Introduction Service Diagrams Parts Accessories Reference

CONTENTS

Introduction ........................................... 1-3

Introduction.............................................. 1

SafePractices......................................... 2

Specifications .......................................... 3

OptionalEquipment ................................. 3

Service..................................................4-11

Maintenance......................................... 4-6

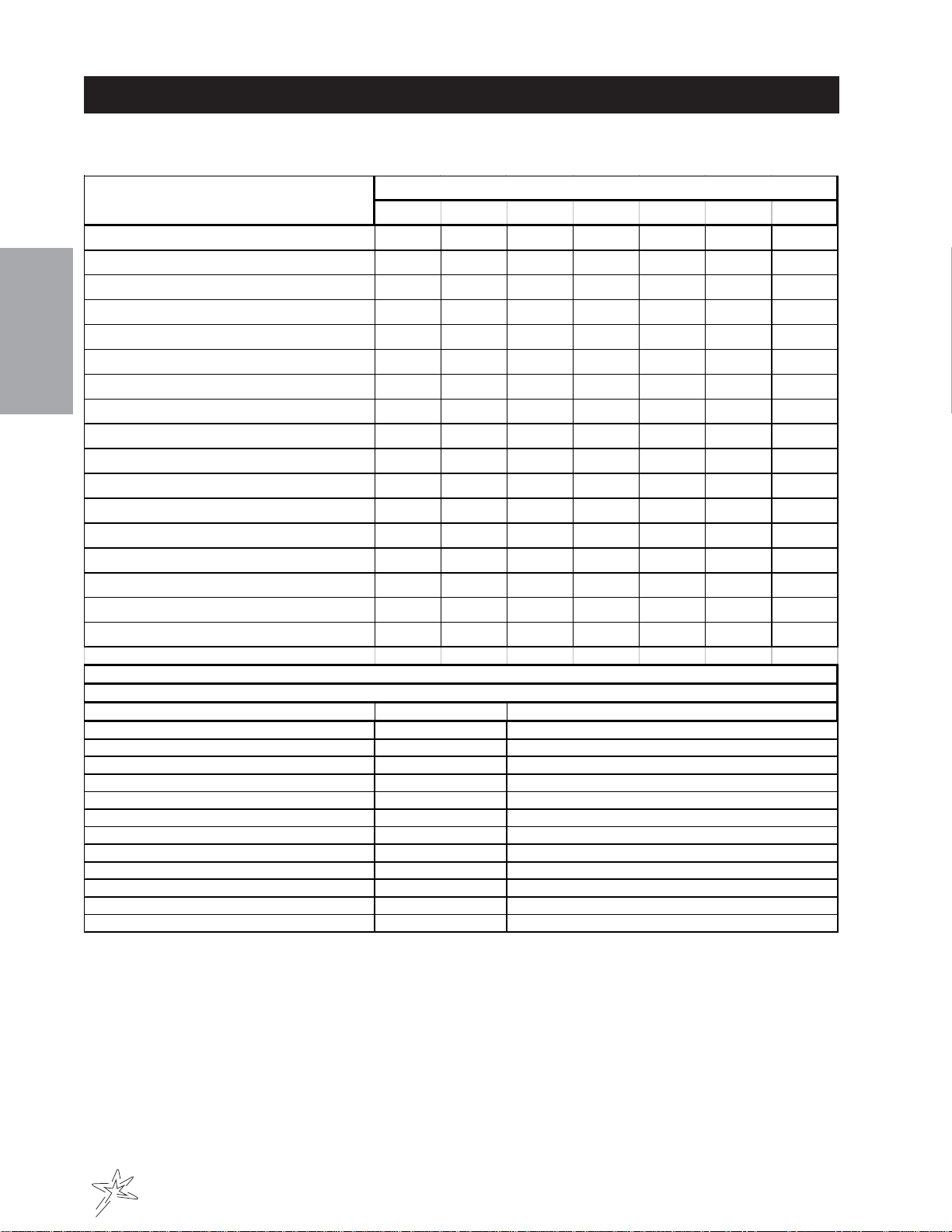

ServiceChart ........................................... 7

End User'sService Chart ......................... 8

Adjustments ........................................9-11

Storage...................................................11

Diagrams.............................................12-15

WiringDiagram..................................12-13

HydraulicDiagram .............................14-15

Parts ....................................................16-41

MainFrame .......................................16-17

3WheelDriveFrontFork ...................18-19

Linkage .............................................20-23

GasTank...........................................24-25

OilTank .............................................26-27

Engine...............................................28-31

RearAxle ..........................................32-33

RakeLift............................................34-35

13-7292-BankHydraulic Valve ..........36-37

76-238FrontWheelMotor .................38-39

42-002 RearWheel Motor ..................40-41

Accessories .......................................42-103

43-003HydraulicSandPlow ..............42-45

42-011 Sand Plow(Steel &Aluminum) ....... 46-47

42-13660"Aluminum Sand Plow .......48-49

42-223AdjustableDiscEdger............50-51

42-008SandCultivator.......................52-53

42-340SandCultivator w/ SpringTine54-55

42-341 Sand Cultivatore w/ Castor Wheels 56-57

42-010ConstructionLeveling Blade ...58-59

42-210GraderBladeKit ....................60-61

42-178InfieldScarifier(vertical blades) ... 62-65

42-179InfieldScarifier(chiselblades) ..... 66-69

42-285 Scarifierw/Vertical Blades ...70-73

42-02684"(213cm)StainlessRake.......74-77

42-128 72"(183cm) Stainless Rake.....78-81

13-438 Rakewith Finishing Blades ....82-83

13-684SandRakeBrushKit .............84-85

13-298FanRake ...............................86-87

13-319 Fan Rake Kit.........................86-87

26-007ProfessionalFieldFinisher .....88-89

42-185DragMatKit ..........................88-89

43-002Flex Field Finisher w/ Brush...90-93

26-008 Flex Action Field Finisher......94-97

43-043BrushKitfor 26-008 ...............98-99

45-282GreenStarRBS Spiker ...... 100-101

42-586GreenStar RBSMainFrame102-103

Reference ........................................ 105-106

Decal List .............................................105

QuickReference...................................106

Warranty................. Inside Back Cover