed, the ARIANE 3 card can enter in operation.

Move the car to a floor in order to have a landing door

associated with the car door.

MECHANICAL EFFICIENCY CHECK

Use the CMD3 function to run the motor at a slow opening and

closing speed by proceeding as follows :

Scroll the menus by successively pressing and select

CMD

by

pressing .

Scroll the CMD functions with up to CMD3

To start the CMD3 function, press

To operate the motor in opening, press

To operate the motor in closing, press

To exit from the CMD3 command, press

Make sure that the motor rotates in the right direction. If not, return

to the parameters and change the SMotparameter.

Make sure that the door operates correctly mechanically from end

stop to end stop and that the skate correctly unlocks the landing door.

OPERATOR TRAVEL LEARNING

Start the travel learning with the CMD1 command.

Scroll the menus by successively pressing and select

CMD

by

pressing .

Scroll the CMD functions with up to CMD1

To start the CMD1 function, press

The door opens up to the end stop, waits a few seconds to confirm its

0 position, and then closes until the skate is completely closed and

waits a few seconds to confirm the travel value.

When the learning is finished, the card automatically exits from the

CMD1 command and waits for controller orders.

THE DOOR IS READY TO OPERATE

Ref : 26702 15 07/01/15

PART 4 : Adjustment of the door operation

To make the door’s operation even more accurate, you can also

trigger on speeds (F), acceleration and deceleration ramps (R),

torques (U) and the travels (C).

OPERATING DIAGRAMS

OPERATING PARAMETERS WITH MOBILE SKATE (TYPE = MOB1)

RA-O

RD-O RD-F

RA-O RD-F

DURO DURF

OPERATING PARAMETERS WITH FIXED SKATE (TYPE = FI)

RA-O

RD-O RD-F

RA-O

DURO DURF

OPERATING PARAMETERS IN FRONT OF SWINGING DOOR (TYPE = BATT)

RD-O RD-F

DURO DURF

U2-O U2-F

FP-O FP-F

<------- CS-F ------->

FS-O RA-F FS-F

U1-S U-FR FF-O U-FR FF-F U1-S

U1-O U1-F

<----- CS-O -----> <-- CL-O --> < CL-F

>

Skate travel Panels travel (Clea opening) Panels travel (Clea opening) Skate travel

FP-O FP-F

U2-O U2-F

FS-O RA-F

U-FR FF-F

U1-O U1-F

<----- CS-O------

>

<-- CL-O -->

<

--- CL-F ---

>

U1-S U-FR FF-O

FF-F

Panels travel (Clea opening) Panels travel (Clea opening)

FP-O FP-F

U2-O U2-F

RA-O RA-F

U-FR FF-O U-FR

U1-O U1-F

<-- CL-O -->

<

--- CL-F ---

>

Panels travel (Clea opening) Panels travel (Clea opening)

CHANGING A PARAMETER

Scroll the menus by successively pressing ,

and select PARAby pressing .

Scroll the parameters with

To read the value, press

To change value, press

To save the new value, press

To exit parameter setting, simultaneously press and

Ref : 26702 16 07/01/15

OPERATING VALUES

The speeds correspond to the frequency sent to the motor and

therefore are expressed in Hz.

They correspond to the various door opening and closing phases. They are called

by their abbreviation : FP-O = Opening Cruise Frequency, or FP-F = Closing

Cruise Frequency

The acceleration or deceleration ramps correspond to the time it

takes to go from 0 to 50 Hz, or from 50 to 0 Hz. They are expressed

in seconds.

By reducing the ramp value, the speed is more abruptly changed, and conversely.

They are called by their abbreviation : RD-O = Opening Deceleration Ramp and

RD-F = Closing Deceleration Ramp.

The travels are expressed in encoder point, which corresponds

roughly to millimetres.

The skate travels allow locking or unlocking the locks in slow speed in order to

minimise the noise.

The slow travels allow adjusting the door dockings according to their speed or

their inertia.

The hardnesses are expressed in % of speed drop.

The card records the real cruise speed each time the door is opened or closed and

analyses abnormal deviations. An exceeding of the adjusted percentage in DURF

during closing triggers a re-opening, and in DURO for opening triggers a finger

unjamming movement for glazed doors.

The torques are directly dependent on the voltage sent to the

motor and therefore are expressed in Volts.

A minimum voltage value is defined for a frequency of 2 Hz (U1-..) and a

maximum voltage value for a frequency of 50 Hz (U2-..).

The voltage sent to the motor for the operation is calculated between these two

extreme values according to the frequency.

There are two separate parameter settings :

Moving torques

Opening (U1-O, U2-O), closing (U1-F, U2-F) and skate (U1-S, U2-S).

Braking torque : U-FR

It allows holding heavy doors better when operation at high speeds is

desired.

Ref : 26702 17 07/01/15

VALUE RANGE TABLE

CAN Car door number PrtE 1, 2 ou 3

CAN Communication speed bAud bauds

Motor type Motr ASYn, bruS

Fault stack Err 0 à 10

Number of cycles in thousands CyCL x 1000

Pre-set table choice Pini 01 à 99

Multifunction relay no. 1 rMF1 buZZ, butE, CAME, Vent

Multifunction relay no. 2 rMF2 butE, CAME, Vent, buZZ

Operator type tyPE Mobi, Fi, bAt

Car Cell connected CELL non, oui

Glazed door Vitr non, oui

Motor direction Smot dir, inv

Travel end stop direction FdC nF, nO

Shock signal direction CHoC nO, nF

Shock management mode ModE MAi1, MAi2, Escl

Hold under voltage during opening Msto yes, no

Hold under voltage during closing MstF yes, no

Opening Cruise Frequency FP-O 2 to 50 Hz

End of Opening Frequency FF-O 2 to 5 Hz

Opening Skate Frequency FS-O 3 to 7 Hz

Opening Handling Frequency FM-O 5 to 10 Hz

Closing Cruise Frequency FP-F 2 to 50 Hz

End of Closing Frequency FF-F 2 to 5 Hz

Closing Skate Frequency FS-F 3 to 7 Hz

Closing controller Frequency FM-F 5 to 10 Hz

Opening Acceleration Ramp RA-O 1 to 3 s

Opening Deceleration Ramp RD-O 1 to 3 s

Opening Acceleration Ramp RA-F 1 to 3 s

Opening Deceleration Ramp RD-F 1 to 3 s

Slow Closing Travel CL-F 1 to 150 Pts

Slow Opening Travel CL-O 1 to 200 Pts

Braking Torque u-Fr 40 to 100 Volts

Opening Hardness durO 0 to 100 %

Closing Hardness durF 0 to 100 %

Min Opening Voltage U1-O 20 to 70 Volts

Max Opening Voltage U2-O 70 to 180 Volts

Min Closing Voltage U1-F 20 to 50 Volts

Max Closing Voltage U2-F 50 to 140 Volts

Min Skate Voltage U1-S 20 to 50 Volts

Max Skate Voltage U2-S 50 to 180 Volts

Opening Skate Travel CS-O 10 to 70 Pts

Closing Skate Travel CS-F 10 to 50 Pts

Open Order Wait Time tA-O 15 to 90 min

Cruise Frequency Reduction R-FP 0 to 50 %

CONFIGURATION

ENTRY POINT IN THE TABLE : "-" = ↗, "+" =↘

O P E R A T I O N

END OF USER AREA

Ref : 26702 18 07/01/15

PART 5 : Saving the parameters

The ARIANE card uses a list of so-called workparameters to operate;

these parameters correspond to those which can be read and changed.

The configuration parameters: MSTO, MSTF, etc.

The operating values: FP-O, FF-O, etc.

The manufacturer parameters: Hidden in use

After the door’s operation has been adjusted, all these values may be

saved to a "save" list by the "SAVE" function so that this adjustment may

be restored at any time with the INITfunction.

,,,

Multifunction relay no. 2 rMF2

Operator type tyPE

Cabin cell connected CELL

Glazed door Vitr

Motor direction Smot

Limit switches stops directio

n

FdC

Shock signal directi on CHoC

Shock management mode ModE

Hold under open voltage Msto

Hold under close voltage MstF

Opening Cruise frequency FP-O

End Of Opening frequency FF-O

Opening Sabre frequency FS-O

,,,

IN xx

INIT

List N°1

List N°2

Work parameters Saved adjusted list

List N°3

List N°…

SAVE

TABLES OF STORED FACTORY VALUES USED VALUE TABLE SAVED SITE

CLASSIFIED BY DOOR TYPE CAN BE READ AND CHANGED PARAMETERS TABLE

To avoid an accidental backup, the "SAVE" instruction is only

accessible in manufacturer mode in the PINIconfiguration

parameter.

To go into manufacturer mode and make a save :

1. Switch off the card power and wait for the relays to break

2. Press and hold the and " keys

3. Still holding the keys, switch power on again

4. When "FP-O" is displayed, release the keys. You are in manufacturer

mode

5. Scroll the parameters with up to PINI

6. Press to validate the choice

7. To reach the SAVEfunction, press

8. To make a save, press

9. Simultaneously press and to confirm the save

Ref : 26702 19 07/01/15

RECORDING YOUR ADJUSTED PARAMETERS

Don’t forget to write down the parameters at the end of commissioning for

maintenance.

Type Description Name Range Value

CAN Car door number PrtE 1, 2 ou 3

CAN Communication speed bAud bauds

Motor type Motr ASYn, bruS

Fault stack Err 0 à 10

Number of cycles in thousands CyCL x 1000

Pre-set table choice Pini 01 à 99

Multifunction relay no. 1 rMF1 buZZ, butE, CAME, Vent

Multifunction relay no. 2 rMF2 butE, CAME, Vent, buZZ

Operator type tyPE Mobi, Fi, bAt

Car Cell connected CELL non, oui

Glazed door Vitr non, oui

Motor direction Smot dir, inv

Travel end stop direction FdC nF, nO

Shock signal direction CHoC nO, nF

Shock management mode ModE MAi1, MAi2, Escl

Hold under voltage during opening Msto yes, no

Hold under voltage during closing MstF yes, no

Opening Cruise Frequency FP-O 2 to 50 Hz

End of Opening Frequency FF-O 2 to 5 Hz

Opening Skate Frequency FS-O 3 to 7 Hz

Opening Handling Frequency FM-O 5 to 10 Hz

Closing Cruise Frequency FP-F 2 to 50 Hz

End of Closing Frequency FF-F 2 to 5 Hz

Closing Skate Frequency FS-F 3 to 7 Hz

Closing controller Frequency FM-F 5 to 10 Hz

Opening Acceleration Ramp RA-O 1 to 3 s

Opening Deceleration Ramp RD-O 1 to 3 s

Opening Acceleration Ramp RA-F 1 to 3 s

Opening Deceleration Ramp RD-F 1 to 3 s

Slow Closing Travel CL-F 1 to 150 Pts

Slow Opening Travel CL-O 1 to 200 Pts

Braking Torque u-Fr 40 to 100 Volts

Opening Hardness durO 0 to 100 %

Closing Hardness durF 0 to 100 %

Min Opening Voltage U1-O 20 to 70 Volts

Max Opening Voltage U2-O 70 to 180 Volts

Min Closing Voltage U1-F 20 to 50 Volts

Max Closing Voltage U2-F 50 to 140 Volts

Min Skate Voltage U1-S 20 to 50 Volts

Max Skate Voltage U2-S 50 to 180 Volts

Opening Skate Travel CS-O 10 to 70 Pts

Closing Skate Travel CS-F 10 to 50 Pts

Open Order Wait Time tA-O 15 to 90 min

Cruise Frequency Reduction R-FP 0 to 50 %

CONFIGURATION

ENTRY POINT IN THE TABLE : "-" = ↗, "+" =↘

O P E R A T I O N

END OF USER AREA

Ref : 26702 20 07/01/15

PART 6 : Details about the command modes (CMD)

With the various command modes (CMD), you can test the door’s

operation according to the adjustments made.

CMD0 : Normal operation :

The card simply executes the controller orders and communicates the

shock and travel end stop signals.

CMD1 : Learning the total travel

When this command is started, the display indicates APPR. The card

triggers an open cycle and then a close cycle at the end of which the

encoder’s absolute value is saved as the reference travel.

If a learning ends not correctly, the

APPR

or

Err6

message (cf.

page 23) will remain displayed at the end of the learning. The

learning should be redone after the fault is eliminated.

CMD3 : Direct motor command

In this mode, the motor is activated in the open direction and in the

close direction .

The motor is stopped when the button is released. This command is,

among others, intended to check the motor’s rotating direction or the

door’s operation.

To quit this mode, press .

This mode activates only the motor and not the card outputs.

CMD5 : Openings and closings by

O

and

F

(Close)

Accessible only if the learning (CMD1) has been done. Pressing

interrupts a close cycle and starts an open cycle. Pressing interrupts

an open cycle and starts a close cycle.

To quit the command mode, press .

This mode does not activate the shock and limit switch stop

signals

CMD7 : Open / close cycles

Accessible only if the learning (CMD1) has been done. In this mode, the

door continuously carries out open/close cycles. Whenever or is

pressed, the door’s opening direction is reversed.

To quit this mode, press .

This mode does not activate the shock and limit switch stop

signals.

Table of contents

Popular Engine manuals by other brands

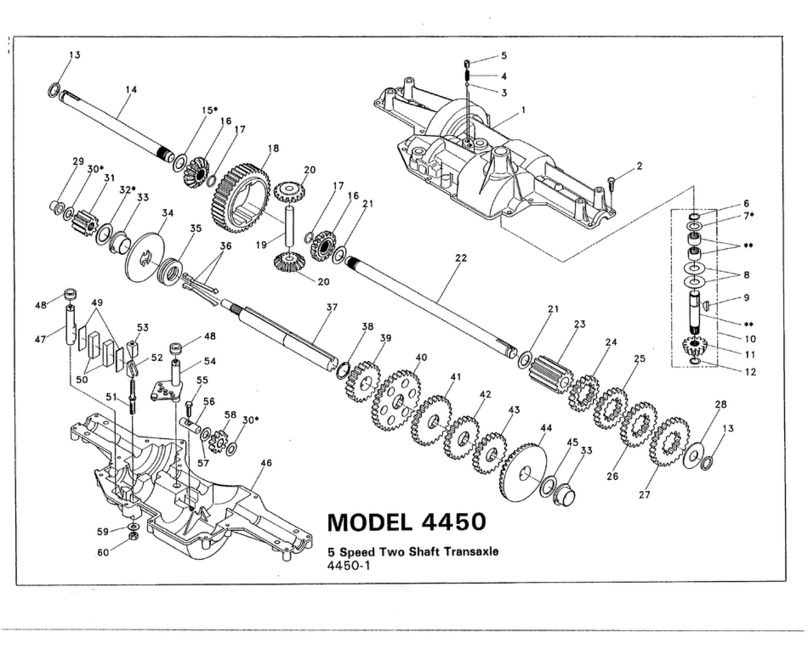

DANA

DANA 4450-1 parts list

HEIDENHAIN

HEIDENHAIN QAN 260L Replacing Instructions

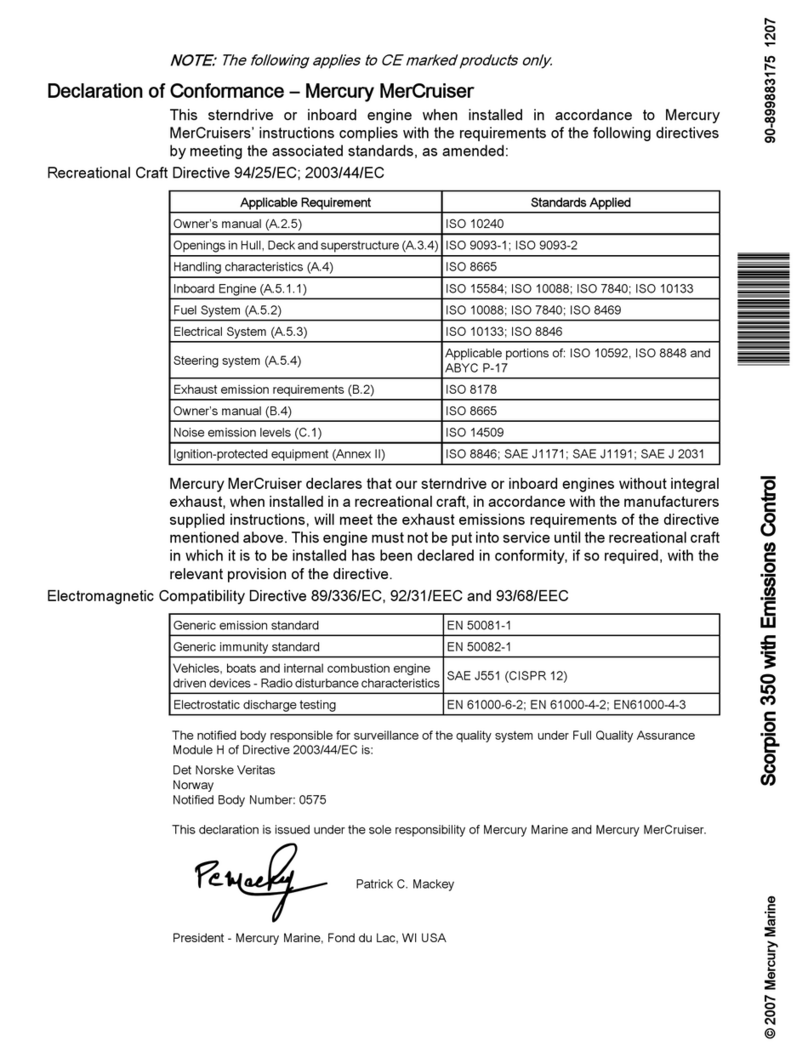

MerCruiser

MerCruiser Scorpion 350 user manual

Briggs & Stratton

Briggs & Stratton 9B900 Operating & maintenance instructions

Stober

Stober PE22 operating manual

Ingersoll-Rand

Ingersoll-Rand MULTI-VANE 3800 Series Operation and Maintenance Information