Conversion Kit

8

7)

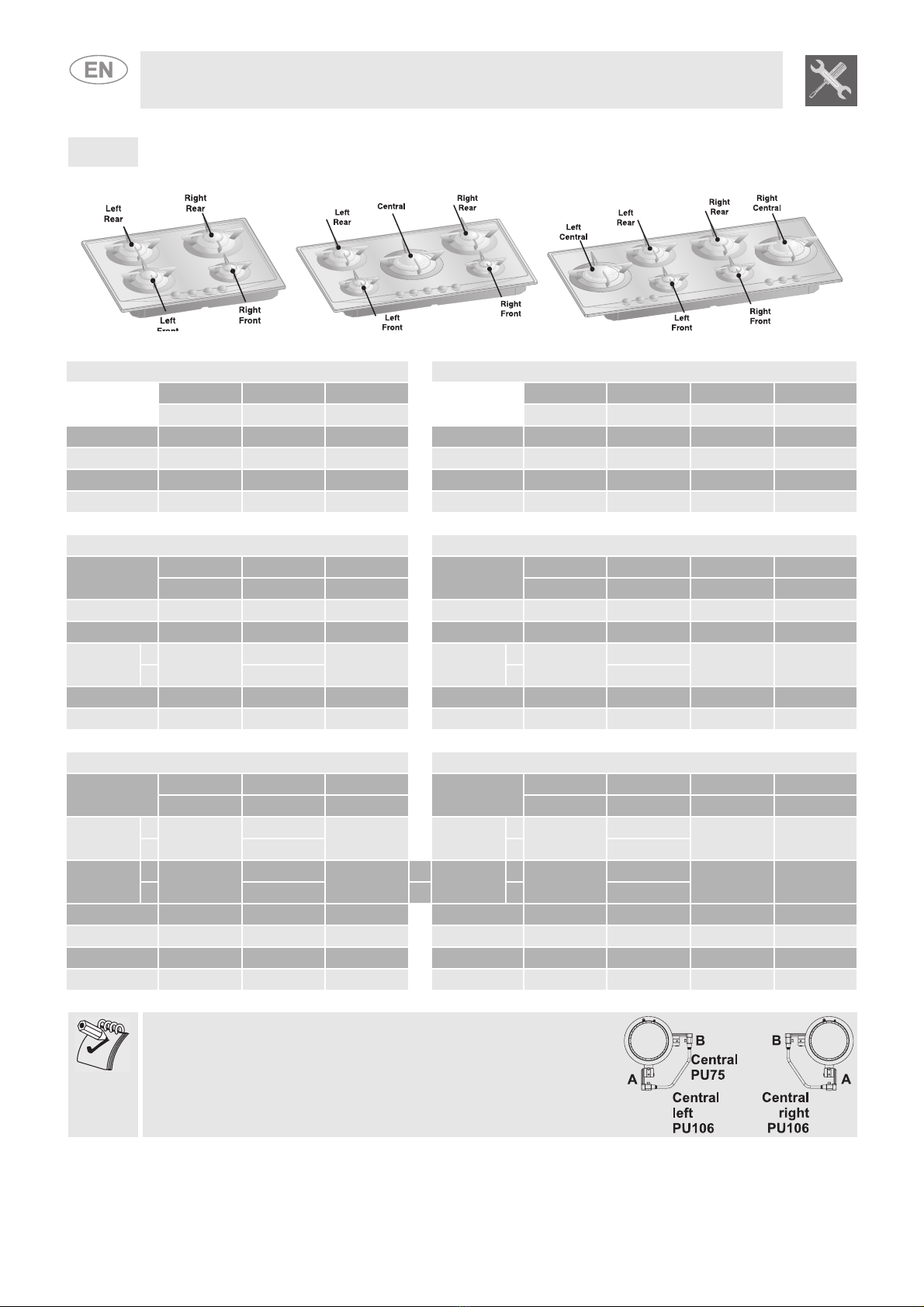

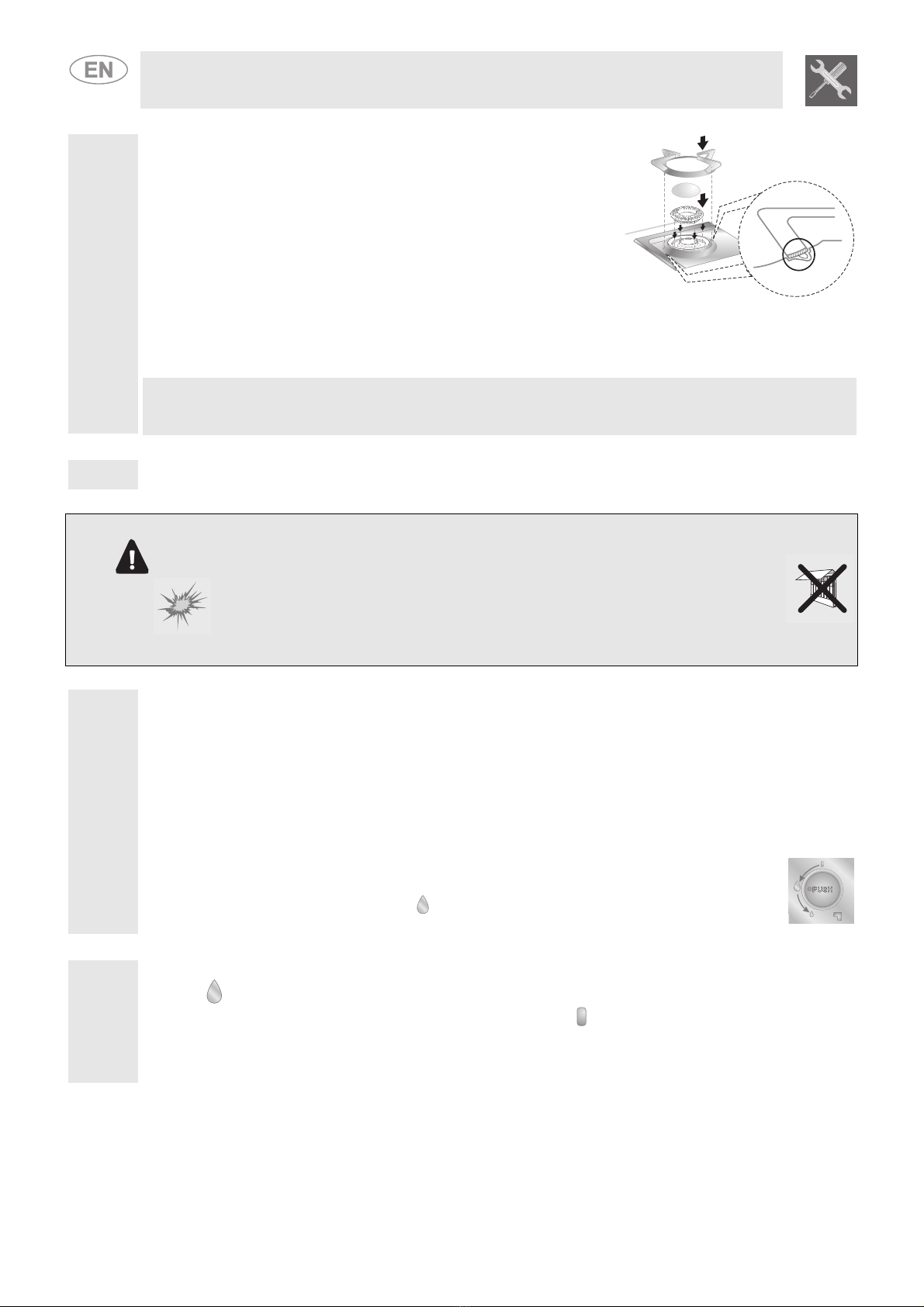

Refit the crowns, flame caps and grids on the cooktop in the following

order:

1 Fit the crowns, ensuring that they are perfectly locked into their

housing on the cooktop.

2 Fit the flame caps on the crowns, ensuring that the edges match

perfectly.

3 Fit the grids, making sure to fasten the side spokes in the special

“A” seats found on the cooktop.

These procedures must be repeated for each burner on the cooktop.

Caution: refit all flame caps in the same points from which they were removed. In fact, it is not possible to

change the flame cap positions. After refitting them, ensure that they are perfectly in place and that there

is no clearance between the cooktop and the flame caps.

8) Complete steps 3, 5 and 6 for each burner on the cooktop.

WARNING

FIRE HAZARD

- Use a soapy solution to check for proper tightness.

- Never test for gas leaks with a match or other flames.

- Failure to follow this instruction can result in death or fire

9)

Leak testing of the appliance must be conducted according to the following instructions:

Use a brush and liquid detergent to test all gas connections for leaks. Bubbles around connections

indicate a leak. If a leak appears, shut off gas valve controls and adjust connections.

Then check the connections again.

NEVER TEST FOR GAS LEAKS WITH A MATCH OR OTHER FLAMES.

Remove all of the detergent solution from the cooktop.

Electronic Ignition System - initial lighting

Cooktop burners use electronic igniters rather than standing pilots. When the cooktop control

knob is pushed in and turned to the " " position, the system lights a spark to ignite the

burner. This sparking continues until the control knob is turned to the desired setting.

10)

Check the operation of the cooktop burners. Push in and turn each control knob to the maximum flame

position ( ). The flame should light within 4 seconds.

If the burners do not light properly, turn the control knob to the position. Ensure that the burner cap is

in the proper position. Ensure that the power supply cord is plugged in and that the circuit breaker or

house fuse has not blown. Ensure that the shut-off valve is on the "ON" position. Check operation again.

If a burner does not light at this point, contact your SMEG dealer for assistance.