SME M2-9R Series User manual

The best pick

-

up arm in the world

INSTRUCTIONS

SERIES M2 MODELS M2

-

9R & M2

-

12R

SERIES M2-9R & M2-12R

INSTRUCTIONS

2

Introduction

SME is an iconic brand founded in 1946 by audio

legend Alastair Robertson-Aikman in West Sussex,

England. Today SME is recognised as makers of

the nest precision turntables and tonearms in

the world. Entirely made in-house by state of the

art manufacturing processes, complemented by

traditional craftsmanship methods.

SME audio has evolved from 75 years of engineering

excellence, innovation and perfection delivering

precise and pure audio reproduction.

The SME M2-9R and M2-12R tonearms are of

meticulous build quality with all the most important

features including lightweight stainless steel tonearm

tube, detachable aluminium headshell with double

draw pins for extra rigidity and azimuth adjustment,

tungsten balance weight, high quality ball race

bearings in all planes and a level of stiffness to suit

a wide range of cartridges.

3

Contents

Page

2 Introduction

4 General Arrangement

5 Dimensions

6 Specications

7 Packing List

8 Parts Identication

9 Preparing Mounting Board

10 Fitting the Tonearm

11 Audio Lead

12 Fitting the Cartridge

13 Fitting the Headshell

14 Longitudinal Balance

15 Vertical Tracking Force (VTF) Adjustment

16 Arm Height (VTA) Adjustment

17 Azimuth Adjustment

18 Horizontal Tracking Angle (HTA) Adjustment

19 Positioning the Armrest

20 Anti-skate Adjustment

21 Operation

22 Adjusting and Cleaning the Arm Lift

23 Appendix

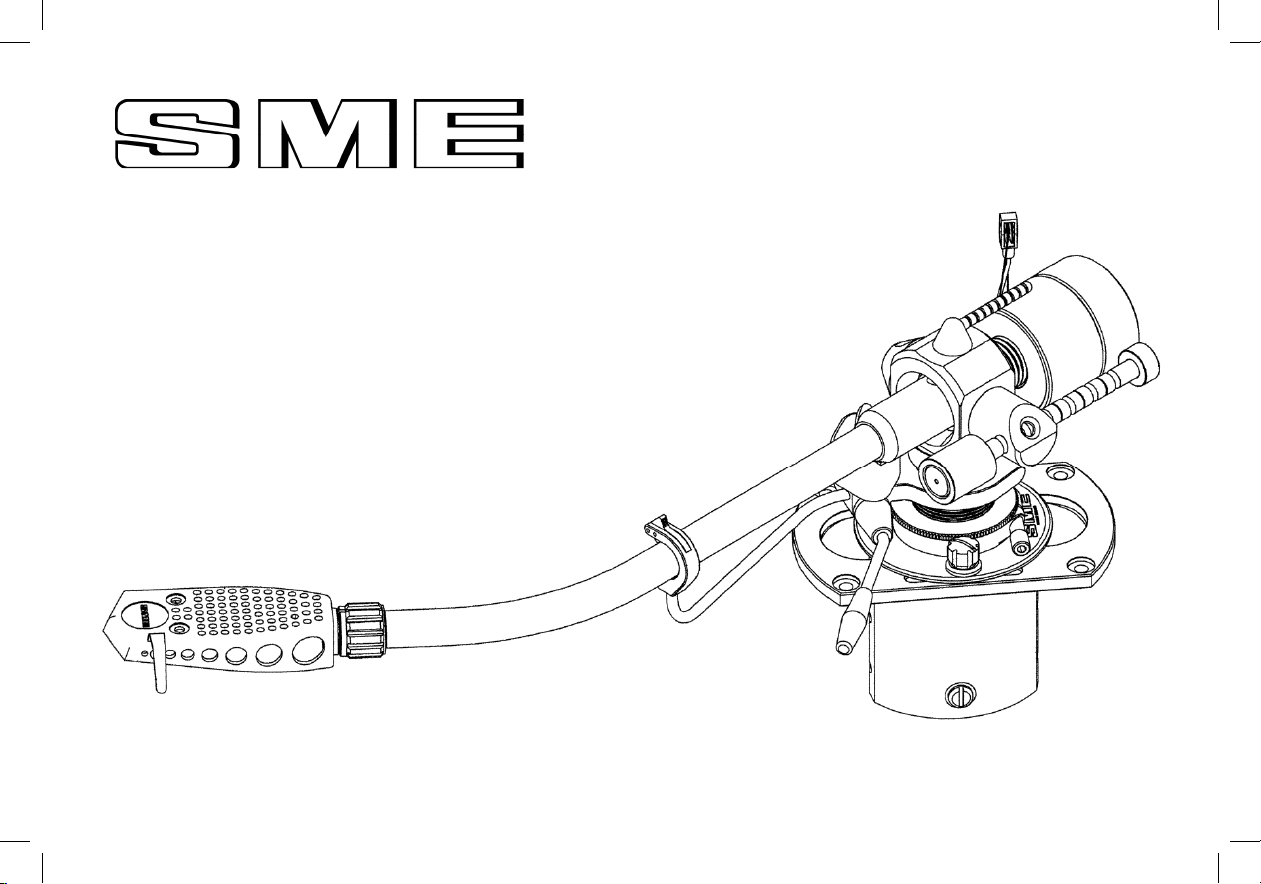

General Arrangement

4

4

General Arrangement

5

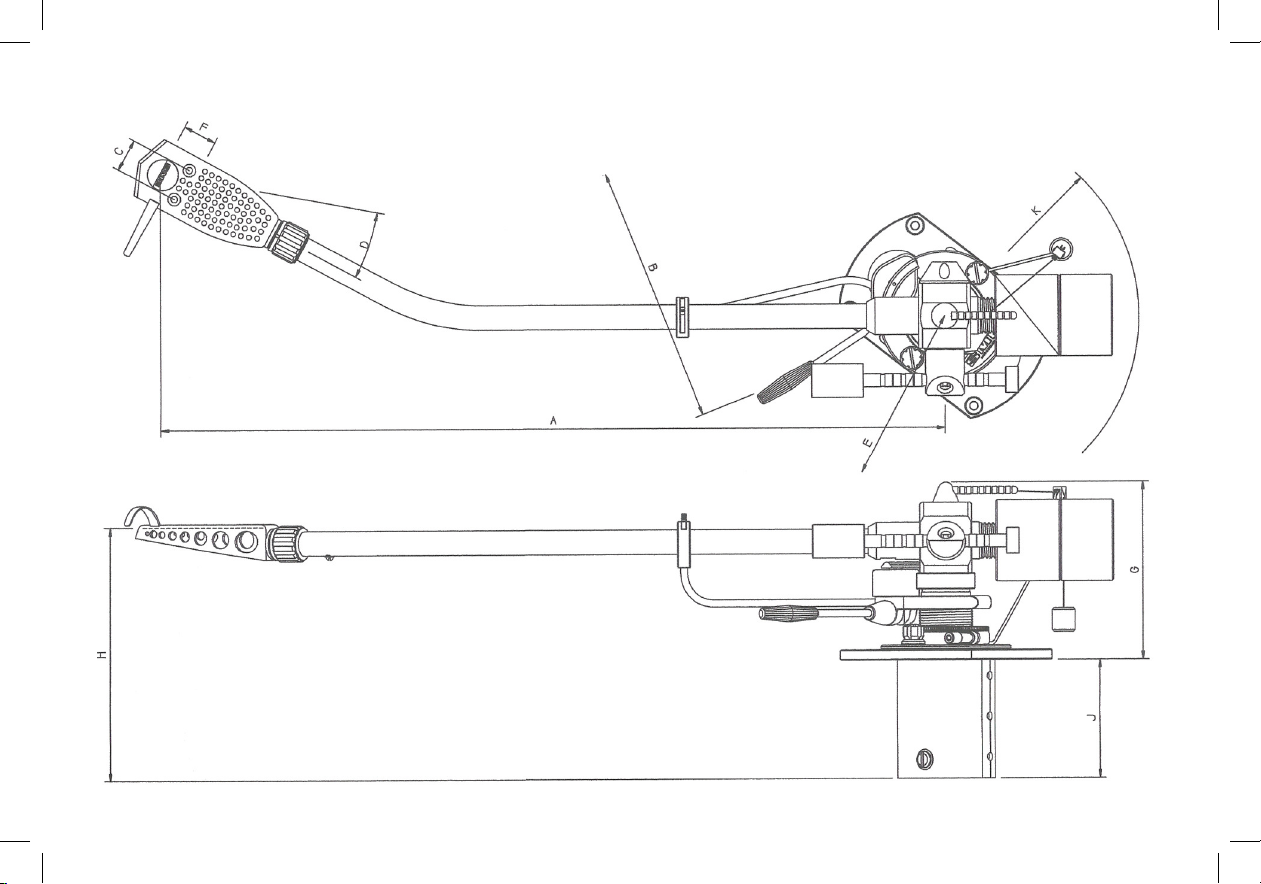

Dimensions

M2-9R M2-12R

A - Pivot to Stylus 233.20 308.81

B - Pivot to Turntable Centre 215.40 295.60

C - Cartridge Fixing Centres 12.70 12.70

D - Offset Angle 23.63º 17.62°

E - Linear Offset 93.47 93.47

F - Overhang 17.80 13.21

G - Height above Mounting Surface 87.00 max 87.00 max

63.00 min 63.00 min

H - Mounting Surface to Underside of Headshell 67.40 max 67.40 max

43.40 min 43.40 min

J - Depth below Mounting Surface 46.00 46.00

K - Balance Weight Radial Clearance 79.00 85.00

6

Specications

M2-9R M2-12R

Effective Mass 9.5g 18g

Cartridge Balance Range

Headshell: up to 38g 38g

Plug-heads: up to 46g 46g

Vertical Tracking Force (VTF) 5g 5g

Maximum Tracking Error (degree/mm) 0.013mm 0.010mm

Null Points: Inner (mm radii) 66.04mm 66.04mm

Outer (mm radii) 120.9mm 120.90mm

Weight, net (g) 735mm 834mm

Audio Lead: 1.2m long balanced hybrid cable

with gold plated phono plug

connections to amplier and

independent ground system

Internal Wiring: Silver Litz

Output: RCA Phono

7

Packing List

Series M2-9R or M2-12R Precision Tonearm

Detachable Headshell

Instruction Book

Mounting Template

Alignment Protractor

Headshell Hardware……… Cartridge Screws/Nuts (alloy)

2mm Hex Wrench

0.89mm Hex Wrench

Mounting Hardware……… Set of M3 x 20mm Button Head Screws

4 Nuts and 4 Washers

4 Tonearm Mounting Washers

2.5mm Hex Wrench

Audio Lead

Bias Weight

Bias Guide

Guarantee Card

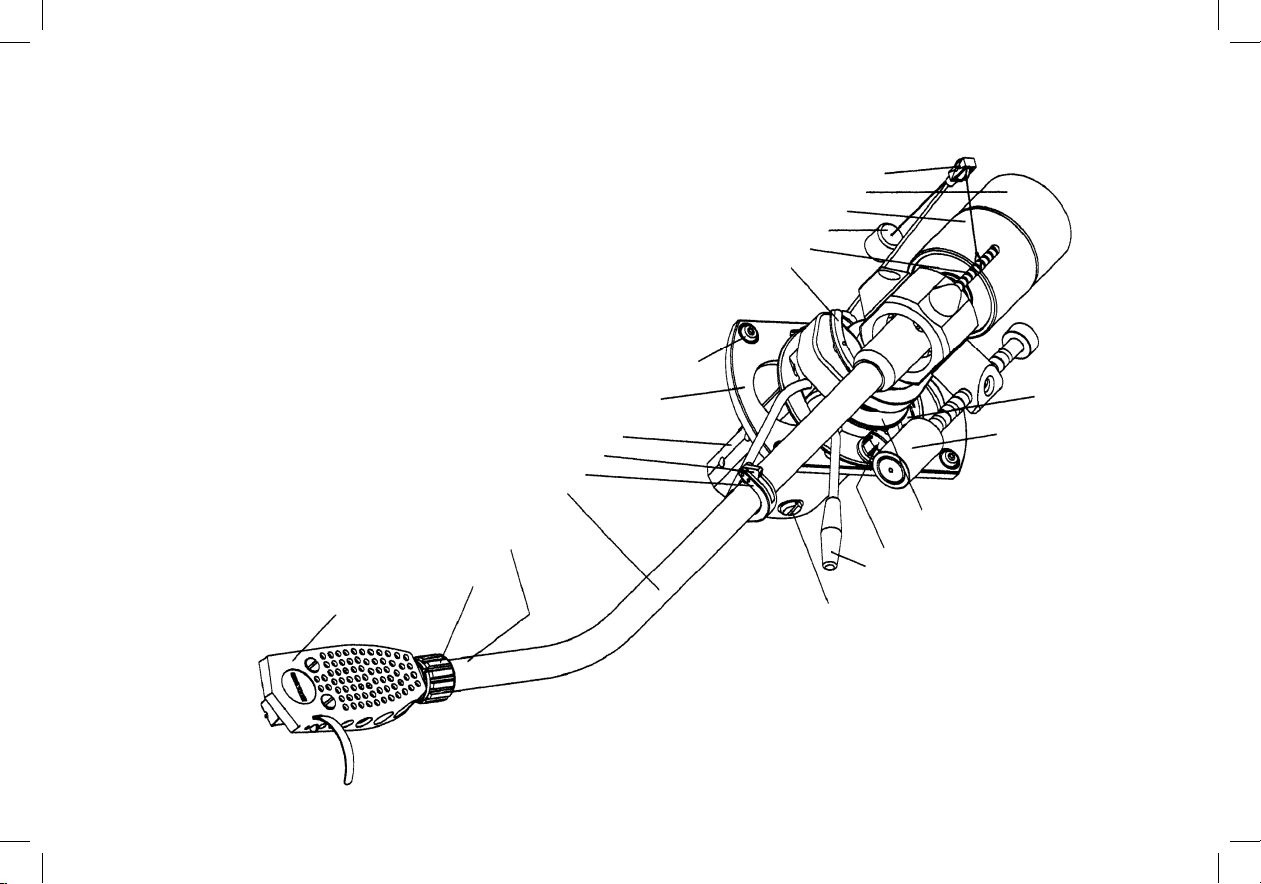

Parts Identification

Anti

-Skate Guide

Accessory Balance Weight

Balance Weight

Anti

-Skate Weight

Anti

-Skate Lever

Arm Lift

M3 Button Head Mounting Screw

& Arm Mounting Washer

Bedplate

Shield Can

Arm Rest Catch

Arm

Rest

Tonearm

Azimuth Locking Screw

underside tonearm at this point

Arm Socket Nut

Detachable Headshell

Ground Terminal

Control Lever

Base Clamp Nut & Washer

VTA Thumbwheel

Wayrod/Rider Weight

Pillar Clamp Screw

8

Parts Identication

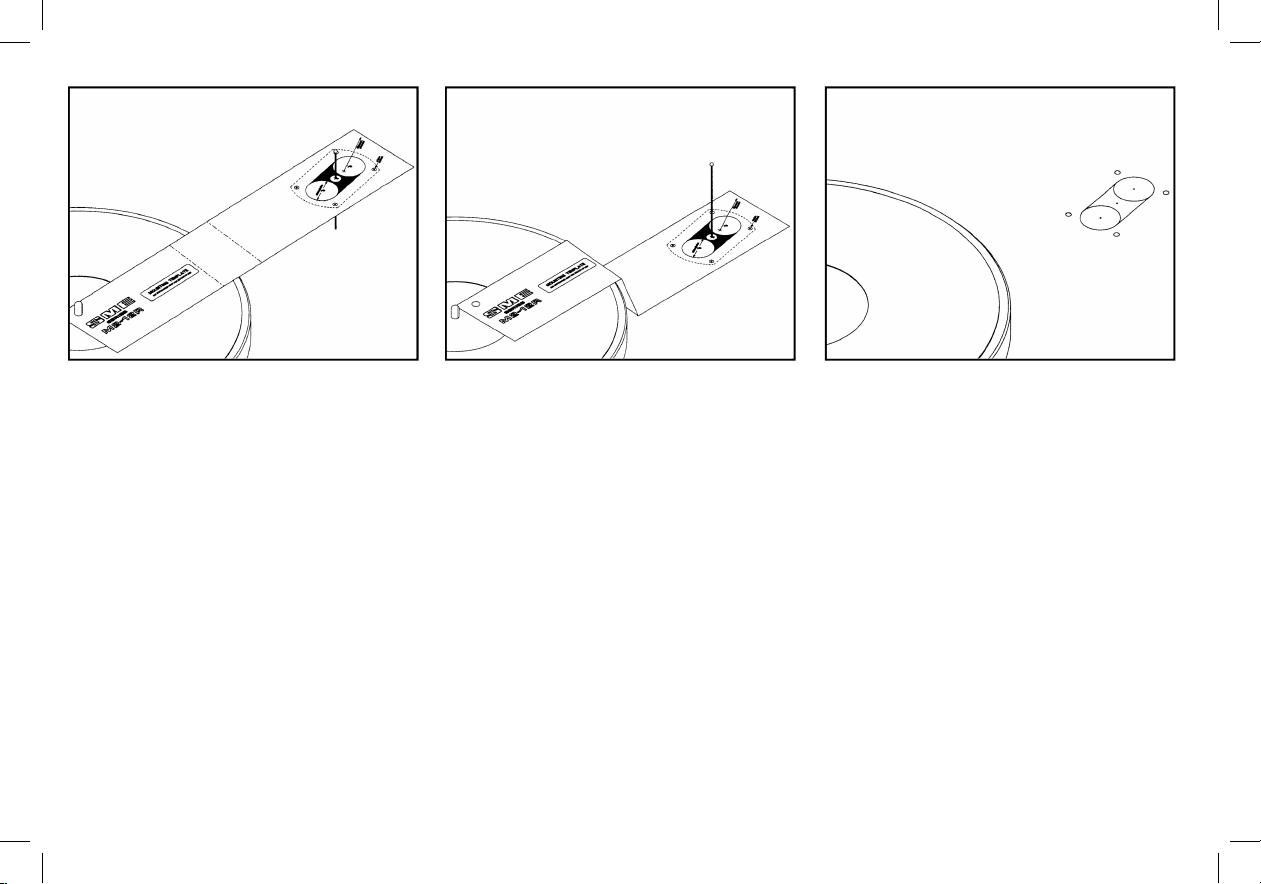

912/101 Preparing the arm mounting Board

Where the deck is not already cut to accept an

SME arm, it will need to be prepared as follows:

Pierce the centre point A of the mounting

template to accept a pin or needle about 50mm

long. Place the template on the record spindle

and keeping it parallel with the surface on which

the arm will be mounted pass the pin vertically

through the centre point A and spike it into the

pick-up arm mounting board.

912/102

Disengage the template from the spindle and

maintaining the same alignment slide it down the

pin and onto the mounting board. This will

position the base for maximum effective

movement when adjusting the horizontal

tracking angle (HTA), see 125. Anti-clockwise

rotation from this position up to approximately

40° can be made to meet individual needs but is

not critical provided that the requirements of the

alignment protractor can be satisfied. Note that

the rear overhang requires a 51mm radial

clearance from the point shown on the template.

912/103

Using a scriber or a compass point, spike

through the centre points B and centres of the

four fixing holes. Remove the template and mark

two Ø28mm circles about the points B already

centred. Join these together tangentially with

two parallel lines to complete marking out.

Drill four Ø4mm fixing holes and two Ø28mm

holes. Cut away the remaining area to form a

slot and finish the edges with a file and

glasspaper. If a hole saw is not available chain

drill a series of small holes around the inside of

the line, saw and file out.

With suitable tools and technique the procedure

is similar for materials other than wood.

9

9

Preparing the Mounting Board

Where the deck is not already cut to accept an

SME tonearm, it will need to be prepared

as follows:

Pierce the centre point A of the mounting

template to accept a pin or needle about 50mm

long. Place the template on the record spindle

and keeping it parallel with the surface on which

the arm will be mounted pass the pin vertically

through the centre point A and spike it into the

tonearm mounting board.

Disengage the template from the spindle and

maintaining the same alignment slide it down the

pin and onto the mounting board. This will position

the base for maximum effective movement

when adjusting the horizontal tracking angle

(HTA). Anti-clockwise rotation from this position

up to approximately 40° can be made to meet

individual needs but is not critical provided that

the requirements of the alignment protractor can

be satised. Note that the rear overhang requires

a 51mm radial clearance from the point shown on

the template.

Using a scriber or a compass point, spike

through the centre points B and centres of the

four xing holes. Remove the template and mark

two Ø28mm circles about the points B already

centred. Join these together tangentially with two

parallel lines to complete marking out.

Drill four Ø4mm xing holes and two Ø28mm

holes. Cut away the remaining area to form a slot

and nish the edges with a le and glasspaper.

If a hole saw is not available chain drill a series

of small holes around the inside of the line, saw

and le out.

With suitable tools and technique the procedure is

similar for materials other than wood.

912/104 Fitting the arm

Remove the inner base clamp nut and base

clamp washer. Pass the loop at the lower end

of the anti-skate guide over the base clamp bolt

and fit the base clamp washer. Ensure that the

loop on the anti-skate guide is fitted into the

counterbore in the underside of the washer and

the slot is aligned with the anti-skate guide.

Replace the base clamp nut and tighten, lightly.

912/105

Fit a mounting washer to each of the four

counterbores in the upper surface of the

bedplate.

912/106

Position the arm on the mounting board and

insert the M3 button head screws into the holes.

If the holes are not tapped M3 to accept the

screws directly, it will be necessary to fit the nuts

and washers under the board. Tighten fully

using the 2.0mm A/F wrench.

10

10

Fitting the Tonearm

Remove the inner base clamp nut and base

clamp washer. Pass the loop at the lower end of

the anti-skate guide over the base clamp bolt and

t the base clamp washer. Ensure that the loop on

the anti-skate guide is tted into the counterbore

in the underside of the washer and the slot is

aligned with the anti-skate guide. Replace the

base clamp nut and tighten, lightly.

Fit a mounting washer to each of the four

counterbores in the upper surface of the bedplate.

Position the tonearm on the mounting board and

insert the M3 button head screws into the holes. If

the holes are not tapped M3 to accept the screws

directly, it will be necessary to t the nuts and

washers under the board. Tighten fully using the

2mm wrench.

11

NOTE:

Connection should be made between

the ground terminals of the deck and

pre-amp unless a path already exists.

GND

GND

MC HEAD AMPLIFIER

/TRANSFORMER

PRE-AMPLIFIER

/CONTROL UNIT

L PHONO R

L PHONO R

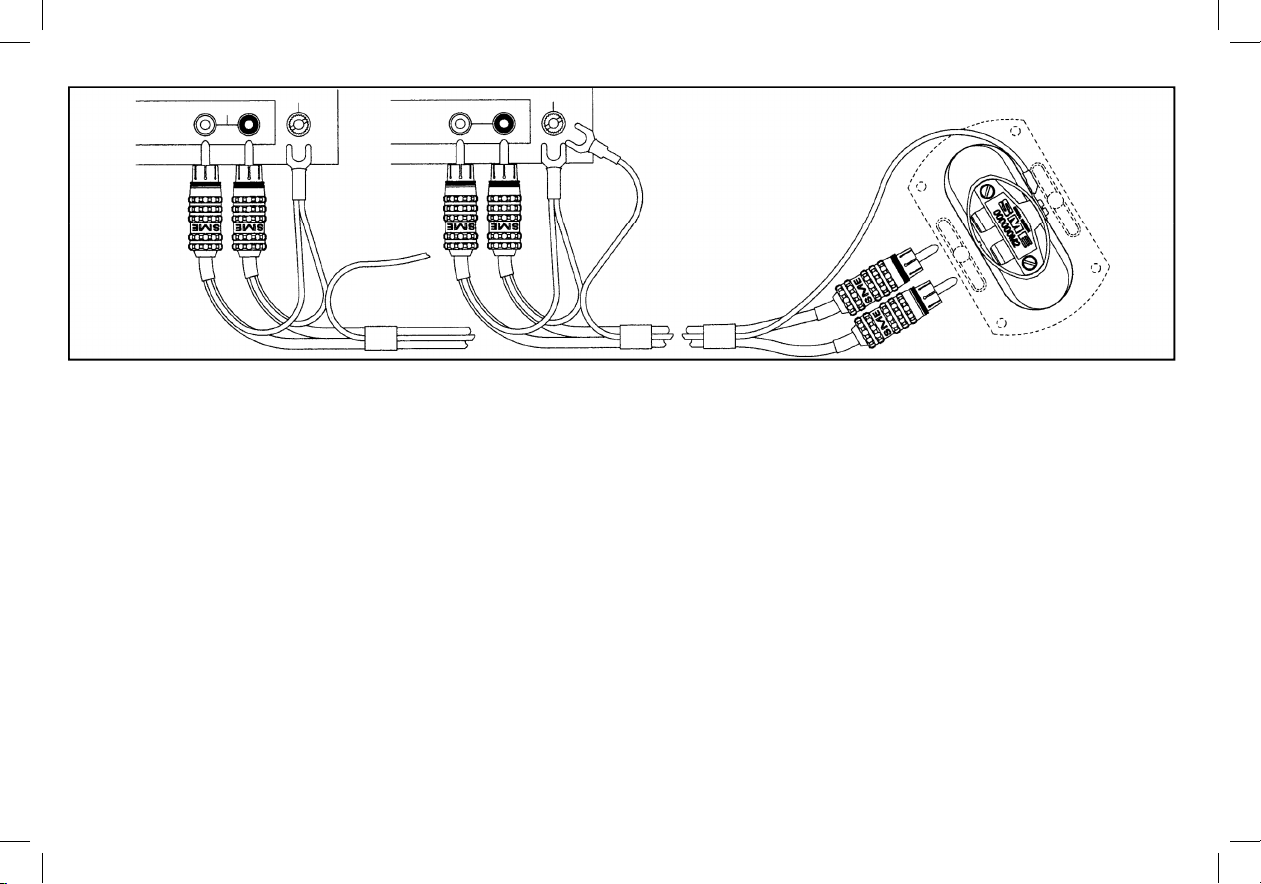

912/107 Audio Lead

The illustration shows use with and without a head amp/transformer and phono plug connections should be made accordingly.

Connect the ground wire serving the arm to the pre-

amp ground, and those from the rear of the phono plugs to the ground terminal on the piece of

equipment to which these plugs are connected.

If the turntable has a ground terminal, it too should be connected to the pre-amp ground, provided it is not already grounded by another path.

The system has been designed for a high signal to noise ratio and if this is not achieved multiple ground paths or the over p

roximity of mains equipment will

be likely causes. Some cartridges have an external foil tag connecting the right channel ground terminal to the cartridge body. For use in

a metal shell it will

be necessary to remove this with a small pair of tweezers or the point of a blade, lifting the tag off over

the terminal pin. If this is not done a ground loop

may be formed, causing hum on the right channel.

CONNECT TO PRE-

AMPLIFIER

GROUND

11

Audio Leads

The illustration shows use with and without a head amp/transformer and phono plug connections should be made accordingly.

Connect the ground wire serving the tonearm to the pre-amp ground and those from the rear of the phono plugs to the ground terminal on the piece of

equipment to which these plugs are connected.

If the turntable has a ground terminal, it too should be connected to the pre-amp ground, provided it is not already grounded by another path.

The system has been designed for a high signal to noise ratio and if this is not achieved multiple ground paths or the over proximity of mains equipment will

be likely causes. Some cartridges have an external foil tag connecting the right channel ground terminal to the cartridge body. For use in a metal shell it will

be necessary to remove this with a small pair of tweezers or the point of a blade, lifting the tag off over the terminal pin. If this is not done a ground loop may

be formed, causing hum on the right channel.

912/108 Fitting the cartridge

See 912/113 - Removing the headshell.

Before fitting the cartridge see that the stylus

guard (not illustrated) is in position as a

precaution against accidental damage.

The cartridge leads have Ø1.2mm receptacles

to suit the cartridge. These may require

adjustment with pliers or a screwdriver blade for

a snug fit on non-standard terminals.

Connections to the cartridge must never be

made by direct soldering.

The coding is as follows:

Red - right channel signal

Green - right channel signal ground

White - Left channel signal

Blue - Left channel signal ground

912/109

Most cartridges are supplied with their own

screws. We provide one pair #3-48 UNC x 11mm

with nuts and washers, other lengths are

available direct.

912/110

Examine the top of the cartridge. It is important

that it presents a good flat face to the underside

of the headshell. Before final tightening check

that the cartridge is lying parallel to the

reference edge of the headshell, as shown.

Tighten the fixing screws securely using a

screwdriver, which must be a good fit in the

screw slots to avoid damage. Hold the nut if

necessary to prevent rotation.

The screws are non-magnetic. Damage can be

caused if a screw is snatched by magnetic

attraction whilst being offered up to the

cartridge. For the same reason do not lay down

tools nearby.

12

12

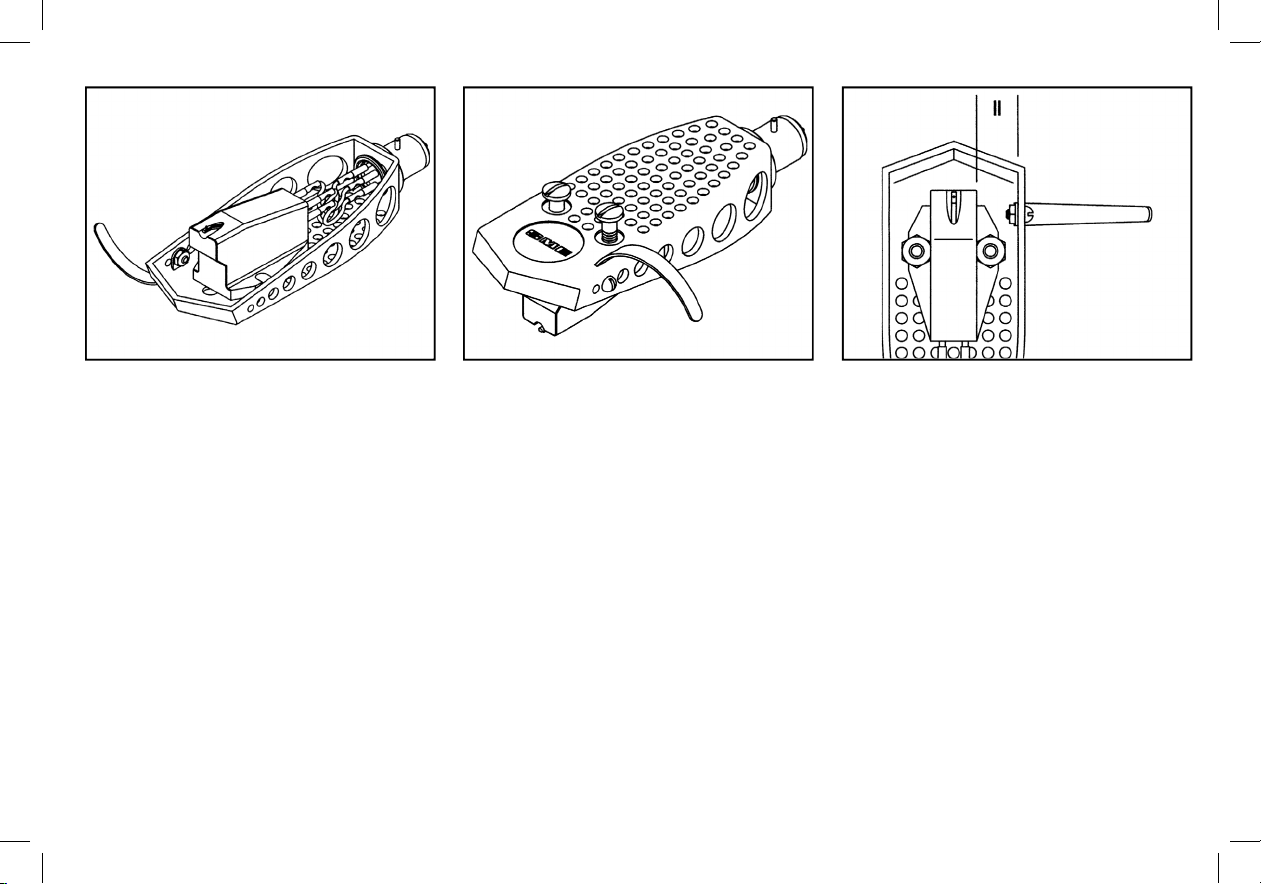

Fitting the Cartridge

Before tting the cartridge see that the stylus

guard (not illustrated) is in position as a precaution

against accidental damage.

The cartridge leads have Ø1.2mm receptacles to

suit the cartridge.

The coding is as follows:

Red - Right Channel Signal

Green - Right Channel Signal Ground

White - Left Channel Signal

Blue - Left Channel Signal Ground

Most cartridges are supplied with their own

screws. We provide one pair #3-48 UNC x

11mm with nuts and washers, other lengths are

available from SME.

Examine the top of the cartridge. It is important

that it presents a good at face to the underside

of the headshell. Before nal tightening check that

the cartridge is lying parallel to the reference edge

of the headshell, as shown.

Tighten the xing screws securely using a

screwdriver, which must be a good t in the screw

slots to avoid damage. Hold the nut if necessary

to prevent rotation.

The screws are non-magnetic. Damage can

be caused if a screw is snatched by magnetic

attraction whilst being offered up to the cartridge.

For the same reason do not lay down tools nearby.

912/111 Cartridge lead replacement

The cartridge leads. Part No. 1806, can be

replaced and may be obtained from your dealer

or direct.

They should be fitted according to the colour

coding shown looking onto the shell from the

front.

912/112 Fitting the headshell

Insert the S2-R headshell into the arm socket

and press firmly inwards until the draw pins

contact the thread of the socket nut. Maintaining

pressure, turn the socket nut anti-clockwise

viewed from the front to draw the headshell

home. It should be tightened firmly but not to the

point of strain.

912/113 Removing the headshell

Removal is the reverse of fitting. Holding the

headshell firmly to prevent rotation turn the

socket nut, clockwise when viewed from the

front, until the headshell is completely released.

Take care to avoid damaging the cartridge

during this operation.

13

WHITE

BLUE

GREEN

RED

912/111 Cartridge lead replacement

The cartridge leads. Part No. 1806, can be

replaced and may be obtained from your dealer

or direct.

They should be fitted according to the colour

coding shown looking onto the shell from the

front.

912/112 Fitting the headshell

Insert the S2-R headshell into the arm socket

and press firmly inwards until the draw pins

contact the thread of the socket nut. Maintaining

pressure, turn the socket nut anti-clockwise

viewed from the front to draw the headshell

home. It should be tightened firmly but not to the

point of strain.

912/113 Removing the headshell

Removal is the reverse of fitting. Holding the

headshell firmly to prevent rotation turn the

socket nut, clockwise when viewed from the

front, until the headshell is completely released.

Take care to avoid damaging the cartridge

during this operation.

13

WHITE

BLUE

GREEN

RED

13

Cartridge Lead Replacement

The cartridge leads can be replaced and are

available from SME.

They should be tted according to the colour

coding shown looking onto the headshell from the

front.

Fitting the Headshell

Insert the headshell into the tonearm socket and

press rmly inwards until the draw pins contact

the thread of the socket nut. Maintaining pressure,

turn the socket nut anti-clockwise viewed from the

front to draw the headshell home. It should be

tightened rmly but not to the point of strain.

Removing the Headshell

Removal is the reverse of tting. Holding the

headshell rmly to prevent rotation turn the socket

nut, clockwise when viewed from the front, until

the headshell is completely released.

Take care to avoid damaging the cartridge during

this operation.

912/114 Longitudinal balance

With only the main balance weight fitted,

cartridges up to 16g may be balanced. However

by removing the balance weight end cap and

coupling the accessory balance weight (as

illustrated) cartridges up to 38g, mounted in the

S2-R headshell or plug in heads up to 46g can

be catered for.

Slide the wayrod/rider weight into the rearmost

zero position and balance the arm by rotating

the balance weight in the required direction.

Remove the accessory balance weight, when

needed, by unscrewing anti-clockwise from the

balance weight. Replace the balance weight

end cap.

14

12/115

Adjust until the arm, with the cartridge fitted,

is either level or slightly low at the front end.

14

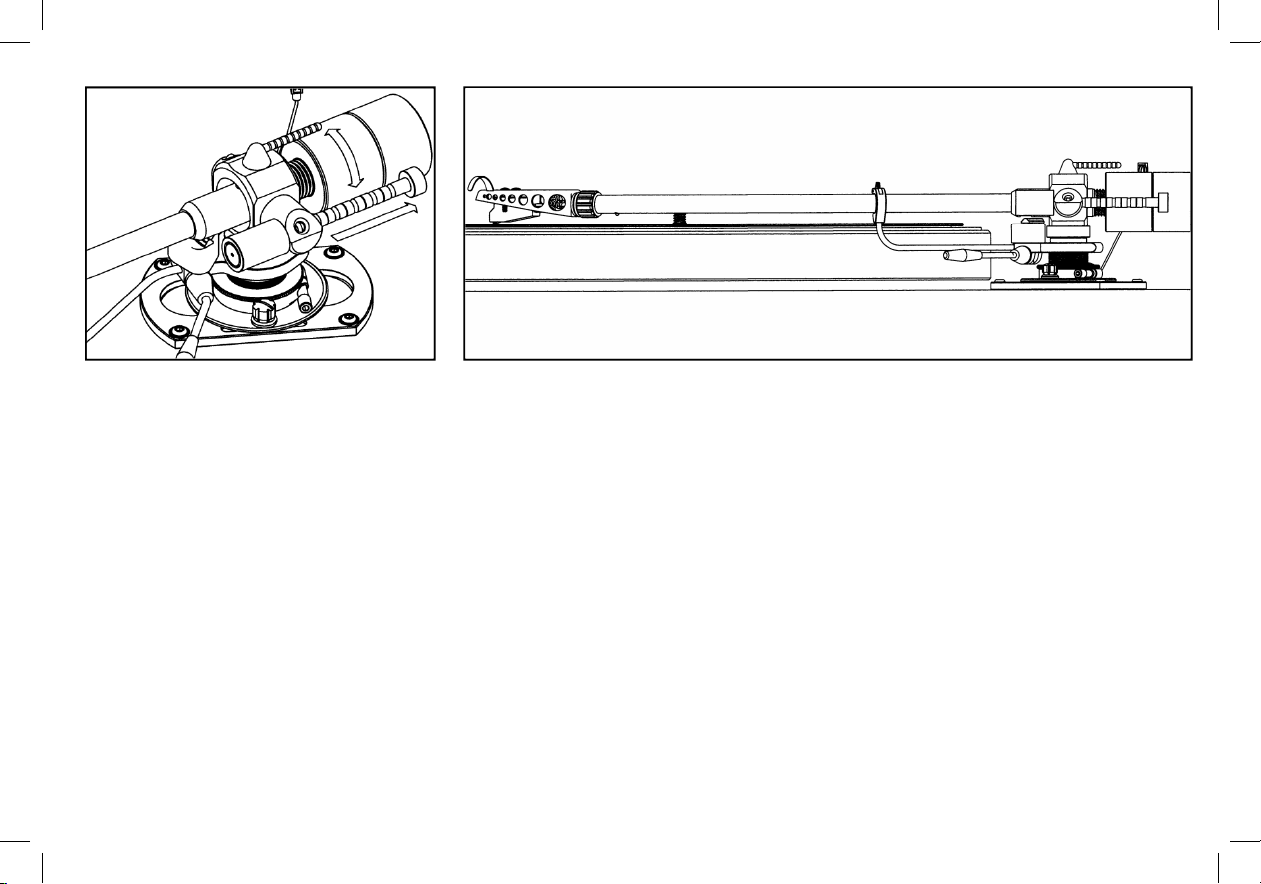

Longitudinal Balance

With only the main balance weight tted,

cartridges up to 16g may be balanced. However

by removing the balance weight end cap and

coupling the accessory balance weight (as

illustrated) cartridges up to 38g, mounted in the

headshell or plug in heads up to 46g can be

catered for.

Slide the wayrod/rider weight into the rearmost

zero position and balance the arm by rotating the

balance weight in the required direction.

Remove the accessory balance weight, when

needed, by unscrewing anti-clockwise from the

balance weight. Replace the balance weight end

cap.

Adjust until the tonearm, with the cartridge tted, is either level or slightly low at the front end.

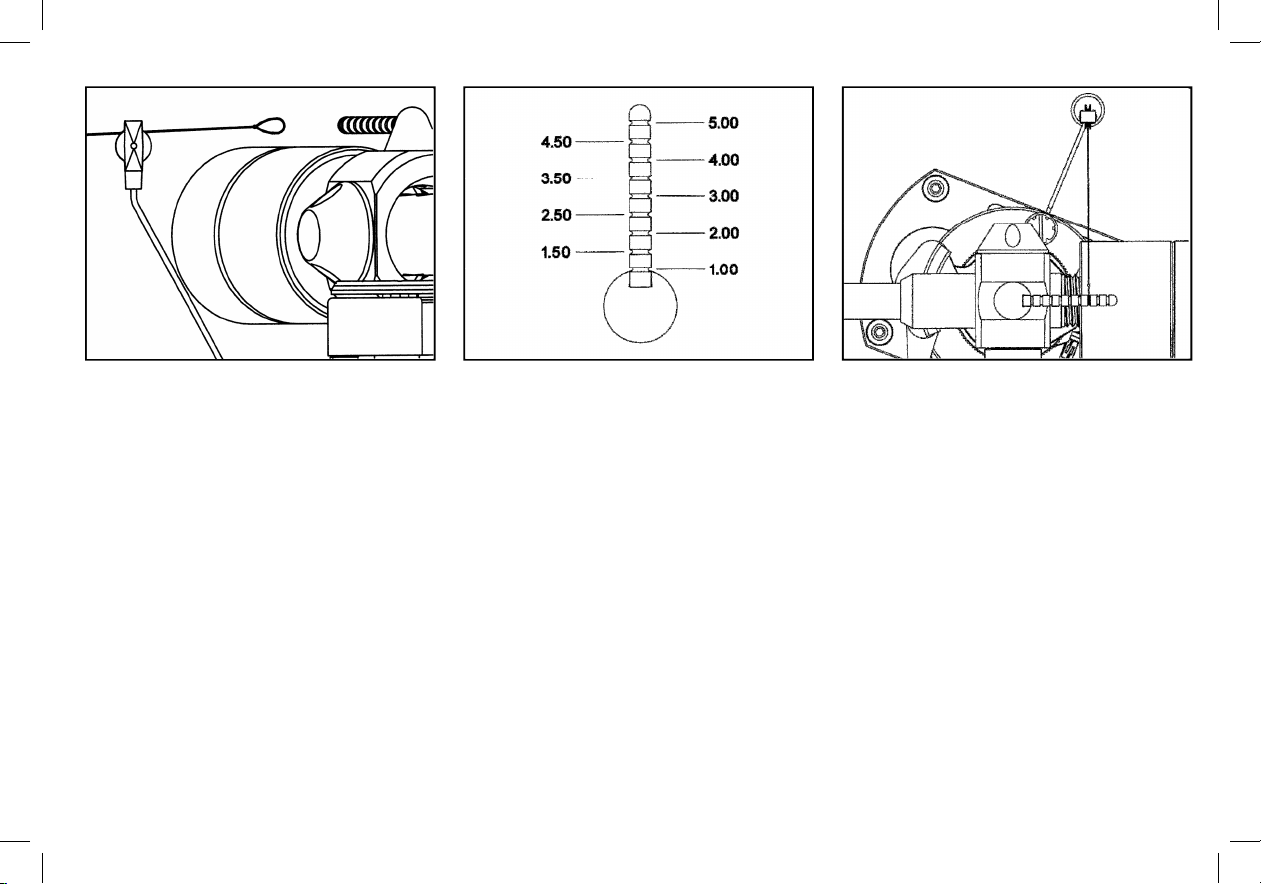

912/116 Vertical tracking force (VTF)

adjustment

For safety the lever of the lowering control

should now be moved in to the raised position.

912/117

VTF is set after longitudinal balancing has been

completed, see 912/114

It is applied by moving the complete Wayrod

assembly forward as indicated. The assembly is

calibrated to provide a maximum of 5.0g VTF in

1.0g increments between the indent positions.

Position shown is the setting for 3.0g VTF.

912/118

Half gram settings are indicated by the shallow

grooves alternating with the indent positions.

.

15

15

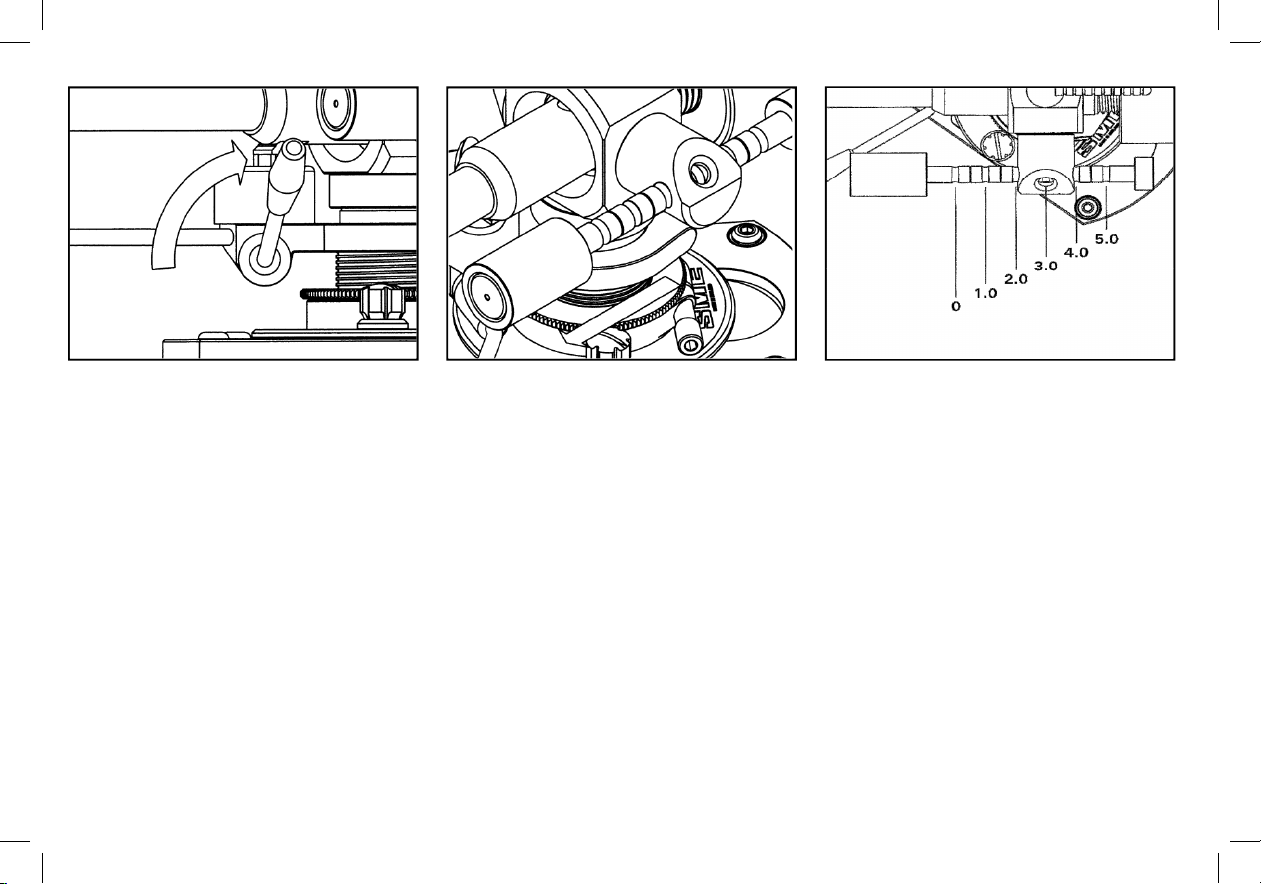

Vertical Tracking Force (VTF) Adjustment

For safety the lever of the lowering control should

now be moved into the raised position.

VTF is set after longitudinal balancing has been

completed.

It is applied by moving the complete wayrod

assembly forward as indicated. The assembly is

calibrated to provide a maximum of 5.0g VTF in

1.0g increments between the indent positions.

Position shown is the setting for 3.0g VTF.

Half gram settings are indicated by the shallow

grooves alternating with the indent positions.

912/119 Arm height (VTA) adjustment

Release the pillar clamp screw, using the 2mm

A/F wrench, by one turn only.

Rotate the VTA thumbwheel clockwise to

increase the height of the tonearm relative to

the base

To lower the tonearm turn the VTA thumbwheel

anti-clockwise. Finger pressure may be

required to move the arm downwards until it

stops on the arm base, at which point further

movement in either direction can be made as

necessary.

912/120

Use an old but unwarped record for the following

procedures in case of accidental damage.

Place the arm about halfway across the record

and move the control lever forward to lower it into

the playing position.

The top of the cartridge is normally the horizontal

datum; correctly fitted it will be parallel with the

tonearm.

Measure the distance from the surface of the

record to the top of the tonearm tube at the front

end using a small non-metallic ruler.

912/121

Repeat the measurement towards the rear of the

tonearm tube and compare it with first one.

Adjust the arm height with the VTA thumbwheel

until similar readings are obtained indicating that

the arm is level with the surface of the record.

Re-lock the pillar clamp screw, view the arm in

the playing position and re-adjust as necessary.

16

16

Arm Height (VTA) Adjustment

Release the pillar clamp screw, using the 2mm

wrench, by one turn only.

Rotate the VTA thumbwheel clockwise to increase

the height of the tonearm relative to the base.

To lower the tonearm turn the VTA thumbwheel

anti-clockwise. Finger pressure may be required

to move the arm downwards until it stops on the

arm base, at which point further movement in

either direction can be made as necessary.

Use an old but unwarped record for the following

procedures in case of accidental damage.

Place the arm about halfway across the record

and move the control lever forward to lower it into

the playing position.

The top of the cartridge is normally the horizontal

datum; correctly tted it will be parallel with the

tonearm.

Measure the distance from the surface of the

record to the top of the tonearm tube at the front

end using a small non-metallic ruler.

Repeat the measurement towards the rear of the

tonearm tube and compare it with rst one. Adjust

the tonearm height with the VTA thumbwheel until

similar readings are obtained indicating that the

tonearm is level with the surface of the record.

Re-lock the pillar clamp screw, view the tonearm

in the playing position and re-adjust as necessary.

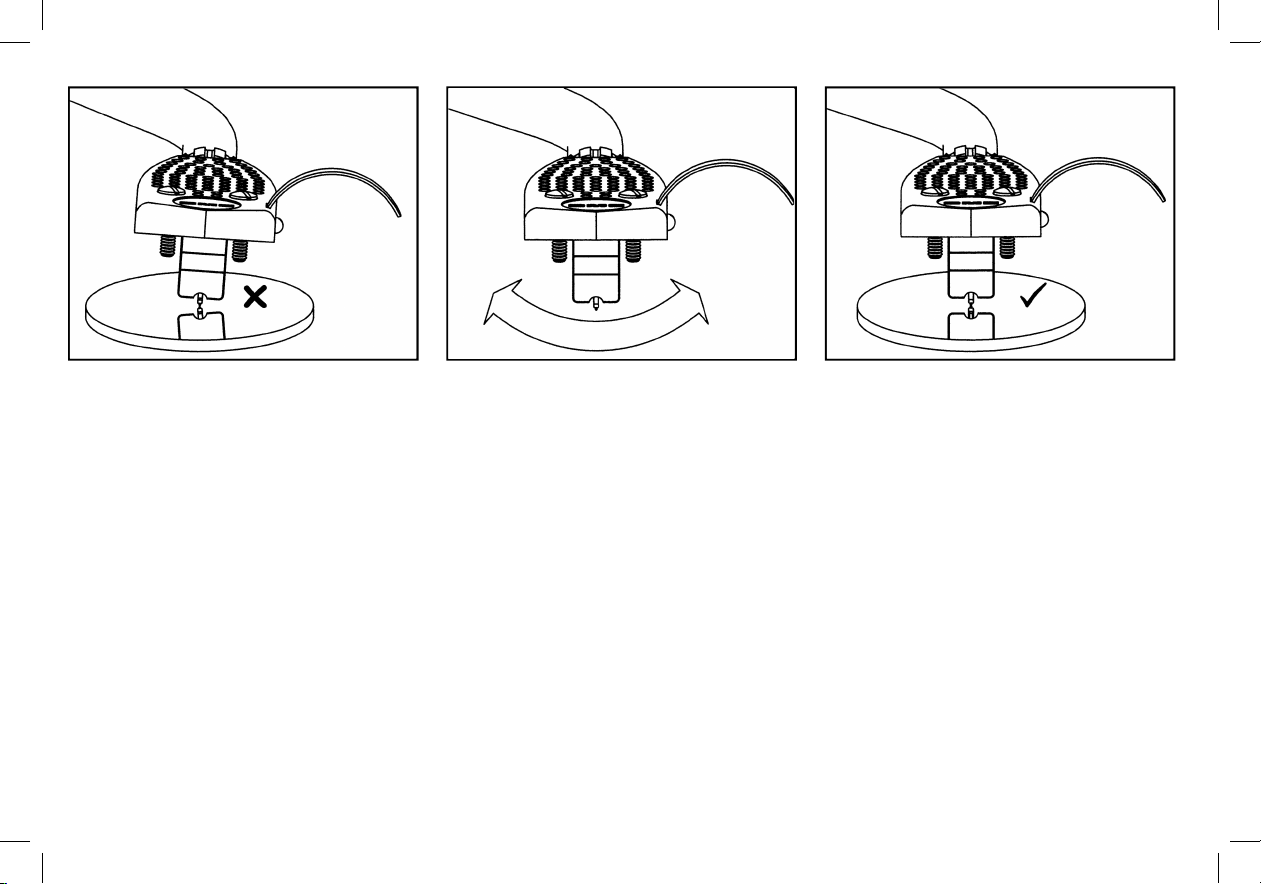

912/122 Azimuth adjustment

Place a small mirror on the turntable and rest

the stylus on it. Viewed in this way any

departure from vertical is accentuated and

easily visible.

912/123

Release the azimuth locking screw underneath

the tonearm, just to the rear of the arm socket

nut. The stylus must be kept clear of the mirror

whilst this is done.

Hold the headshell firmly close to the tonearm

with one hand and twist it in the required

direction holding the tonearm firmly with the

other. The stylus must remain clear of the mirror

at all times during this operation.

Movement of the socket in the end of the

tonearm is limited by the locking screw.

912/124

Re-check with the mirror and when satisfied

lightly re-lock the screw underneath the tonearm.

17

17

Azimuth Adjustment

Place a small mirror on the turntable and rest the

stylus on it. Viewed in this way any departure from

vertical is accentuated and easily visible.

Release the azimuth locking screw underneath

the tonearm, just to the rear of the tonearm socket

nut. The stylus must be kept clear of the mirror

whilst this is done.

Hold the headshell rmly close to the tonearm

with one hand and twist it in the required direction

holding the tonearm rmly with the other. The

stylus must remain clear of the mirror at all times

during this operation.

Movement of the socket in the end of the tonearm

is limited by the locking screw.

Re-check with the mirror and when satised

lightly re-lock the screw underneath the tonearm.

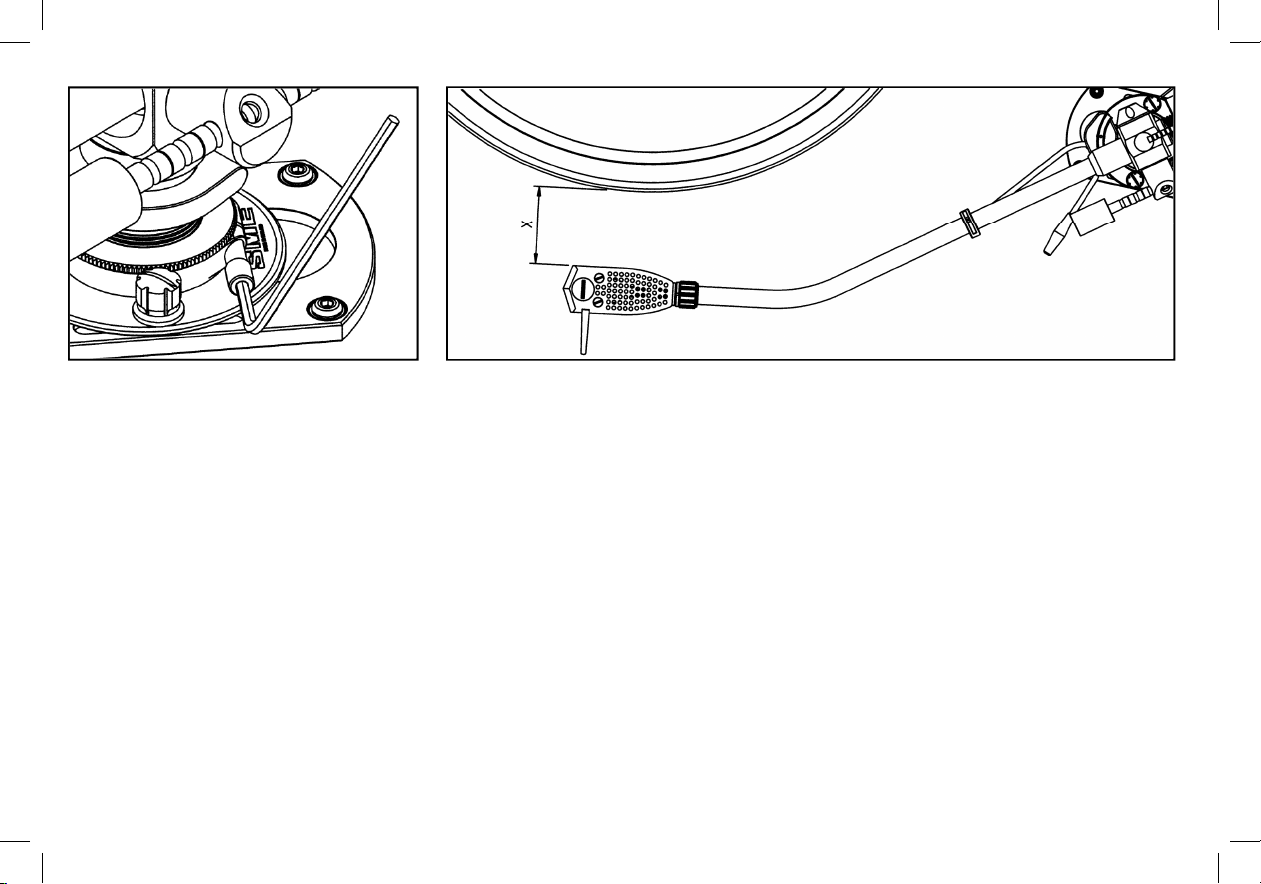

912/125 Horizontal tracking angle (HTA)

adjustment

Place the tonearm into the armrest and release

the two base clamp nuts, using a snugly fitting

screwdriver.

Move the base on the bedplate as far forward

as it will go.

912/126

With a record on the turntable and having pierced

the alignment protractor for the stylus, place it on

the turntable spindle. Check that the VTF has

been set to suit the cartridge in use. Move the

arm out of the armrest and place it so that the

stylus enters the point where the alignment

protractor has been pierced. The protractor

provides two null points, the inner at 66.0mm and

the outer at 121.0mm radius. Move the base on

the bedplate until the cartridge and headshell

appear symmetrical with the lines on the

protractor at the inner point.

Inaccuracy is shown and the arrow indicates the

direction of movement required to correct it.

912/127

Similarly check the outer point and adjust the

arm until the conditions shown in the illustration

above are met.

Firmly re-lock the outer base clamp nut only.

18

18

Horizontal Tracking Angle (HTA)

Adjustment

Place the tonearm into the armrest and release

the two base clamp nuts, using a snugly tting

screwdriver.

Move the base on the bedplate as far forward as

it will go.

With a record on the turntable and having pierced

the alignment protractor for the stylus, place it

on the turntable spindle. Check that the VTF has

been set to suit the cartridge in use. Move the

tonearm out of the armrest and place it so that

the stylus enters the point where the alignment

protractor has been pierced. The protractor

provides two null points, the inner at 66mm and

the outer at 121mm radius. Move the base on the

bedplate until the cartridge and headshell appear

symmetrical with the lines on the protractor at the

inner point.

Inaccuracy is shown and the arrow indicates the

direction of movement required to correct it.

Similarly check the outer point and adjust

the tonearm until the conditions shown in the

illustration above are met.

Firmly re-lock the outer base clamp nut only.

912/128 Positioning the armrest

Release the pillar clamp screw, using the 2mm

A/F wrench.

Height adjustment will be maintained by the

VTF thumbwheel.

19

912/129

Rotate the pillar to position the

armrest conveniently in relation to the turntable. The dimension ‘X’

should not be more than 110mm or less than 50mm.

Tighten the pillar clamp screw firmly, avoiding excessive force.

19

Positioning the Armrest

Release the pillar clamp screw, using the 2mm

wrench.

Height adjustment will be maintained by the VTF

thumbwheel.

Rotate the pillar to position the armrest conveniently in relation to the turntable. The dimension ‘X’

should not be more than 110mm or less than 50mm.

Tighten the pillar clamp screw rmly, avoiding excessive force.

912/130 Anti-skate adjustment

Thread the filament through guide pulley

housing and pass the loop over the anti-skate

lever.

912/131

Drop the loop into the groove corresponding to

the vertical tracking force being used.

Anti-skating is always a matter of compromise.

The values indicated are a good starting point.

Note how the stylus enters the run-in groove.

‘Snatch’ would indicate the need for a lower

value.

912/132

Loosen the inner base clamp nut enough to

allow movement of the anti-skate guide. Position

the guide so that the filament is approximately

90

o

to the anti-skate lever when the stylus is over

the outer groove of a twelve inch record. Firmly

relock the base clamp nut. Rotate the guide

pulley housing to align it with the filament, which

must lie in the groove of the pulley.

20

20

Anti-skate Adjustment

Thread the lament through guide pulley housing

and pass the loop over the anti-skate lever.

Drop the loop into the groove corresponding to

the vertical tracking force being used.

Anti-skating is always a matter of compromise.

The values indicated are a good starting point.

Note how the stylus enters the run-in groove.

‘Snatch’ would indicate the need for a lower value.

Loosen the inner base clamp nut enough to allow

movement of the anti-skate guide. Position the

guide so that the lament is approximately 90˚

to the anti-skate lever when the stylus is over

the outer groove of a twelve inch record. Firmly

relock the base clamp nut. Rotate the guide pulley

housing to align it with the lament, which must lie

in the groove of the pulley.

This manual suits for next models

1

Table of contents

Other SME Accessories manuals

Popular Accessories manuals by other brands

CASUALPLAY

CASUALPLAY saco instructions

Rittal

Rittal 7030.430 Installation and Short User Guide

GE

GE WR72X10313 Install instructions

Philips

Philips DLA67006D brochure

Black Diamond Equipment

Black Diamond Equipment HELIO 180 INSTALLATION, USE AND MAINTENANCE GUIDEBOOK

river systems

river systems EggTech series user manual