smirthwaite HARDROCK User manual

1/12

HARDROCK

INSTRUCTIONS FOR USE

Codes 8202-8204

Hardrock

1

CONTENTS PAGE

1.0 INTRODUCTION 1

2.0 ILLUSTRATION OF YOUR CHAIR 2

3.0 FOR YOUR SAFETY 3

4.0 UNPACKING YOUR CHAIR 4

5.0 SETTING UP AND ADJUSTING YOUR CHAIR 6

6.0 CARE & MAINTENANCE 11

7.0 GUARANTEE & SERVICE 15

8.0 CONTINOUS IMPROVEMENT 16

9.0 WARRANTY & AFTERSALE 17

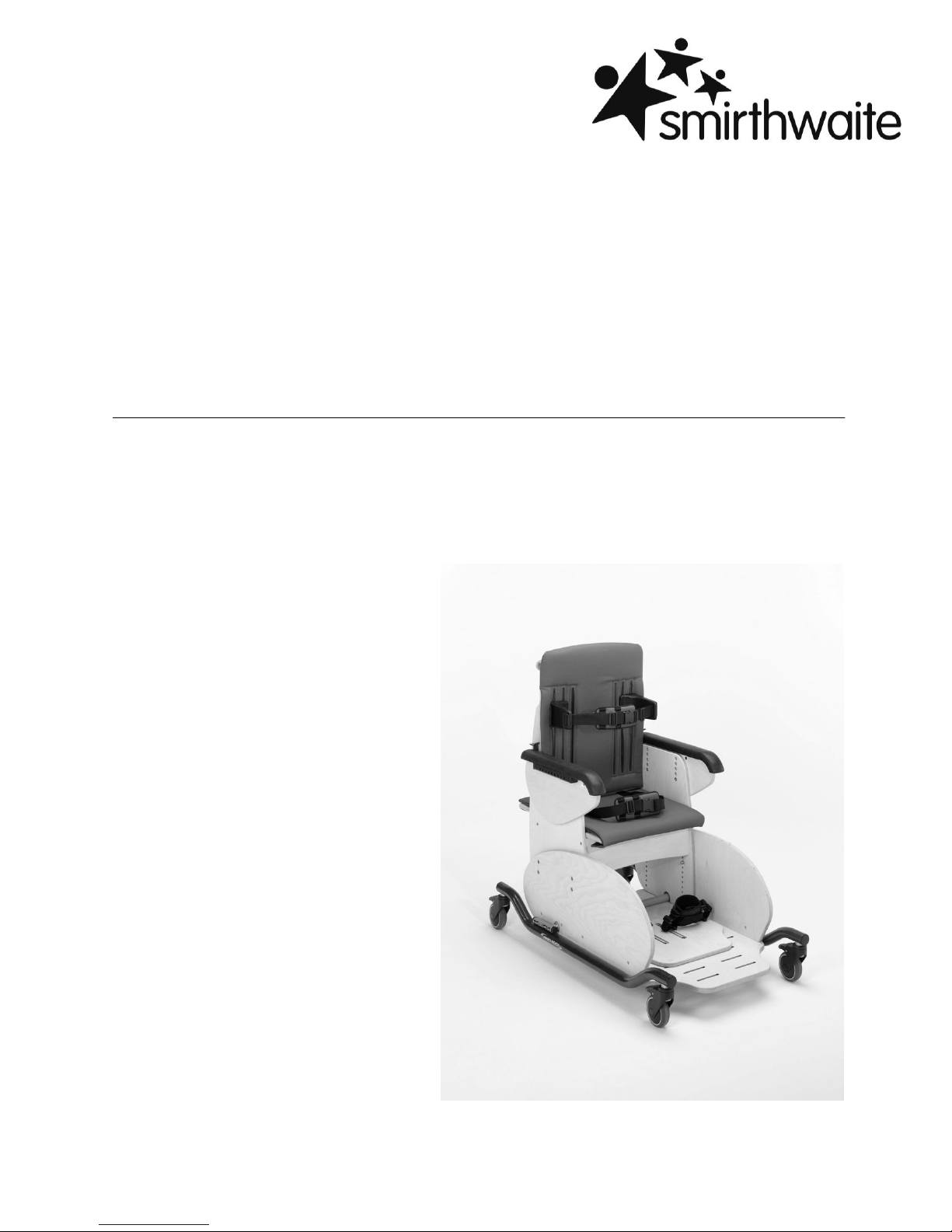

INTRODUCTION

Thank you for choosing the Hardrock. It is an extremely durable, robust and stable chair

that has been specifically designed for children with complex learning difficulties and

children who are inclined to rock when seated.

It provides a moderate level of postural support and a safe and secure environment to

enable the children to engage in education, play and everyday activities necessary for

their development. It is suitable for use at home and in schools.

IMPORTANT!

These instructions should be read by all therapists and carers using

the equipment and should be retained for future reference. The

product should always be used under adult supervision.

Any incorrect use of the product and failure to follow the instructions

may put the user at risk or impede the function.

This product has been designed and manufactured specifically and

solely for use by clients with special needs.

Hardrock

2

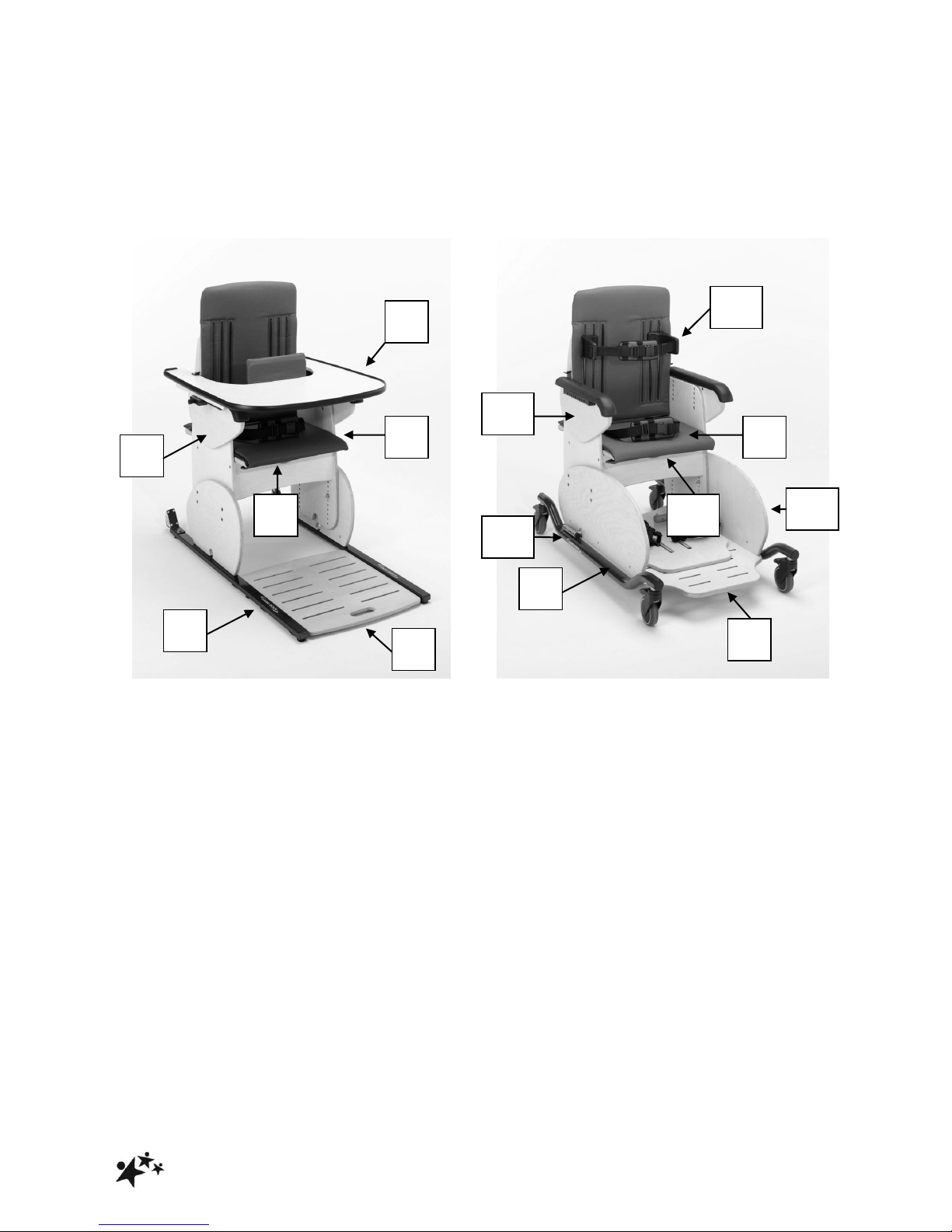

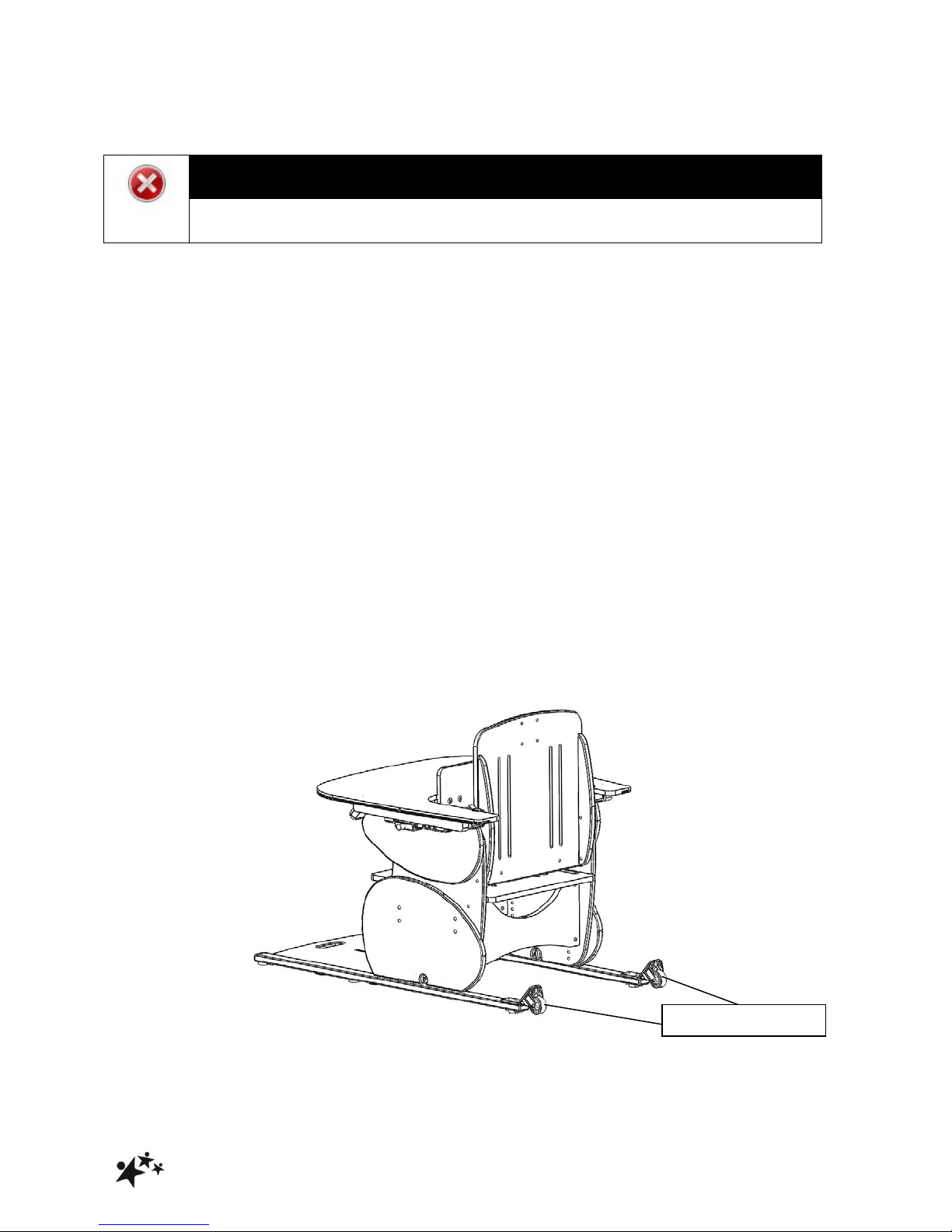

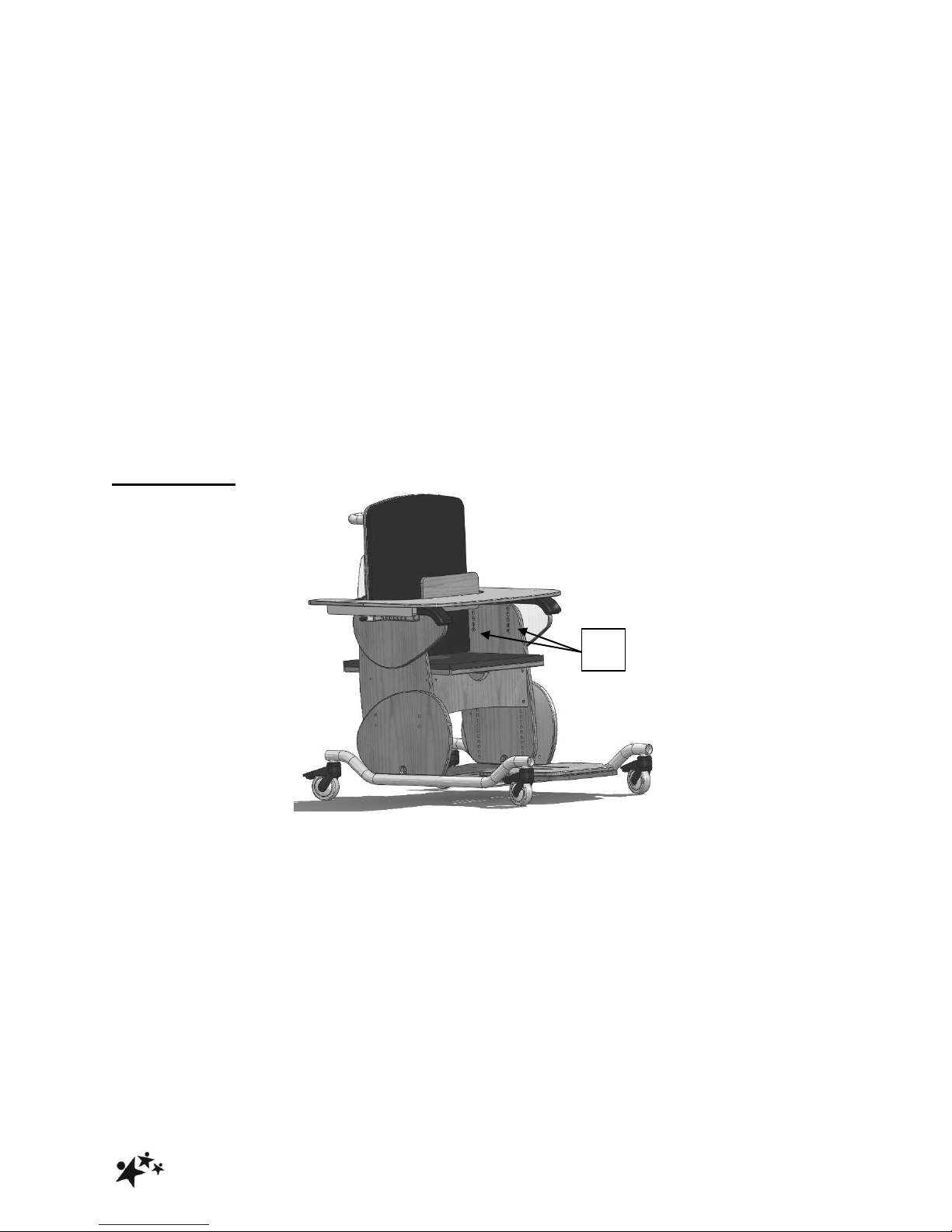

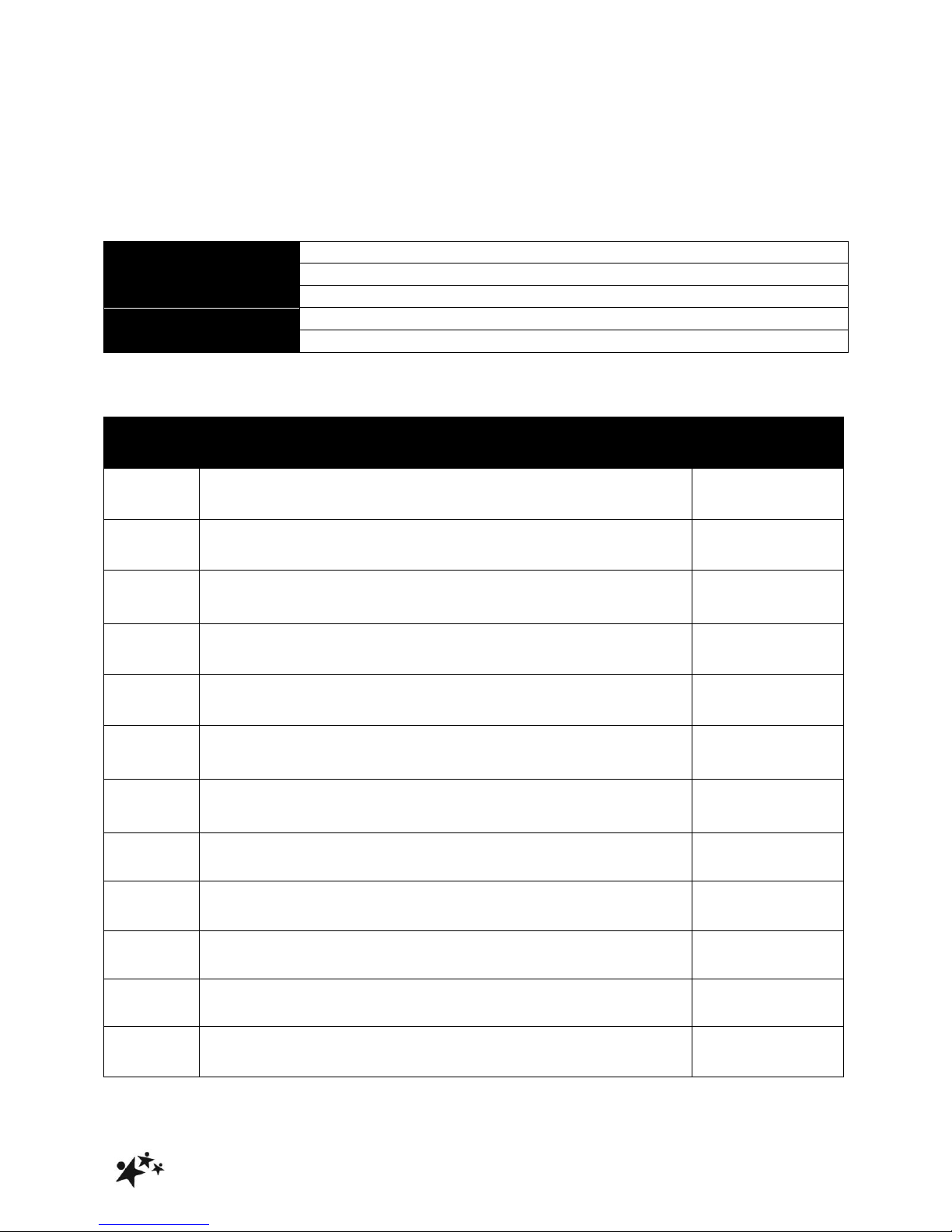

2.0 ILLUSTRATION OF YOUR CHAIR

HARDROCK SIZE 2 & 3

Code 8202-8203

HARDROCK SIZE 4

Code 8204

1.Ski

2.Pelvic strap

3.Footboard

4.Anti-thrust cushion

5.Armrest

6.Tray

7.Mobile Base with lockable castors

8.Pelvic strap

9.Footboard

10.Anti-thrust cushion

11.Armrest

12.Extended gables (optional)

13.Stabilisers (optional)

14.Thoracic supports (optional)

Note: Size 4 also comes with tray as standard (not

shown)

1

2

3

6

5

4

7

8

9

10

11

13

12

14

Hardrock

3

3.0 FOR YOUR SAFETY

STOP!

Please read these instructions CAREFULLY and THOROUGHLY.

The user should NOT be left unattended whilst in the Hardrock. Always ensure a

responsible therapist or carer is in attendance.

For the initial setting up of the Hardrock and at subsequent/future review of the child,

measurements of the child’s seat depth and height is required.

The therapist should be familiar with the methods of adjustment and have completed

all adjustments appropriately to meet the needs of the child using the measurements

taken before transferring the child into the chair.

Adjusting the seat height of the Hardrock is easier and safer if carried out by two

people.

Ensure all castors on the mobile base are locked with castors facing inwards by

tilting the chair slightly onto its side before making any adjustments.

Rear transporter wheels have been fitted onto the skis to facilitate moving the chair.

DO NOT use whilst the child is seated in the chair.

Rear transporter wheels

Hardrock

4

If rear transporter wheels have not been fitted, Hardrock should only be

moved by two people.

Only Hardrock fitted onto mobile base can be used as an indoor transit chair.

The Hardrock castors are designed for indoor use only and may be damaged if used

outdoors.

The Hardrock is only to be used on a flat level surface.

DO NOT EXCEED MAXIMUM WEIGHT LIMITS SPECIFIED

Regular maintenance checks and cleaning are essential for the safe use of this

equipment (see care and maintenance section).

If any part is loose, damaged or functioning incorrectly, do not use until rectified.

Always fasten the pelvic strap and any other straps provided.

Regularly check that they are not showing any signs of tearing or fraying and that

they fasten correctly.

Ensure that all nuts, bolts and handwheels are securely tightened and that none are

missing.

Always keep this product away from naked flames, cigarettes and sources of heat

including open fireplaces, radiators, heaters etc.

DO NOT fit parts or accessories of other manufacturers to this product unless

authorized to do so in writing by G&S Smirthwaite Ltd. Failure to follow these

instructions will not only invalidate the guarantee but could make the chair

dangerous to use. G&S Smirthwaite Ltd will not accept liability for any injury or

damage incurred through such malpractices. Any repairs required must be carried

out by G&S Smirthwaite Ltd authorized personnel.

The Hardrock is CE marked. This certifies that it meets all relevant European safety

requirements.

STOP!

If you believe this product to be faulty – DO NOT USE

Hardrock

5

4.0 UNPACKING YOUR CHAIR

STOP!

If in any doubt, ALWAYS seek ADVICE.

Always turn hand wheels, levers and screws clockwise to tighten or

anti-clockwise to loosen.

When delivered, the Hardrock will be supplied fully assembled except for the tray.

Please take note of any instructions on the packaging/box when unpacking the chair.

Once the chair has been carefully unpacked, please check all parts.

If any part is loose, damaged or functioning incorrectly, do not use until rectified.

Hardrock

6

5.0 SETTING UP AND ADJUSTING YOUR CHAIR

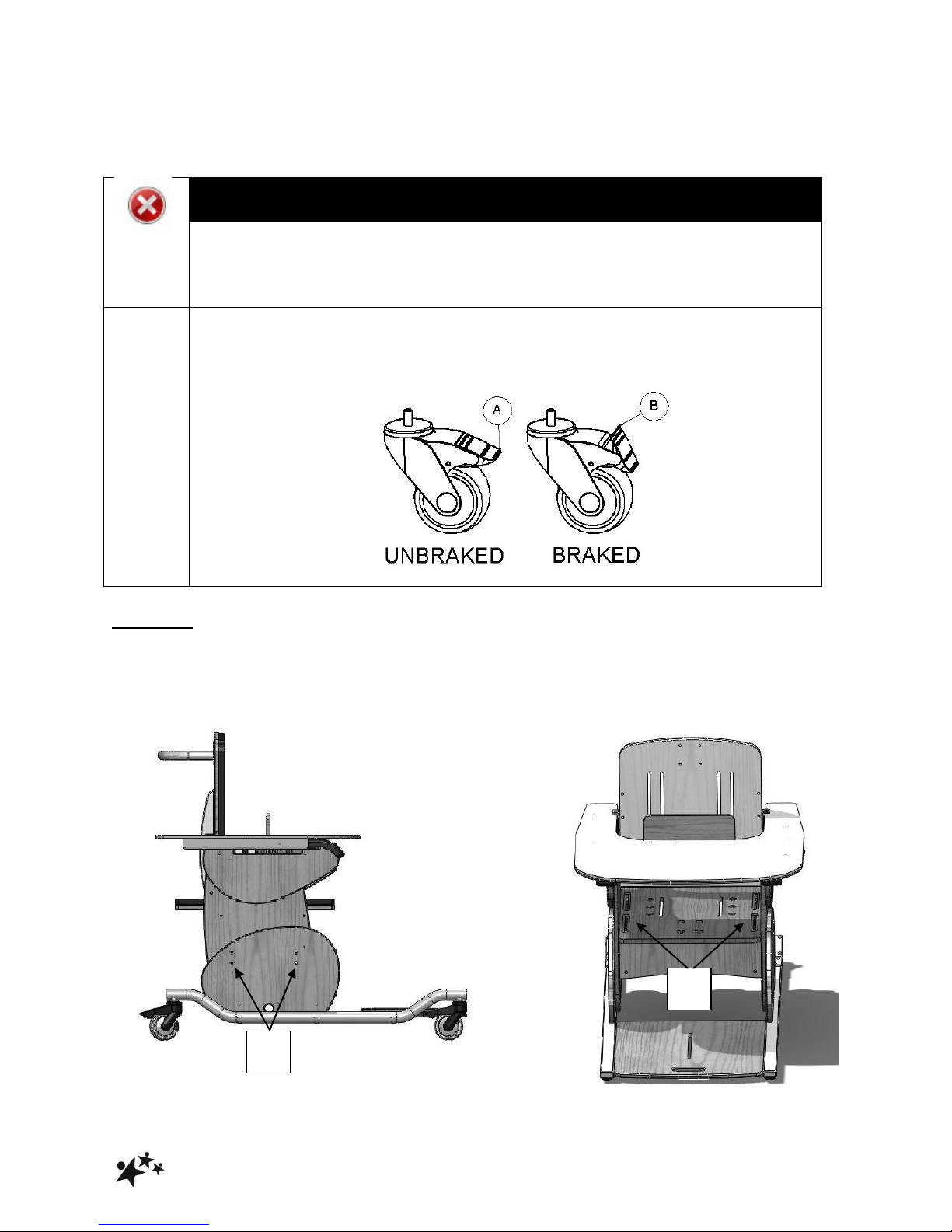

STOP!

If in any doubt, ALWAYS seek ADVICE.

Always turn hand wheels, levers and screws clockwise to tighten or

anti-clockwise to loosen.

ALWAYS LOCK THE CASTORS WHEN ATTACHING ITEMS OR

MAKING ADJUSTMENTS. TO LOCK, APPLY FOOT TO POINT (A) TO

UNLOCK APPLY FOOT TO

POINT (B)

5.1 SEAT

5.1.1 SEAT AJUSTMENTS

Two adjustments can be made to the seat; height and depth.

A

B

Hardrock

7

5.1.2 HEIGHT

Lay the chair on its side. (2 people required)

Remove the 4 hexagon head screws (A) on each side.

With one person holding the top seat section of the chair, slide the seat section to the

required height.

Replace the 8 screws.

Ensure all 8 screws match each other equally in height holes.

Tighten the screws.

Return chair to upright position

5.1.3 DEPTH

Lift the front edge of the seat pad attached with Velcro under the seat.

Loosen the 4 hexagon screws (B) in the slots on the edge of the seat by a just a couple of

turns.

Slide the seat back or forwards to desired depth.

Tighten the screws.

5.2 ARMREST

Loosen the 2 hexagon screws ( C )

Position at required height using any of the holes available.

Tighten the screws.

Ensure that both armrests are set at the same height and horizontal.

C

Hardrock

8

5.3 TRAY

Hold the sides of the tray

Pull 2 plunger pins (D) out to rest and park at an angle.

Rest back of tray on armrest.

Slide back of tray under the tray retainer (E) and then to desired position.

Release pins securely into position in the holes along the armrest (F)

Ensure chest pad is correctly positioned in front of child for safety, appropriate support and

reduce undesired movement.

D

E

F

Hardrock

9

5.4 THORACIC SUPPORTS

Two adjustments can be made to the thoracic supports; size 3 upwards.

5.4.1 HEIGHT

To adjust:

Loosen handwheels on rear of seat.

Move the thoracic support up or

down to desired position.

Re-tighten the handwheels.

5.4.2 WIDTH

To adjust:

Loosen handwheels on rear of seat,

and remove from the vertical slots.

Position the thoracic support

appropriate vertical slot for the

desired width.

Re-tighten the handwheels.

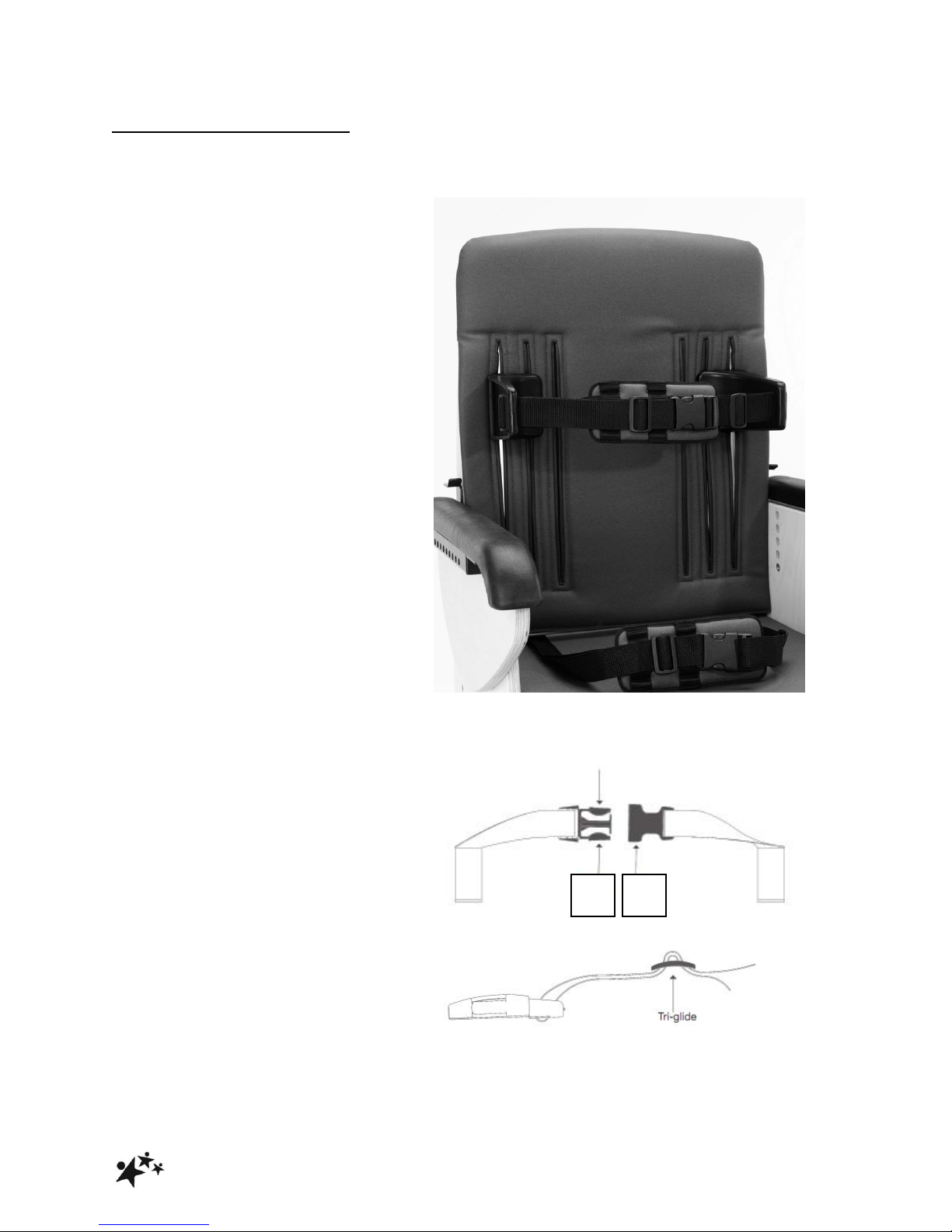

5.5 STRAPS

The buckle is secured by pushing

(G) into (H).

To release the buckle, press both

sides of (G)

The strap length can be altered by

adjusting the tri-glide (as shown

opposite)

G

H

Hardrock

10

5.6 HEELSTOP FOR HEEL

HUGGY ACCESSORY

The heel stop can be adjusted in depth.

Loosen the screws (I) by a couple

of turns.

Slide it back or forwards to desired

depth.

Re-tighten screws.

5.7 POMMEL

Pommels have to be specified at the

time of order. A pommel cannot be

retrofitted.

To adjust:

Loosen hand wheel

Position the pommel in or out to the

desired position.

Re-tighten handwheels.

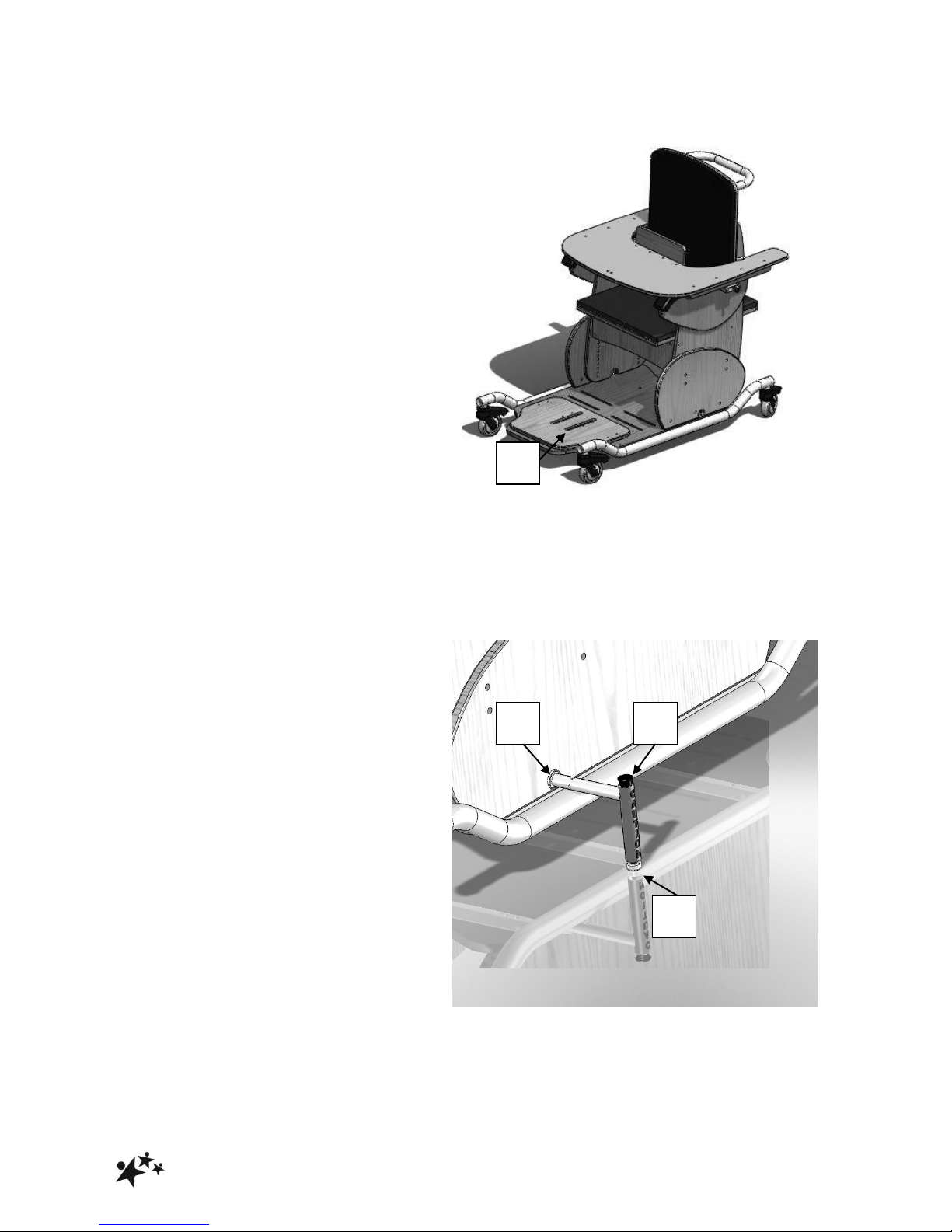

5.8 STABLISERS

Stabilisers can be ordered as an

accessory at time of order or retrofitted,

giving additional stability to the

Hardrock product.

5.8.1 Retrofitting

Slacken side panel fixing screws

located under the chassis

Insert stabilizers through the

‘mouse-hole’ (J) of the side panel.

Turn the stabilizer to the vertical

position (as shown above).

If needed, drill M8 clearance hole

through the baseboard

Secure stabilizers with M8 cap

screws, nuts and washers.

Re-tighten leg/side panel fixing

screws under the chassis

5.8.2 Extend stabilizer

Depress button (K)

Pull stander tube out (L)

Release button.

Turn it vertical to the ground - there

will be an audible click when

locked.

I

J

K

L

Hardrock

11

6.0 CARE AND MAINTENANCE

IMPORTANT!

CLEANING IS RECOMMENDED ON A REGULAR BASIS

THE CLIENT SHOULD NOT BE SEATED IN THE CHAIR WHEN

CLEANING OR UNDERTAKING MAINTENANCE

All our wooden chairs are easy to clean. Each chair has anti-bacterial properties

ensuring that surfaces are kept hygienic to reduce any risk of cross infection.

Clean upholstery and wooden parts with a damp cloth and mild detergent.

Stubborn marks on the woodwork should be cleaned by using a soft brush.

Do not soak or immerse the chair in water.

The pelvic strap can be cleaned with a damp cloth. In cases of extreme soiling it

can be machined washed at low temperature with mild detergent but must be

drip dried.

Store the chair in a cool dry place out of direct sunlight.

DO NOT use bleach, solvents, abrasives, synthetic detergents, wax polishes,

antibacterial sprays or wipes.

For further information please refer to MHRA or your NHS cleaning guidelines.

6.1 DAILY CHECKS

Check the product for damage or loose components.

Check all upholstery for signs of wear and tear.

Check the straps for signs of wear and tear.

Check the castors are running freely and brakes are in working order

6.2 MONTHLY CHECKS

Repeat daily checks.

Check all mechanical movements operate fully.

Check the structure of the product for signs of damage, wear and tear.

6.3 ANNUAL SERVICE

The Hardrock chair should be serviced annually. Servicing must only be undertaken by

a Smirthwaite service engineer, or by a Smirthwaite trained representative.

Hardrock

12

6.4 NOMINAL SERVICE LIFE

Your product has a nominal service life of 7 years, during which full post-sales support

will be available with regard to spares and servicing.

Product service life has been determined based upon the design complexity of product,

and the anticipated exposure to normal use.

Good practice dictates all Smirthwaite products have been designed and manufactured

to high levels of safety and quality, and will meet requirements of normal use when

maintained in line with our servicing recommendations.

STOP!

If the product has been out of use for an extended period of time (6

months or more) it should always be serviced prior to being

reissued.

If the product has been subjected to ‘heavy’ or ‘constant’ use, the

service should be reduced to half the recommended period.

Constant and/or heavy use is considered to be:

Daily use above 7 hours duration

Weekly use above 5 days duration

Monthly use above 10 months per year

Use by a client who is at 90% to 100% of the maximum weight limit of

the product. The maximum weight limit must NEVER be exceeded

Use by a client who is extremely active, either voluntarily or

involuntarily

Hardrock

13

6.5 EXTENDING NOMINAL SERVICE LIFE

At Smirthwaite we are proud to produce products that have a reputation for quality and

durability.

We believe our products have the potential to provide benefits to our clients beyond the

nominal service life documented above.

We will continue to provide full support beyond the nominal service life provided the

following conditions are met:

1. A full service schedule has been maintained.

2. A full service and inspection is undertaken at the end of the nominal service life

period

3. The product is subsequently serviced annually (or biannually if under

‘heavy/constant’ use conditions)

4. Smirthwaite reserve the right to limit support where parts/components are no

longer available

6.6 DOCUMENTATION/RECORDS

It is the responsibility of the current equipment owner to ensure the ‘Instructions for

Use’ manual and any further manuals for accessories fitted to the equipment are

handed over to the new owner at the time of exchange/sale

It is the responsibility of the current equipment owner to ensure the service and

inspection record form is kept up to date

6.7 PRODUCT CONFIGURATION

Smirthwaite will document and maintain a record of the original product configuration

at the time of first sale

Smirthwaite will not be held responsible for any subsequent changes to this

configuration unless authorized to do so in writing by G&S Smirthwaite Ltd

It is the equipment owner’s responsibility to maintain their own records of changes to

the equipment configuration and to be able to provide such records to subsequent

owners to maintain traceability

Hardrock

14

We recommend an inspection/service by a Smirthwaite Service Engineer (or

Smirthwaite trained engineer) whenever a significant change is made to product

configuration to ensure the product is safe to use. If in any doubt, ALWAYS seek

ADVICE

IMPORTANT REMINDER!

DO NOT fit parts or accessories of other manufacturers to this product

unless authorized to do so in writing by G&S Smirthwaite Ltd.

Any servicing or repairs required must be carried out by G&S Smirthwaite

Ltd (or a Smirthwaite trained engineer).

If you believe this product to be faulty – DO NOT USE

If in any doubt, ALWAYS seek ADVICE.

Hardrock

15

7.0 GUARANTEE & SERVICE

The Hardrock is issued with a full parts and labour guarantee for 2 years from the date

of delivery. This guarantee does not apply to accidental damage caused through

inappropriate use of the Hardrock. This guarantee is issued at the discretion of G & S

Smirthwaite Ltd on RTB (Return to Base) basis.

Hardrock

16

8.0 CONTINUOUS IMPROVEMENT

G & S Smirthwaite Ltd are committed to continuous improvement to their product range.

G&S Smirthwaite Ltd reserve the right to change the specification or material without

prior notice.

Hardrock

17

9.0 WARRANTY & AFTERSALE

9.1 Product Information

Model

Size

Date of Manufacture

Serial Number

Final Inspection

9.2 Service & inspection record form:

Date

Procedure

Service

Personnel

Hardrock

18

Notes

Hardrock 19

Other manuals for HARDROCK

1

Table of contents

Other smirthwaite Wheelchair manuals

Popular Wheelchair manuals by other brands

Permobil

Permobil Corpus 3G owner's manual

SPEX

SPEX constructa Installation & user manual

Invacare

Invacare FDX user manual

Drive DeVilbiss Healthcare

Drive DeVilbiss Healthcare ROTEC Instructions for use

Invacare

Invacare Solara Brochure & specs

Freedom Concepts

Freedom Concepts Chill-Out Rock'er owner's manual