SMC Corporation EX250-SCN1 Manual

No.EX##-OMJ0001

SI unit for ControlNet

PRODUCT NAME

EX250-SCN1

Model / Series

No. EX##-OMJ0001

Table of Contents

Safety Instructions 2

Model No. of product and how to order 6

Contents of package 6

Description and Function of Each Part 6

Mounting/Installation method 8

Howtoinstall 8

Wiring and connection 9

Setting/Adjustment 13

Setting of address and HOLD/CLEAR of output 13

ControlNet CONFIGURATION WITH RSLogix 5000TM 14

Specification 15

Specification 15

Outline with Dimensions 16

Maintenance procedure 17

Troubleshooting 17

Troubleshooting flow chart 17

Trouble 18

-1-

No. EX##-OMJ0001

Safety Instructions

This SI unit and this manual contains essential information to prevent possible injury and damage to

(users and other people, and property) and to ensure correct handling.

Please confirm understanding the meaning of the following messages (signs) before reading the

remaining the text, and always follow the instructions.

Also carefully read the instruction manual for any relevant equipment or apparatus before use.

Indications

IMPORTANT MESSAGES

Read this manual and follow the instructions. Signal words such as WARNING, CAUTION and

NOTE, will be followed by important safety information that must be carefully reviewed.

Indicates a potentially hazardous situation which could result in death or

serious injury if you do not follow instructions.

Indicates a potentially hazardous situation which if not avoided, may

result in minor injury or moderate injury.

NOTE Gives you helpful information.

Operator

♦This manual has been written for those who have knowledge of machinery and apparatuses

that use pneumatic equipment and have full knowledge of assembly, operation and

maintenance of such equipment.

♦Please carefully read and understand this manual before assembling, operating or performing

maintenance on the SI Unit.

Usage Restrictions

♦This product is designed to be used in general equipment for factory automation. Never use this

product with equipment or apparatus that directly concerns human lives*1, or in which a

malfunction or failure can cause a great loss.

*1:Equipment or apparatus that directly concerns human lives refers to the following:

•Medical equipment such as life support systems or equipment used in operating rooms

•Compulsory equipment required by law such as the Fire Prevention Law, Construction Law

and etc.

•Equipment or apparatus that conforms with those mentioned above.

♦Contact our sales department when plans are made for the product to be used for the system*2

including equipment that concerns itself with the safety of persons or that seriously affects the

public. Such usage requires special consideration*3.

*2:A system or equipment that concerns itself with the safety of persons or that seriously affects

the public refers to the following:

•Nuclear reactor control systems in a nuclear power plants, safety protection systems or other

systems important for safety in nuclear power facility

•Driving control system for a mass transportation system, and flight control systems

•Equipment or apparatuses that comes in contact with foods or beverages

*3:Special consideration refer to discussing usage with our engineers to establish a safe system

designed as fool-proof, fail-safe, redundant and etc.

♦Special consideration*4should be taken regarding safety or maintainability to prevent a failure or

malfunction which can cause a hazard or less. That is likely to occur under certain

environmental stress (deterioration).

*4:Special consideration means to fully review the equipment or apparatus in design stage and

to establish a back up system in advance, such as a redundant system or fail-safe system.

-2-

No. EX##-OMJ0001

1.The compatibility of pneumatic equipment is the responsibility of the person who designs the

pneumatic system or decides its specifications.

Since the products specified here are used in various operating conditions, their compatibility

with the specific pneumatic system must be based on specifications or after analysis and / or

tests to meet your specific requirements.

2.Only trained personnel should operate pneumatically operated machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar with it. Assembly, handling or

repair of pneumatic systems should be performed by trained and experienced operators.

3.Do not service machinery / equipment or attempt to remove components until safety is

confirmed.

•Inspection and maintenance of machinery /equipment should only be performed after

confirmation of safe locked-out control positions.

•When equipment is to be removed, confirm the safety process as mentioned above. Cut the

supply pressure for the equipment and exhaust all residual compressed air in the system.

•Before machinery / equipment is re-started, take measures to prevent quick extensions of the

cylinder piston rod etc. (Bleed air info the system gradually to create back-pressure.)

4.Contact SMC if the product is to be used in any of the following conditions:

•Conditions and environments beyond the given specifications, or if product is used outdoors.

Installation on equipment in conjunction with atomic energy, railway, air navigation, vehicles,

medical equipment, food and beverage, recreation equipment, emergency stop circuits, press

applications, or safety equipment.

•An application which has the possibility of having negative effects on people, property, or

animals, requiring special safety analysis.

♦Do not disassemble, modify (including printed circuit board) or repair.

An injury or failure can result.

♦Do not operate outside of the specification range.

Fire, malfunction or SI unit damage can result.

Please use it after confirming the specification.

♦Do not use the product in environments with possible presence of flammable, explosive or

corrosion gas.

Otherwise fire, explosion or corrosion can result.

The product is not designed to be explosion proof.

♦Do not apply voltage exceeding 250V between a lead wire and a metal fitting.

•Pay attention to perform an insulation test because it could damage an insulation of the lead

wire and accordingly cause failure and generate heat and smoke.

♦These instructions must be followed when using the production in an interlocking circuit:

•Provide double interlocking thorough another system such as mechanical protection

•Check the product regularly to ensure proper operation

Otherwise a malfunction can cause an accident.

♦These instruction must be followed while in maintenance:

•Turn off the power supply

•Stop the air supply, exhaust the residual pressure and verify that the air is released before

performing maintenance work.

Otherwise it can cause injury.

♦Perform proper functional checks after completing maintenance work.

Stop operation when an abnormality is observed or the product is not working properly.

Safety cannot be secured due to unexpected malfunctions.

-3-

No. EX##-OMJ0001

NOTE

♦Follow the instructions given below when handling reduced-wiring system:

Or it will have a risk of being damaged and operating failure.

♦The instructions on selection (installation, wiring, environment of use, adjustment, operation and

maintenance) described below must also be followed.

∗Product specifications

•The direct-current power supply to combine should be UL authorization power supply.

(1)Limited voltage current circuit in accordance with UL508

A circuit which power is supplied by secondary coil of a transformer that meets the following

conditions

. Maximum voltage (with no load) : less than 30Vrms (42.4V peak)

. Maximum current : (1) less than 8A(including when short circuited)

(2) limited by circuit protector (such as fuse) with the following ratings

No load voltage (V peak) Max. current rating (A)

0 to 20 [V] 5.0

Above 20 to 30 [V] 100 / peak voltage

(2)A circuit using max. 30Vrms or less (42.4V peak), which power is supplied by Class-2 power

supply unit in accordance with UL1310 or UL1585

•Operate reduced-wiring system with the specified voltage.

Operation with a voltage beyond specifications could cause malfunction or damage of the unit.

•Reserve a space for maintenance

Be sure to keep a space for maintenance when designing layout of the unit.

•Do not remove nameplate.

Otherwise maintenance error and misreading of an operation manual could cause damage or

malfunction.

It may also result in nonconformity to safety standards.

♦Precautions on handling

∗Installation

•Do not drop, hit or apply excessive shock to the unit.

Otherwise the unit could be damaged so much as to result in.

•Follow the specified tightening torque.

Excessive tightening torque can break screws.

The screw should be tighten with the specified torque, otherwise IP40 protection

can not be guaranteed.

∗Wiring (including plugging in/out of connector)

•Do not bend the cables or apply excessive force to them by pulling or placing heavy load.

Wiring subject to bending or tensile stress could cause the cables to break.

•Connect wires and cables correctly.

Incorrect could wiring break the reduced-wiring system to its extent.

•Do not connect wires while the power is supplied.

Otherwise it can break the reduced-wiring system or I/O devices could be damaged or

malfunction.

•Do not connect power cable or high-voltage cable in the same wiring route as the unit.

Otherwise the wires to the reduced-wiring system can be interrupted with noise or induced

surge voltage from power lines or high-voltage lines and malfunction could be caused.

Separate wiring of the unit and each I/O device from that of power line and high voltage line.

-4-

No. EX##-OMJ0001

•Verify the insulation of wiring.

Insulation failure (interference with other circuit, poor insulation between terminals and etc.)

could introduce excessive voltage or current to the reduced-wiring system or each I/O device and

damage them.

•Separate power line for solenoid valves from power line for input and control unit.

Otherwise wires can be interrupted with noise or induced surge voltage causing malfunction.

•Take proper measurements such as noise filter against noise when the reduced-wiring system

is incorporated in equipment or devices.

Otherwise contamination with noise can cause malfunction.

∗Environment

•Select an operation environment according to enclosure. (IP40)

•Take sufficient shielding measures when the unit is installed.

Insufficient measures could cause malfunction or failure.

Verify the effect of the measures after incorporation of the unit in equipment or devices:

(1) A place where noise due to static electricity is generated

(2) A place where electric field strength is high

(3) A place where there is radioactive irradiation

(4) A place near power line

•Do not use the unit near by a place where electric surge is generated.

Internal circuit elements of the reduced-wiring system can deteriorate or break when equipment

generating a large surge (electromagnetic lifter, high frequency induction furnace, motor, etc.) is

located near the reduced-wiring system. Provide surge preventives, and avoid interference with

line for the equipment.

•Use the reduced-wiring system equipped with surge absorber when a surge-generating load

such as solenoid valve is driven directly.

Direct drive of a load generating surge voltage can damage reduced wiring system.

•Prevent foreign matter such as remnant of wires from entering the unit.

Take proper measures for the remnant not to enter the reduced-wiring system in order to

prevent failure or malfunction.

•Do not expose the reduced-wiring system to vibration and impact.

Otherwise failure or malfunction could be caused.

•Keep the specified ambient temperature range.

Otherwise malfunction could be caused.

Do not use reduced-wiring system in a place where temperature suddenly changes even within

the specified range.

•Do not expose the reduced-wiring system to heat radiation from a heat source located nearby.

Malfunction could be caused.

∗Adjustment and Operation

•Use precision screwdriver with for small flat blade for setting Rotary switch.

∗Maintenance

•Perform maintenance and check regularly.

Otherwise an unexpected malfunction of components could of the unit occur due to a

malfunction of the whole unit.

•Perform a proper functional check.

Stop operation when an abnormality is observed such that the device doesn't work properly.

Otherwise an unexpected malfunction of the unit component can occur.

•Do not use solvents such as benzene, thinner or other to clean the reduced-wiring system.

They could damage the surface of the body and erase the indication on the body.

Use a soft cloth to remove stains. For heavy stains, use a cloth soaked with diluted neutral

detergent and fully squeezed, then wipe up the stains again with a dry cloth.

-5-

No. EX##-OMJ0001

Model No. of product and how to order

Contents of package

Make sure that all the components pictured below are included.

If some components are missing, or different from the ordered ones, please contact SMC sales

representative.

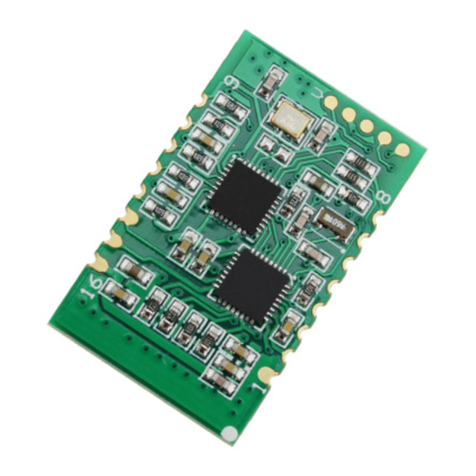

Description and Function of Each Part

Body

•Communication connector

To connect the communication line.

•Power supply connector for output equipment, SI unit and Input block

To supply power to the output equipment such as a solenoid valve, and Output block, SI unit and Input block.

•Output equipment connection connector

To connect the output equipment such as a solenoid valve and Output block.

•Input block connection connector

To connect the Input block.

•Indication and address setting part

To provide the setting of LED to indicate the condition of the unit, address

and hold HOLD/CLEAR.

•Ground terminal

To be connected to the ground.

Accesssory

•Tie rod (2pcs)

They are used for assembly and disassembly.

•Operation manual

Option

•End plate(M3×10(2pcs))

For direct mounting typePart No. : EX250-EA1

DIN rail mounting typePart No. : EX250-EA2

-6-

No. EX##-OMJ0001

LED indication

-7-

No. EX##-OMJ0001

Mounting/Installation method

How to install

The SI unit is not designed to be a standalone device. Always use with solenoid valves or Output blocks.

In addition, if an Input block is not needed, directly connect an endplate to the SI unit

(Part number:EX250-EA1, EX250-EA2).

Example of installation

* The above dimensions show VQC1000 solenoid valve series with EX250 series.

Please note that standard dimensions of L2 are up to 10pcs. Please contact sales representatives if the

dimensions for 11pcs or more are necessary.

See the separate specifications for other solenoid valve and SI unit series.

All wiring (power supply, communication, input and output) and pneumatic piping are connected on one

side.

Please allow for sufficient room when mounting the unit.

-8-

No. EX##-OMJ0001

Wiring and connection

1. Connection

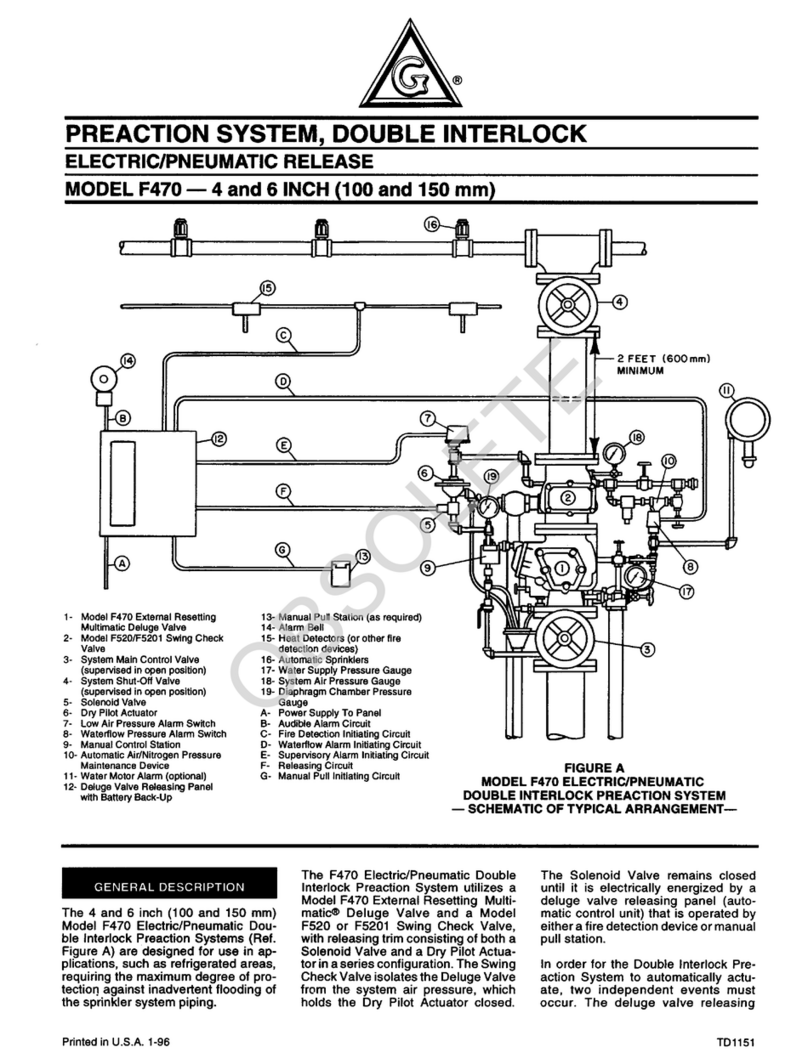

ControlNet network consists of nodes, taps, trunk cables, drop cables and repeaters.

Wiring should be arranged in accordance with ControlNet specifications.

Term Definition

Network A collection of connected nodes

the connection paths between any pair of devices may include repeaters and

bridges.

Link A collection of nodes with unique addresses in the range of 1 to 99.

Segment Trunk-cable sections connected via taps with terminators at each end and with no

repeaters.

Trunk cable The bus or central part of a cable system.

Trunk-cable section A length of a cable between any two taps.

Repeater A two-port active physical layer component that reconstructs and retransmits all

traffic it receives on one segment side to another segment side.

Tap The connection between any device and the ControlNet cable system.

Bridge A device that allows traffic to pass from one link to another link.

Node Any physical device connecting to the ControlNet cable system which requires a

network address in order to function on the network a link may contain a

maximum of 99 nodes.

This address must be in the range of 1-99 and be unique to that link.

Terminator A 75Ωresistor mounted in a BNC plug.

-9-

No. EX##-OMJ0001

Total cable length for segment

A segment is comprised of several sections of trunk cable separated by taps. The total cable length of a

segment is equal to the sum of all of the trunk-cable sections.

The total allowable length of a segment depends upon the number of taps in your segment. There is no

minimum trunk-cable section length requirement. The maximum allowable total length of a segment is 1,000m

(3,280ft.) with two taps connected. Each additional tap decreases the maximum length of the segment by

16.3m (53ft). The maximum number of taps allowed on a segment is 48 with a maximum length of 250m

(820ft.).

Allowable maximum length of segment = 1000m (3280feet) - 16.3m (53.4 feet) x [number of tap - 2]

Example

If your segment requires 10 taps, the maximum segment length is :

1000m (3280ft.)-16.3m (53.4ft.) X [10-2]

1000m (3280ft.)-130.4m (427.7ft.))

= 869.6m (2852.3ft.)

Since the total length of trunk cables or the number of taps may increase if a repeater is installed in a segment,

create one more segment in that case.

* Wiring should be arranged in accordance with Control specifications.

-10-

No. EX##-OMJ0001

2.Connection example

* SMC only provides the SI unit and the power cable. Please refer to other manufactures for additional parts

needed.

3. Power supply wiring

The power supply connector features two independent electrical circuits, one for the output devices

and one for the SI unit / Input blocks. Both, a single or two individual power supplies can be used.

See schematic below.

* In case of single power supply, apply power supply voltage within a specified value.

-11-

No. EX##-OMJ0001

SW power supply is applied to the sensor connected to the Input block. Since a maximum of approx. 1V

voltage may drop in the unit, select a sensor considering the voltage drop. If 24V needs to be supplied by any

means, SW power supply voltage should slightly be increased in order to maintain the sensor voltage at 24V

with the actual load applied (allowable voltage of SW power supply ranges from 19.2 to 28.8V).

-12-

No. EX##-OMJ0001

Setting/Adjustment

Setting of address and HOLD/CLEAR of output

The setting for the address and HOLD/CLEAR of output can be performed with 2 rotary switches and 1 DIP

switch located under the cover.

Address setting

Each address is assigned to the unit with an

address setting switch. The address is set

using two rotary decimal switches. The setting

range is from 1 to 99 (decimal). At the time of

shipment from the factory, the address is set to

“00” as shown in the above figure.

HOLD/CLEAR setting

The HOLD/CLEAR of output setting

is performed with the HOLD/CLEAR

setting switch. The setting value is

obtained from the following table.

At the time of shipment from the factory, the default setting is “0”, which means “CLEAR” is selected.

*Be sure to turn off the power supply when any setting is performed in the SI unit.

I/O mapping

I/O memory map of SI unit is stated as below.

Input Data

MSB LSB

(n=0)

15 7

Word(n) I15 I14 I13 I12 I11 I10 I9 I8 I7 I6 I5 I4 I3 I2 I1 I0

Word(n+1) I31 I30 I29 I28 I27 I26 I25 I24 I23 I22 I21 I20 I19 I18 I17 I16

Word(n+2) Reserve DI_CHK DO_CHK Reserve

Output Data

MSB LSB

(n=0)

15 7

Word(n) O15 O14 O13 O12 O11 O10 O9 O8 O7 O6 O5 O4 O3 O2 O1 O0

Word(n+1) O31 O30 O29 O28 O27 O26 O25 O24 O23 O22 O21 O20 O19 O18 O17 O16

* In general, the SI unit possesses 6byte for input and 4byte for output, and can monitor the following status.

DI_CHK: Over current status from Input block. (When over current is detected, to be “0” state. Usually it is ”1”.)

DO_CHK: Solenoid valve power status. (When power is down (around 19V or less), to be “0” state. Usually, it is “1”.)

-13-

No. EX##-OMJ0001

ControlNet CONFIGURATION WITH RSLogix5000TM

When setting up the node with RSLogix5000, specific values must be entered for

the assembly instance with regards to Input, Output and Configuration.

Please see the diagram below for a Rockwell Automation’s RSLogix5000 programming software

example.

Connection Parameter

Assembly Instance values:

Description Decimal (Hex)

Input 6 (6h)

Output 36 (24h)

Configuration 1 (1h)

Size:

Description Size

Input 3 words

Output 2 words

Configuration 0 word

Comm Format:

Description Data

Comm Format “Data - INT”

-14-

No. EX##-OMJ0001

Specification

Specification

General specification

Item Specification

Operating ambient temp. +5 to +45°C

Storage ambient humidity 35 to 85%RH (No condensation)

Storage ambient temp. -20 to 60°C

Vibration proof 10 to 57Hz 0.35mm (Constant amplitude)

57 to 150Hz 50m/s2(Constant acceleration)

Impact proof 150m/s2 (peak), 11ms x three times in each direction +/- X, Y and Z.

Withstand voltage 500VAC for 1min. Between body and external terminals.

Insulation resistance 500VDC 10M ohm or more. Between body and external terminals.

Operating environment No corrosive gas

Weight 250g or less

Enclosure IP40

Network specification

Item Specification

Applicable system ControlNet Version 2.0 Errata 3 adapter class

Address setting range 1 to 99 (Setting by rotary switch)

Communication speed 5Mbps fixed

Network update time (NUT) Min. 2ms applicable

Device Type 7 (General Purpose Discrete I/O)

Product code 2501

Revision Refer to EDS file

Vendor ID 7

Consumed I/O connection size 4 bytes

Produced I/O connection size 6 bytes

Support Message Cyclic I/O Message, CIP Message

Redundancy media Not provided

Electrical specification

Item Specification

Power supply for SI unit/Input block 24VDC ±20%

Power supply

voltage Power supply for output equipment 24VDC

Current consumption 100mA Max. *1

Input point 32 points

Input type TTL

Connected input equipment Input block *3

Input block supply voltage 24VDC ±20%

Input spec.

Block supply current Total 1A Max.

Output points 32 points

Output type N-ch MOS-FET High side switch (PNP output)

Connected output equipment Solenoid valve (24VDC, 1.5W or less, With light

surge suppressor), Output block

Output block supply voltage 24VDC ±10%

Residual voltage 0.3V or less

Output spec.

Load current consumption *2 Total 2A Max.

*1: Current consumption by SI unit internal power supply.

*2: Maximum load current supplied by output equipment power supply.

*3: See the following table for the applicable blocks.

-15-

+10%

−5

%

No. EX##-OMJ0001

Input/Output block

Part No. Remark

Input component EX250-IE1 M12 connector, 2-input

Input component EX250-IE2 M12 connector, 4-input

Input component EX250-IE3 M8 connector, 4-input

Output component EX9-OET1 M12 connector, PNP output (-COM), For low watt

Output component EX9-OEP1 M12 connector, PNP output (-COM), For high watt

Output component EX9-PE1 M12 connector, Power block

Applicable solenoid valve series

Valve series Type

VQC VQC1000*1, VQC2000*1, VQC4000

SV SV1000, SV2000, SV3000

*1 : Negative common valve only

Outline with Dimensions

-16-

No. EX##-OMJ0001

Maintenance procedure

How to replace SI unit

•Remove screws mounted on the endplate, and separate it from the valve unit.

•Replace the SI unit (Tie rods should not be removed).

Mount the removed endplate, and tighten it with the same screws with a specified tightening torque.

(0.6N⋅m)

Precautions on maintenance

(1) Be sure to check that all the power supply is turned off.

(2) Foreign substances shall not be intruded in the unit.

(3) Foreign substances or scratches shall not be present on the gasket.

(4) Screws shall be tightened with a specified tightening torque.

If they are not set properly, it will lead to board failure, or liquid and or dust might be intruded in the unit.

How to assemble and disassemble SI unit

Troubleshooting

Troubleshooting flow chart

If a SI unit malfunctions, select the specific trouble with the flow chart stated below.

-17-

No. EX##-OMJ0001

Trouble

Trouble No.1

Trouble Possible cause Investigation method of cause Remedy

Wrong wiring of

power supply for

communication

Check that wiring of power supply for

communication and connector are not

loosened.

Connect

them properly.

RWR lights off Failure of power

supply for

communication

Check the status of power supply for

communication.

Apply DC26.5 to 31.6V of

power supply voltage for

communication.

Trouble No.2

Trouble Possible cause Investigation method of cause Remedy

AUX lights off Failure of power

supply for output

Check the status of power supply for

output

Apply DC24V+10%/-5% of

power supply voltage for

output.

Trouble No.3

Trouble Possible cause Investigation method of cause Remedy

COM-ERR lights up Communication error

•Check components that generate

noise in the peripheral of

communication line, and if high

voltage lines exist.

•Check communication line between

PLC and SI unit is properly

connected.

- Keep the communication

line away from the noise

source.

- Master setting

- Properly set the master

unit.

Trouble No.4

Trouble Possible cause Investigation method of cause Remedy

RWR and AUX light

up and COM-ERR

lights off

Address setting error Check address setting. Set the proper address.

-18-

No. EX##-OMJ0001

Revision history

URL http://www.smcworld.com

Phone

AUSTRIA / (43) 2262-62 280 ITALY / (39) 02-92711

BELGIUM / (32) 3-355 1464 NETHERLANDS / (31) 20-531 8888

CZECH REP. / (420) 5-414 24611 NORWAY / (47) 67 12 90 20

DENMARK / (45) 70 25 29 00 POLAND / (48) 22-548 50 85

FINLAND / (358) 9-859 580 PORTUGAL / (351) 2 610 89 22

FRANCE / (33) 1-64 76 1000 SPAIN / (34) 945-18 4100

GERMANY / (49) 6103 4020 SWEDEN / (46) 8-603 0700

GREECE / (30) 1- 342 6076 SWITZERLAND / (41) 52-396 3131

HUNGARY / (36) 1-371 1343 TURKEY / (90) 212 221 1512

IRELAND / (353) 1-403 9000 UNITED KINGDOM / (44) 1908-56 3888

Note: Please acknowledge that this content might change without a previous notice beforehand.

Each company might be using the name of the commodity of this manual publishing respectively as a trademark.

2004 SMC Corporation All Rights Reserved

Table of contents

Other SMC Corporation Control Unit manuals

SMC Corporation

SMC Corporation EX260-SIL1-X207 User manual

SMC Corporation

SMC Corporation VNA1 series User manual

SMC Corporation

SMC Corporation IL211 Series User manual

SMC Corporation

SMC Corporation VT315 User manual

SMC Corporation

SMC Corporation EX260-SPN1 User manual

SMC Corporation

SMC Corporation IL201 series User manual

SMC Corporation

SMC Corporation ASP-X369 Series User manual

SMC Corporation

SMC Corporation VT307 Series User manual