isobar fs mont uk / Senest udskrevet den 15-08-01 11:01 / MW.

English

Installation Guide IsoBar

2-65, 3-65, 2-70, 3-70, 2-72, 3-72, 4-60

This installation guide gives basic instructions which

are to be observed during installation, operation and

maintenance of the pump. It is therefore imperative

that this manual is read by the responsible

person/operator prior to the installation and should

always be kept available at the site.

It is not only the general safety instructions under this

main heading "Safety" that are to be observed but also

the specific information provided under the other main

headings.

Serial No: See nameplate

Application

The IsoBarcirculating pumps are used in all types

of heating systems. Via an internal speed Control, the

pump maintains predetermined differential heads at

varying flows (see control details under the heading

"Duty control"). This design concept gives electrical

and thermal savings together with reduced noise level

in the installation.

Pump medium

Clean, thin, nonaggressive and nonexplosive fluids

without any solids or fibres.

Antifreeze without any mineral oil (special model

available upon request).

Kinematic viscosity: Max. 10mm2/s

Please note: If any liquid other than water is being

pumped, were commend that you contact

T. Smedegaard A/S or their representative as the

pump characteristics may change.

Technical data

Electricai data: See nameplate

Max. working pressure: 10 bar (1000 kPa)

Min. static head at 82°C: 4 - 5 m depending upon

model

Min. static head at 95°C: 5 - 7 m depending upon

model

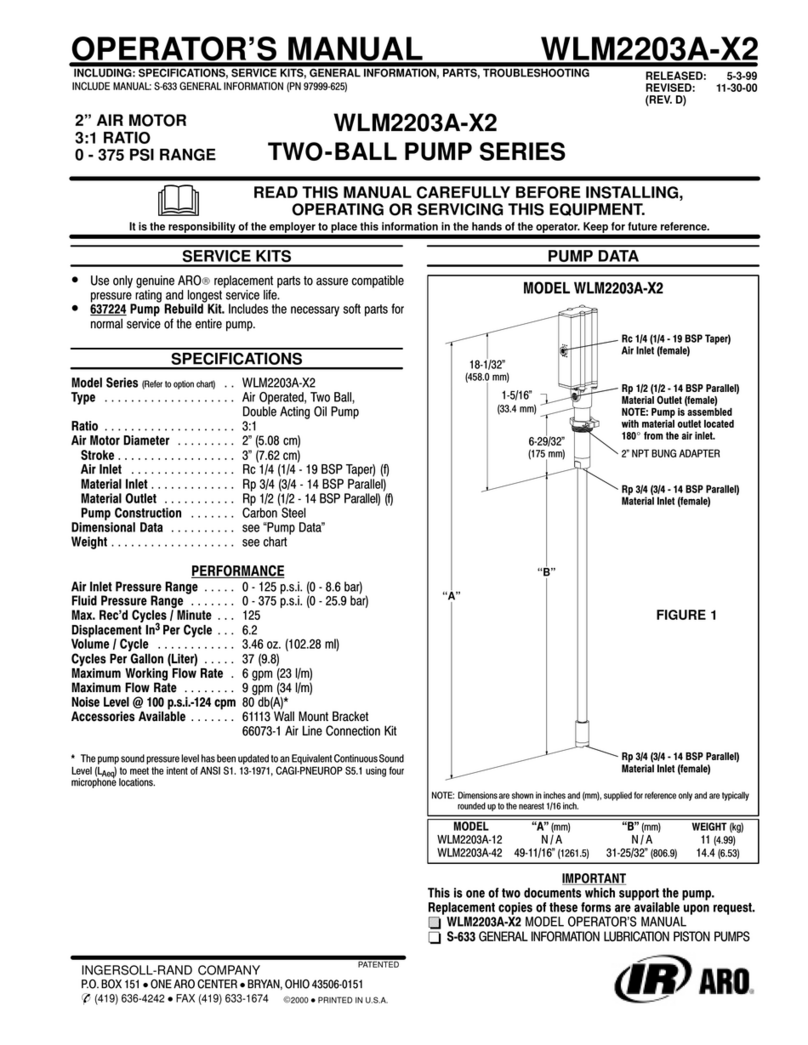

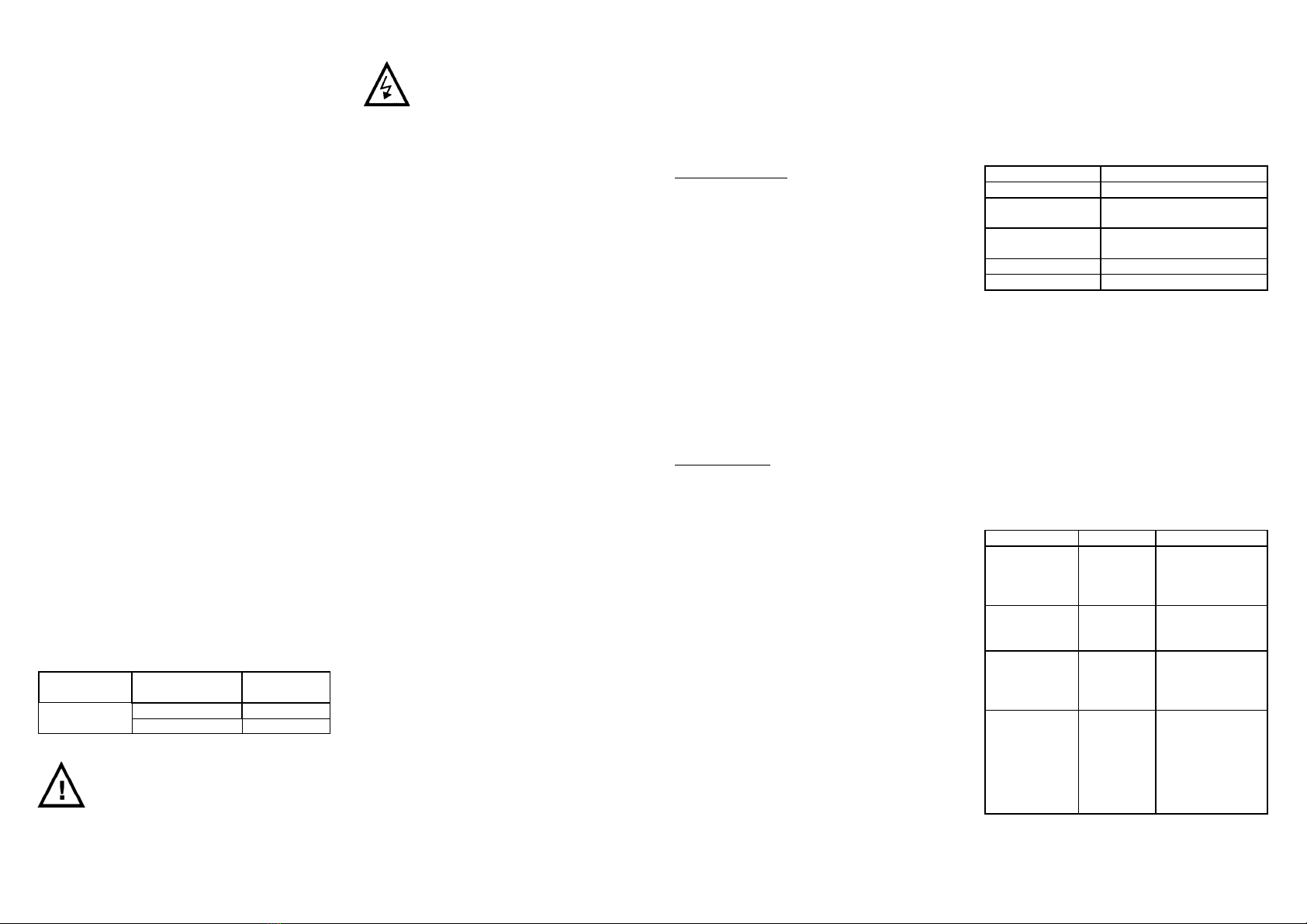

IsoBar type Water temp.

Range max. [C°]

Max. ambient

temp. [C°]

2/3-65, 2/3-70, 110 30

2/3-72, 4-60 90 40

Safety

-The surface temperature might be hot.

-When venting the pump (see fig. 3), it

could result in a slight escape of hot water

or steam!

-Pump should be wired in line with the

existing regulations.

-The mains electrical supply must be

isolated before any work is carried out

on the pump. The IsoBar pump must be

earthed.

Personnel qualification and training

Personnel responsible for operation, maintenance,

inspection and installation of the pump must be

adequately qualified.

The person responsible for the complete installation

must ensure that the contents of this manual are fully

understood by any personnel working on the system.

Airborne sound pressure level

IsoBar 2-65 to IsoBar 4-75: Max. 33 dB(A)

According to EN 12639

Installation

1) The pump should always be installed with the

pump shaft horizontal (see fig. 1). Direction of

flow through the pump casing is indicated by an

arrow.

2) If terminal box is to be repositioned by rotating

head, care must be taken to ensure the casing "0"

ring is correctly positioned.

3) Ensure pipwork alignment and the pump and

pipework are adequately supported. Sharp bends

should be avoided adjacent to the pump.

4) If pump is mounted in vertical pipework, flow

should be upwards. If flow is downwards, an air-

vent must be fitted at the highest point before

pump suction.

5) Pump should never be allowed to operate for a

long period in a closed valve condition.

6) To avoid accumulation of impurities in the pump,

make sure that it is not mounted at the lowest

point in a system.

7) It is recommended that isolating valves are fitted

on either side of the pump.

8) System should be thoroughly flushed out to clear

any solder, steel wool, plaster or any other foreign

matter that may be lodged in the pump.

Electrical connection

Electrical data is shown on the nameplate and a wiring

diagram is located in the terminal box (see figs. 2a).

The pump needs no external protection but must be

earthed.

The IsoBar circulating pumps, with the exception of

the IsoBar 2-65, 3-65 are fitted with a potential free

status relay, (open at alarm) which opens under a fault

condition or by disconnection of mains. The relay is

using terminals 1 and 2 (see figs. 2b). Maximum

load: - 250V AC /1A, 30V DC/5A

Venting

Once the system has been filled and pressurised, vent

the pump before start-up. Venting can be achieved by

removing the plug positioned in centre of nameplate

(see fig. 3) This process should be repeated

periodically until all air held in suspension in the

system water has been removed.

Duty Control

Please note: IsoBar 2-65, 3-65 can not be controlled

by external input.

Without external input

There are two modes for controlling the pumps.

Mode 1: Controlled to follow a works pre-set system

characteristic (orange LED).

Mode 2: Controlled to follow a specific defined

differential head at different flows (green

LED).

Mode change is achieved by simultaneously pushing

the two control buttons located on the terminal box

(see fig. 4a).

Mode 2 adjustment: Push + button - set point

increases.

Push - button - set point decreases. Indication

of set point - red flash LED according to the

following:

Min set point 1 flash with an interval of 1

sec.

Max. set point 10 flashes with an interval of

1 sec.

With extemal input

The pumps can also be controlled by external input.

There are three functions of control.

1) Control by integrated analog input, terminals 4

and 5 to be used (see fig. 2c).

Terminal 4: 2,5-10 VDC & 4-20mA

Terminal 5: Common (1)

Integration time from minimum to maximum

duty, approximately 60 sec.

2) Night-setback, terminals 3, 4 and 5 to be used

(see fig. 2d).

Terminal 3: 10 VDC & 10mA

Terminal 5: Common

3) External stop of pump, terminals 3 and 5 to be

used (see fig. 2e).

Terminal 3 and 4: 10 VDC & 30mA

Terminal 5: Common

When controlled by external input, it will be indicated

by Green flash LED.

In the case of the function being inactive, the pump

will revert to the Mode last chosen (see under

Without external input).

Note: The pump is works supplied set in mode 1.

General

In all IsoBar pumps, Pressure Loss Compensation

(P.L.C.) is included in the control, which means that

the pump does not follow a constant differential head

but takes into account the decreasing pressure needs at

decreasing flow (see fig. 5b).

Signals

The IsoBarpumps have one or two LED's on the

terminal box for external fault indication (see fig. 5a).

When indicating fault the pump is stopped. Reset is

carried out by switching the mains supply off for 5

sec. and then on.

IsoBar 2-65, 3-65, 2-70, 3-70, 3-72 and 4-60

Signal LED Description

No light Main supply switched off

Orange Running in Mode 1.(see under

heading "Duty control")

Green Running in Mode 2. (see under

heading "Duty control")

Green flash Controlled by external input

Red Blocked / too hot motor

Service/Maintenance

Smedegaard's IsoBar range of glandless pumps are

virtually maintenance free and in a well designed

system should give many years of operation. If motor

shaft is seized as a result of pump standing for a long

period without use or by a limited accumulation of

magnetite or other impurities, it should be freed. Insert

a screwdriver through vent plug hole into the slot in

the end of the shaft and rotate (see fig. 3).

Please note: Any repairs required to the internal

electrical parts of the pump/terminal box, except

points mentioned under the heading "Electrical

connection", are to be carried out by a Service

Department approved by T. Smedegaard A/S.

Fault finding

Fault Cause Action

The pump is not

running.

See under

heading

"Signals"

Reset fault

indication.

Check main supply

and fuses.

Pump will not

start / is running

irregular.

Impurities in

the pump.

See under heading

“Service/

Maintenance".

The pump is

running but no

flow.

Air in the

system.

Closed

valve.

Vent pump and

system.

Open valve.

Pump noisy. Pump speed

too high.

Static head

too low.

Air in

system.

Decrease set point

of control. Increase

inlet pressure.

Vent pump and

system.