Design / Selection

1. Confirm the specifications.

Products represented in this manual are designed only for use

in compressed air systems including vacuum).

Do not operate at pressures or temperatures, etc., beyond the

range of specifications, as this can cause damage or

malfunction. Refer to the specifications.)

Please contact SMC when using a fluid other than compressed

air including vacuum).

We do not guarantee against any damage if the product is

used outside of the specification range.

2. Actuator drive

When an actuator, such as a cylinder, is to be driven using a

valve, take appropriate measures cover installation or

approach prohibition) to prevent potential danger caused by

actuator operation.

3. Effect of bac pressure when using a manifold

Use caution when valves are used on a manifold, because an

actuator may malfunction due to back-pressure.

For single acting sylinder, take appropriate measures to

prevent malfunction by using it with an individual exhaust

manifold.

4. Holding pressure (including vacuum)

Since the valves are subject to air leakage, they cannot be

used for applications such as holding pressure including

vacuum) in a pressure vessel.

5. Not suitable for use as an emergency shutoff valve,

etc.

The valves listed in this manual are not designed for safety

applications such as an emergency shutoff valve. If the valves

are used for the mentioned applications, additional safety

measures should be adopted.

6. Release of residual pressure

For maintenance purposes install a system for releasing

residual pressure.

7.

. .

. Operation in a vacuum condition

When a valve is used for switching a vacuum, take measures

to install a suction filter or similar to prevent external dust or

other foreign matter from entering inside the valve. In addition,

at the time of vacuum adsorption, be sure to vacuum at all

times. Failure to do so may result in foreign matter sticking to

the adsorption pad, or air leakage causing the workpiece to

drop.

8. Regarding a vacuum switch valve and a vacuum

release valve

If a non-vacuum valve is installed in the middle of piping

system having a vacuum, the vacuum condition will not be

maintained. Use a valve designed for use under vacuum

condition.

9. Ventilation

Provide ventilation when using a valve in a confined area, such

as in a closed control panel. For example, install a ventilation

opening, etc. in order to prevent pressure from increasing

inside of the confined area.

10. Extended periods of continuous energization

・If a valve will be continuously energized for an extended

period of time, the temperature of the valve will increase due to

the heat generated by the coil. This will likely adversely affect

the performance of the solenoid valve and any nearby

peripheral equipment. Therefore, when it is continuously

energized or the energized period per day is longer than the

de-energized period use low power consumption specification,

or continuous energization type..

Also, please contact SMC because depending on the

application, there may be additional valves not mentioned

above that may be used especially in DC specification).

In addition, it is possible to shorten the energized time by

making a valve with an N.O. normally open) specification.

・If valves are mounted on a control panel, please take

measures to release heat so that the temperature would fall

within the temperature specified for the valve.

Please note in particular that the temperature rise will be large

if three or more adjoining valves are continuously energised on

a manifold at the same time for an extended period of time.

11. Do not disassemble the product or ma e any

modifications, including additional machining.

It may cause human injury and/or an accident.

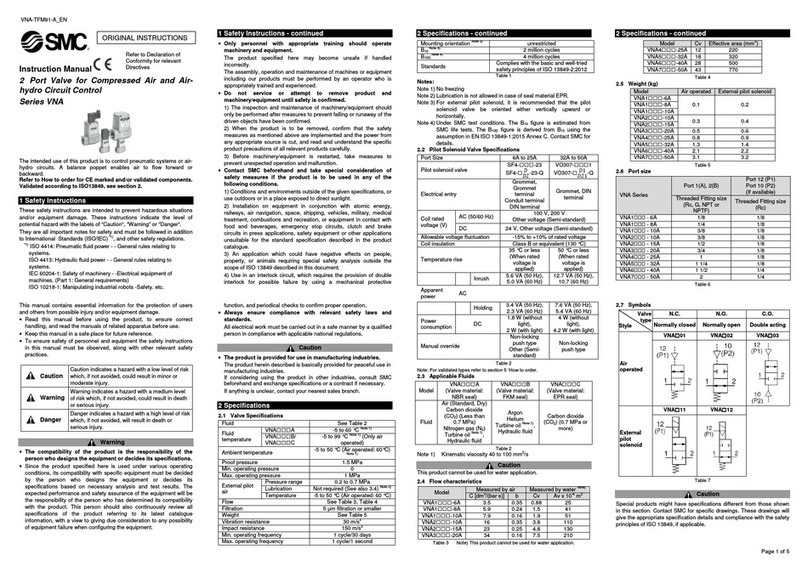

1. Lea age voltage

Take note that the leakage voltage will increase when a

resistor is used in parallel with switching element or a C-R

circuit surge voltage suppressor) is used for protecting a

switching device because of the passing leakage voltage

through the C-R circuit.

The suppressor residual leakage voltage should be as follows.

DC coil 3% or less of rated voltage

AC coil 15% or less of rated voltage

2. Solenoid valve drive for AC with solid state output

(SSR, TRIAC output, etc.)

1) Current lea age

When using a snubber circuit C-R element) for surge

protection of the output, a very small amount of electrical

current will continue to flow even during the OFF state. This

results in the valve not returning. In the a situation where the

tolerance is exceeded, as in the above case, take measures

to install a bleeder resistor.

2) Minimum allowable load amount(Min. load current)

When the consumption current of a valve is less than the

output’s minimum allowable load volume or the margin is small,

the output may not switch normally. Please contact SMC.

3. Surge voltage suppressor

If a surge protection circuit contains nonstandard diodes, such

as Zener diodes or varistor, a residual voltage that is in

proportion to the protective circuit and the rated voltage will

remain. Therefore, take into consideration the surge voltage

protection of the controller. In the case of diodes, the residual

voltage is approximately 1 V.

VT307 Series

Precautions for 3 Port Solenoid Valve

①

①①

①