Summary

1 PRODUCTIDENTIFICATION.................................................................................................................................3

1.1 Application,general functions and intended use........................................................................................ 3

1.2 Name and address of manufacturer or distributor...................................................................................... 3

Smeg S.p.A............................................................................................................................................................. 3

1.3 Declarationof conformity to product standards......................................................................................... 3

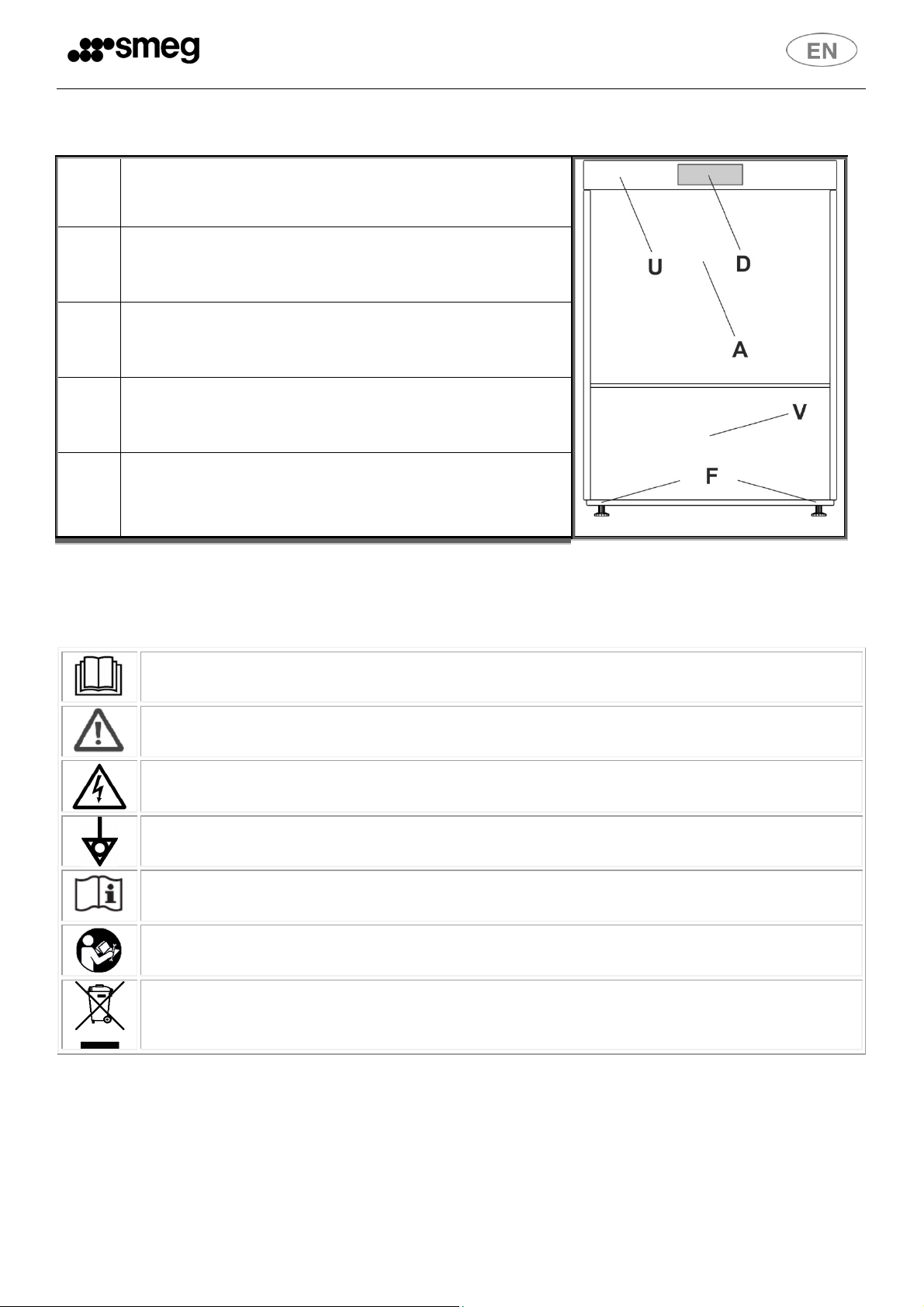

1.4 Description of the appliance....................................................................................................................... 4

2. SYMBOLS USED IN THE MANUAL........................................................................................................................ 4

3. SAFETYPRECAUTIONSAND INSTRUCTIONS........................................................................................................5

3.1Correctinstallation ..........................................................................................................................................5

3.2 Safe use........................................................................................................................................................... 6

3.3Correctmaintenance .......................................................................................................................................6

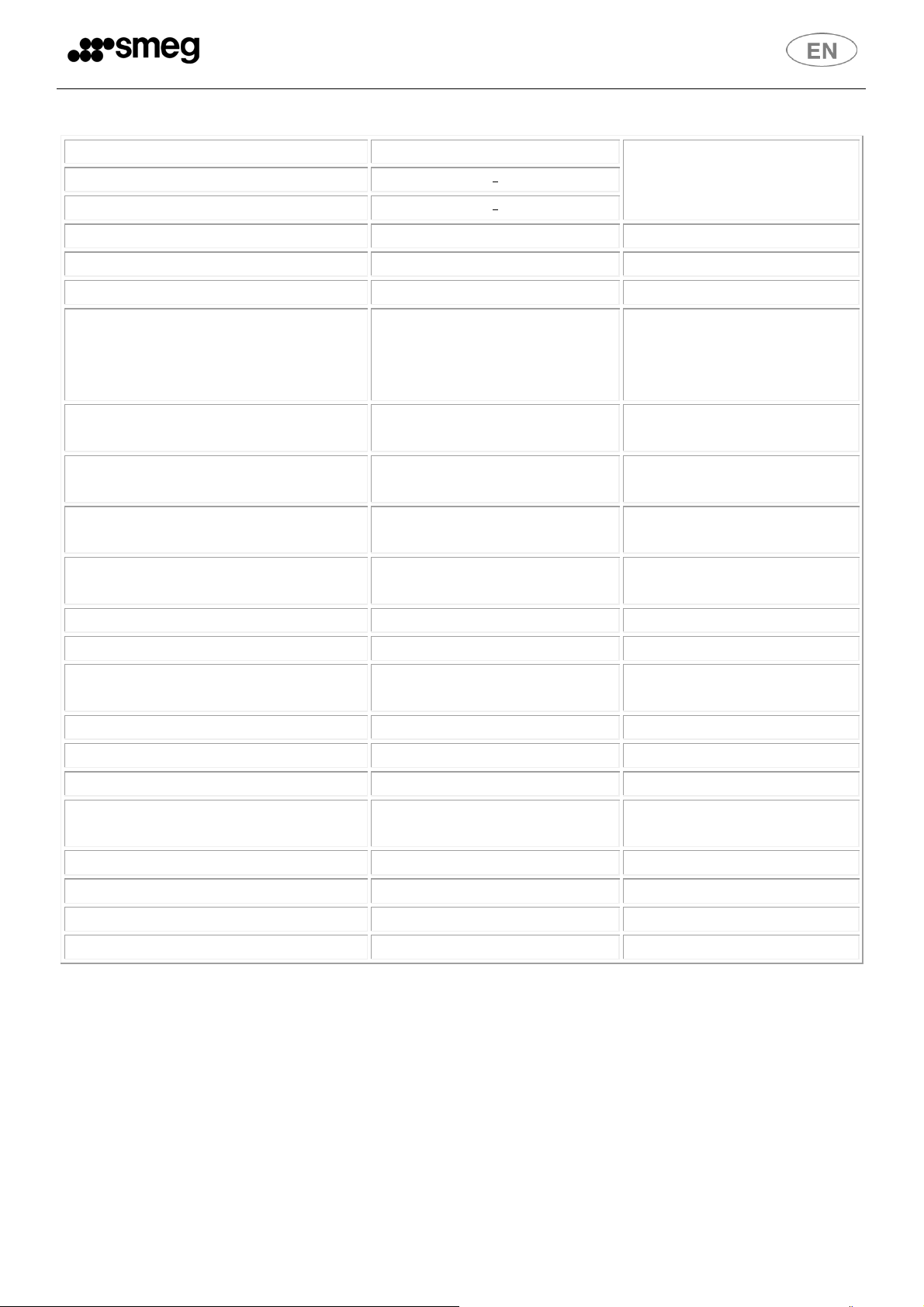

4. PRODUCT CHARACTERISTICS.............................................................................................................................. 7

4.1Overall dimensionsforbuilt-under installation.................................................................................................7

4.2Technical characteristics..................................................................................................................................8

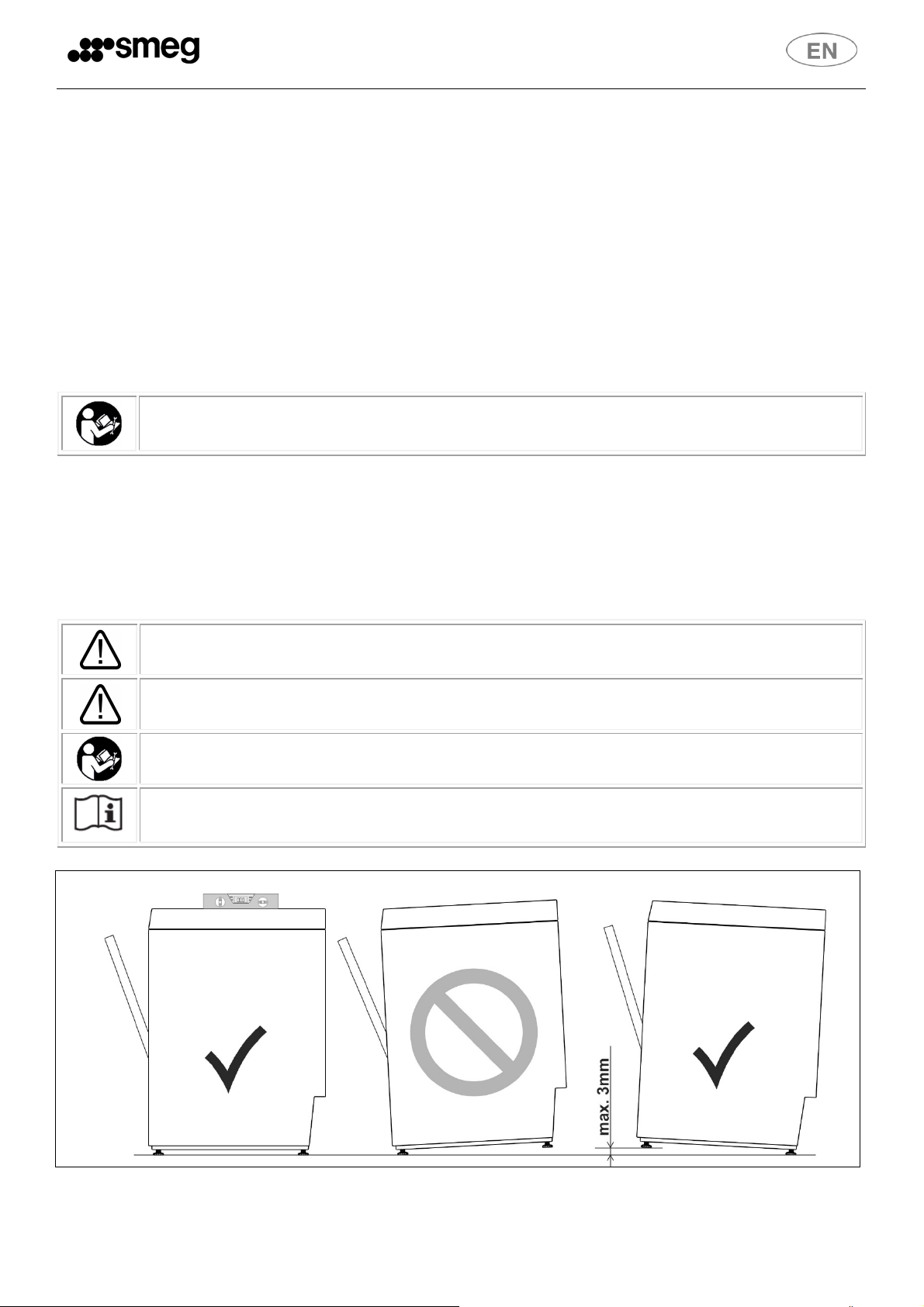

5. PREPARINGTHEAPPLIANCEFOR USE.................................................................................................................9

5.1Positioning andinstallation.............................................................................................................................. 9

5.2 Connection to the watersupply..................................................................................................................... 10

5.3Drain connection............................................................................................................................................ 10

5.4 Connection to the electricity supply............................................................................................................... 11

6. FIRSTSTART-UP...............................................................................................................................................11

6.1 Using the water softener (on models with this feature only).................................................................... 12

7. SET-UP (Authorised technical staff only) .......................................................................................................... 13

7.1 Contentsofdisplay................................................................................................................................... 14

7.2 Note on display of temperatures.............................................................................................................. 14

7.3 Parameter programming procedure (setup)............................................................................................. 14

7.4 Modifiable parameters............................................................................................................................. 15

7.5 Adjusting detergent and rinse aid dispensing (only available on certain models)...................................... 15

Rinse aid – Grams/liter dosage (depends on model)- The display reads “ri”..................................................... 15

Detergent - Grams/liter dosage (depends on model) - The display reads “dE”................................................. 15

7.6 Starting the peristaltic pumps in manual mode – rapid filling of detergent and rinse aid circuit................ 16

7.7 Adjusting the regeneration frequency (models with softener only) .......................................................... 16

7.8 Mains waterhardnesssetting table.......................................................................................................... 16

7.9 Extra rinse option (long rinse). -Display reads “E.r”.................................................................................. 16

7.10 "Clean water cycle" option - Display reads “CL”........................................................................................ 17