SmartOne 70-600000-001 User manual

TM

Effective: October 2016

Remote Releasing Module

DESCRIPTION

The Remote Releasing Module (RRM) is a UL Listed, FM Approved

SmartOne® Field Device. The RRM provides the ability to remotely activate

extinguishing-system control devices. Connection is via the SmartOne com-

patible control panel’s Signaling Line Circuit (SLC). The module is eld-pro-

grammable using the control panel keypad or Hand-Held Programmer.

The RRM provides internal supervision of communication with the control

unit, connections to external power supply, and memory status.

Solenoid release circuits are power-limited and supervised for short circuit

by using an In-line Releasing-Circuit Device (P/N 06-220023-001). In the

event of a ground fault, open, short or a relay contact failure, the device

will transmit a trouble status to the control unit.

A status LED is mounted on the RRM and indicates the module’s status:

Normal is indicated by a ash every 9 seconds; Output Activity is indicated

by the LED on continuously (no ashing); Trouble is indicated by the LED

being OFF.

The RRM is intended for indoor dry location use, and is available in two

models, one for mounting in a standard electrical box and a second model

for mounting in suitable UL-864 Listed cabinets.

P/N 70-600000-001: Standard Mounting

•North American 4-11/16 in. electrical box with a double gang plaster

ring (Rayco Model 841 or equivalent), 1/2 in. raised

•4 in. square, 2-1/8 in. deep electrical box

P/N 70-600000-002: In-Cabinet Mounting

•Any suitable UL-864 Listed enclosure with no other electronics.

The module terminal block will accept #12, #14, #16 and #18 AWG wire

(4.0 mm2, 2.5 mm2, 1.5 mm2 and 1.0 mm2 respectively). Size #18 being a

minimum requirement. The use of solid wire is recommended.

TM

KIDDE-FENWAL INC.

400 MAIN STREET, ASHLAND, MA 01721

TEL: (508) 881-2000 FAX: (508) 881-8920

This literature is provided for informational purposes only.

KIDDE-FENWAL,INC. assumes no responsibility for the

product’s suitability for a particular application. The product

must be properly applied to work correctly.

If you need more information on this product, or if you have

a particular problem or question, contact KIDDE-FENWAL

INC., Ashland, MA 01721. Telephone: (508) 881-2000

06-236636-001 Rev. AD ©2016 Kidde-Fenwal, Inc.

INSTALLATION INSTRUCTIONS

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause any harmful interference, and (2) This device must

accept any interference received, including interference that may cause undesired operation.

Control Unit

Part Number

Installation,

Operation and

Maintenance Manual

Part Number

Configuration

Software

User's Guide

Part Number

FenwalNET 6000:

74-600000-00106-236529-00106-236529-002

74-600000-51006-236529-00106-236529-002

ARIES:

76-600000-00406-236530-00106-236530-002

FenwalNET 8000-ML:

74-800100-00106-237041-00106-237042-001

74-800101-00206-237041-00106-237042-001

74-800200-00106-237041-00106-237042-001

74-800201-00206-237041-00106-237042-001

ARIES NETLink:

76-800100-00106-237058-00106-237059-001

76-800101-00206-237058-00106-237059-001

76-800200-00106-237058-00106-237059-001

76-800201-00206-237058-00106-237059-001

74-800102-00106-237041-00106-237042-001

74-800202-00106-237041-00106-237042-001

76-800102-00106-237058-00106-237059-001

76-800202-00106-237058-00106-237059-001

2 7

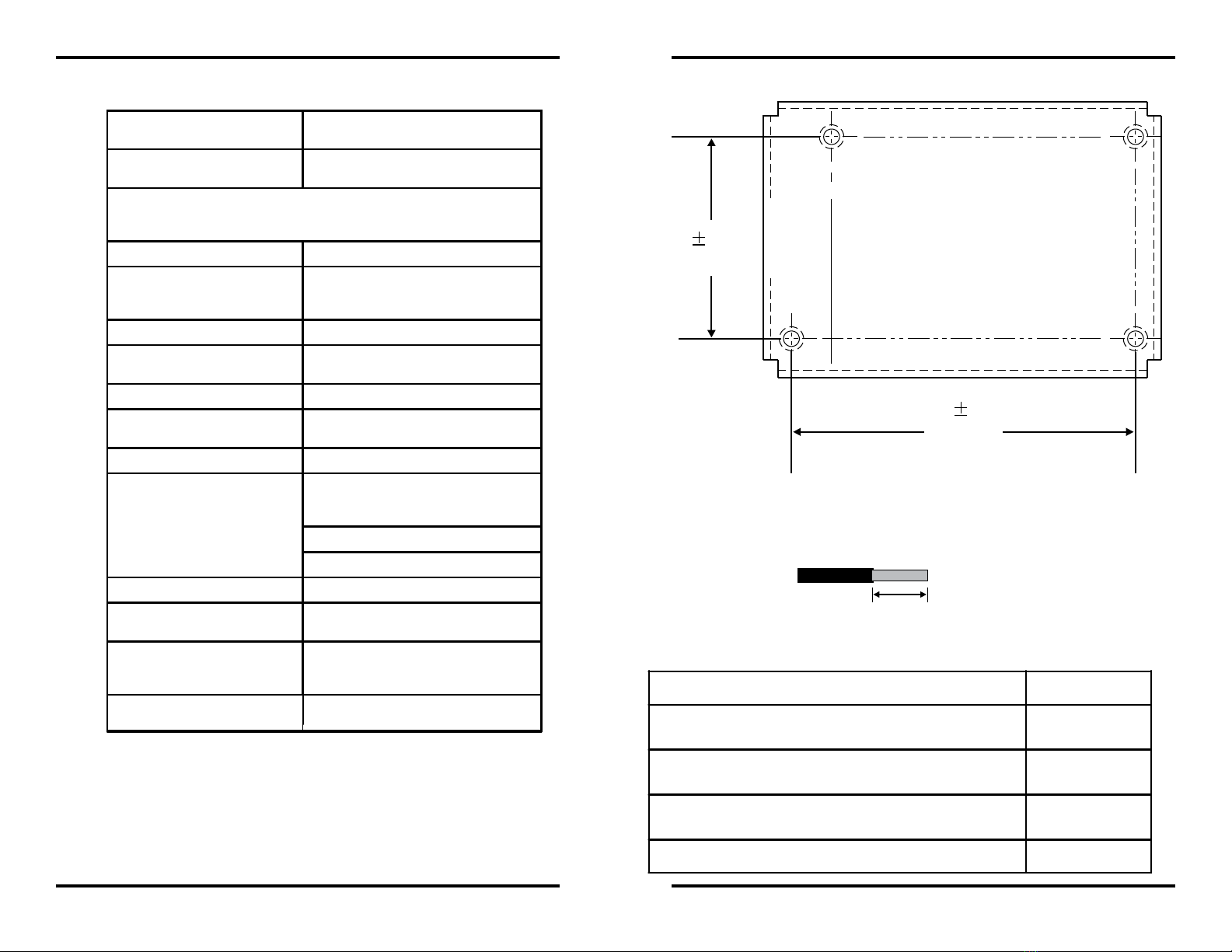

3.00 in.

0.01 in.

1.80 in.

0.01 in.

Figure 5. RRM Mounting Template

ORDERING INFORMATION

Description Part Number

Remote Releasing Module

(With Standard Bracket and Front Cover Plate) 70-600000-001

Remote Releasing Module

(With In-Cabinet Bracket and Mounting Hardware) 70-600000-002

Inline Releasing Device (One Required For Each Solenoid

Release Circuit to be Supervised and Power Limited) 06-220023-001

End of Line Resistor, 4.7 K, 0.5 W 06-129025-006

SPECIFICATIONS

WIRE STRIPPING

Strip 1/4 in. from the ends of all wires that connect to the terminal block of the

module.

1/4 in.(6.4mm)

Figure 1. Wire Stripping

Single-Loop Panel Activation * Up to 4 groups of 16 RRMs activated

simultaneously

Multi-Loop Panel Activation * Up to 7 groups of 20 RRMs activated

simultaneously

*For further information on activation of RRMs, refer to the applicable

Installation, Operation and Maintenance manual and Configuration Software

User's Guide for your control unit.

Operating Voltage 24 VDC Nominal

Device Current (Remote Supply)

6.1 mA Standby

45 mAAlarm (Excluding Releasing

Devices)

Device Current (SLC) 410 µA Standby and Alarm

Operating Temperature Range 32ºF to 120ºF

(0ºC to 49ºC)

Operating Humidity Range 0% to 93% RH

Construction High Impact Polymer Faceplate with a 16

gauge Aluminum Bracket

Shipping Weight 10.5 oz (298 g)

Compatible Electrical Boxes

North American 4-11/16 in. electrical box

with a double gang plaster ring (Rayco

Model 841 or equivalent)

4 in. square 2-1/8 in. deep box

Any suitable UL-864 Listed Enclosure

Releasing Circuit Output Current 2.4A Max. @ 24.0 VDC

Trouble Circuit Input 4.7K End of Line Resistor

"Open" contact = normal condition

SLC Wiring Configuration

•Class A,

•Class B,

•Class A, Style-7

Wiring Unshielded

(See Note 12 for use of shielded wire)

Note: To ensure that all SLC-based output devices are activated within the

required time period, refer to the associated control unit’s Installation,

Operation and Maintenance manual.

3

GENERAL NOTES

1. Terminal connection supports wiring from #18 AWG (1.0 mm2) to #12

AWG (4.0 mm2). Wire sizes determine electrical box depth.

2. Refer to applicable Control Panel Manual for addressable loop wiring

specication.

3. SLC Line wiring is power-limited and supervised.

4. Do not attach power-limited and non-power-limited wiring to the same

terminal block.

5. Route non-power-limited wires at least 1/4 in. away from all power-

limited wiring.

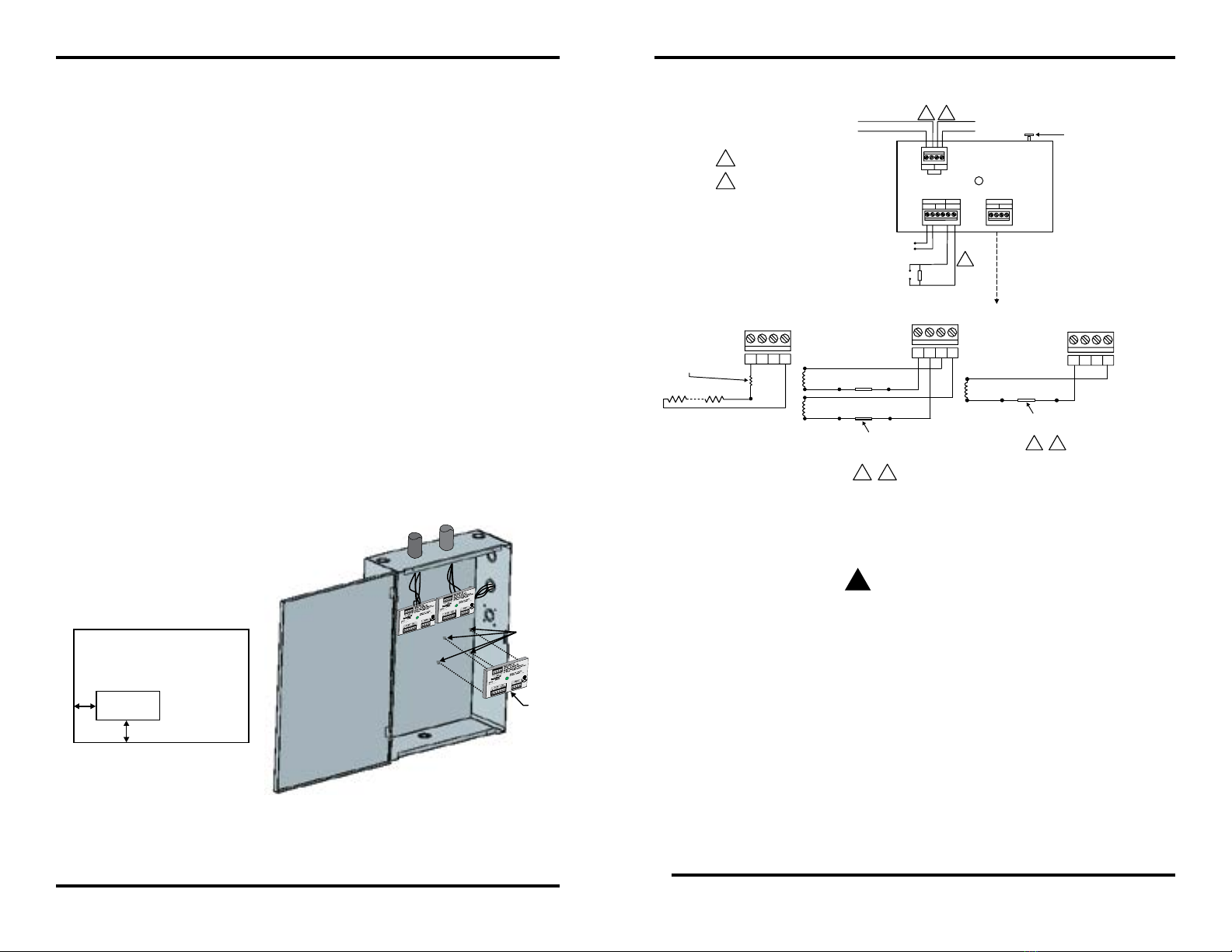

WIRING DIAGRAM

Figure 2. RRM Wiring

6

APPROVED

FM

APPROVED

FM

APPROVED

FM

STANDOFFS

INSULATOR

2. Using the template in Figure 5, mark the mounting holes in the

cabinet that the RRM is going to be installed.

3. Drill the mounting holes in the enclosure.

4. Install provided standoffs in the cabinet mounting holes.

5. Mount the cabinet.

6. Run the necessary wiring and conduit to the cabinet.

Note: See Appendix E of the corresponding Control Unit’s Installa-

tion, Operation and Maintenance Manual for routing guidelines for

power-limited and non-power-limited wiring. Refer to the reference

table on the last page for the part number of the applicable manual.

7. Remove the insulator from the RRM.

8. On the RRM, loosen the mounting screws until each screw is ush

with the back of the module.

9. Place the RRM over the standoffs in the enclosure. Secure the

mounting screws to the standoffs.

10. Make all wiring connections as shown in the wiring diagram.

Ensure that all wiring is free of opens, shorts and ground faults.

Verify that all wires are insulated up to and touching the terminal

block, and that each terminal screw is tight.

11. Replace the insulator on the RRM.

Figure 4. Minimum RRM Clearance and

Mounting the RRM in a UL Listed Enclosure

WARNING

!

Ensure that all releasing devices are physically disconnected from

the releasing circuits before performing any testing or maintenance.

RRM

½ in. (13 mm)

½ in.

(13 mm)

UL LISTED ENCLOSURE

S

S

S

S

SP

P

P

P

REMOTE RELEASE MODULE (RRM)

TB2

TB3

TB1

4.7k EOL

Control Unit

SLC (TB1)

24 VDC Release

+++

-+-

PSU

STATUS

213456

--

TB1

TB1

TB1

Or

DUAL-SOLENOID CIRCUIT SINGLE-SOLENOID CIRCUIT

To next loop device

Blk Red

Blk Red

Blk Red

Current Limiting Resistor

Other Assemblies

See the applicable Control Unit’s

Installation, Operation and

Maintenance Manual for a list of other

compatible releasing devices and

device-specific wiring instructions.

In-Line Releasing Device,

P/N 06-220023-001 (Must be close

nippled to solenoid enclosures)

In-Line Releasing Device, P/N 06-220023-001

(Must be close nippled to solenoid enclosures)

(Non-Power-Limited when an In-Line Releasing

Device not used) See General Note 4.

(W

ircuit is non-power-limited and not supervised

for shorts.)

hen an In-Line Releasing Device is not used, the

c

Supervised for open circuits and ground

faults.

OTHER COMPATIBLE

RELEASING DEVICES

AABB

12 34

SLC

2134

To PSU dry contact trouble relay

(Trouble = contacts closed)

Legend:

Supervised

Power Limited

For a list of all compatible

releasing devices, refer to

Appendix C of the corresponding

Control Unit’s Installation, Operation

and Maintenance Manual.

Release Circuit:

Voltage:

Current:

24 VDC (nom.)

2.4 A(max.)

Or

213421342134

Max. Current under Fault Conditions: 5A

To Earth Ground

(screw on mounting

bracket)

For a list of all compatible

power supplies, refer to

Chapter 1 of the corresponding

Control Unit’s Installation, Operation

and Maintenance Manual.

4

INSTALLATION FOR A 4-11/16 IN. SQUARE OR 4 IN. SQUARE

ELECTRICAL BOX (SEE FIGURE 3)

Note: The depth of the box is to be determined per Article 370 of the National

Electrical Code. RRM volume is 8.94 cubic-inches.

1. It is recommended that the module address be programmed prior to instal-

lation. Refer to the control unit manual for device address programming.

Using a handheld programmer to set the module address requires a 24 VDC

power supply (see Figure 2). A handheld programmer can only program the

module address. All other congurations can be set using with the control

panel or conguration software.

2. Make all wiring connections as shown in the wiring diagram (see Figure 2).

Ensure that all wiring is free of opens, shorts and ground faults. Verify that

all wires are insulated up to and touching the terminal block, and that each

terminal screw is tight. Connect the Earth-Ground to the green screw on the

mounting bracket.

3. Mount the module to the 4 in. square or 4-11/16 in. electrical box (use adapter

ring for the 4-11/16 in. electrical box) .

4. Using the 2 provided screws, mount the wall plate to the electrical box as

shown in Figure 3.

Note: See Appendix E of the corresponding Control Unit’s Installation, Operation

and Maintenance Manual for routing guidelines for power- limited and

non-power-limited wiring. Refer to the reference table on the last page

for the part number of the applicable manual.

6. The RRM is shipped from the factory as an assembled component and

is not eld-serviceable.

7. For ease of wiring, especially with solid wire, an extension ring or deeper

box can be used.

8. For Power-Limited Circuits, use Type FPL, FPLR, or FPLP cable per

Article 760 of the National Electrical Code (NEC). The note located on

product label “ALL OTHERS-POWER LIMITED” must be removed if

connected to a non-power limited supply source.

9. For a list of power supplies, refer to Chapter 1 of the applicable Control

Unit’s Installation, Operation and Maintenance Manual. Refer to the

reference table on the last page for the part number of the applicable

manual.

10. For a list of compatible solenoids, refer to Appendix C of the applicable

Control Unit’s Installation, Operation and Maintenance Manual. Refer to

the reference table on the last page for the part number of the applicable

manual.

11. To congure the RRM, refer to the applicable Control Unit’s Conguration

Software User’s Guide. Refer to the reference table on the last page for

the part number of the applicable user’s guide.

Note: Releasing devices are Control Unit- and Conguration Software-depen-

dent.

12. The use of shielded wire is not allowed for the Release Circuit, PSU

Trouble Circuit and 24VDC Power Circuit, except for very short

runs. The maximum amount of shielded wire which can be spliced into

or used on the referenced circuits is a combined total of 50 feet. When

multiple Remote Release Modules, Addressable Signal Modules, and

Addressable Input Modules attached to the same SLC loop are using

shielded wire on their initiating circuits, remote LED circuits, 24V power

circuits, auxiliary circuits, notication appliance circuits or release circuits,

the total combined shielded wire on all of these circuits (not including the

SLC itself) must not exceed 200 feet. Refer to the control unit Installation,

Operation and Maintenance Manual for SLC loop wiring requirements.

SUPERVISION

Each Circuit is supervised for short circuit (only when using inline device

06-220023-001 for solenoids), open circuit, and ground faults in order to be listed

as power limited. Initiators are an exception; they are not supervised for short

circuits, and are not listed as Non-Power Limited.

5

APPROVED

FM

Figure 3. Mounting the RRM in an Electrical Box

INSTALLATION FOR AN IN-CABINET RRM ENCLOSURE

(SEE FIGURE 4)

The RRM module is intended for mounting inside a suitable UL-864 Listed enclo-

sure with no other electronics. Use the mounting hardware (standoffs and screws)

provided with the module. Provide a minimum 1/2 in. of clearance between the

RRM(s) and enclosure (See Figure 4).

It is recommended that the module address be programmed prior to installation.

Refer to the control panel manual for device address programming. Using a hand-

held programmer to set the module address requires a 24 VDC power supply (see

Figure 2). A handheld programmer can only program the module address. All

other congurations can be set using the control panel or conguration software.

This manual suits for next models

1

Popular Control Unit manuals by other brands

Emerson

Emerson White Rodgers 36C53 Series installation instructions

Burkert

Burkert 0258 operating instructions

Parker

Parker DINCon II Installation, operating, & maintenance instructions

Infineon

Infineon TLE9262-3BQX manual

Telit Wireless Solutions

Telit Wireless Solutions UE910 series Hardware user's guide

Acromag

Acromag BusWorks 900EN Series user manual

Allen-Bradley

Allen-Bradley Rockwell Automation 1734-4IOL user manual

Bosch

Bosch MP 100 Installation instruction

Burkert

Burkert FieldConnect ME64 operating instructions

Just Motion Control

Just Motion Control 2DM860 manual

Vitec Multimedia

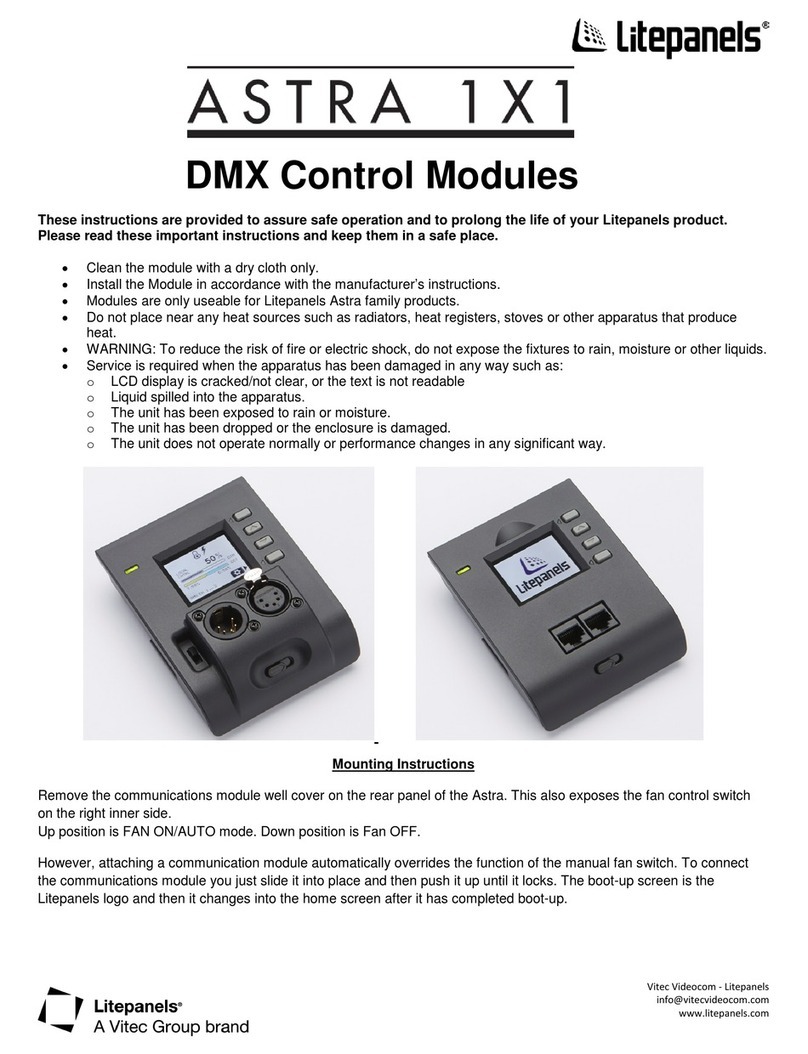

Vitec Multimedia Litepanels ASTRA 1X1 manual

Nibco

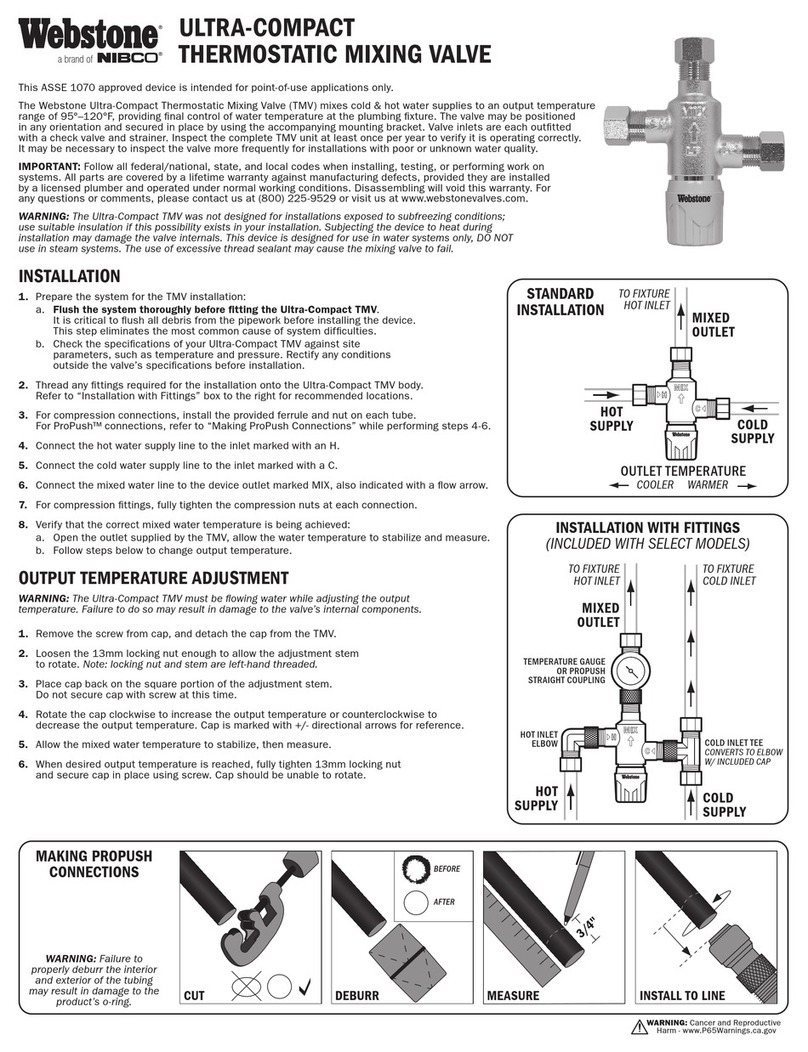

Nibco Webstone Series manual