Stober PE22 User manual

PE22 – PE52 gear units, geared motors

Operating manual

en-US

03/2021

ID 443252_en.00

Table of contents

ii

03/2021 | ID 443252_en.00

Table of contents

1 User information ....................................................................................................................................................... 4

1.1 Storage and transfer ................................................................................................................................................ 4

1.2 Original language ..................................................................................................................................................... 4

1.3 Formatting conventions........................................................................................................................................... 4

1.4 Terms ....................................................................................................................................................................... 5

1.5 Supporting documents............................................................................................................................................. 5

1.6 Limitation of liability ................................................................................................................................................ 5

1.7 Product names and brands ...................................................................................................................................... 5

1.8 Copyright notice....................................................................................................................................................... 5

2 General safety instructions........................................................................................................................................ 6

2.1 Intended use ............................................................................................................................................................6

2.2 Requirements for personnel .................................................................................................................................... 6

2.3 Prevention of personal injury .................................................................................................................................. 6

2.3.1 Mechanical hazards ................................................................................................................................ 6

2.3.2 Thermal hazards ..................................................................................................................................... 7

2.4 Prevention of property damage............................................................................................................................... 7

3 Product description ................................................................................................................................................... 8

3.1 Basic structure ......................................................................................................................................................... 8

3.2 Type designation...................................................................................................................................................... 8

3.3 Nameplate ............................................................................................................................................................... 9

3.4 Direction of rotation ................................................................................................................................................ 9

3.5 Ambient conditions................................................................................................................................................ 10

3.6 Other product features..........................................................................................................................................10

3.7 Additional documentation ..................................................................................................................................... 11

4 Transport and storage ............................................................................................................................................. 12

4.1 Transport ............................................................................................................................................................... 12

4.2 Storage................................................................................................................................................................... 12

5 Installation .............................................................................................................................................................. 13

5.1 Cleaning agent and solvent.................................................................................................................................... 13

5.2 Mounting the motor on a gear unit ....................................................................................................................... 13

5.2.1 Permitted tilting torques at the gear unit input ................................................................................... 14

5.2.2 Tolerances for the add-on motor ......................................................................................................... 14

5.2.3 Mounting the motor on a gear unit...................................................................................................... 15

5.3 Mounting drive elements on a solid shaft .............................................................................................................18

5.4 Mounting the gear unit on the machine................................................................................................................19

Table of contents

03/2021 | ID 443252_en.00

iii

5.5 Tightening torques................................................................................................................................................. 20

6 Commissioning ........................................................................................................................................................ 21

6.1 Before commissioning............................................................................................................................................ 21

6.2 During commissioning............................................................................................................................................ 21

7 Servicing.................................................................................................................................................................. 23

7.1 Cleaning ................................................................................................................................................................. 23

7.2 Inspection .............................................................................................................................................................. 23

7.3 Remedying faults ................................................................................................................................................... 24

7.4 Servicing................................................................................................................................................................. 24

7.5 Service.................................................................................................................................................................... 24

8 Removal and disposal.............................................................................................................................................. 25

8.1 Removal ................................................................................................................................................................. 25

8.2 Disposal.................................................................................................................................................................. 25

1 | User information

4

03/2021 | ID 443252_en.00

1 User information

This documentation is a part of the product. It applies to products in the standard design according to the corresponding

STOBER catalog.

1.1 Storage and transfer

As this documentation contains important information for handling the product safely and efficiently, it must be stored in

the immediate vicinity of the product until product disposal and be accessible to qualified personnel at all times.

Also pass on this documentation if the product is transferred or sold to a third party.

1.2 Original language

The original language of this documentation is German; all other language versions are derived from the original language.

1.3 Formatting conventions

Orientation guides in the form of signal words are used to emphasize specific information so that you are able identify it in

this documentation quickly.

Safety notes indicate special risks when handling the product and are accompanied by relevant signal words that express

the extent of the risk. In addition, warning notes for possible property damage and useful information are also indicated by

signal words.

DANGER!

Danger

This word with a warning triangle indicates that there is a considerable risk of fatal injury

▪ if the stated precautionary measures are not taken.

WARNING!

Warning

This word with a warning triangle means there may be a considerable risk of fatal injury

▪ if the stated precautionary measures are not taken.

CAUTION!

Caution

This word with a warning triangle indicates that minor personal injury may occur

▪ if the stated precautionary measures are not taken.

ATTENTION!

Attention

This indicates that damage to property may occur

▪ if the stated precautionary measures are not taken.

1 | User information

03/2021 | ID 443252_en.00

5

Information

Information indicates important information about the product or serves to emphasize a section in the documentation that

deserves special attention from the reader.

Embedded warning information

Embedded warning information is integrated directly into the instruction manual and is structured as follows:

SIGNAL WORD! Type of hazard, its cause and possible consequences of disregarding it! Measures for avoiding the hazard.

Signal words in embedded warning information have the same meaning as in the normal warning information described

previously.

1.4 Terms

This documentation describes both STOBER gear units and gear components of STOBER geared motors. For reasons of

clarity, the collective term drives is used for these.

1.5 Supporting documents

Separate documents apply to the drive components which can be attached to STOBER gear units, depending on the design.

These documents can be found by entering the serial number of the gear unit at https://id.stober.com or by scanning the

QR code on the nameplate of the gear unit.

Alternatively, you can find supporting documents at http://www.stoeber.de/en/downloads/. Enter the ID of the

documentation in the Search... field:

Drive components Operating manual ID

LM Lean motor 443048_en

EZ synchronous servo motor 443032_en

1.6 Limitation of liability

This documentation was created taking into account the applicable standards and regulations as well as the current state of

technology.

No warranty or liability claims for damage shall result from failure to comply with the documentation or from use that

deviates from the intended use of the product. This is especially true for damage caused by individual technical

modifications to the product or the project configuration and operation of the product by unqualified personnel.

1.7 Product names and brands

Product names that are registered as brands are not specifically identified in this documentation. Existing property rights

(patents, trademarks, protection of utility models) are to be observed.

1.8 Copyright notice

Copyright © STOBER. All rights reserved.

2 | General safety instructions

6

03/2021 | ID 443252_en.00

2 General safety instructions

There are risks associated with the product described in this documentation that can be prevented by complying with the

described warning and safety instructions as well as the included technical rules and regulations.

2.1 Intended use

The drives described in this documentation are intended for installation in industrial machines or systems.

The following are considered non-intended use:

§Any overloading of the drives

§Operation in ambient conditions that deviate from those described in the corresponding technical documentation

§Modifying or refitting the drives

§Using the drives for an application other than that defined during project configuration

Commissioning the machine in which the drives are installed is prohibited until it has been determined that the machine

corresponds to regional laws and guidelines. In particular, the (Machinery) Directive 2006/42/EC is to be observed in the

respective scope.

Operation of the drives in potentially explosive atmospheres is prohibited, unless they are expressly designed for this.

2.2 Requirements for personnel

All mechanical tasks that arise during the assembly, commissioning, maintenance and removal of the product may be

performed only by specialized personnel who hold a corresponding qualification in the field of metal technology.

All electrical tasks that arise during the assembly, commissioning, maintenance and removal of the product may be

performed only by electrically skilled persons who hold a corresponding qualification in the field of electrical engineering.

Tasks that arise during transport, storage and disposal may be performed by personnel who have been instructed in the

suitable method for doing so.

Furthermore, personnel who handle the product must carefully read, understand and observe the valid regulations, legal

requirements and applicable basic rules as well as this documentation and the safety instructions it contains.

2.3 Prevention of personal injury

2.3.1 Mechanical hazards

WARNING!

Dangerous movements of machine parts!

Moving machine parts can cause serious injuries or even death!

üBefore starting the motor or drive:

▪ Install all protective devices necessary for operation.

▪ Make sure that no one is standing in the danger area or able to enter it unchecked.

▪ Leave the danger area.

2 | General safety instructions

03/2021 | ID 443252_en.00

7

WARNING!

Sinking or falling of gravity-loaded axes or vertical axes after switching off the motor due to gravity!

Falling gravity-loaded axes or vertical axes can cause serious injuries or even death!

▪ Be aware that the holding brake of the motor does not offer sufficient safety for persons that are in the hazard area

of gravity-loaded axes or vertical axes.

▪ Move gravity-loaded axes or vertical axes to their lowest position and lock or brace them mechanically before

allowing people to enter the danger area.

WARNING!

Unsecured feather keys or drive elements can be thrown due to the rotation of the input shaft!

Flying metal parts can cause serious injuries!

▪ Mount the provided drive elements properly or remove them before a test run.

2.3.2 Thermal hazards

CAUTION!

The surface of the drive can reach temperatures over 65°C during operation!

Touching the hot surface of the drive can cause severe skin burns!

▪ Do not touch the drive during operation or immediately afterward.

▪ Allow the drive to cool sufficiently before carrying out work on the drive.

▪ Wear protective gloves when working on the drive.

2.4 Prevention of property damage

ATTENTION!Damage to bearings and shafts due to improper assembly! Never use force when installing

machine elements with fittings, e.g. hitting power transmission elements, shafts or the motor or gear housing with a

hammer, but rather install them in accordance with the following instructions.

ATTENTION!Shaft seal rings can be damaged by solvents! Prevent shaft seal rings from coming into contact with

solvents when cleaning and degreasing unpainted surfaces.

3 | Product description

8

03/2021 | ID 443252_en.00

3 Product description

In this chapter, you can find product details that are relevant for assembly, commissioning and maintenance. Detailed

technical data on your gear unit/geared motor can be found in the order confirmation. You will find more product

information and dimensional drawings in the corresponding catalog (Additional documentation [}11]). The respective

separate technical documentation applies to the attached motors.

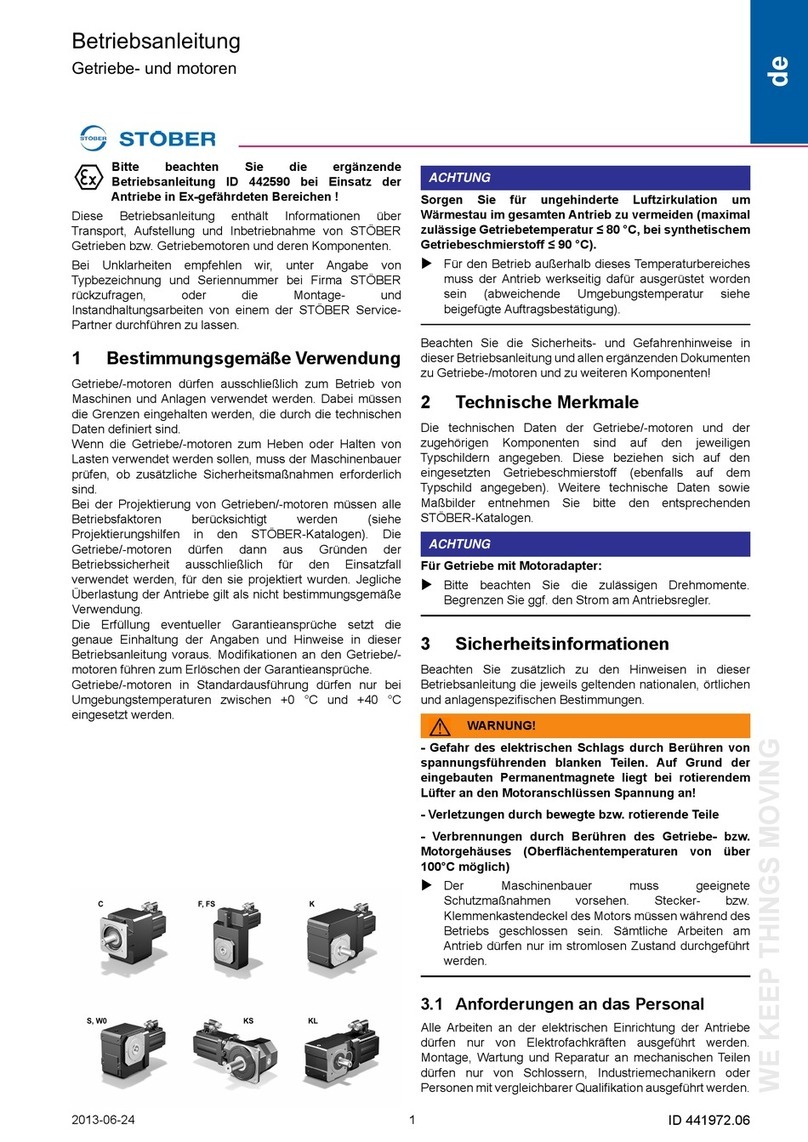

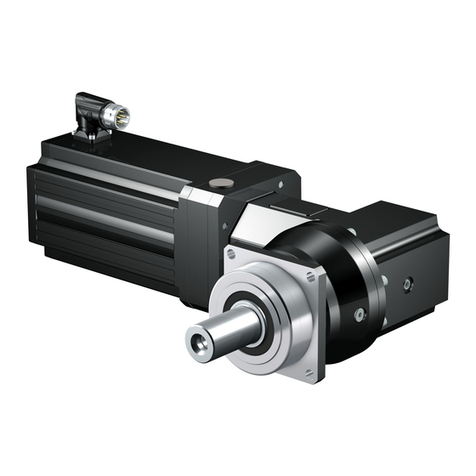

3.1 Basic structure

6

4

3

5

2

1

6

3

4

5

2

1

Tab. 1: Basic structure of a PE222 two-stage gear unit (left) and PE521 single-stage gear unit (right)

1 Solid shaft 2 Feather key

3 Output flange 4 Gear housing

5 Nameplate 6 ME motor adapter

3.2 Type designation

In this chapter, you can find an explanation of the type designation of the PE gear unit.

Sample code

PE 4 2 2 S P S S 0200 ME

Explanation

Code Designation Design

PE Type Planetary gear unit

4Size 4 (example)

2Generation Generation 2

1

2

Stages Single-stage

Two-stage

SHousing Standard

PShaft Solid shaft with feather key

3 | Product description

03/2021 | ID 443252_en.00

9

Code Designation Design

SBearing Standard bearing

SBacklash Standard

0200 Transmission ratio (i x 10) i = 20 (example)

ME

MEL

Motor adapter Motor adapter with EasyAdapt coupling

Motor adapter with EasyAdapt coupling for large motors

3.3 Nameplate

An example gear unit nameplate is explained in the figure below.

1

2

345678910

Code Designation

1 Name of manufacturer

2 Type designation

3 Gear ratio of the gear unit

4 Serial number of the gear unit

5 Dimensions of the motor adapter (diameter of pilot/bolt circle/motor shaft)

6 Customer-specific data

7 Lubricant specification

8 Lubricant fill volume

9 Date of manufacture (year/calendar week)

10 QR code (link to product information)

3.4 Direction of rotation

The input and output shafts of the planetary gear unit rotate in the same direction.

3 | Product description

10

03/2021 | ID 443252_en.00

3.5 Ambient conditions

Standard ambient conditions for transport, storage and operation of the gear unit are described in this chapter. Deviating

ambient conditions for special designs are specified in the order confirmation. Ambient conditions for motors attached to a

gear unit can be found in the technical documentation of the motor.

Feature Description

Transport/storage surrounding temperature −10 °C to +50 °C

Surrounding operating temperature 0 °C to +40 °C

Installation altitude ≤ 1000 m above sea level

Notes

In order to prevent corrosion damage and damage to the shaft seal rings, protect the drive from the following influences:

§Environments with harmful oils, acids, gases, vapors, dust or radiation

§Extreme temperature fluctuations with high humidity

§Condensation or icing

§Strong UV radiation (e.g. direct sunlight)

§Presence of salt spray

§Sparks

In potentially explosive atmospheres, only gear units in an explosion-proof design in accordance with (ATEX) Directive

2014/34/EU may be used. Separate documentation applies to the explosion-proof design.

3.6 Other product features

Other features of gear units in the standard design can be found in the following table.

Feature Description

Maximum permitted gear unit temperature (on the surface

of the gear unit)

≤ 80 °C

Paint Black RAL 9005

Lubricant Synthetic; for specification and quantity, see nameplate

Ventilation Gear housing closed on all sides, no ventilation provided

Weight See order documents

Protection class IP64

With a geared motor, keep in mind that the motor protection class may be lower.

3 | Product description

03/2021 | ID 443252_en.00

11

3.7 Additional documentation

You will find more information about the product at http://www.stoeber.de/en/downloads/. Enter the ID of the

documentation in the Search... field.

Product combination Catalog title ID

Gear unit + ME/MEL/MF/MFL motor adapter Servo gear units 443054_en

Gear unit + EZ synchronous servo motor EZ synchronous servo geared motors 442437_en

Gear unit + LM Lean motor Lean motors 443016_en

If you have questions about your drive that are not answered by this documentation, please contact STOBER Service

(Service [}24]).

4 | Transport and storage

12

03/2021 | ID 443252_en.00

4 Transport and storage

STOBER products are packaged carefully and delivered ready for installation. The type of packaging depends on the product

size and the transport method.

Observe the following information during transport and storage:

§Inspect the delivery for any transport damage immediately upon receiving it and report any transport damage

immediately. Do not put damaged products into operation.

§Check your delivery for completeness using the delivery note and report any missing parts to the supplier.

§Transport and store the product in the original packaging in order to protect it from damage. Remove the original

packaging and transport safety devices shortly before assembly.

Ambient conditions

The ambient conditions for transport and storage can be found in the chapter Ambient conditions [}10].

4.1 Transport

WARNING!

Suspended loads!

Loads that become loose and fall during the lifting process can cause serious injuries or even death!

▪ Observe the following instructions.

▪ Cordon off the danger zone and ensure that no one stands under the suspended loads.

▪ Wear safety shoes.

Lifting and transporting the drive may require lifting gear (e.g. a crane), depending on the weight. The weight of your drive

is specified in the accompanying delivery documents.

Lift and transport the drive as follows:

§Use lifting gear with a sufficient lifting capacity for the weight of the drive.

§Run hoist slings directly around the drive housing and secure the hoist slings from slipping.

In order to prevent the drive from falling or getting damaged during transport, observe the following:

§Do not lift or fasten the drive on the output shaft or attached parts.

§Fasten the motor installed on the gear unit as well and make sure that there is no diagonal pull.

4.2 Storage

Store the drive in a dry, dust-free environment in the original packaging at a storage temperature between −10°C and

+50°C.

5 | Installation

03/2021 | ID 443252_en.00

13

5 Installation

This chapter contains information on how to correctly mount standard STOBER drive designs and avoid injury to persons or

damage to property. Differing information for customer-specific designs is included in the order documents.

Observe the technical documentation of the motor for the assembly and electrical connection of the motor.

Inspect the drive for transport or storage damage. If the drive is damaged, do not install it and contact the STOBER Service

department.

The following tools and equipment are required for mounting the drive:

§If necessary due to the overall weight, lifting gear with appropriate fastening elements and sufficient lifting capacity

§Open-end wrench set

§Socket wrench set

§Long hexagon insert set

§Torque wrench

§Grease

§Cleaning agent or solvent

Information about the specific tools or equipment can be found in the respective chapter.

5.1 Cleaning agent and solvent

Upon delivery, unpainted surfaces of the drive are protected by a corrosion protection agent. The corrosion protection

agent must be removed from contact surfaces such as shaft ends and flange contact surfaces before assembly. STOBER

recommends removing the corrosion protection with a suitable cold cleaner (e.g. Carlofon Autocleaner) which, in contrast

to volatile solvents, is almost odorless and does not weaken the sealing lips of the shaft seal rings. Otherwise, you can use

commercially available solvents.

Be aware that all surfaces that come into contact with each other in a clamp connection must be degreased with a cold

cleaner or solvent for error-free torque transmission. Additional information can be found in the following chapters.

ATTENTION!Shaft seal rings can be damaged by solvents! Prevent shaft seal rings from coming into contact with

solvents when cleaning and degreasing unpainted surfaces.

5.2 Mounting the motor on a gear unit

This chapter contains information on how to mount a motor on a STOBER gear unit with a motor adapter. The motor

adapter type of your gear unit can be found on the nameplate of the gear unit. STOBER recommends using a motor with a

shaft without a feather key, since the keyway negatively affects smooth operation.

If you have a STOBER geared motor, you can skip this chapter.

ATTENTION!Damage to encoders, bearings and shafts due to improper assembly! Never use force when

mounting drive elements with fittings, e.g. hitting drive elements, shafts or the motor or gear housing with a hammer, and

instead install them in accordance with the instructions in the documentation.

Information

To make mounting the motor easier, stick to the following principal assembly order when possible:

▪ First mount the motor on the gear unit, then the geared motor on the machine

▪ Mount the motor on the gear unit with the motor shaft pointing down vertically in order to prevent unfavorable

shifting and tilting of the motor shaft.

5 | Installation

14

03/2021 | ID 443252_en.00

5.2.1 Permitted tilting torques at the gear unit input

If you mount a STOBER gear unit on the machine in a horizontal mounting position, check that the permitted tilting torque

is not exceeded on the gear unit input before mounting the corresponding motor. Information on the permitted tilting

torque can be found in the corresponding catalog (Additional documentation [}11]).

5.2.2 Tolerances for the add-on motor

This chapter describes tolerances for motors that are required for assembly on a STOBER gear unit with motor adapter.

Dimensional drawings of the motor adapter can be found in the corresponding catalog (Additional documentation [}11]).

Tolerances for shafts in accordance with DIN 748-1

Diameter [mm] Tolerance

≤ 50 ISO k6

> 50 ISO m6

Tolerances for centering diameter on the motor flange in accordance with EN 50347

Centering diameter [mm] Flange size [mm] Tolerance

≤ 230 65 – 300 ISO j6

> 230 350 – 500 ISO h6

Tolerances for radial runout, axial runout and concentricity in accordance with IEC 60072-1 (normal class)

Symbol Unit Explanation

kx µm Concentricity of the flange centering in relation to the shaft

pl µm Axial runout of the flange mounting surface in relation to the shaft

r µm Radial runout of the shaft end

5 | Installation

03/2021 | ID 443252_en.00

15

∅d [mm] r [µm]

d ≤ 10 30

10 < d ≤ 18 35

18 < d ≤ 30 40

30 < d ≤ 50 50

50 < d ≤ 80 60

Centering diameter [mm] Flange size kx [µm] pl [µm]

50 – 95 65 – 115 80 80

110 – 130 130 – 165 100 100

250 – 450 300 – 500 125 125

5.2.3 Mounting the motor on a gear unit

This chapter describes the assembly of a motor on a planetary gear unit with an ME/MEL motor adapter.

Prerequisites

§Dimensional tolerances of the motor correspond to the requirements in the chapter Tolerances for the add-on motor

[}14]

§The permitted tilting torque on the gear unit input is not exceeded (see Permitted tilting torques at the gear unit input

[}14])

§Four screws of strength class 8.8 are available for mounting the motor on a gear unit. The minimum screw depth for

these screws is 1.6x the nominal diameter of the screw

§The necessary tools and aids are available (see Installation [}13])

§The information in the chapter Cleaning agent and solvent [}13] is observed

Procedure

In order to prevent unfavorable shifting or tilting of the motor shaft, STOBER recommends mounting the motor on the gear

unit with the motor shaft pointing down vertically.

1. Position the gear unit (5), if necessary with the aid of lifting gear, on a suitable support (1) so that the motor can be

mounted in a vertical position. Make sure that the weight of the gear unit is not supported on the output shaft.

2. Remove the transport cover of the motor adapter.

3. If a feather key is installed on the motor shaft, remove it.

4. Remove all corrosion protection from the motor shaft and contact surfaces of the motor and motor adapter.

5. Carefully remove any lubricant from the inner hole of the clamping hub (15) and, if available, the inner and outer

surface of the adapter bushing (6) for the motor shaft.

6. Unscrew the screw plug (13).

7. Turn the clamping hub so that the locking screw (11) can be turned over the bore for the screw plug (13), guide the

hexagon insert (3) through the bore and insert it into the hexagon socket of the locking screw.

8. If an adapter bushing (6) is necessary, insert the adapter bushing into the inner hole of the clamping hub (15) as far as

it will go and turn the adapter bushing so that the slot of the adapter bushing coincides with the slot of the clamping

hub (10).

5 | Installation

16

03/2021 | ID 443252_en.00

9. If necessary, use two suitable attachment points to secure the motor with the lifting gear so that the motor shaft is

pointing down vertically.

10. Turn the motor in an axial position to the gear unit so that the nameplates are on the same side, if possible, and can

also be read after installation in the machine.

11. If the motor shaft has a keyway, position the motor shaft so that the keyway faces the slot of the clamping hub (10).

12. An elastic bellow coupling is installed in the MF/MFL motor adapter that can assume a slightly tilted position, as long

as the clamping hub is not connected with the motor shaft. Correct any existing tilt of the clamping hub before

inserting the motor shaft.

13. Carefully place the motor on the motor adapter (4) and make sure that the motor shaft is inserted (7) in the clamping

hub (15) so that it is centered and not at an angle.

14. If the motor shaft cannot be inserted into the clamping hub, do not use force and instead turn the locking screw (11)

counterclockwise one quarter rotation with the hexagon insert (3) (in this process, the clamping hub widens because

the grooved pin (12) locks against the cylinder head of the locking screw). The size of the hexagon insert can be found

on the adhesive label (14) as well as in the following tables.

15. If necessary, repeat the previous step.

16. The contact surfaces of the motor flange and motor adapter flange must fit together without a gap. If this is not the

case, do not use force and instead check the dimensions of the motor.

17. Mount the motor on the motor adapter with screws (9). Tighten the screws evenly, with increasing torque and

alternating diagonally. The tightening torque can be found in the chapter Tightening torques [}20].

18. Insert the torque wrench (2) in the hexagon insert (3) and tighten the locking screw (11). The corresponding tightening

torque can be found in the following table and on the adhesive label on the motor adapter.

19. If the motor flange does not fully cover the bores or openings of the motor adapter, seal off the openings with a

suitable sealant. This maintains the protection class of the gear unit so that dust and water cannot get into the interior

of the motor adapter.

20. Plug the access hole with the screw plug (13) by screwing it in until it is flush with the surface of the motor adapter.

5 | Installation

03/2021 | ID 443252_en.00

17

Fig.1: Mounting a motor on a P planetary gear unit with ME motor adapter (example)

1 Support 2 Torque wrench

3 Hexagon insert 4 Motor adapter

5 Planetary gear unit 6 Adapter bushing (if present)

7 Motor shaft 8 Motor

9 Screw 10 Slot of the clamping hub

11 Locking screw 12 Grooved pin

13 Screw plug 14 Adhesive label

15 Clamping hub

5 | Installation

18

03/2021 | ID 443252_en.00

Tightening torques for the locking screw (11) for PE planetary gear units

Type ME MEL

KS s MAKS s MA

[mm] [Nm] [mm] [Nm]

PE221 M4 3 4.5 – – –

PE222 M4 3 4.5 – – –

PE321 M5 4 9.0 M6 5 16

PE322 M4 3 4.5 – – –

PE421 M6 5 16 M8 6 40

PE422 M5 4 9.0 M6 5 16

PE521 M8 6 40 M10 8 75

PE522 M6 5 16 M8 6 40

Abbreviations used:

§KS = Nominal diameter of the locking screw (11)

§MA = Tightening torque for the locking screw (11)

§s = Size of the hexagon insert (3)

5.3 Mounting drive elements on a solid shaft

This chapter describes the assembly of drive elements, such as hubs, belt drives, couplings, pinions or sprockets, on the

output of a gear unit with a solid shaft and feather key.

When mounting drive elements on a solid shaft without a feather key, observe the technical documentation of the drive

element in question.

ATTENTION!Damage to encoders, bearings and shafts due to improper assembly! Never use force when

mounting drive elements with fittings, e.g. hitting drive elements, shafts or the motor or gear housing with a hammer, and

instead install them in accordance with the instructions in the documentation.

Prerequisites

§The drive element does not cause any impermissible shaft loads (e.g. tensioning the belt on a belt drive). Information

on permissible shaft loads can be found in the corresponding catalog (see Additional documentation [}11]).

§The drive element is balanced.

§The tolerance of the inner hole of the drive element corresponds to ISO H7.

§The keyway of the drive element corresponds to DIN 6885-1 (if not otherwise specified).

§The information in the chapter Cleaning agent and solvent [}13] is observed

§A mounting device suitable for the drive element is available (not included in the scope of delivery).

Procedure

1. Remove the corrosion protection from the solid shaft.

2. Degrease the inner hole of the drive element.

3. Mount the drive element on the solid shaft with the aid of a mounting device positioned on the centering hole of the

solid shaft. Details can be found in the following figure and table.

5 | Installation

03/2021 | ID 443252_en.00

19

4. If the drive element is difficult to hoist, do not use force and instead heat it to about 80°C beforehand.

5. If the length of the solid shaft is greater than the length of the drive element, use an appropriate spacer bushing that

you position between the plate (1) and drive element (5).

Fig.2: Mounting device for a belt drive (example)

1 Washer 2 Nut

3 Threaded pin 4 Axial bearing

5 Belt drive (example) 6 Solid shaft

5.4 Mounting the gear unit on the machine

Prerequisites

§The connecting structure for the drive in the machine is designed according to the weight and torque and takes into

account forces that act on the drive.

§The connecting structure is flat, vibration-reducing and torsion-resistant.

The perpendicularity deviation of the flange contact surface of the connecting structure to the gear unit shaft axis does

not exceed 0.03mm per 100mm.

§The gear housing is grounded via the connecting structure or attached motor.

§The centering diameter of the connecting structure has the tolerance of ISO H7.

§Sufficient ventilation for the mounted drive is ensured.

Procedure

1. Position the gear unit so that the nameplate of the gear unit is still visible after mounting.

2. If the gear unit is to be operated in reverse operation, make sure that the output shaft is positioned according to the

specifications in the chapter .

3. Center the gear unit in the connecting structure using the pilot/pilots of the gear housing.

4. Mount the output flange of the gear unit to the connecting structure using screws. Details on the screws can be found

in the following table.

5. Tighten the screws evenly in multiple passes with increasing torque and alternating diagonally. The tightening torques

can be found in the chapter Tightening torques [}20].

5 | Installation

20

03/2021 | ID 443252_en.00

3

4

2

1

3

4

2

1

Tab. 2: Mounting the gear unit on the machine, using PE222 (left) and PE521 (right) as an example

1 Solid shaft 2 Feather key

3 Output flange bore 4 Housing pilot

Gear unit type Number of screws Screw size Min. screw-in depth

[mm]

Strength class

PE2 4 M4 8 10.9

PE3 4 M5 10 10.9

PE4 4 M6 13 10.9

PE5 4 M8 16 10.9

Tab. 3: Information on screws for mounting the gear housing on the machine

5.5 Tightening torques

Note that the following tightening torques apply to screws that are used for mounting the motor on the gear unit or the

gear unit on the machine. For clamp couplings, clamping screws of shrink rings and other connection elements, other

tightening torques apply that are specified in the specific context.

Tightening torque MA [Nm]

Thread Strength class 8.8 Strength class 10.9 Strength class 12.9

M4 3.3 4.8 5.6

M5 6.5 9.5 11.2

M6 11.3 16.5 19.3

M8 27.3 40.1 46.9

M10 54 79 93

M12 93 137 160

Tab. 4: Tightening torques for screws with metric standard thread in accordance with DIN 13-1 (coefficient of friction µges =

0.14).

This manual suits for next models

1

Table of contents

Other Stober Engine manuals

Stober

Stober PHQ53K User manual

Stober

Stober PHV94 User manual

Stober

Stober PHQ43 User manual

Stober

Stober PH53K User manual

Stober

Stober KS Series User manual

Stober

Stober P Series User manual

Stober

Stober PH33KX User manual

Stober

Stober P53K User manual

Stober

Stober PK Series User manual

Stober

Stober F1 User manual

Popular Engine manuals by other brands

Robin

Robin EX13D owner's manual

O.S. engine

O.S. engine GF40 Owner's instruction manual

O.S. engine

O.S. engine MAX-75AX instruction manual

Shandong

Shandong HUAFENGDONGLI 4102 Series Operation and maintenance manual

Grundfos

Grundfos MS6000 Service instructions

KEM

KEM KODIAK MARINE LT4 SUPERCHARGED Operator's manual